Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "High theoretical capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

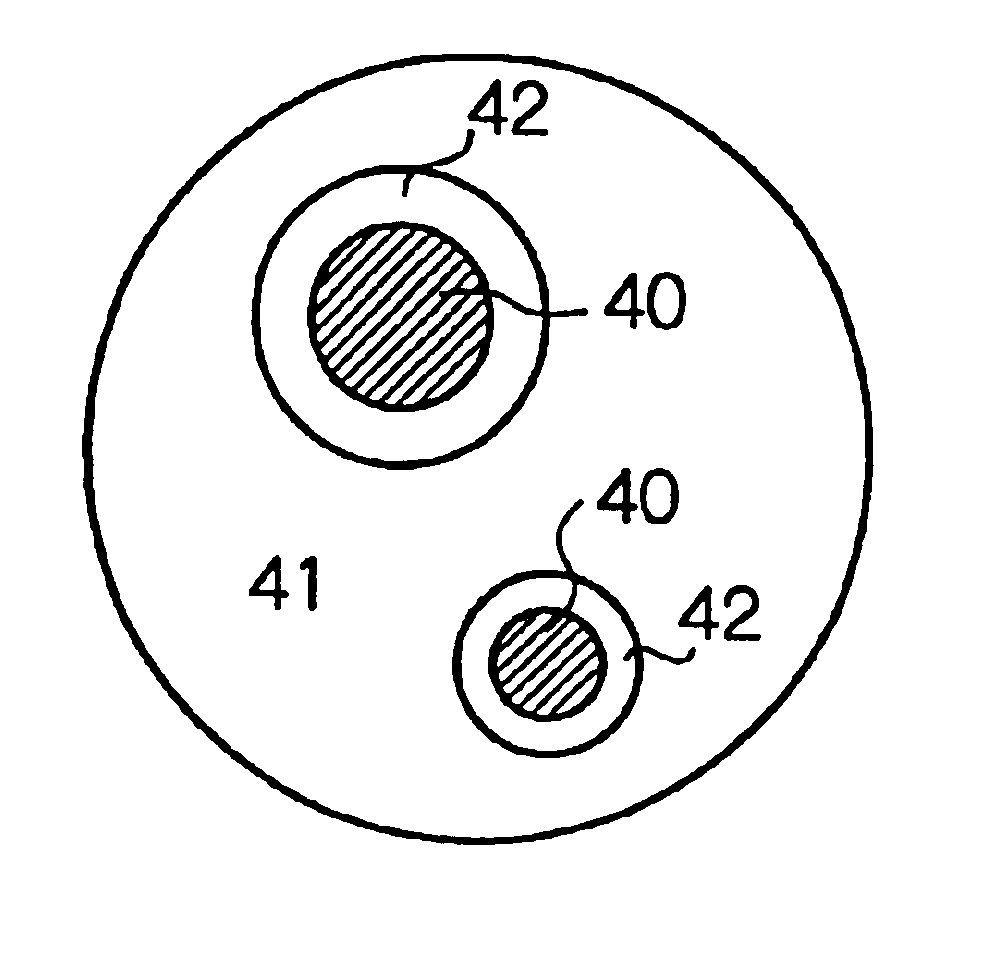

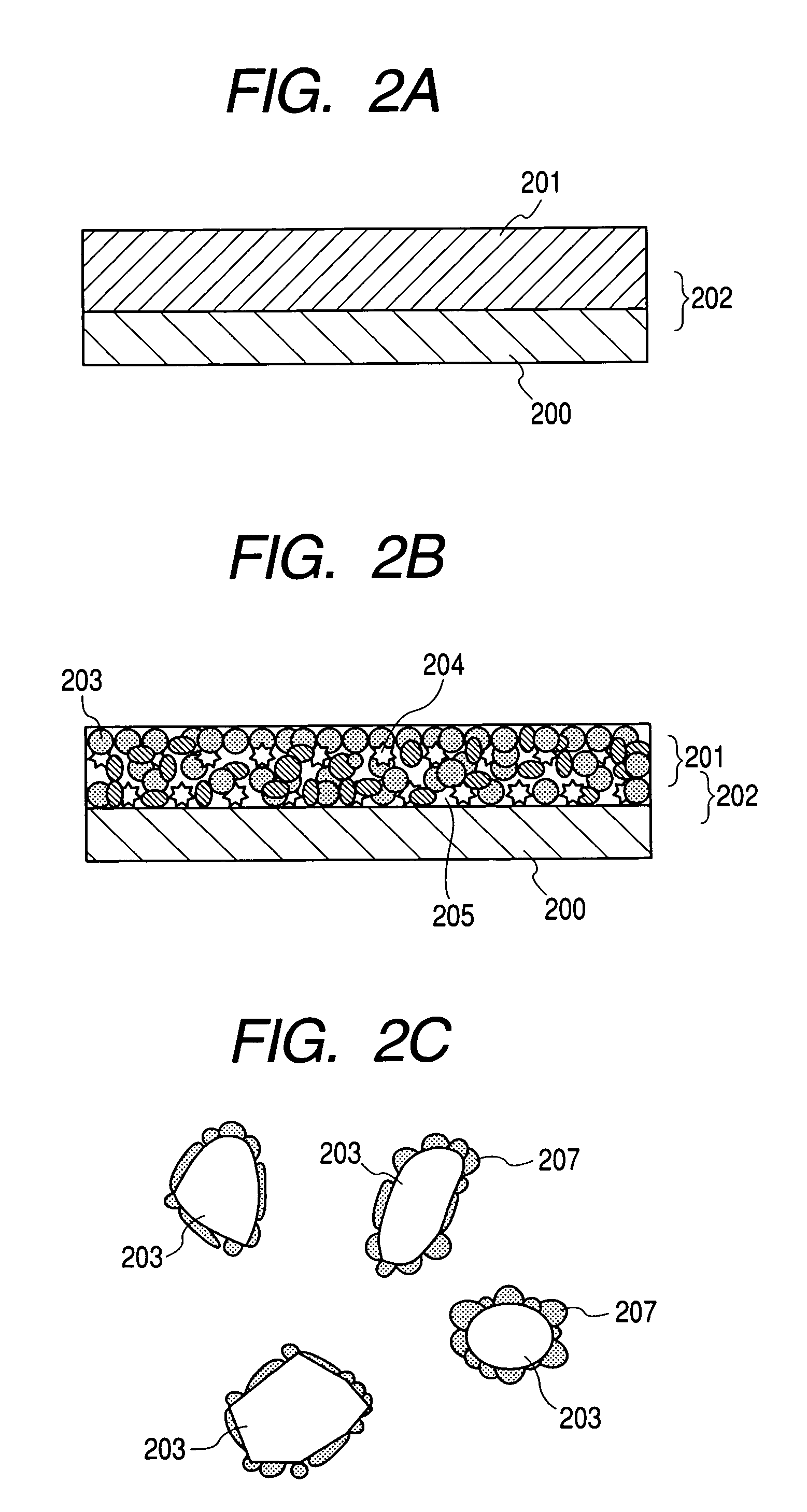

Process for manufacture of negative electrode material for a non-aqueous electrolyte secondary battery

InactiveUS20030175589A1Maintain good propertiesReduce battery sizeSolid electrolytesElectrode manufacturing processesAlloySolid solution

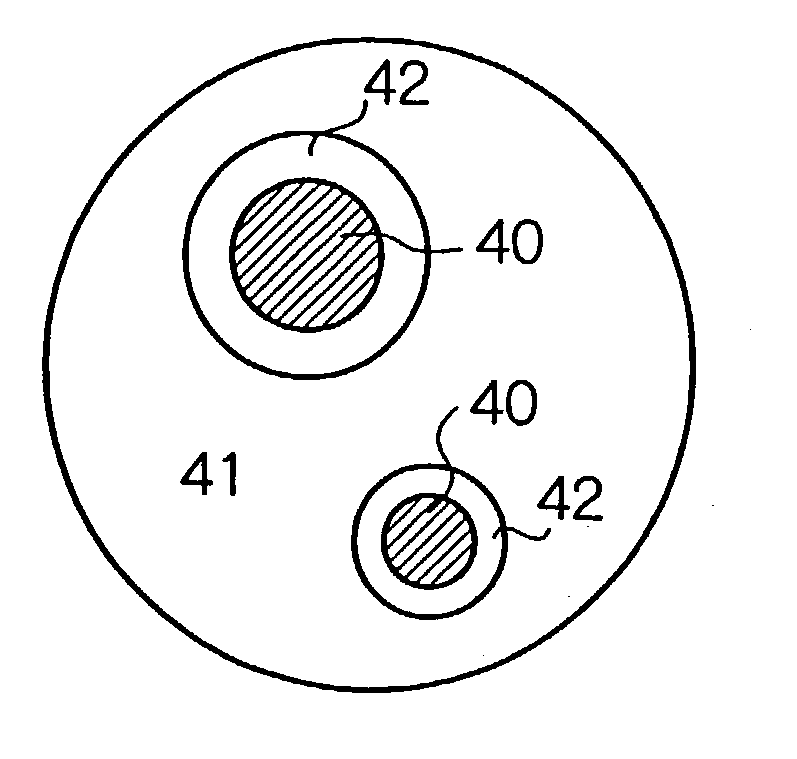

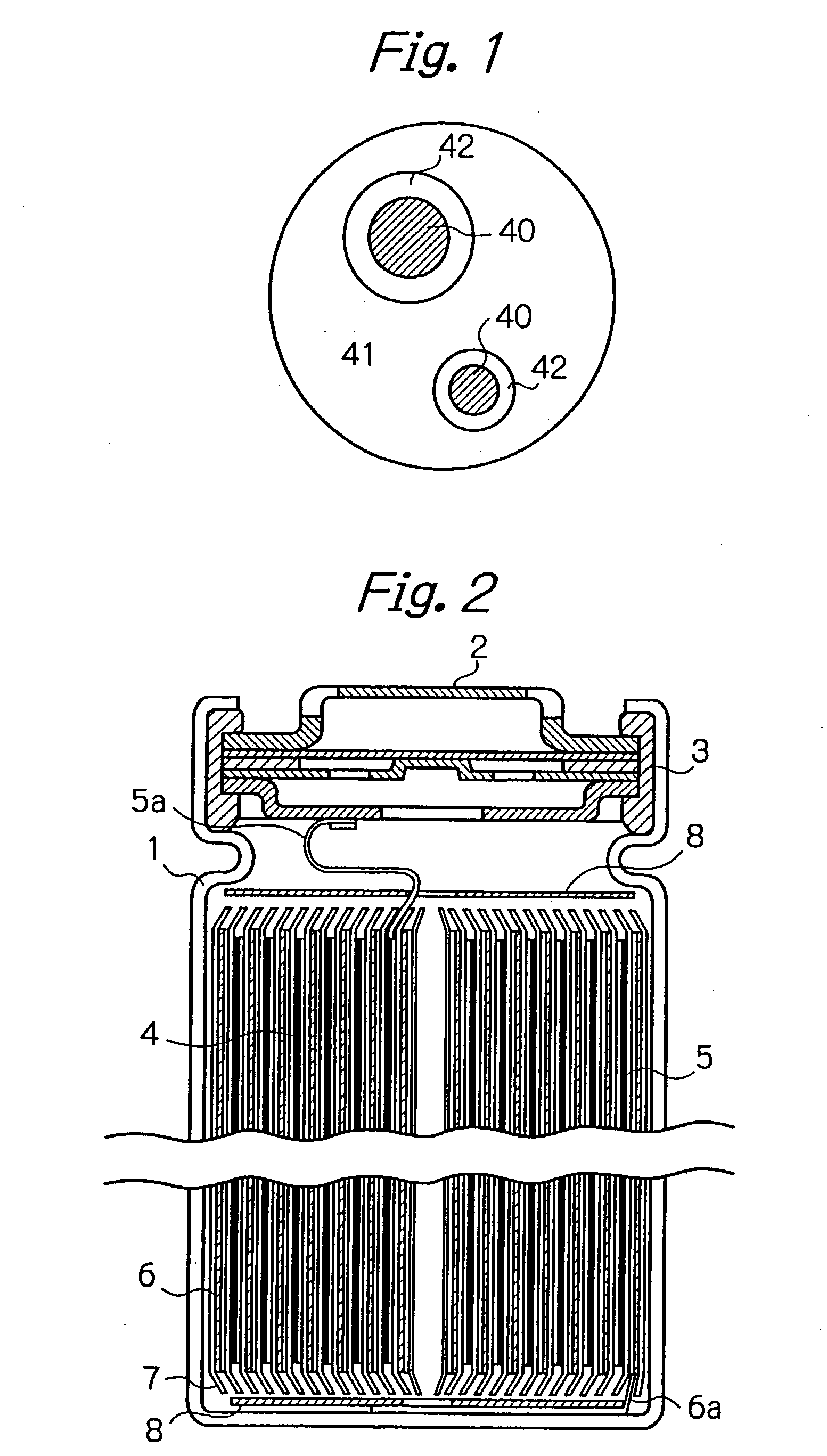

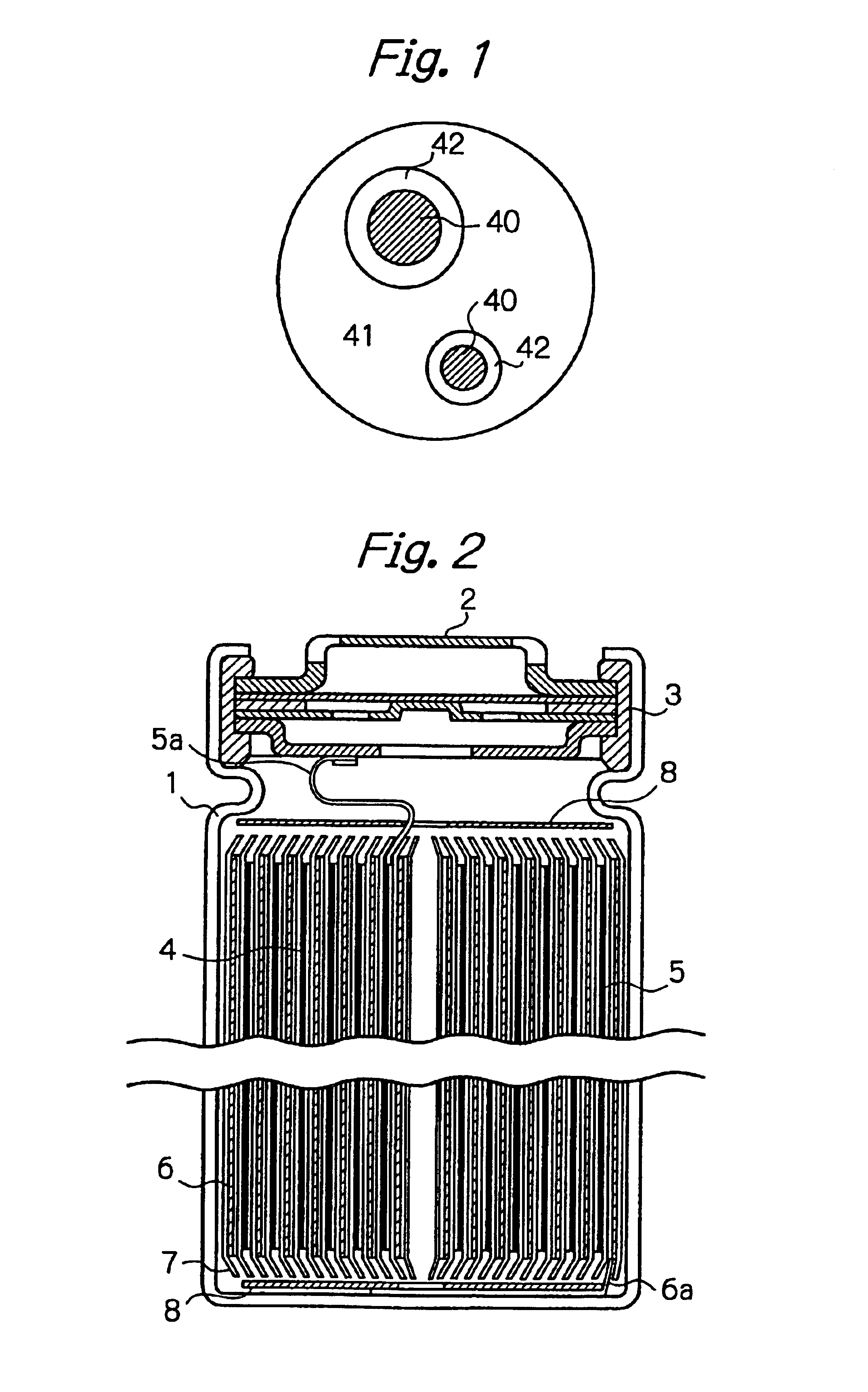

A negative electrode material for a nonaqueous electrolyte secondary battery having a high discharge capacity and a good cycle life is made from alloy particles having an average particle diameter of 0.1-50 mum and including Si phase grains 40 and a phase of a solid solution or an intermetallic compound of Si and other element selected from Group 2A elements, transition elements, Group 3B elements, and Group 4B elements from the long form periodic table (for example, an NiSi2 phase 42 and an [NiSi2+NiSi] phase 41) at least partially enveloping the Si phase grains. 5-99 wt % of this material is Si phase grains. The alloy particles can be manufactured by rapid solidification (such as atomization or roller quenching) of a melt including Si and the other element, or by adhering the other element to Si powder by electroless plating or mechanical alloying and then performing heat treatment. Even if rapid solidification is carried out, a negative electrode material having a good discharge capacity and cycle life is obtained without heat treatment.

