Preparation method of porous silicon/graphite/carbon composite negative electrode material for lithium-ion secondary battery

A secondary battery and negative electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that cannot meet the actual application requirements, cannot meet the actual application, unfavorable industrial production, etc., and achieve large industrial application value and good cycle Stability, convenient and feasible process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The porous silicon of the present invention can be prepared by the following methods:

[0031] (1) Kaolin pretreatment

[0032] (1) Mix kaolin with 1mol / L hydrochloric acid solution according to the mass ratio of 1:20, stir at 30℃ for 5h and then stand for 1h, suck the supernatant, filter and wash, dry at 120℃ for 10h to remove the kaolin Impurities.

[0033] (2) Put the kaolin treated in step (1) into a muffle furnace, heat up to 800°C at a rate of 10°C / min, keep it for 8 hours, and cool to room temperature to remove the hydroxyl groups in the kaolin.

[0034] figure 1 It is the SEM image of natural kaolin. From the figure, it can be seen that natural kaolin is composed of some nanoparticles. These particles are small in size, ranging from tens to hundreds of nanometers in diameter.

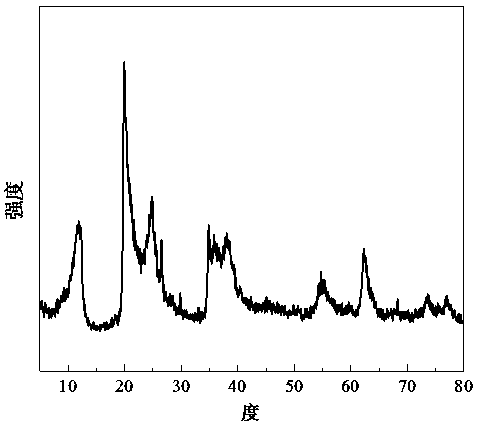

[0035] figure 2 It is the XRD pattern of natural kaolin. These diffraction peaks are typical characteristic peaks of kaolin, indicating that the sample is relatively pure.

[0036] (2) Preparation...

Embodiment 2

[0049] (1) Kaolin pretreatment

[0050] (1) Mix kaolin with 1mol / L sulfuric acid solution in a mass ratio of 1:15, stir at 40℃ for 4h, then stand for 1h, suck the supernatant, filter, wash, dry at 120℃ for 10h to remove the kaolin Impurities.

[0051] (2) Put the kaolin treated in step (1) into a muffle furnace at a rate of 10°C / min to raise the temperature to 700°C, keep it for 10 hours, and cool to room temperature to remove the hydroxyl groups in the kaolin.

[0052] (2) Preparation of porous silicon

[0053] (1) Using aluminum-magnesium alloy powder as the reducing agent, the pretreated kaolin and the reducing agent are mixed in a planetary ball mill at a speed of 300 rpm for 3 hours according to a certain mass ratio, and the ball-to-battery ratio is 15:1 to obtain a primary mixture.

[0054] (2) Mix the primary mixture, anhydrous aluminum chloride and anhydrous magnesium chloride according to a certain mass ratio to obtain a mass ratio of kaolin, aluminum-magnesium alloy powder, a...

Embodiment 3

[0065] (1) Kaolin pretreatment

[0066] (1) Mix kaolin with 1mol / L phosphoric acid solution in a mass ratio of 1:10, stir at 100°C for 10 hours and then stand for 1 hour, suck the supernatant, filter, wash, and dry at 120°C for 10 hours to remove the kaolin Impurities.

[0067] (2) Put the kaolin treated in step (1) into a muffle furnace, heat up to 600°C at a rate of 10°C / min, keep it for 6 hours, and cool to room temperature to remove the hydroxyl groups in the kaolin.

[0068] (2) Preparation of porous silicon

[0069] (1) Using aluminum-lithium alloy powder as the reducing agent, the pretreated kaolin and the reducing agent are mixed in a planetary ball mill at a speed of 350 rpm for 8 hours according to a certain mass ratio, and the ball-to-battery ratio is 15:1 to obtain a primary mixture.

[0070] (2) Mix the primary mixture, anhydrous aluminum chloride, and anhydrous lithium chloride uniformly according to a certain mass ratio to obtain kaolin, aluminum-lithium alloy powder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com