Owner:CHUO DENKI KOGYO CO LTD

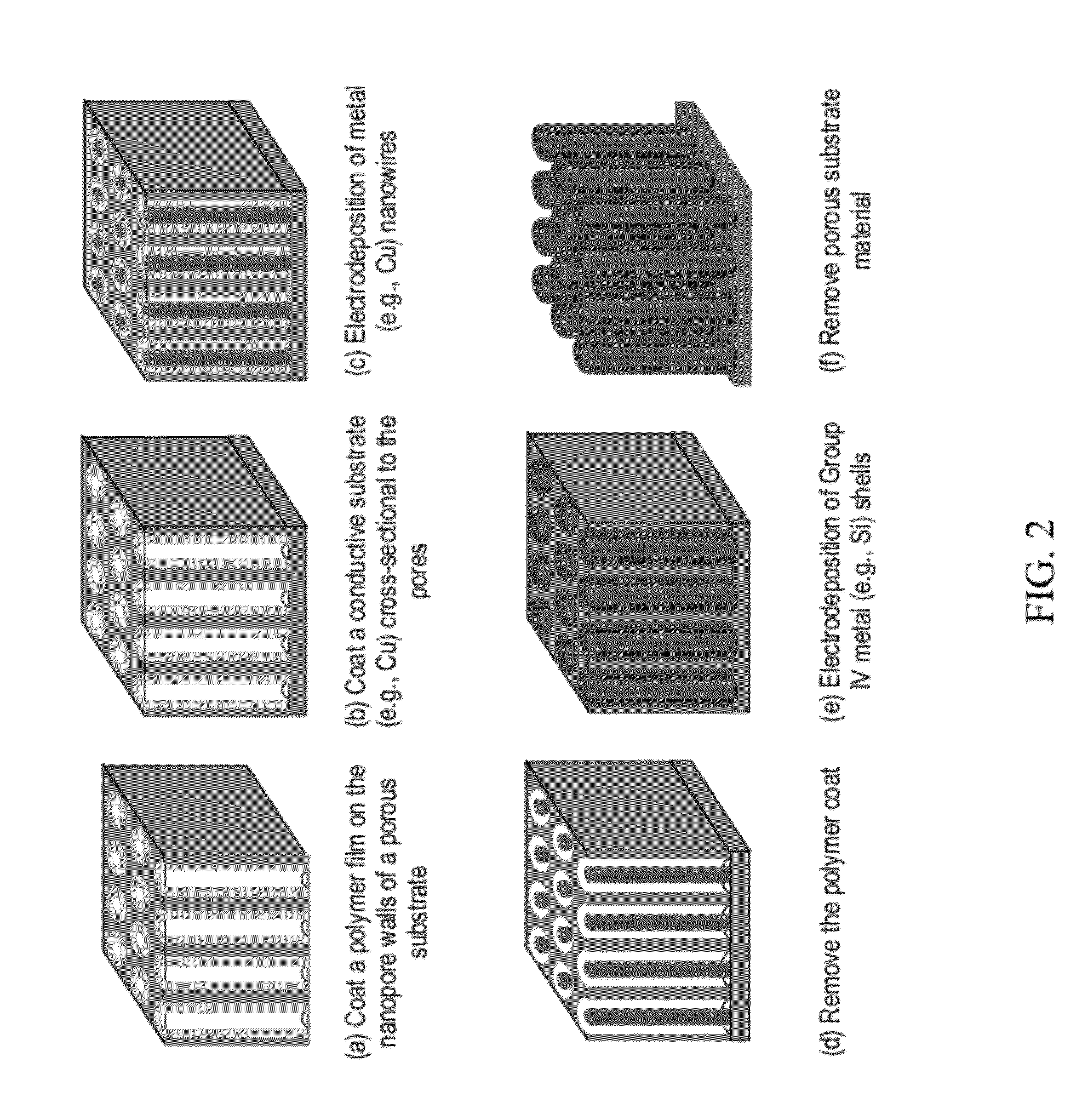

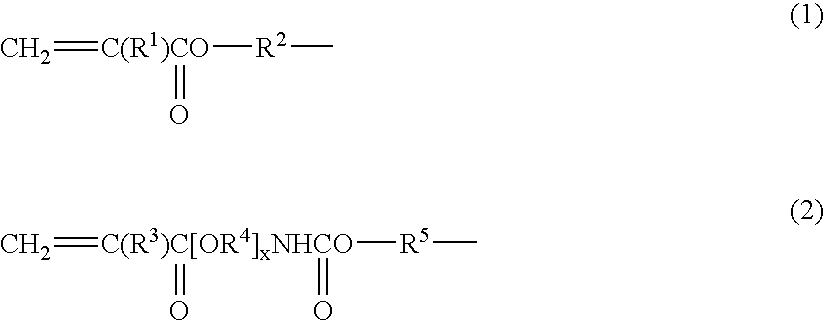

Composite nanowire compositions and methods of synthesis

InactiveUS20120094192A1Improve capacity retentionEnergy efficientMaterial nanotechnologyConductive layers on insulating-supportsPhysicsChemistry

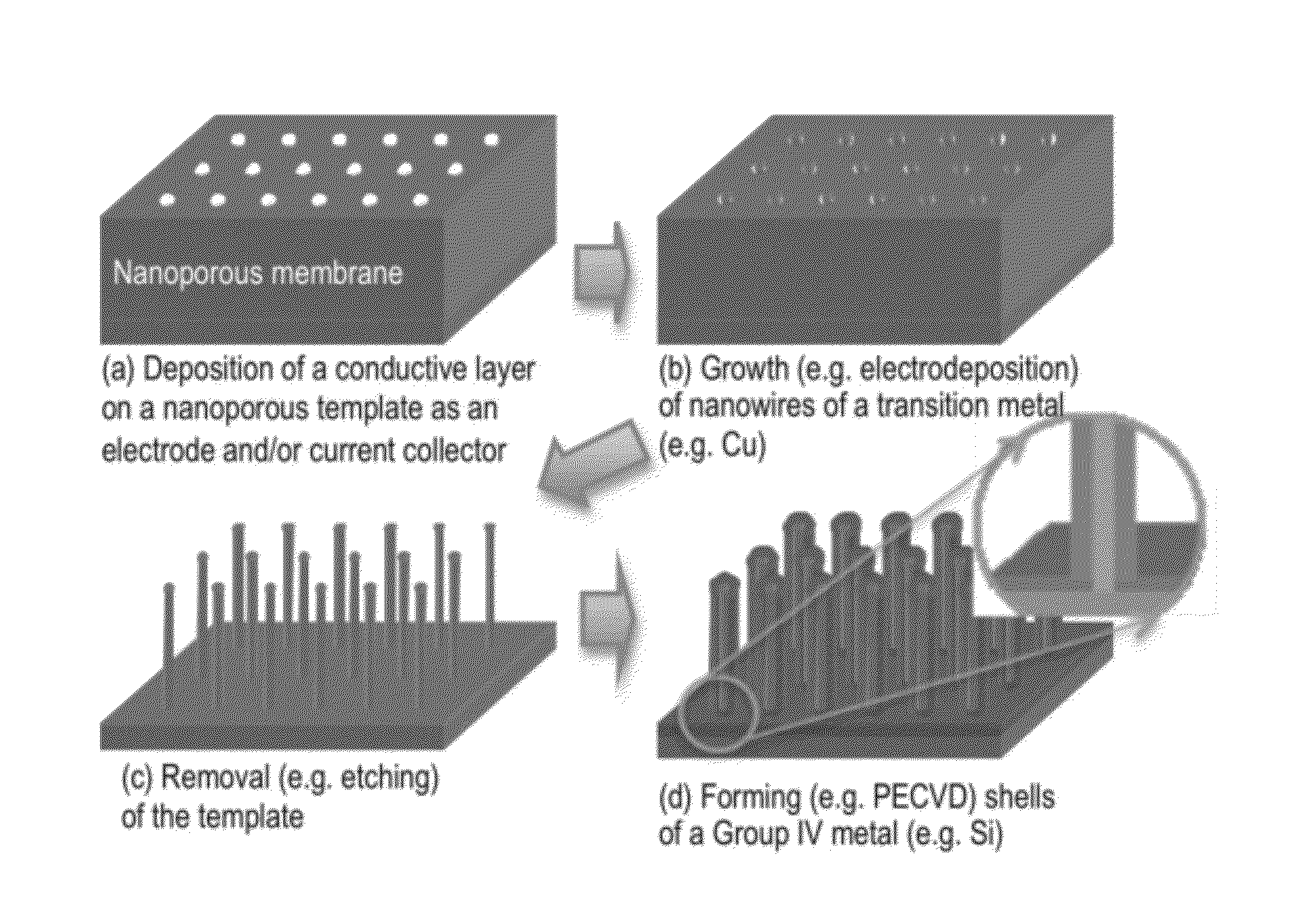

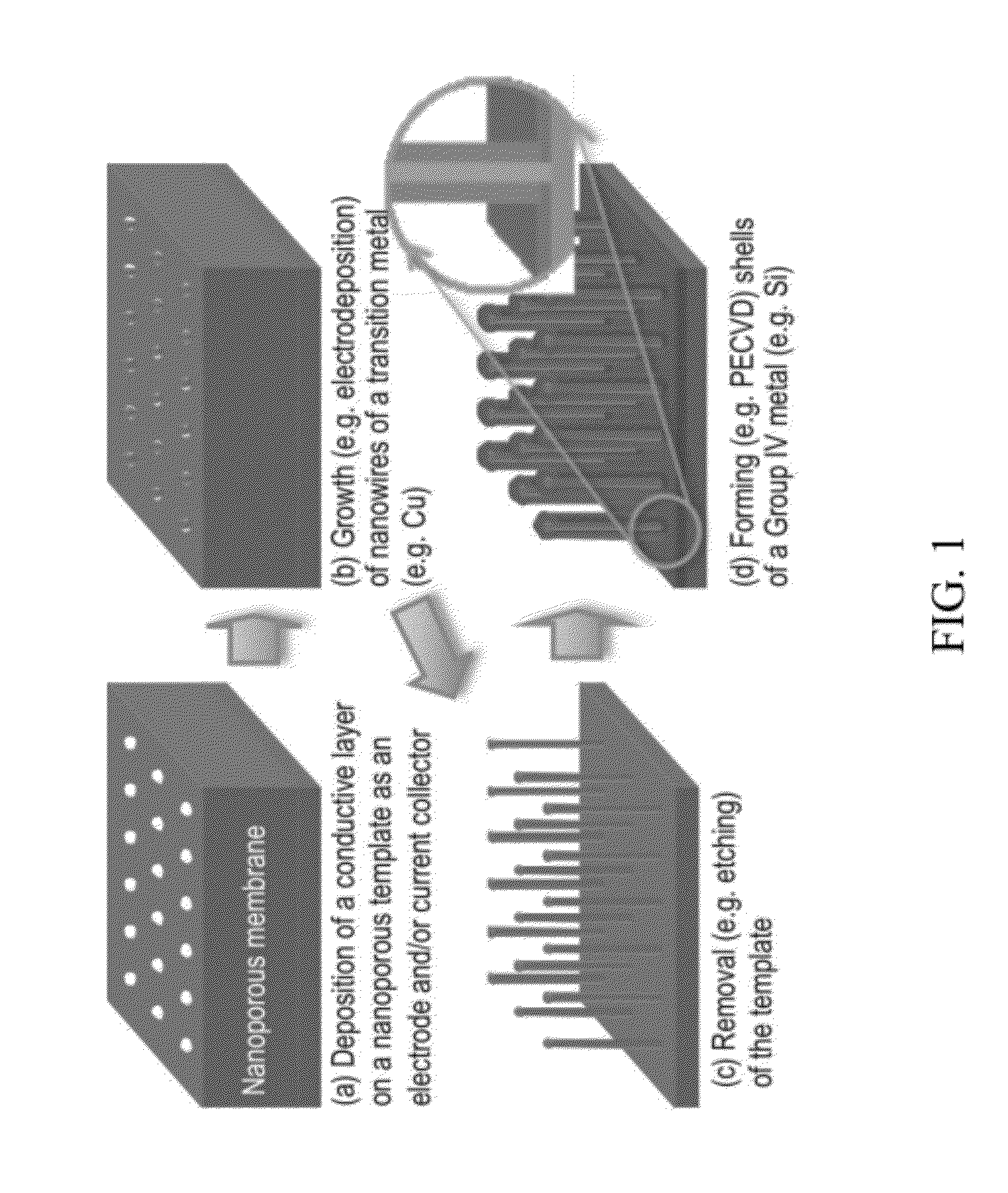

Nanowire array compositions in which nanowires containing at least one Group IV metal (e.g., Si or Ge) in a single layer or core-shell nanowire structure, wherein, in particular embodiments, the nanowires have a transition metal core and / or are surrounded by or embedded within a metal oxide or metal oxide-ionic liquid ordered host material. The nanowire compositions are incorporated into the anodes of lithium ion batteries. Methods of preparing the nanowire compositions, particularly by low temperature methods, are also described.

Owner:UT BATTELLE LLC

High density electrode and battery using the electrode

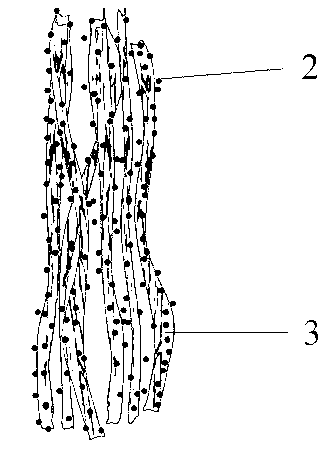

InactiveUS20060188784A1Impairment of electrolytic solution permeability can be preventedHigh theoretical capacityActive material electrodesLi-accumulatorsElectrolytic agentFiber

The invention relates to a high-density electrode, comprising an electrode active substance and carbon fiber having a filament diameter of 1 to 1,000 nm, wherein the porosity of the electrode is 25% or less. According to the invention, electrolytic solution permeability and electrolytic solution retainability, which are matters of importance in realizing a high-density electrode for achieving a battery having a high energy density, can be improved.

Owner:SHOWA DENKO KK

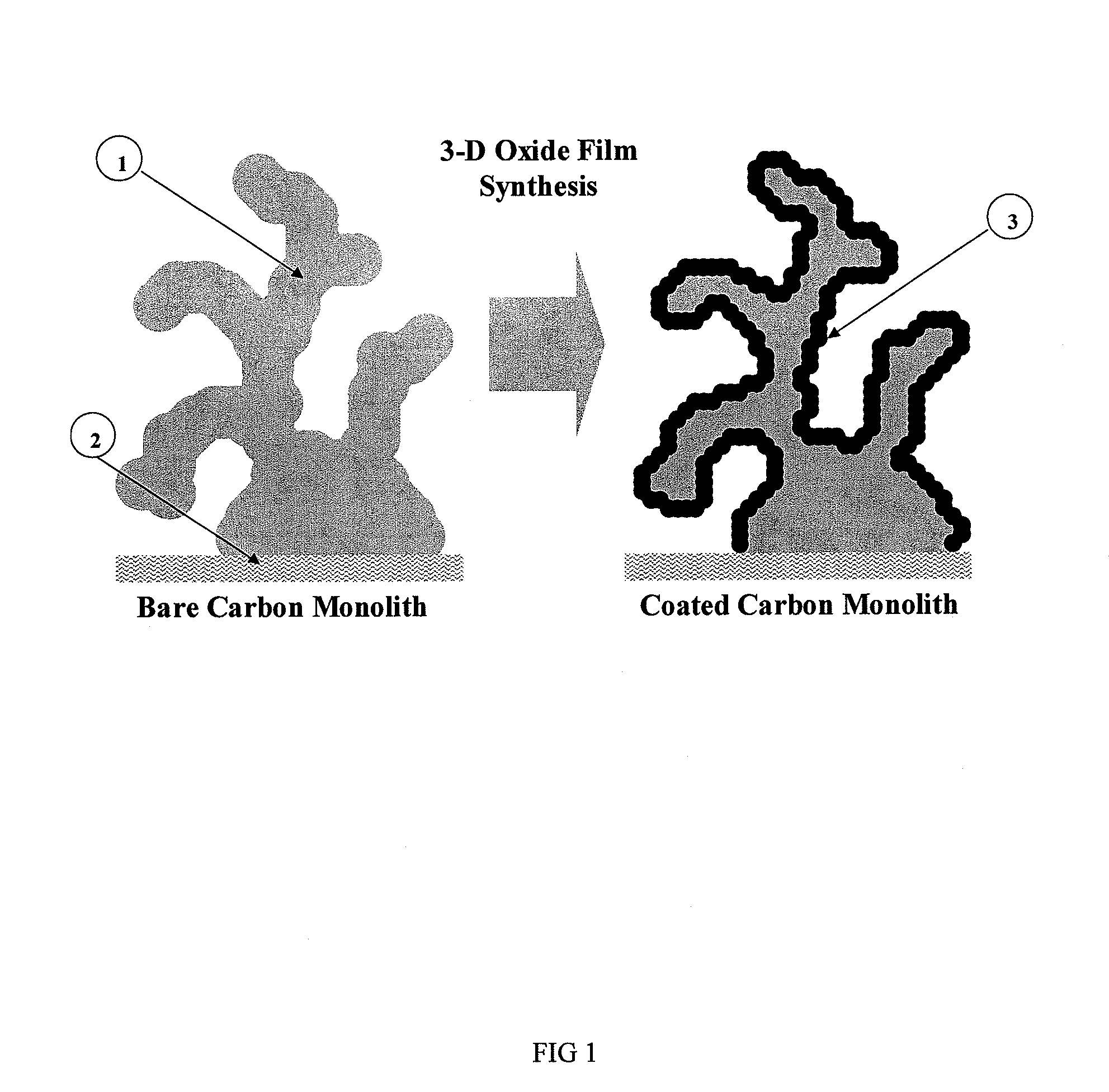

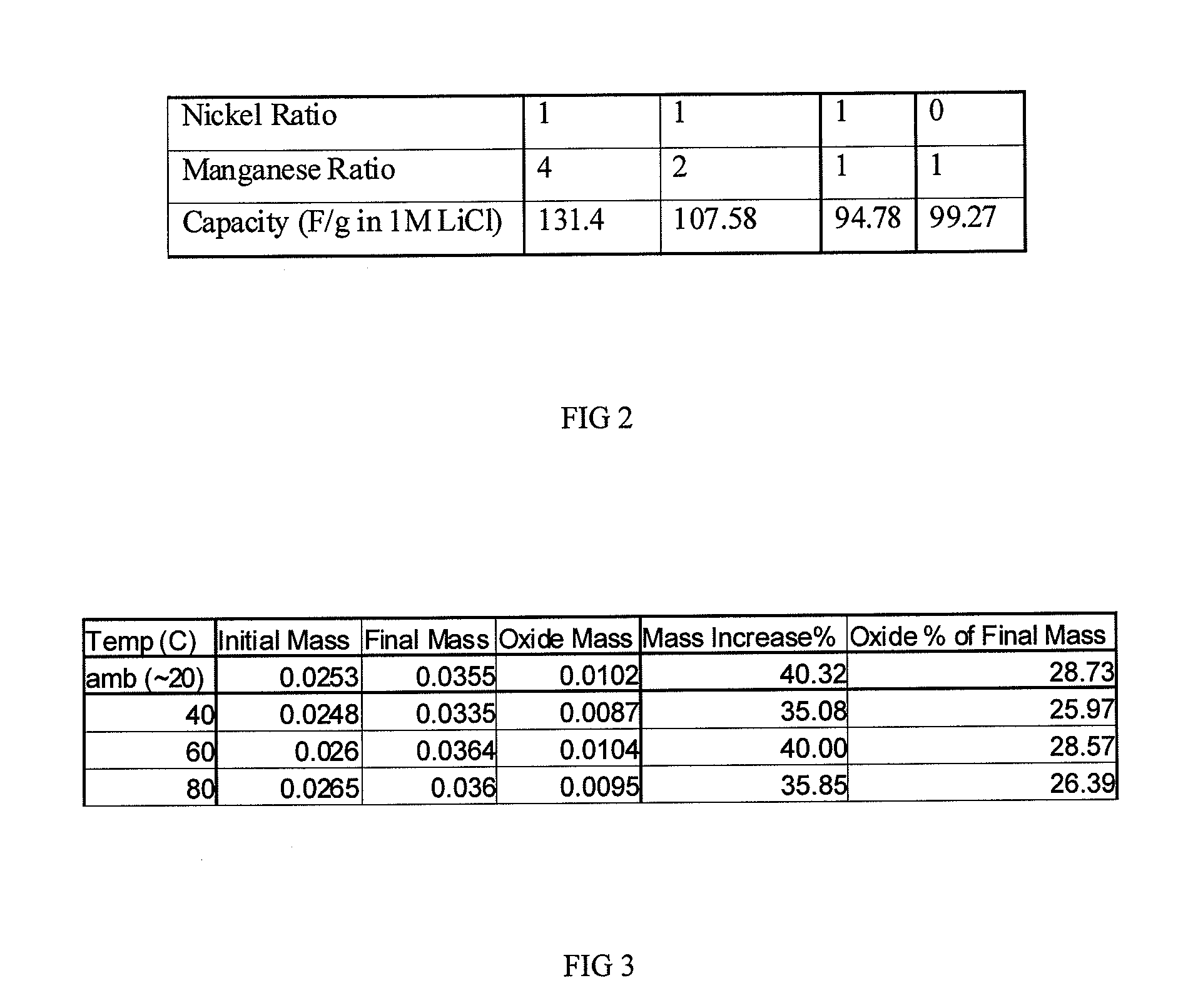

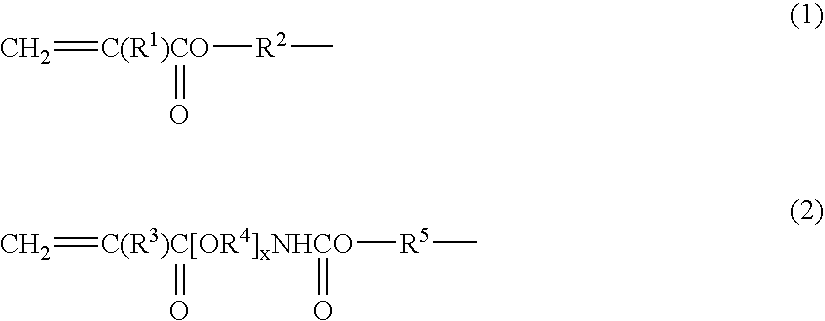

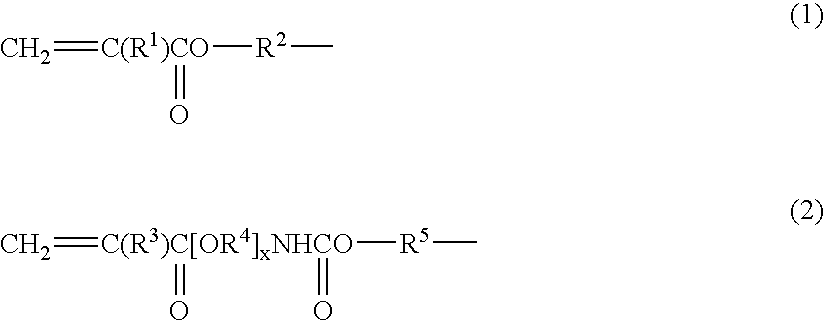

Monolithic electrode, related material, process for production, and use thereof

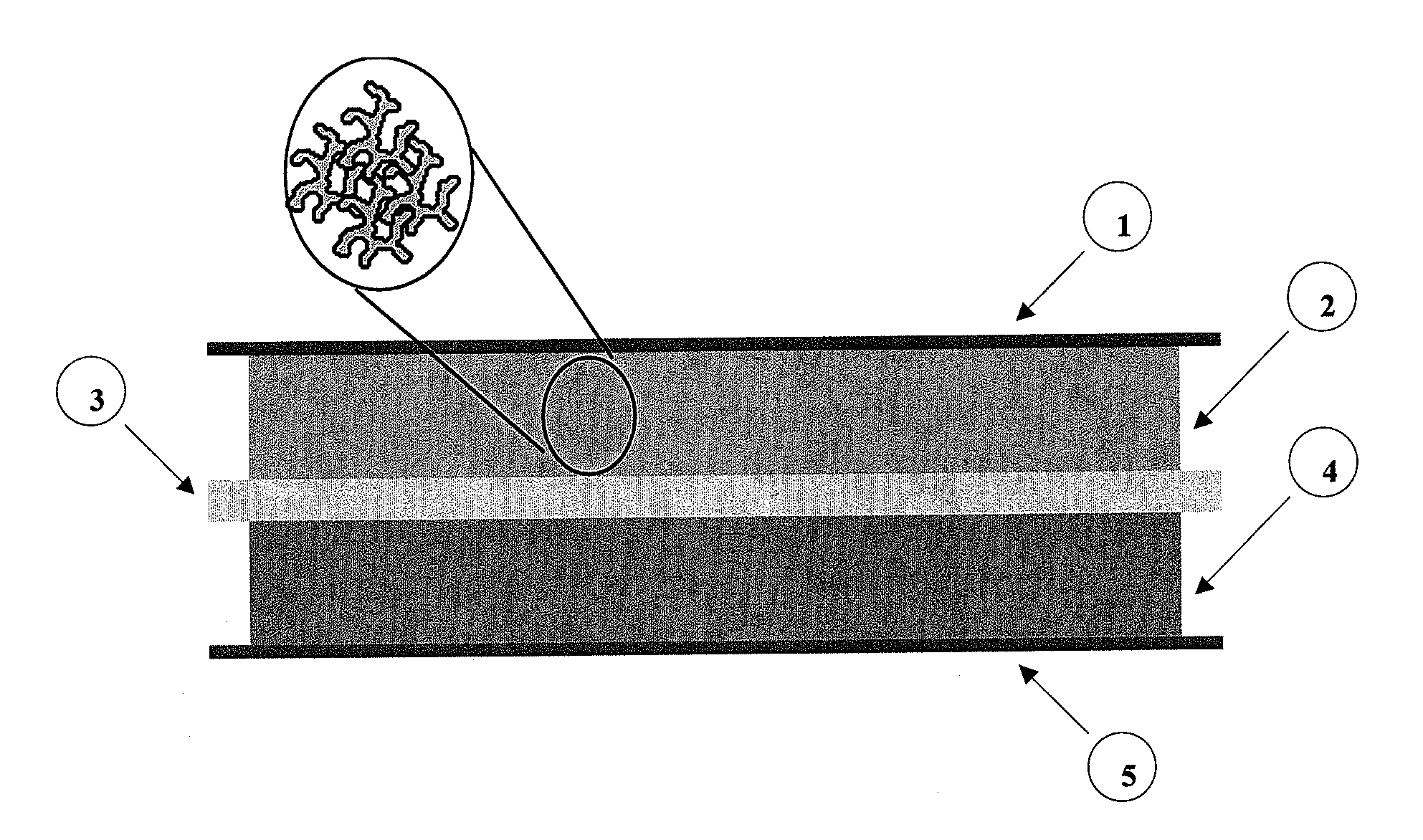

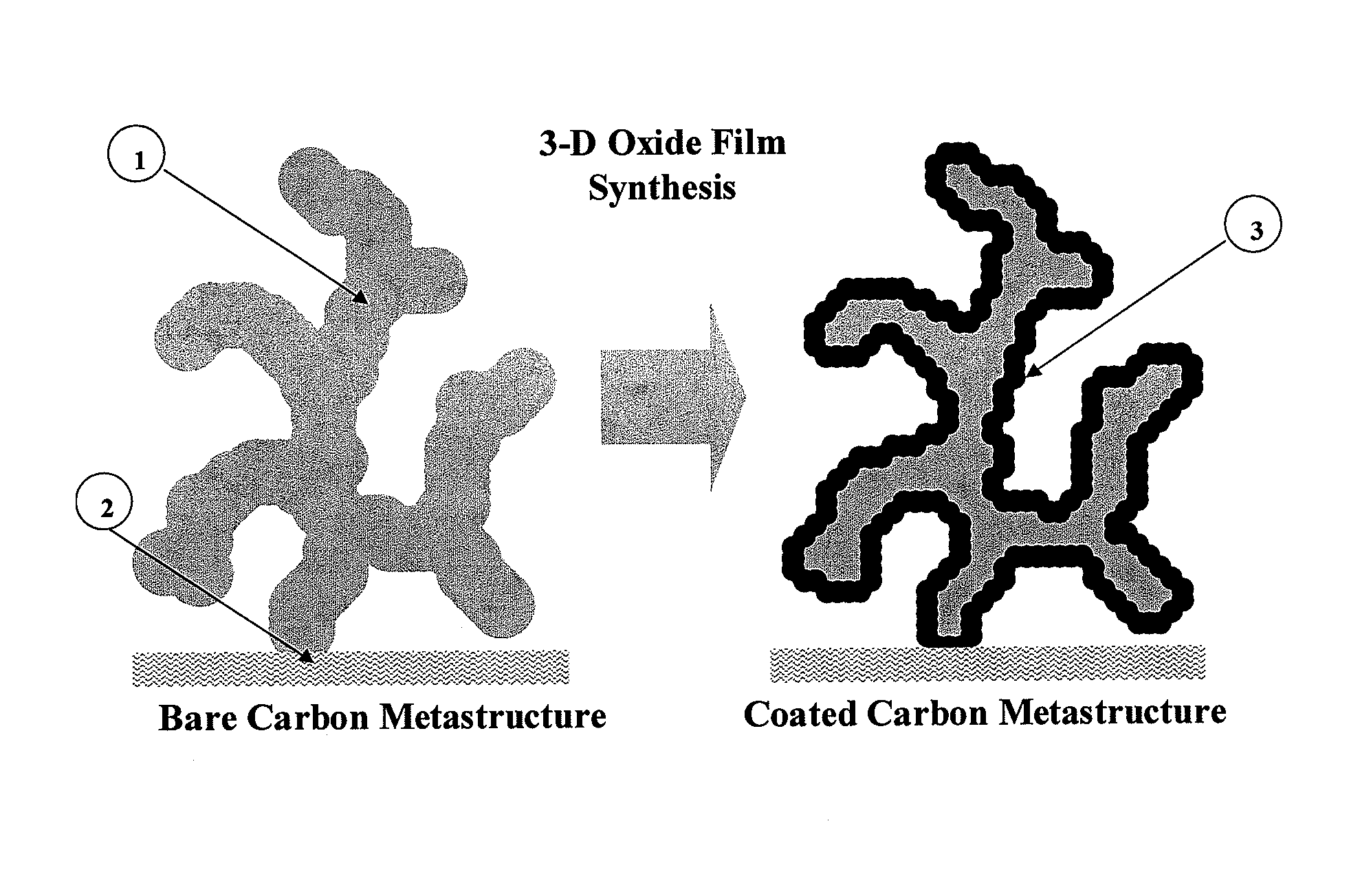

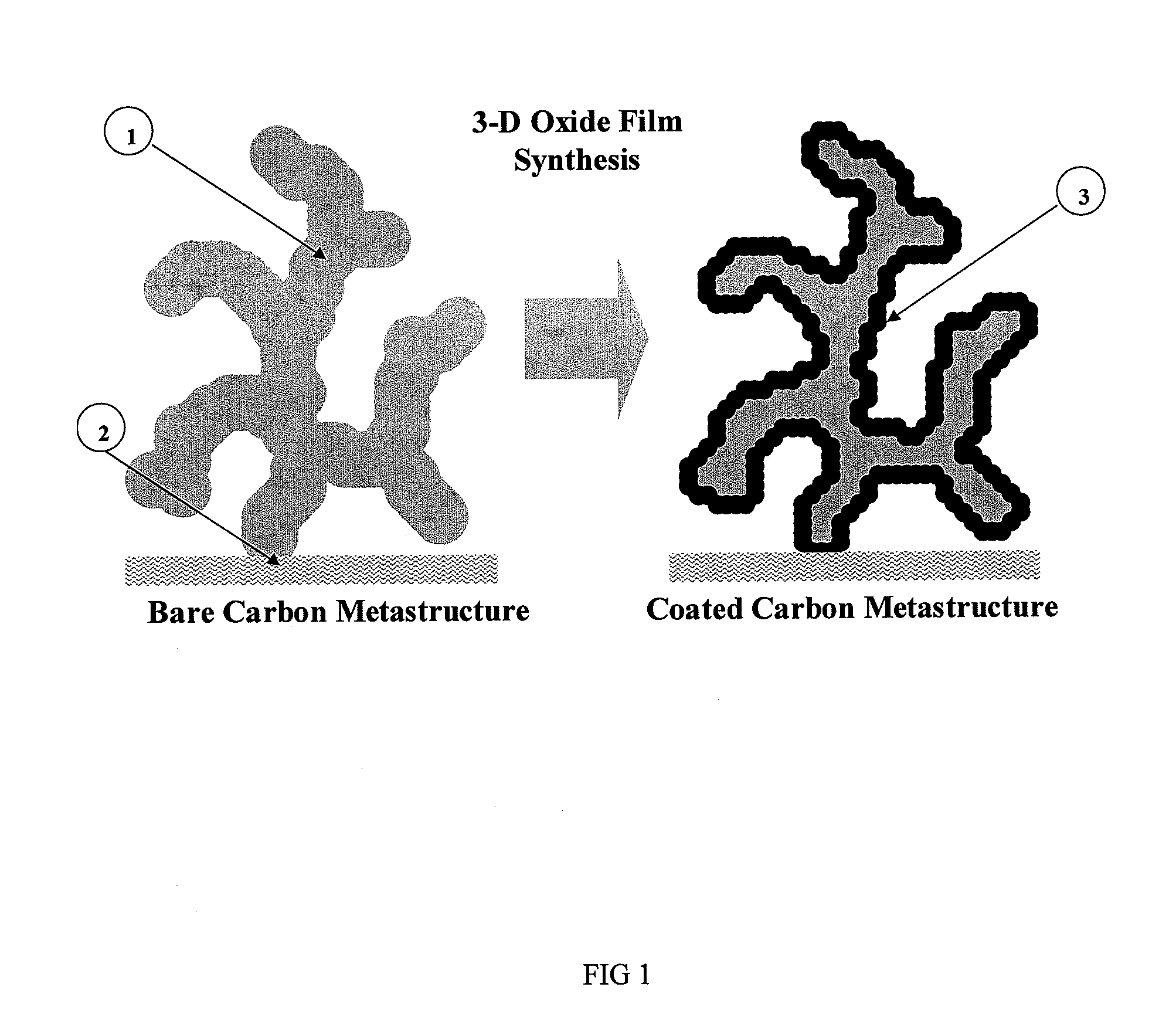

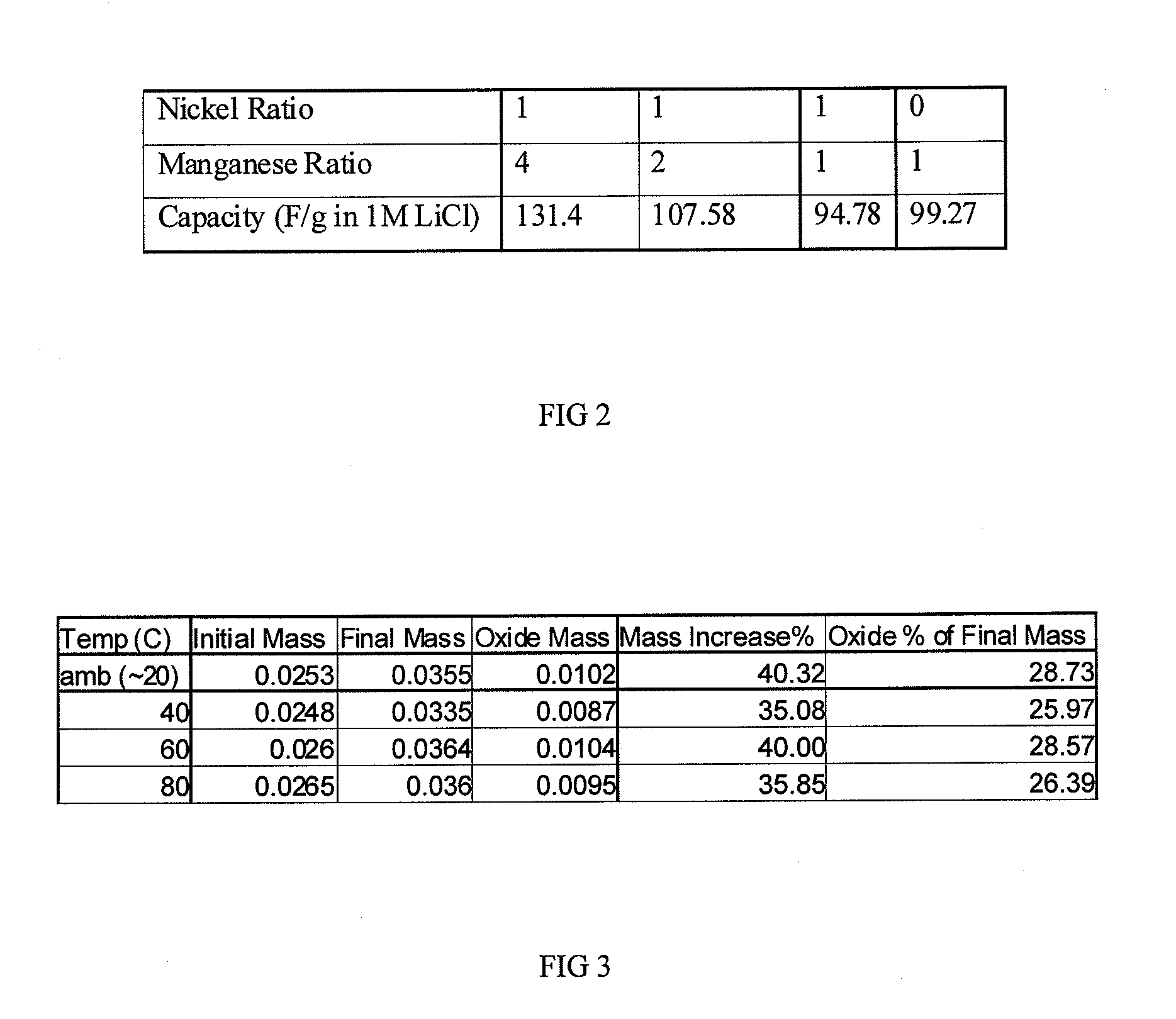

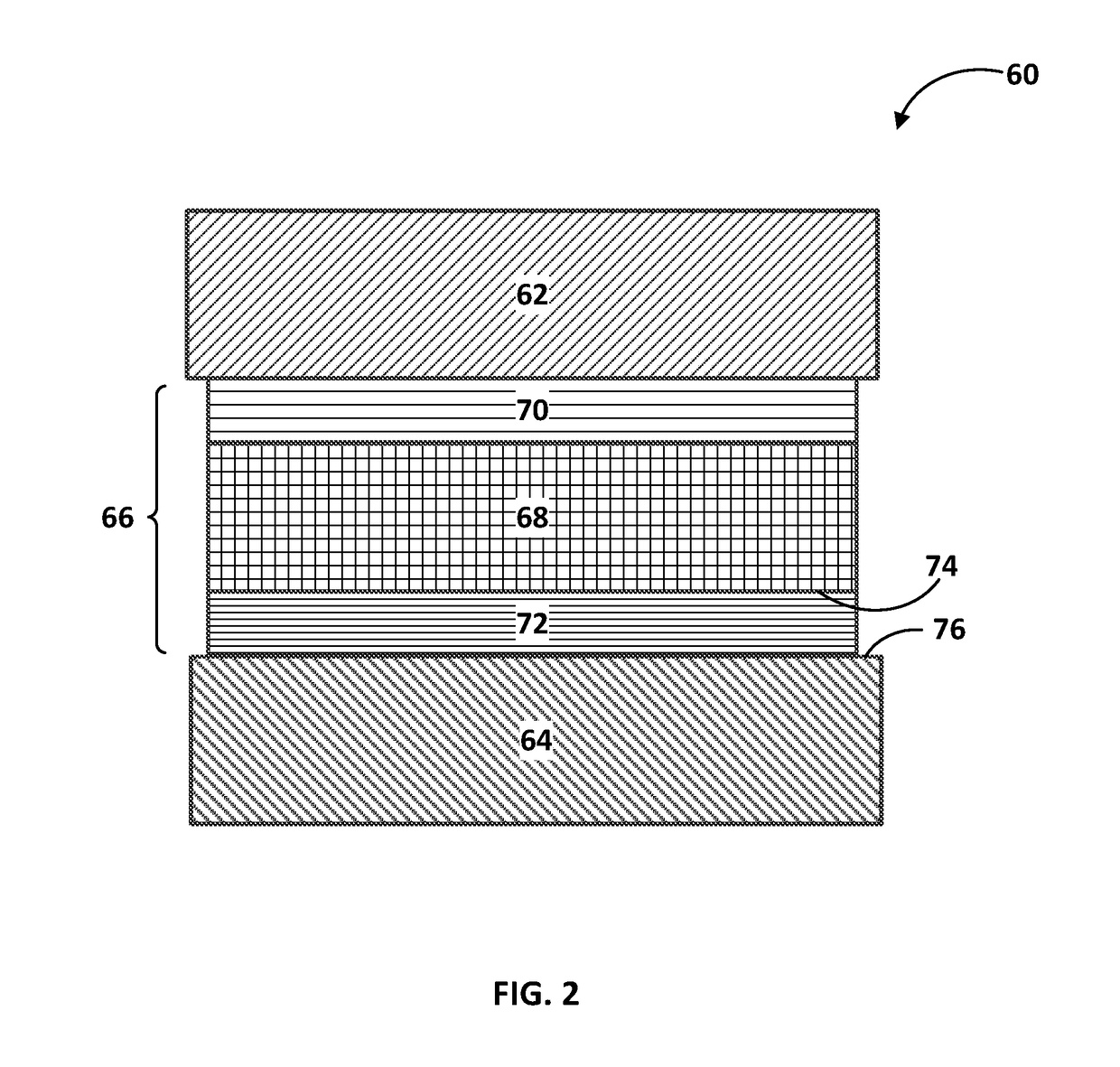

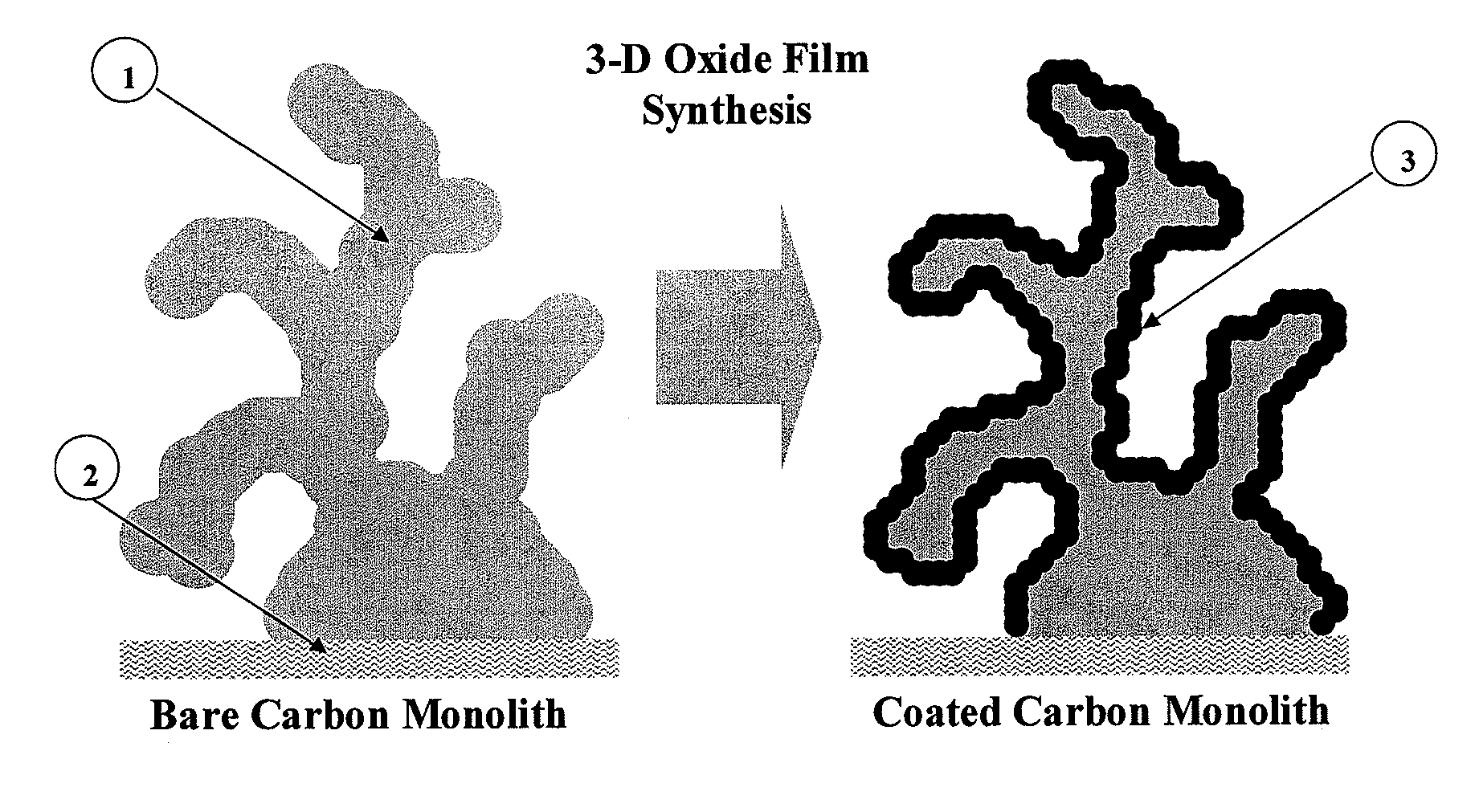

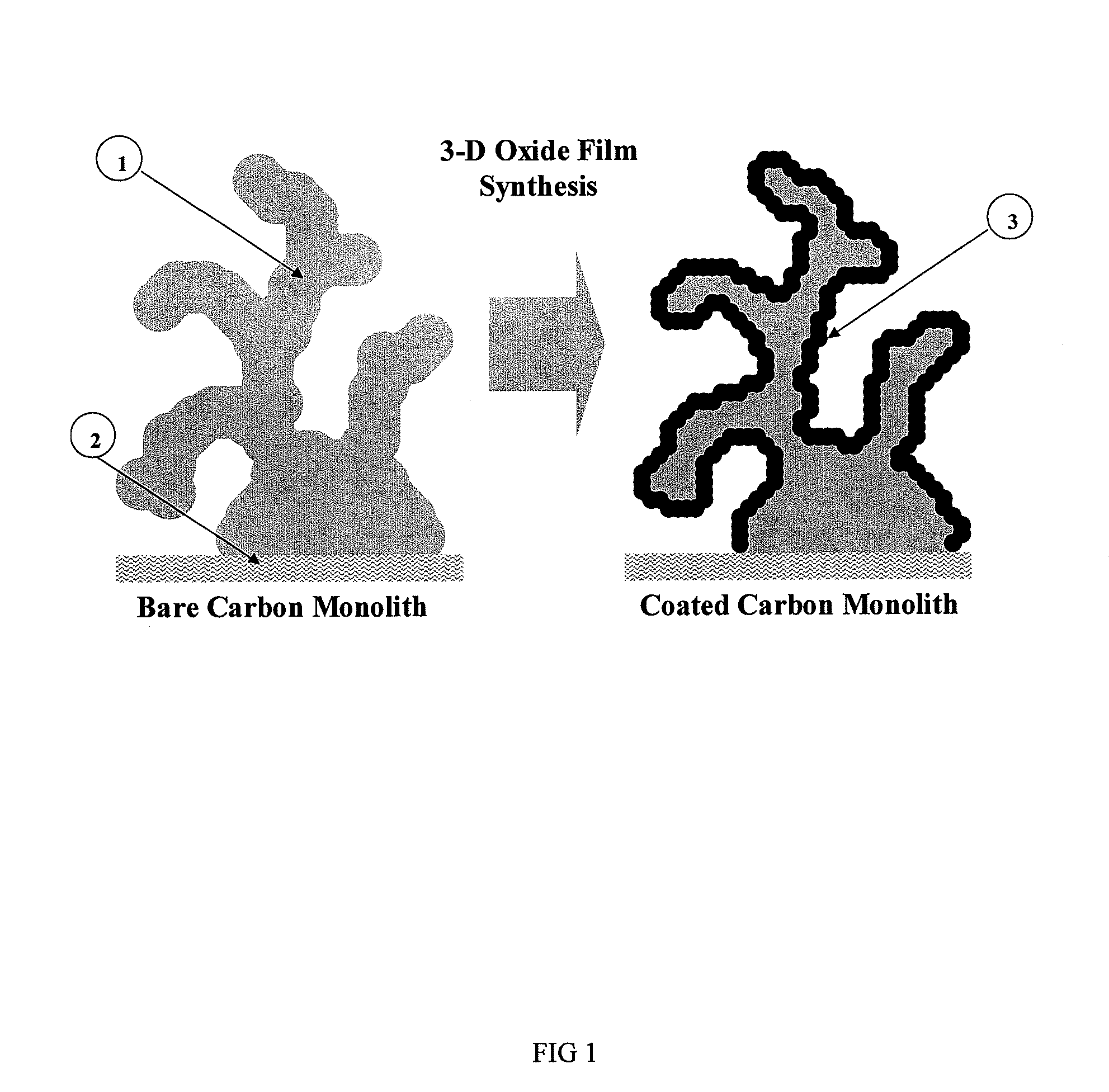

InactiveUS20110281174A1Increase capacityProlong lifeAlkaline accumulatorsHybrid capacitor electrodesRechargeable cellConformal coating

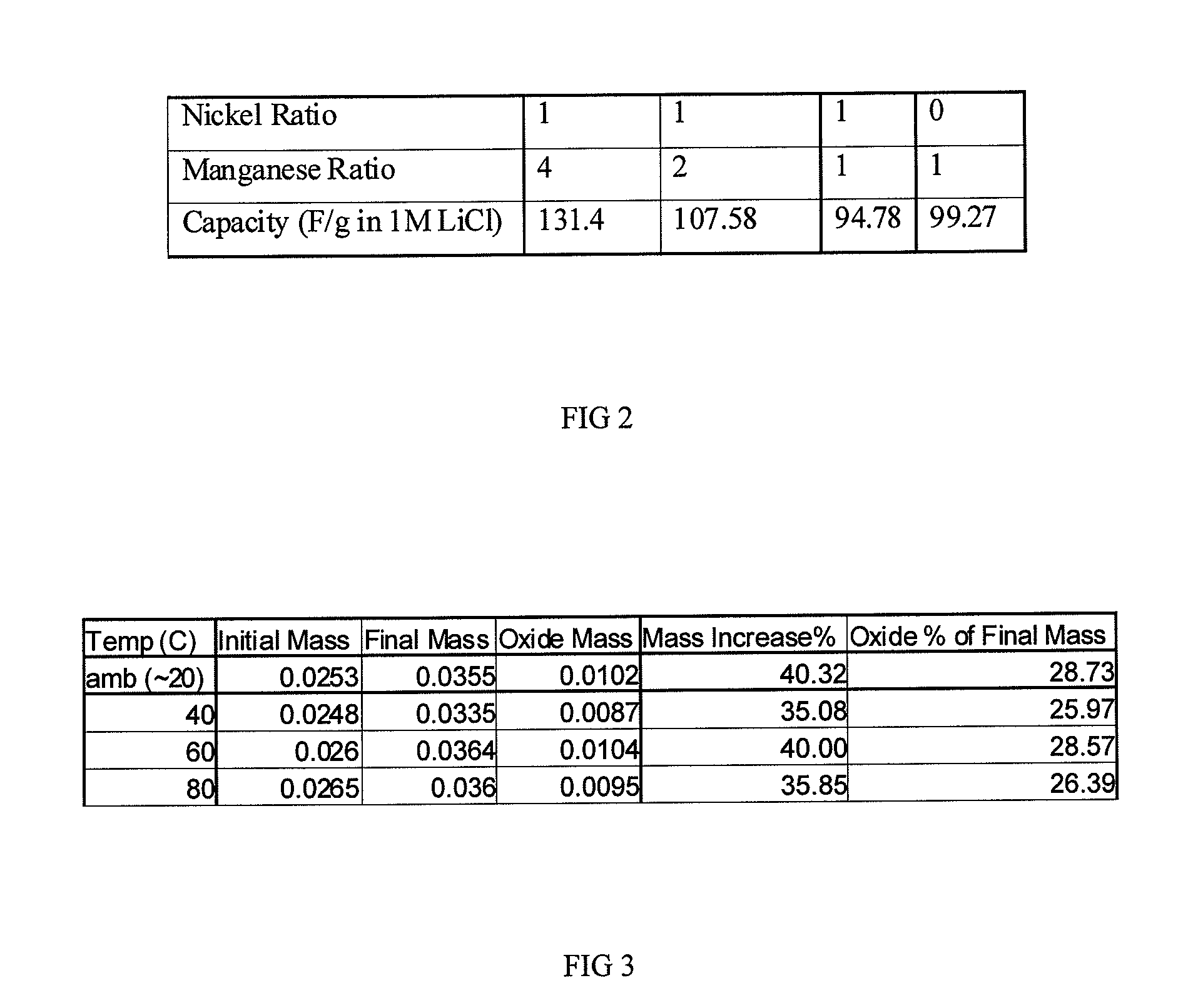

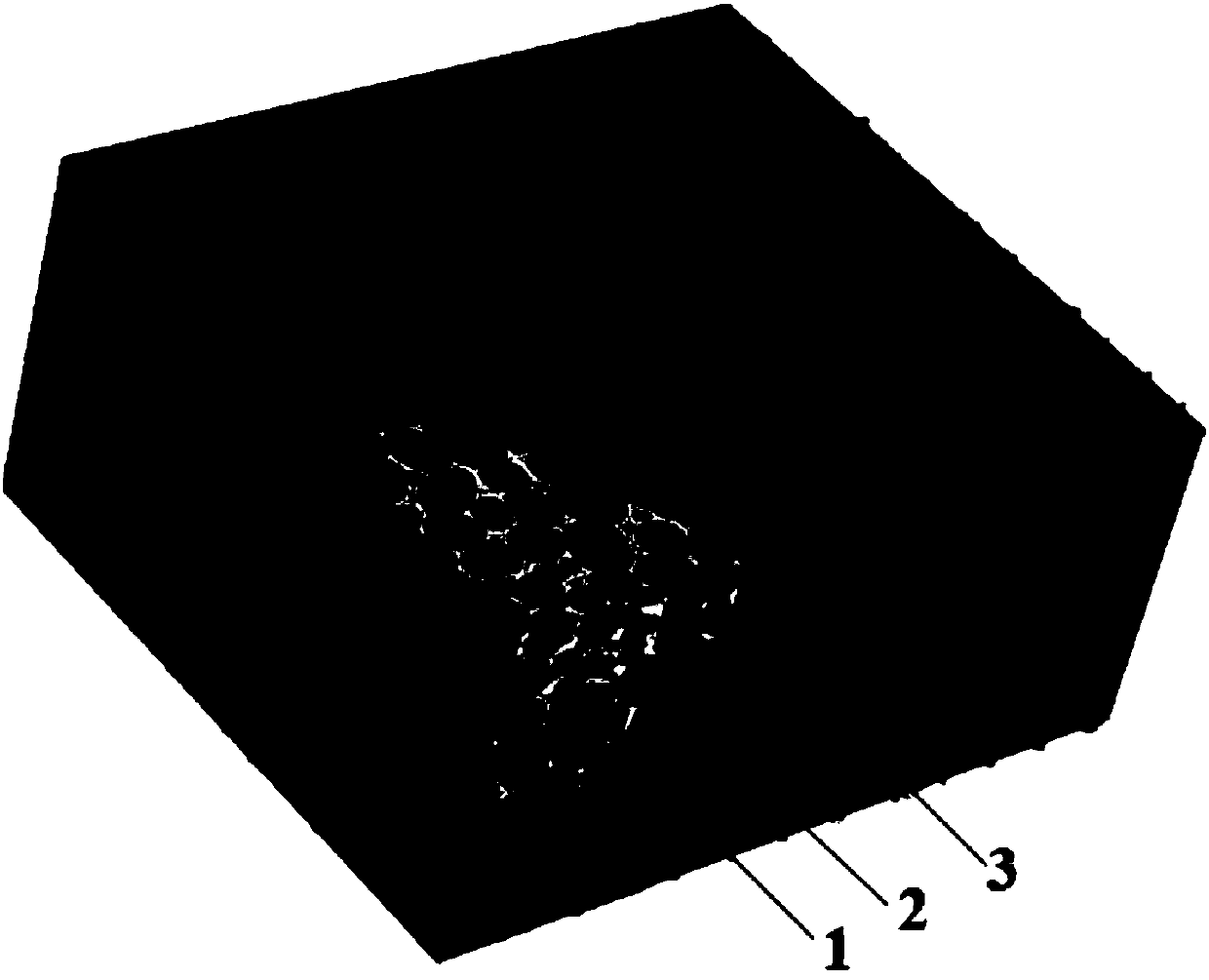

An electrode material is created by forming a thin conformal coating of metal oxide on a highly porous monolithic carbon structure. The highly porous carbon structure performs a role in the synthesis of the oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of metal oxide. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

High density electrode and battery using the electrode

ActiveUS20070111101A1Permeability impairmentHigh theoretical capacityNon-metal conductorsSolid electrolytesHigh energyElectrolyte

The invention relates to a high-density electrode, obtained by impregnating a high-density electrode which comprises an electrode active substance and carbon fiber having a fiber filament diameter of 1 to 1,000 nm and has a porosity of 25% or less, with a solid polymer electrolyte; and to a battery including the resultant (high-density) electrode. According to the invention, electrolytic solution permeability and electrolytic solution retainability, which are matters of importance in realizing a high-density electrode for achieving a battery having a high energy density, can be improved.

Owner:SHOWA DENKO KK

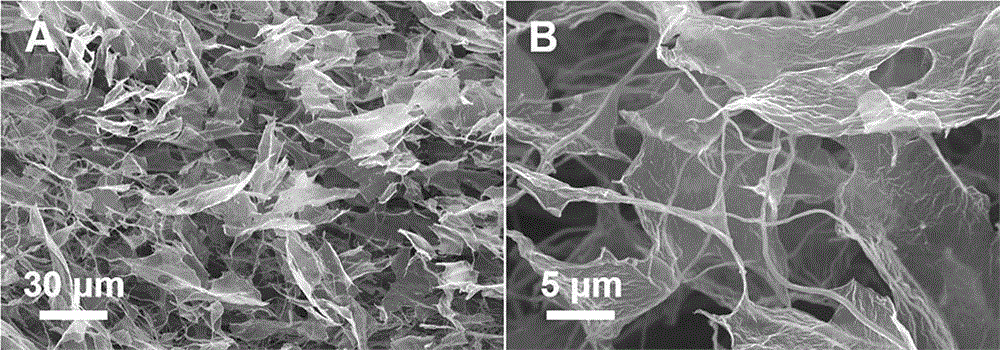

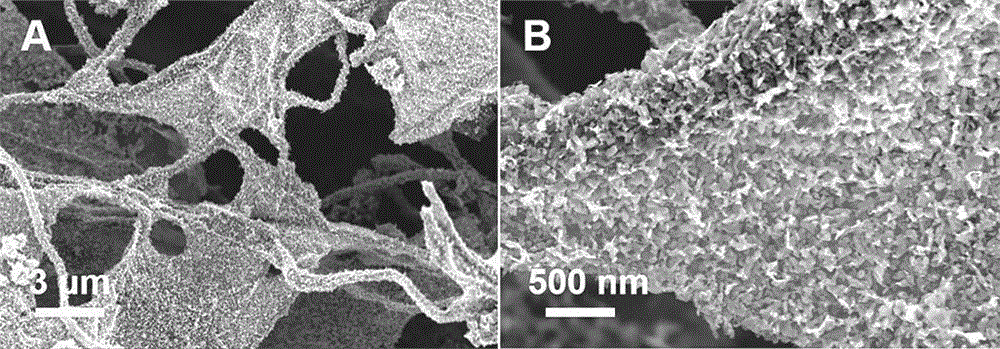

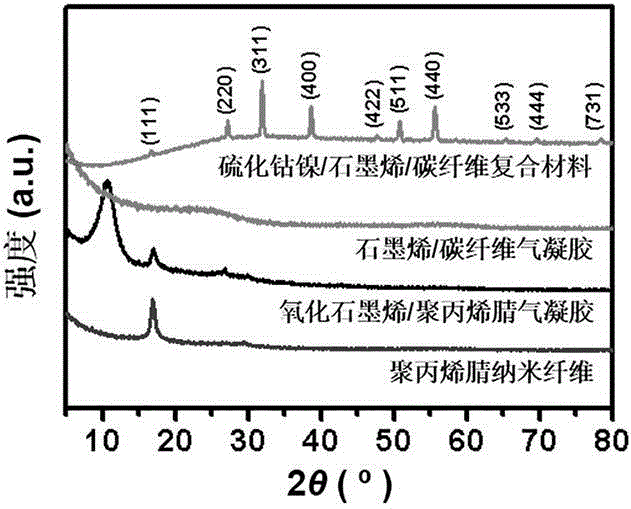

Vulcanized cobalt-nickel/graphene/carbon nano fiber composite material and preparation method thereof

InactiveCN105293590AEasy to prepareEasy to operateHybrid capacitor electrodesCell electrodesLithium electrodeCarbon nanofiber

The invention belongs to the technical field of transition metal sulfide-carbon materials, and particularly relates to a vulcanized cobalt-nickel / graphene / carbon nano fiber composite material and a preparation method thereof. The preparation method includes the steps that polyacrylonitrile nano fibers are prepared through electrostatic spinning, oxidized graphene / polyacrylonitrile nano fiber aerogel is prepared through mechanical stirring and freezing drying, then graphene / carbon nano fiber aerogel is prepared through high-temperature carbonization, and finally, vulcanized cobalt-nickel nanosheets grow in situ on the graphene / carbon nano fiber aerogel through the one-step hydrothermal method. The vulcanized cobalt-nickel / graphene / carbon nano fiber composite material prepared through the method has the advantages that the material has a three-dimensional porous space structure, conductivity is good and chemical properties are stable, and can serve as an ideal high-performance electro-catalysis material and electrode materials of new energy devices such as lithium ion batteries and solar batteries.

Owner:FUDAN UNIV

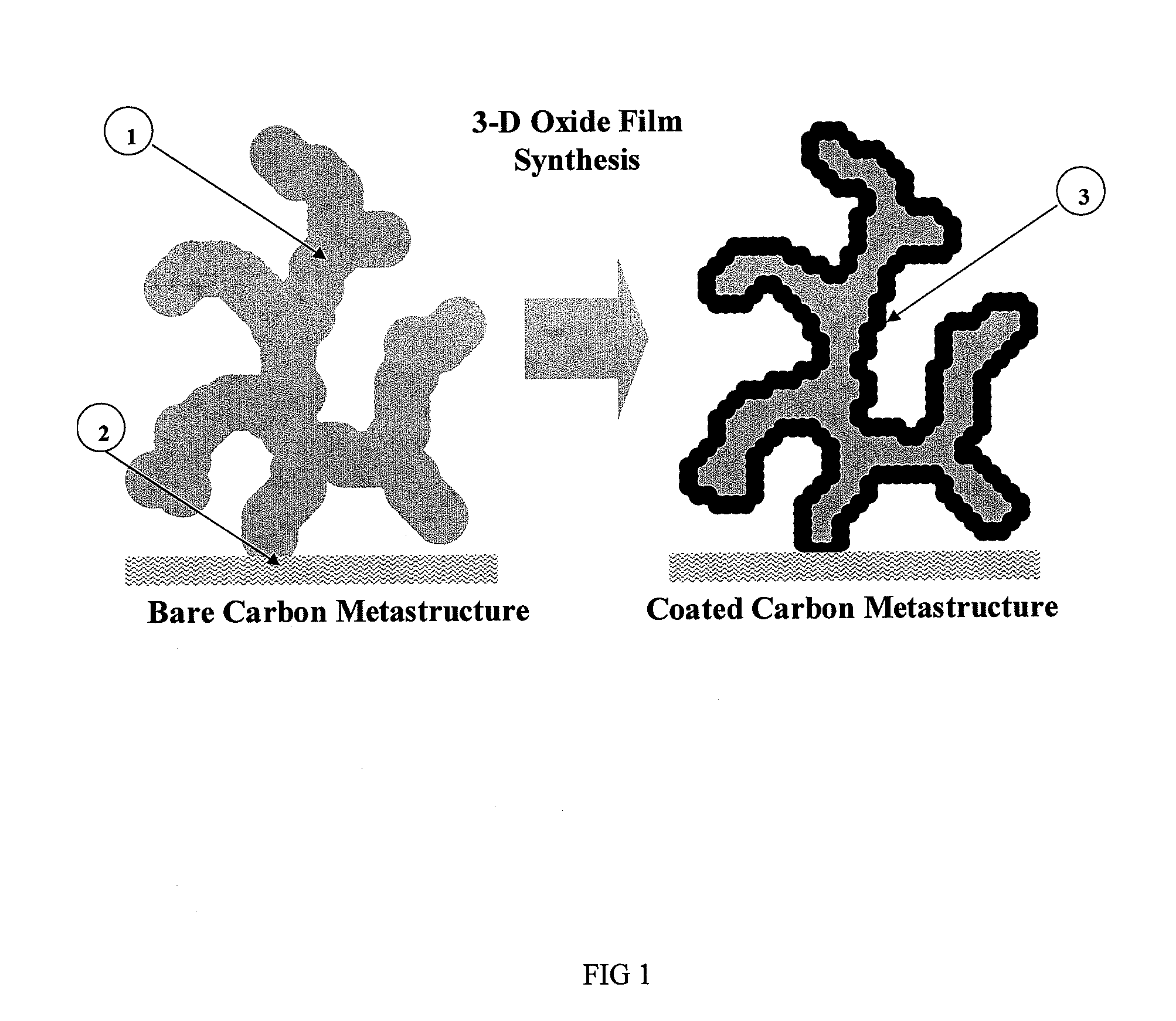

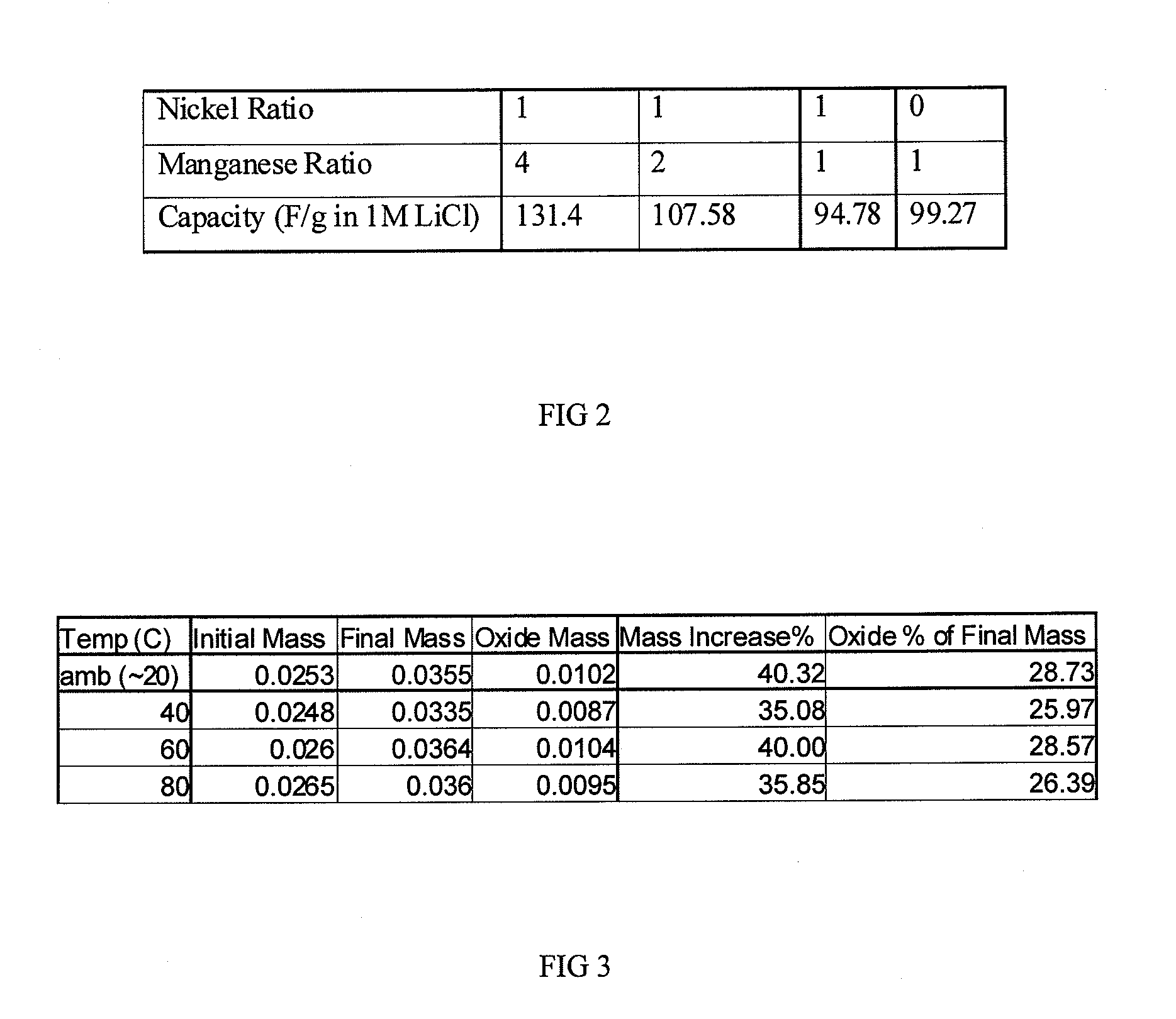

Electrode, related material, process for production, and use thereof

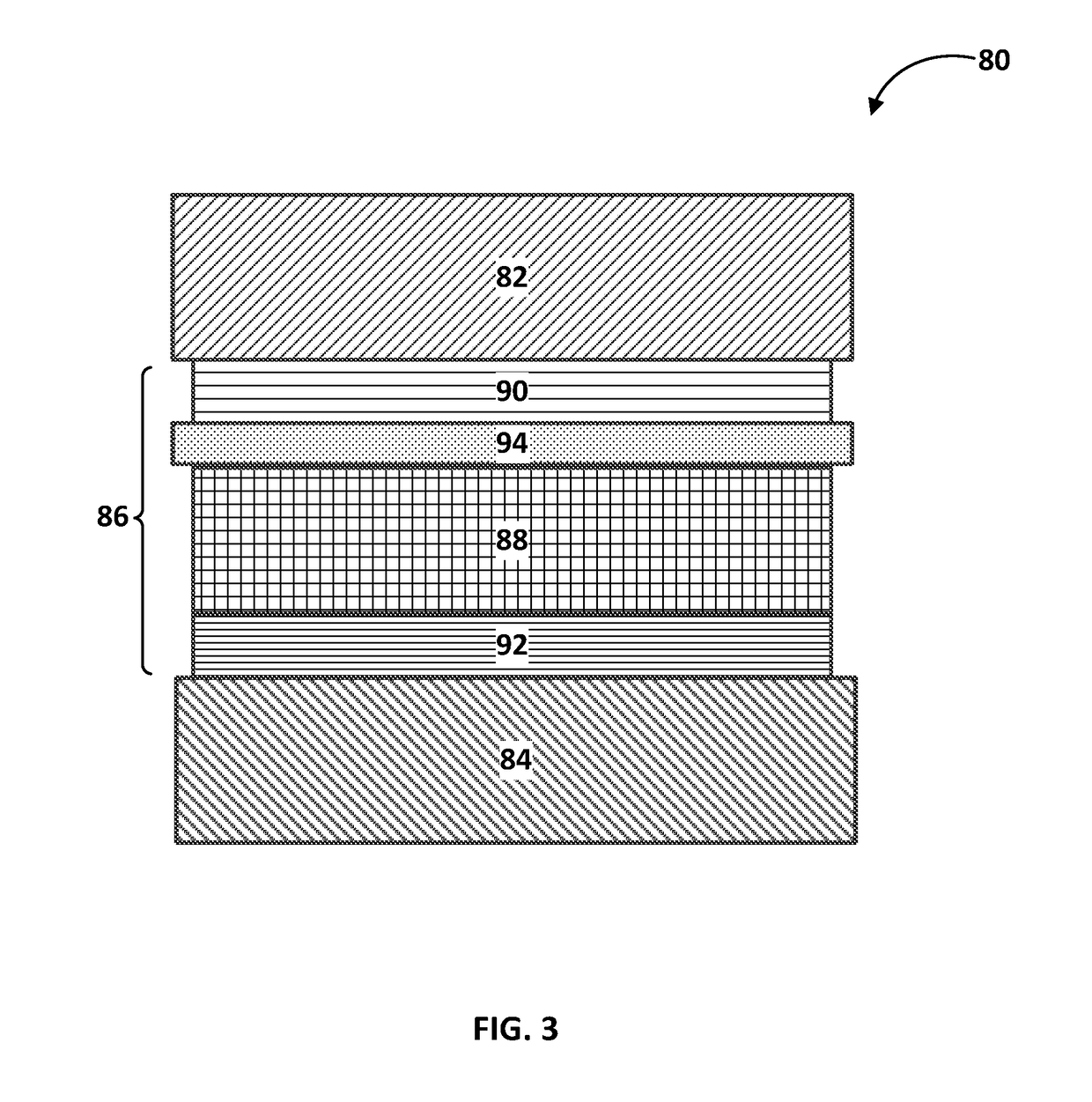

InactiveUS20110281157A1Increase capacityProlong lifeMaterial nanotechnologyElectrode manufacturing processesMeta structureConformal coating

An electrode material is created by forming a thin conformal coating of metal oxide on a highly porous carbon meta-structure. The highly porous carbon meta-structure performs a role in the synthesis of the oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of metal oxide. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

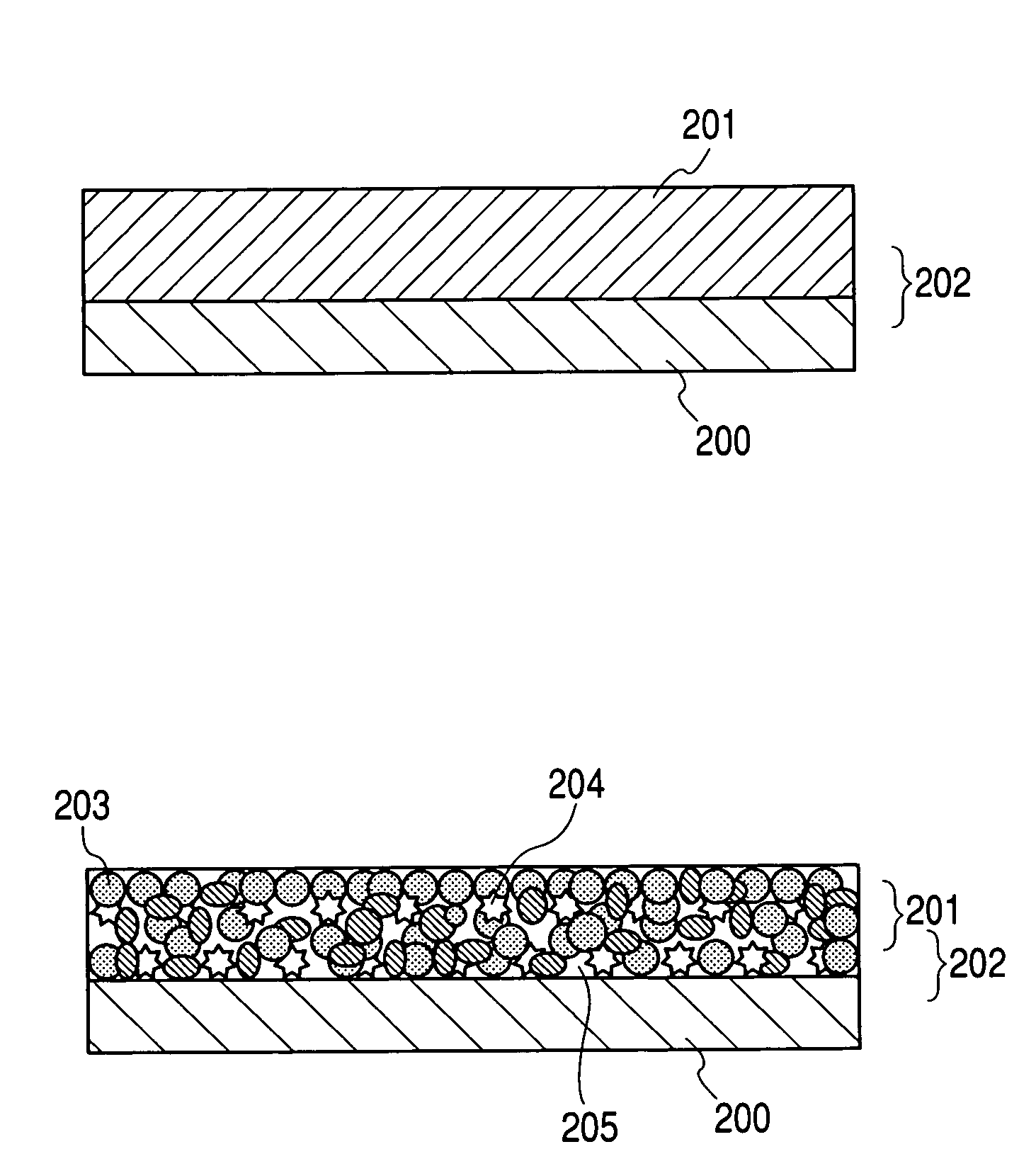

Negative electrode material for a non-aqueous electrolyte secondary battery and processes for its manufacture

InactiveUS6835496B1Maintain good propertiesReduce battery sizeSolid electrolytesElectrode manufacturing processesAlloySolid solution

A negative electrode material for a nonaqueous electrolyte secondary battery having a high discharge capacity and a good cycle life is made from alloy particles having an average particle diameter of 0.1-50 mum and including Si phase grains 40 and a phase of a solid solution or an intermetallic compound of Si and other element selected from Group 2A elements, transition elements, Group 3B elements, and Group 4B elements from the long form periodic table (for example, an NiSi2 phase 42 and an [NiSi2+NiSi] phase 41) at least partially enveloping the Si phase grains. 5-99 wt % of this material is Si phase grains. The alloy particles can be manufactured by rapid solidification (such as atomization or roller quenching) of a melt including Si and the other element, or by adhering the other element to Si powder by electroless plating or mechanical alloying and then performing heat treatment. Even if rapid solidification is carried out, a negative electrode material having a good discharge capacity and cycle life is obtained without heat treatment.

Owner:PANASONIC CORP

Electrode, related material, process for production, and use thereof

InactiveUS8503162B2Increase capacityProlong lifeNon-metal conductorsLiquid electrolytic capacitorsMeta structureConformal coating

An electrode material is created by forming a thin conformal coating of metal oxide on a highly porous carbon meta-structure. The highly porous carbon meta-structure performs a role in the synthesis of the oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of metal oxide. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

Transition metal chalcogenide nanosheet material and preparation method thereof, battery anode material, secondary battery and application thereof

InactiveCN109650348AImprove performanceHigh specific capacityMaterial nanotechnologySecondary cellsSulfurSilicon dioxide

The invention provides a transition metal chalcogenide nanosheet material and a preparation method thereof, a battery anode material, a secondary battery and an application thereof, and belongs to thetechnical field of transition metal chalcogenides. The invention provides a preparation method of a transition metal chalcogenide nanosheet material, comprising the following steps: dissolving raw materials in an aqueous solution of soluble salt, removing moisture to obtain a solid, sintering the solid, and washing to obtain a transition metal chalcogenide nanosheet material, wherein the raw materials include a chalcogen precursor and a transition metal precursor. According to the preparation method, the soluble salt is used as a template, is inexpensive, is environmentally friendly and is easy to remove in post-treatment, and the obtained transition metal chalcogenide nanosheet material has a thinner sheet thickness. Compared with a traditional silica template method or a hydrothermal method, the preparation method of the invention greatly shortens the synthesis cycle, is simple and feasible, is controllable, has characteristics of high yield and simple experimental operation, and issuitable for large-scale production.

Owner:SHENZHEN INST OF ADVANCED TECH

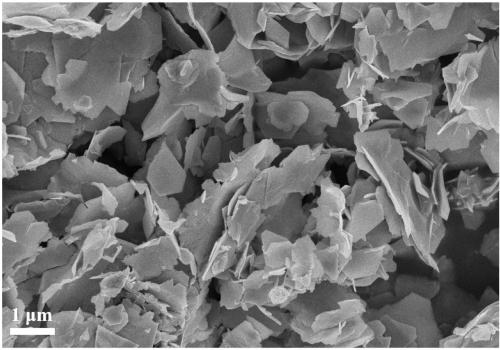

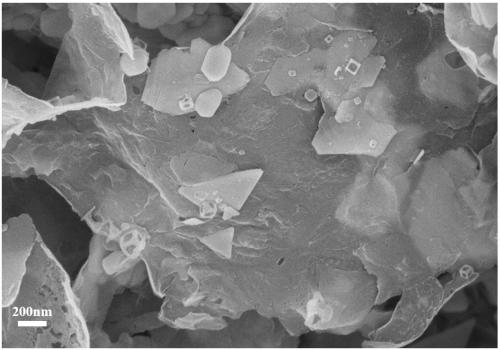

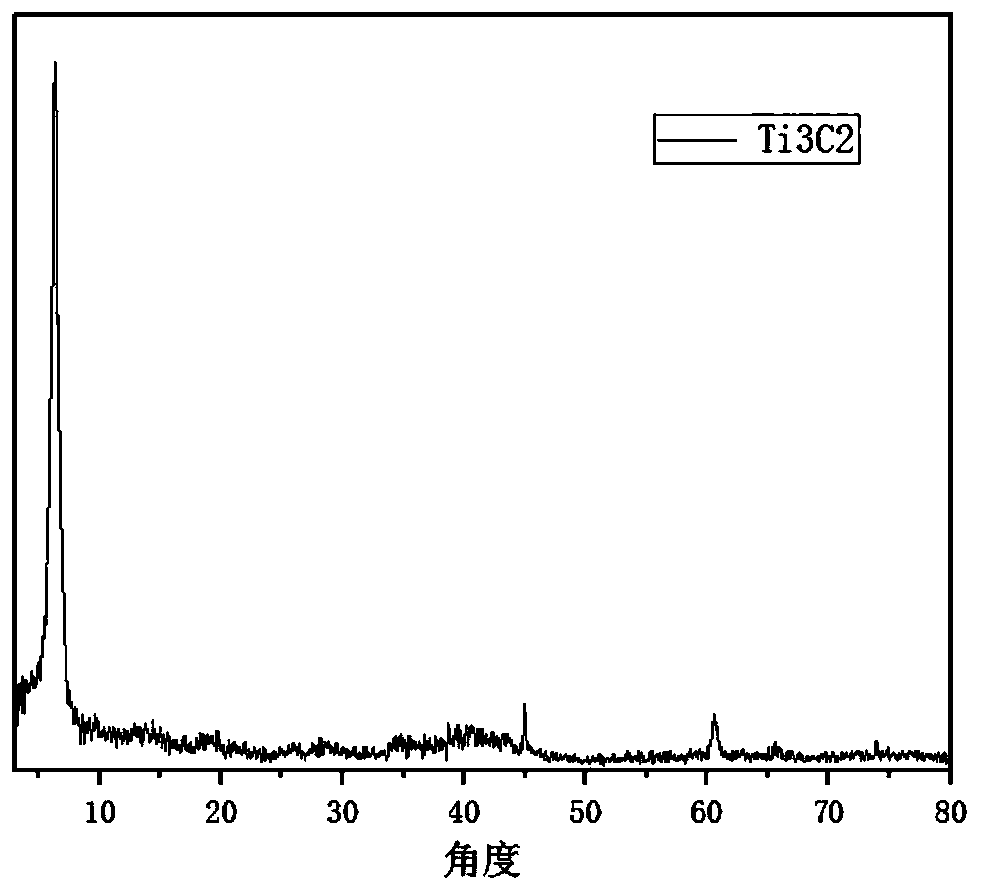

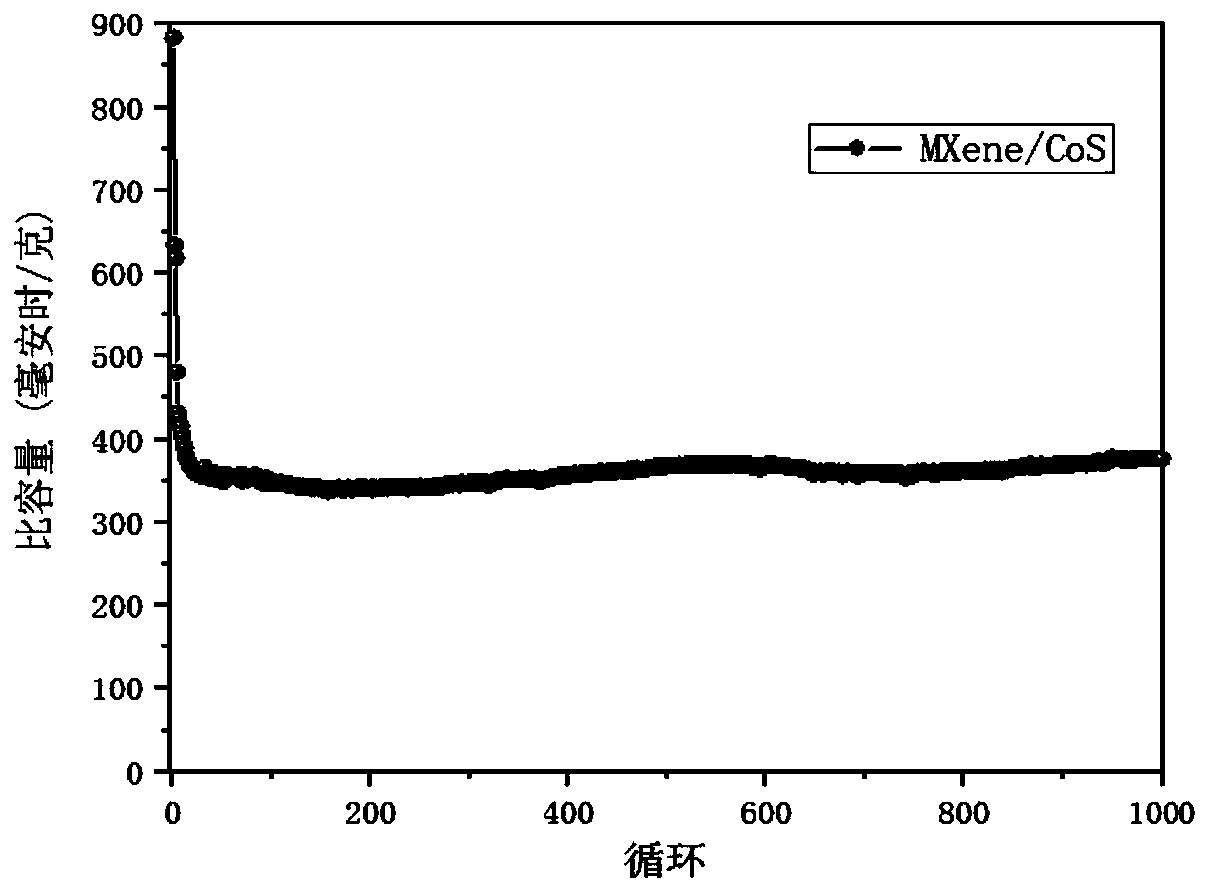

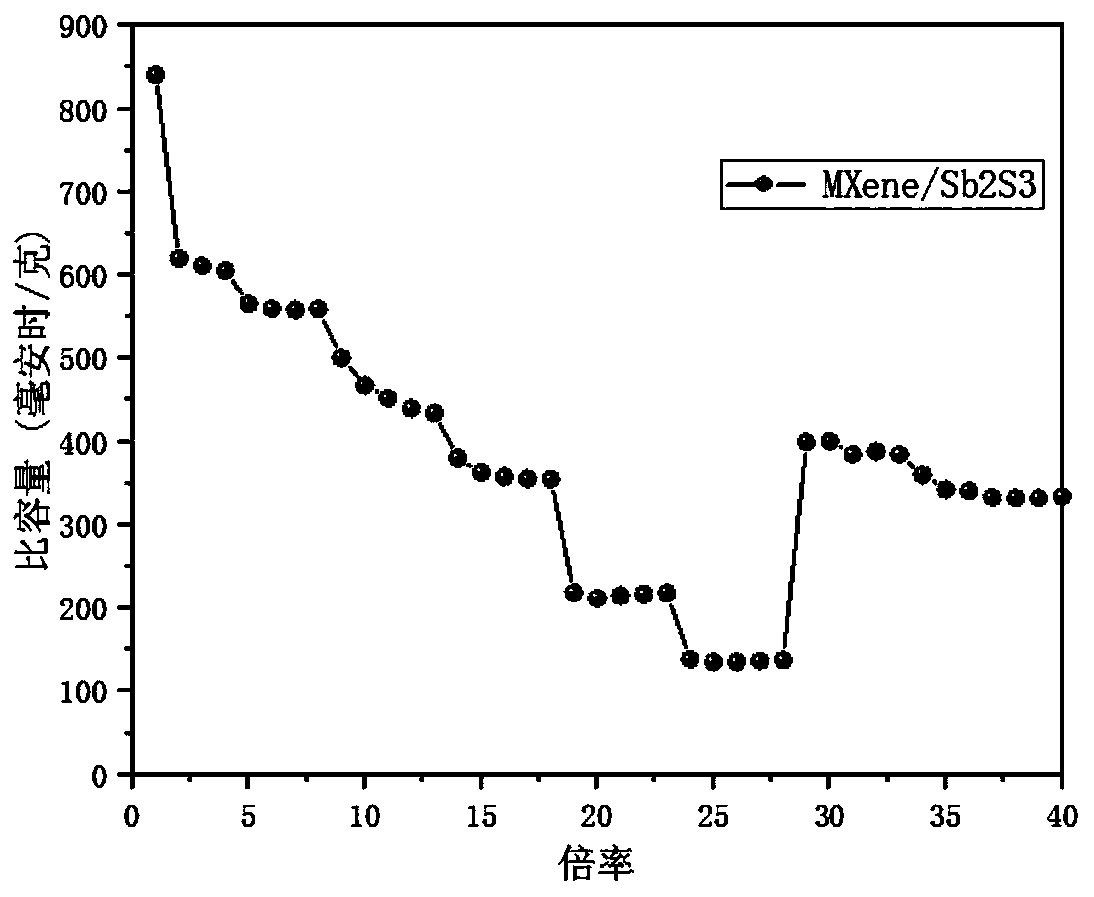

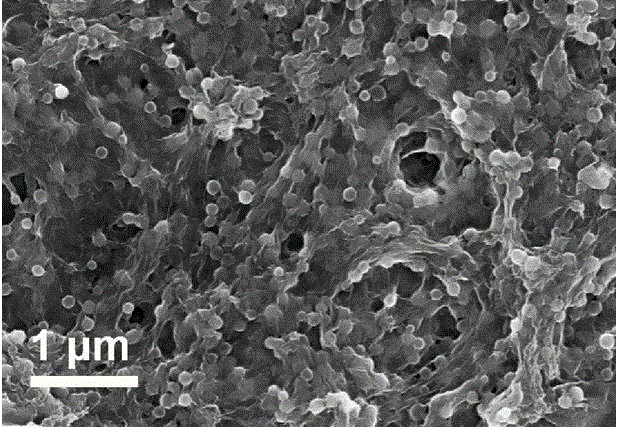

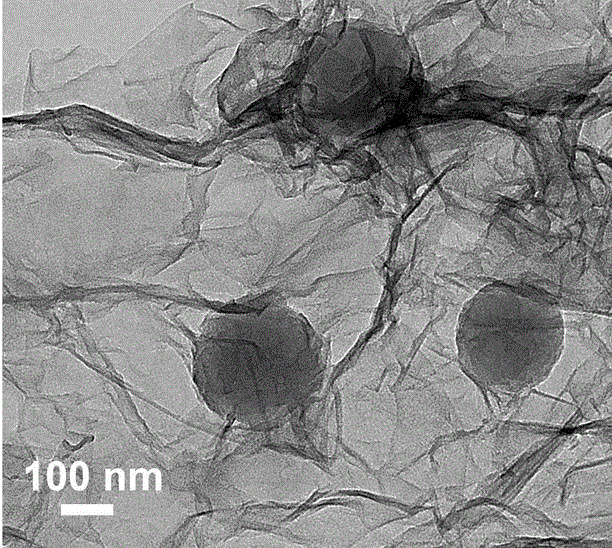

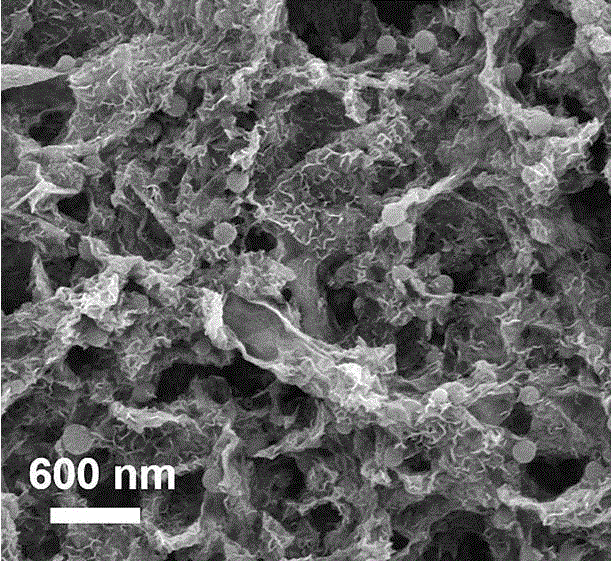

MXene/metal sulfide composite material, anode material and preparation and application

ActiveCN111180694AHigh theoretical capacityLow costNegative electrodesSecondary cellsHigh energyMetallic sulfide

The invention belongs to the technical field of high-performance / high-energy-density lithium ion battery negative electrodes, and particularly relates to an MXene / metal sulfide composite material, ananode material and preparation and application. The preparation method comprises the following steps: mixing and stirring a metal salt of a transition metal element and an MXene material, and carryingout solid-liquid separation and drying to obtain an MXene / metal salt mixture; and under a protective atmosphere, mixing the MXene / metal salt mixture with a sulfur source, and carrying out heat treatment to obtain the MXene / metal sulfide composite material. The invention also provides a sulfur-doped MXene / metal sulfide-based composite battery anode material. The anode material comprises the MXene / metal sulfide composite material. The anode material provided by the invention has good long-cycle stability, high energy density and excellent rate capability, and can be applied to various fields.

Owner:GUANGDONG UNIV OF TECH +1

Molybdenum sulfide/graphene/carbon nanoball composite material and preparing method thereof

InactiveCN105293581AEasy to makeEasy to operateMaterial nanotechnologyHybrid capacitor electrodesNew energySolar battery

The invention belongs to the technical field of transition metal sulfide / carbon materials, and particularly discloses a molybdenum sulfide / graphene / carbon nanoball composite material and a preparing method thereof. The preparing method includes the steps that carbon nanoballs are prepared with a hydrothermal method, then the carbon nanoballs and graphene oxide are mixed, molybdenum sulfide nanosheets grow on the graphene oxide / carbon nanoballs with a one-step hydrothermal method, and the molybdenum sulfide / graphene / carbon nanoball composite material is prepared with a thermal reduction method. The prepared molybdenum sulfide / graphene / carbon nanoball composite material has the advantages of being of a three-dimensional porous structure, being good in electrical conductivity and stable in chemical performance and the like, and can serve as an ideal high-performance electro-catalysis material and an electrode material of new energy devices such as a lithium-ion battery and a solar cell.

Owner:FUDAN UNIV

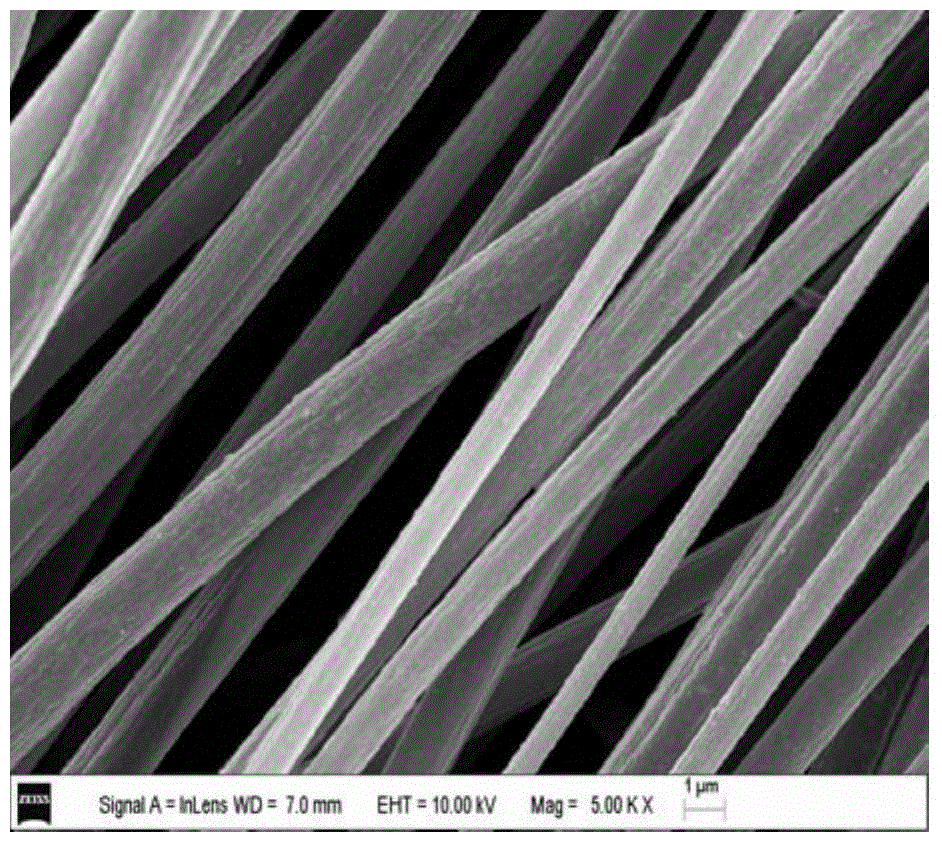

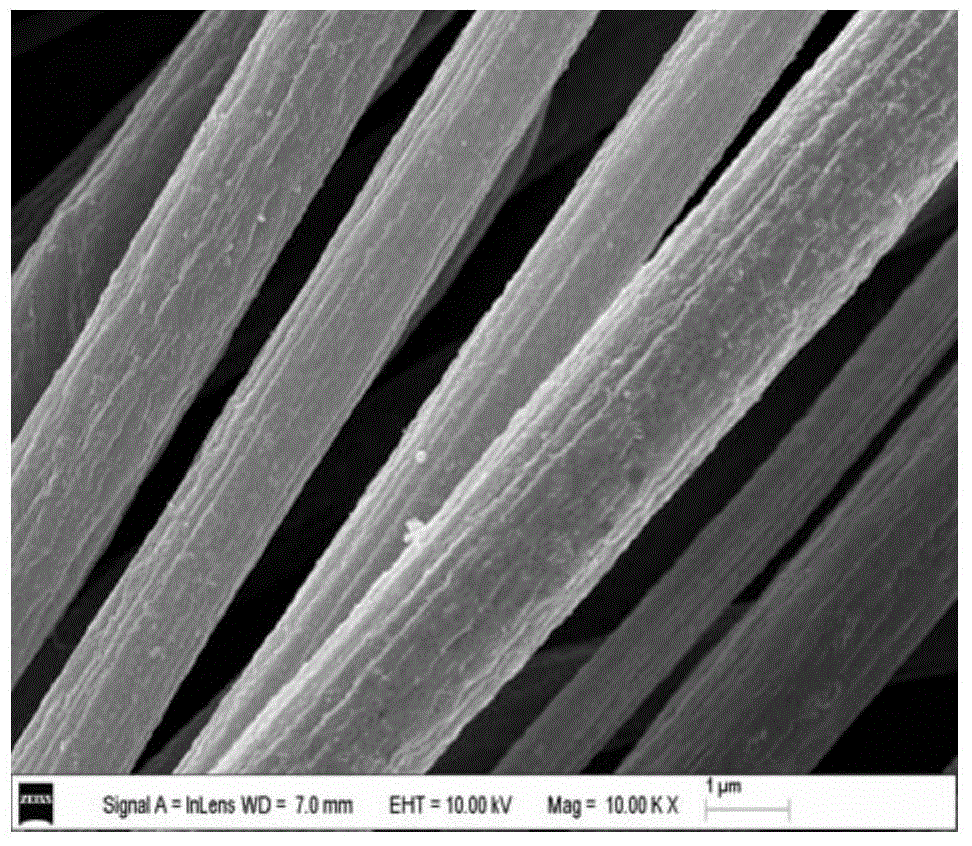

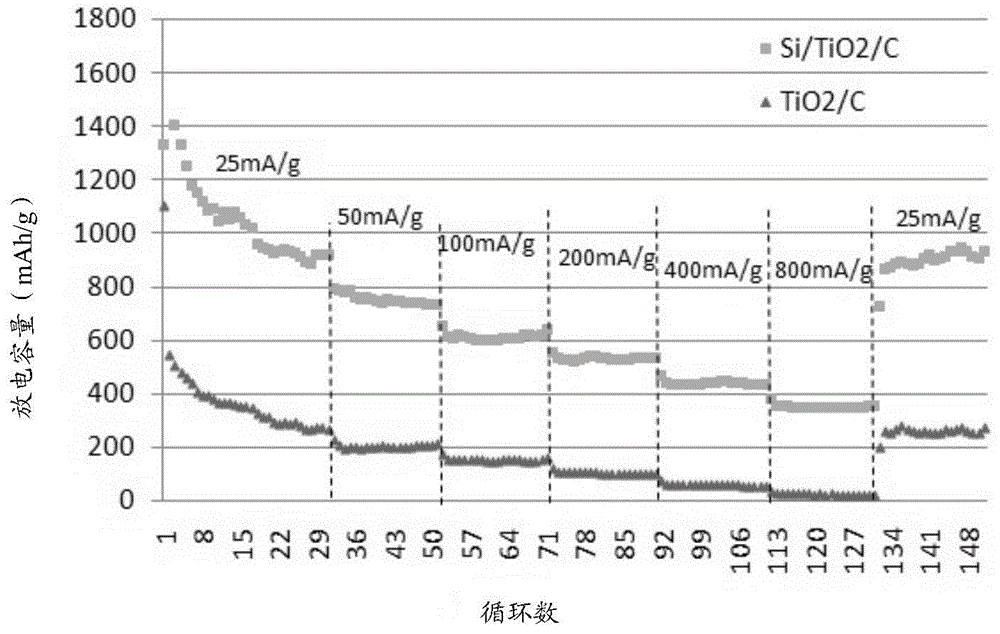

Si-TiO2-C nano fiber composite thin film, preparation method and application thereof

ActiveCN104835949AImprove the preparation of Si-TiO

<sub>2</sub>

Efficiency of -C nanofiber composite filmsImprove efficiencyMaterial nanotechnologyCell electrodesFiberNano silicon

The invention provides a Si-TiO2-C nano fiber composite thin film, a preparation method and an application thereof. The preparation method for preparing the Si-TiO2-C nano fiber composite thin film includes following steps: (1) providing a spinning liquid which contains nano silicon powder, a titanium precursor and a carbon precursor; (2) performing electrostatic spinning to the spinning liquid to prepare a nano fiber film; (3) pre-oxidizing the nano fiber film under an oxygen-containing atmosphere at 100-300 DEG C to obtain a stabilized nano fiber film; and (4) carbonizing the stabilized nano fiber film under an non-oxidizing atmosphere at 500-1000 DEG C to obtain the Si-TiO2-C nano fiber composite thin film. By means of the method, the Si-TiO2-C nano fiber composite thin film can be prepared quickly and effectively. The preparation method is simple in operations, is convenient and quick, and can easily achieve large-scale production.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

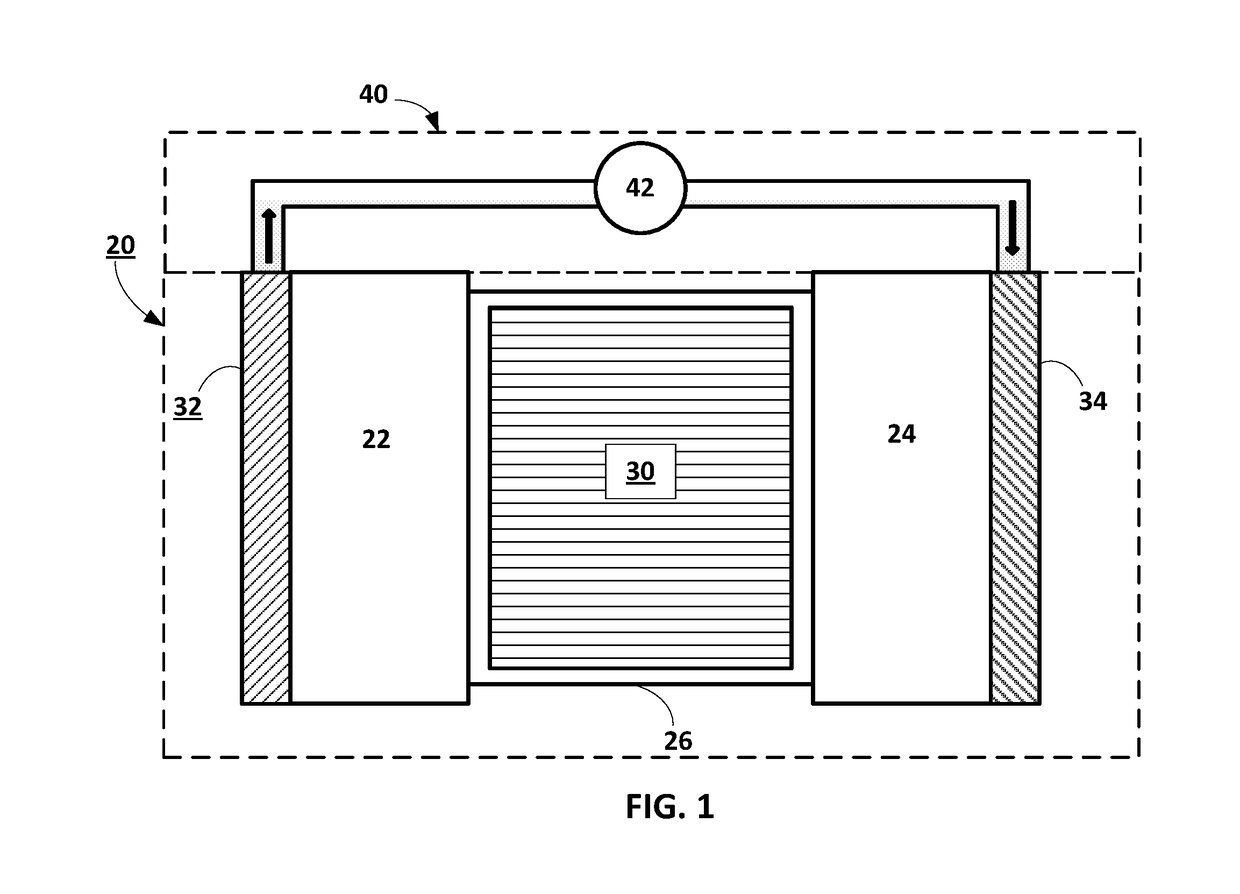

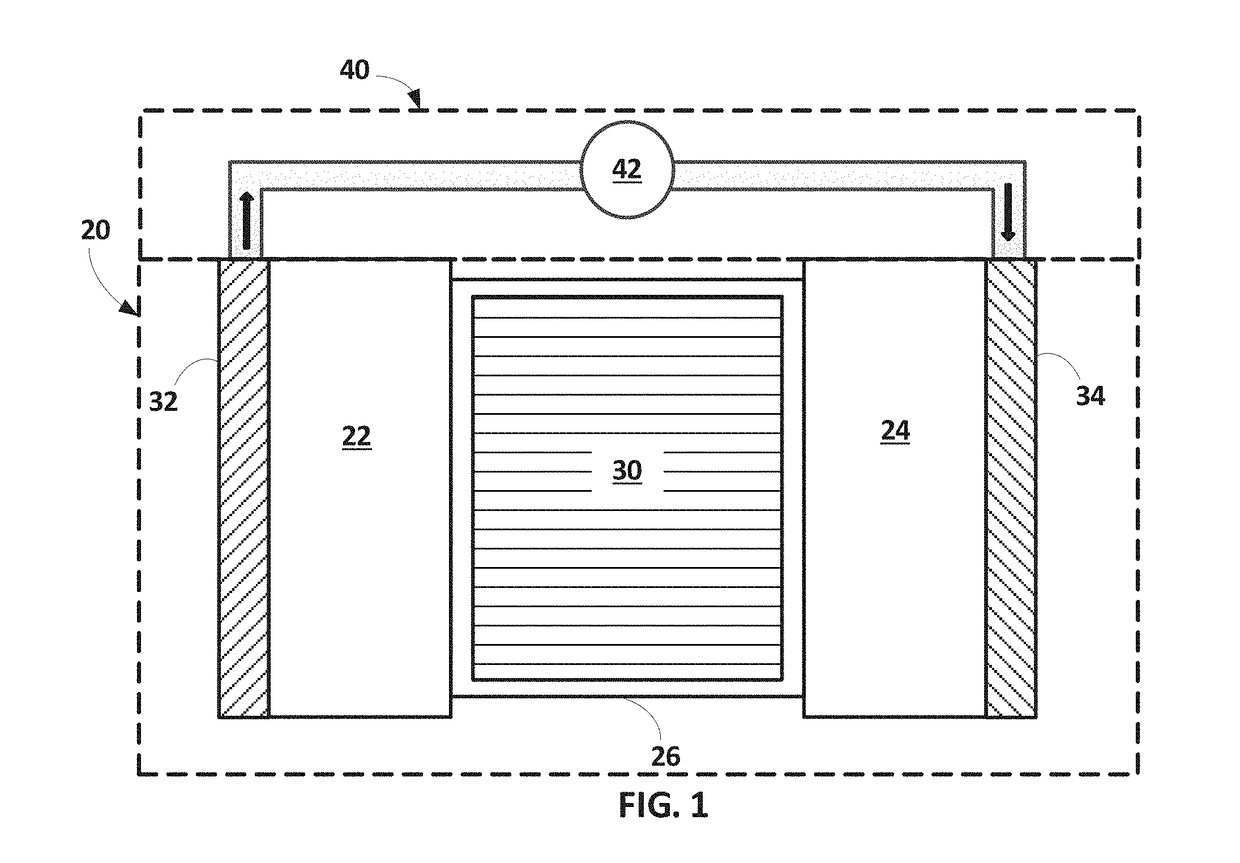

Lithium metal battery with hybrid electrolyte system

ActiveUS20190058210A1Improve complianceIncrease contactOrganic chemistryCell electrodesSolid state electrolyteLithium metal

An electrochemical cell includes a negative electrode that contains lithium and an electrolyte system. In one variation, the electrolyte system includes a first liquid electrolyte, a solid-dendrite-blocking layer, and an interface layer. The solid dendrite-blocking layer is ionically conducting and electrically insulating. The dendrite-blocking layer includes a first component and a distinct second component. The dendrite-blocking layer has a shear modulus of greater than or equal to about 7.5 GPa at 23° C. The interface layer is configured to interface with a negative electrode including lithium metal on a first side and the dendrite blocking layer on a second opposite side. The interface layer includes a second liquid electrolyte, a gel polymer electrolyte, or a solid-state electrolyte. The dendrite-blocking layer is disposed between the first liquid electrolyte and the interface layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

Monolithic electrode, related material, process for production, and use thereof

InactiveUS8493711B2Increase capacityProlong lifeAlkaline accumulatorsHybrid capacitor electrodesConformal coatingOxide coating

An electrode material is created by forming a thin conformal coating of metal oxide on a highly porous monolithic carbon structure. The highly porous carbon structure performs a role in the synthesis of the oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of metal oxide. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

Silicon-carbon composite material of closed cage structure and preparation method of silicon-carbon composite material of closed cage structure

ActiveCN107863513AExtend your lifeImprove buffering effectMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite material of a closed cage structure and a preparation method of the silicon-carbon composite material of the closed cage structure. The silicon-carboncomposite material of the closed cage structure is a hollow filled structure material in a closed cage form; the core of the hollow filled structure material is a silicon material-filled porous carbon material; the porous carbon material is filled with a silicon material; the silicon material has the void content of 50-95% in the porous carbon material; and a carbon material coats the outside ofthe silicon material-filled porous carbon material and the specific component of the carbon material is (SiOx)yC, wherein x is smaller than or equal to 2 and greater than or equal to 0 and y is smaller than or equal to 1 and greater than 0. When the silicon-carbon composite material of the closed cage structure is used as a negative electrode of a battery, contact of the silicon material and an electrolyte is isolated, the life of the battery is prolonged and the capacity performance and the cycle performance of the battery are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

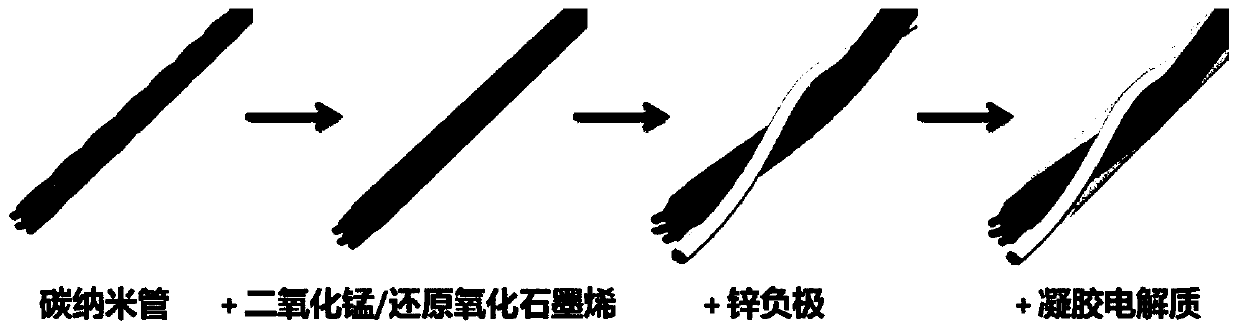

Aqueous zinc ion battery based on manganese dioxide/graphene and preparation method

ActiveCN110729518AImprove performanceExtend your lifeCell electrodesFinal product manufactureOxide compositeCarbon nanotube

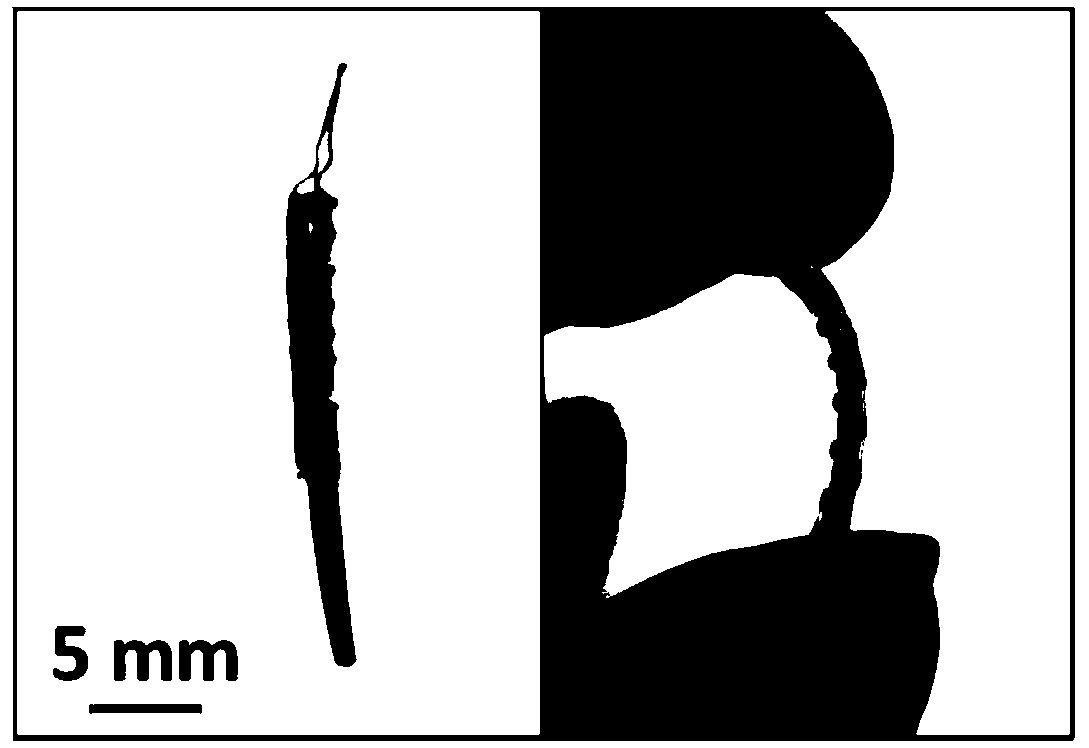

The invention belongs to the technical field of zinc ion batteries and relates to an aqueous zinc ion battery based on manganese dioxide / graphene and a preparation method. According to the zinc ion battery, carbon nanotube fiber uniformly loaded with a manganese dioxide / reduced graphene oxide composite material is used as a positive electrode, a fibrous zinc wire is used as a negative electrode; and the surfaces of the two electrodes are uniformly coated with a gel electrolyte, and then the two electrodes are mutually wound to form a winding structure. The preparation method comprises the following steps of: the preparation of a graphene oxide dispersion liquid; the preparation of a fibrous manganese dioxide / reduced graphene oxide positive electrode; and the assembly of a fibrous aqueous rechargeable zinc ion battery. The manganese dioxide / reduced graphene oxide composite material has a three-dimensional reticular frame structure with high conductivity, and therefore, the contact areaof a current collector and an active substance can be increased, contact resistance can be reduced, the performance of the fibrous battery can be improved, and the service life of the fibrous batterycan be prolonged. With the fiber battery woven into a fabric, wearable electronic equipment with excellent performance can be prepared.

Owner:FUDAN UNIV

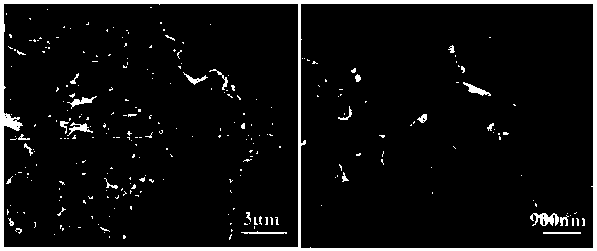

Cobaltous oxide/carbon composite hollow nanostructure material of dodecahedron structure and application thereof in negative electrodes of lithium batteries

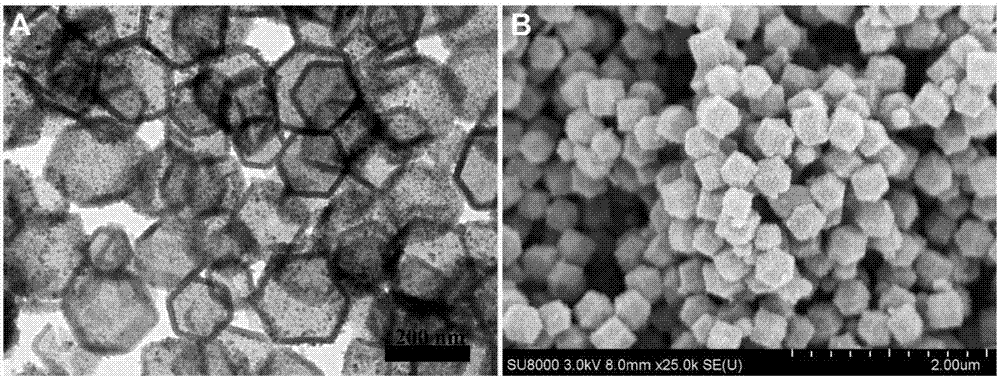

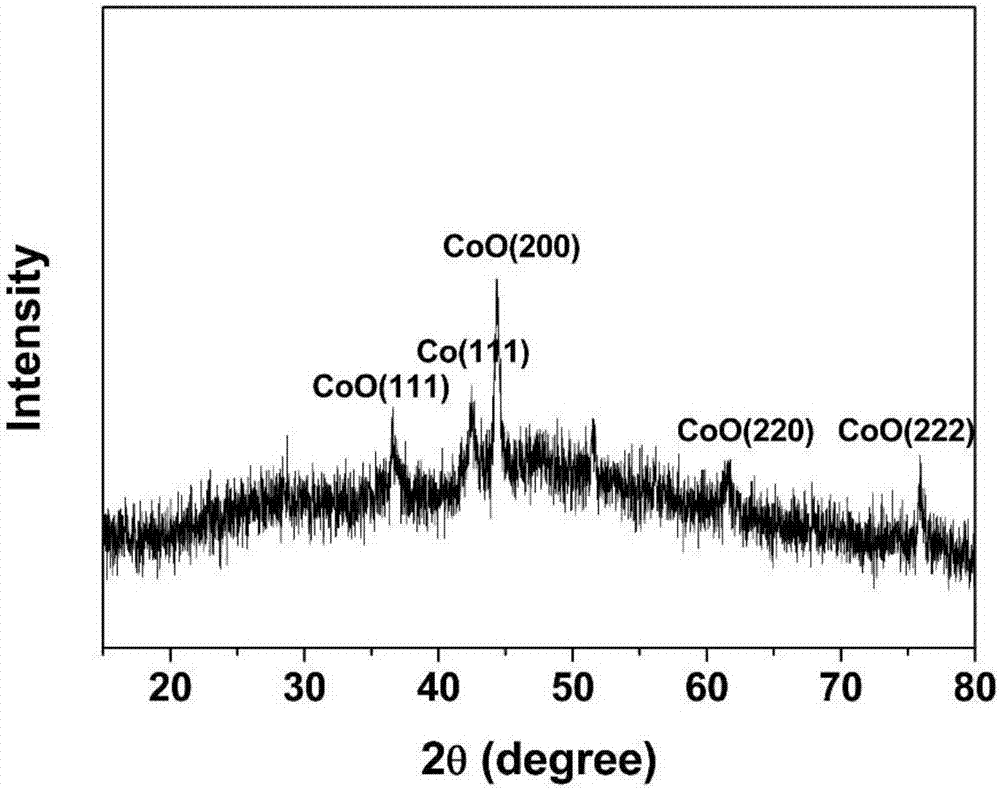

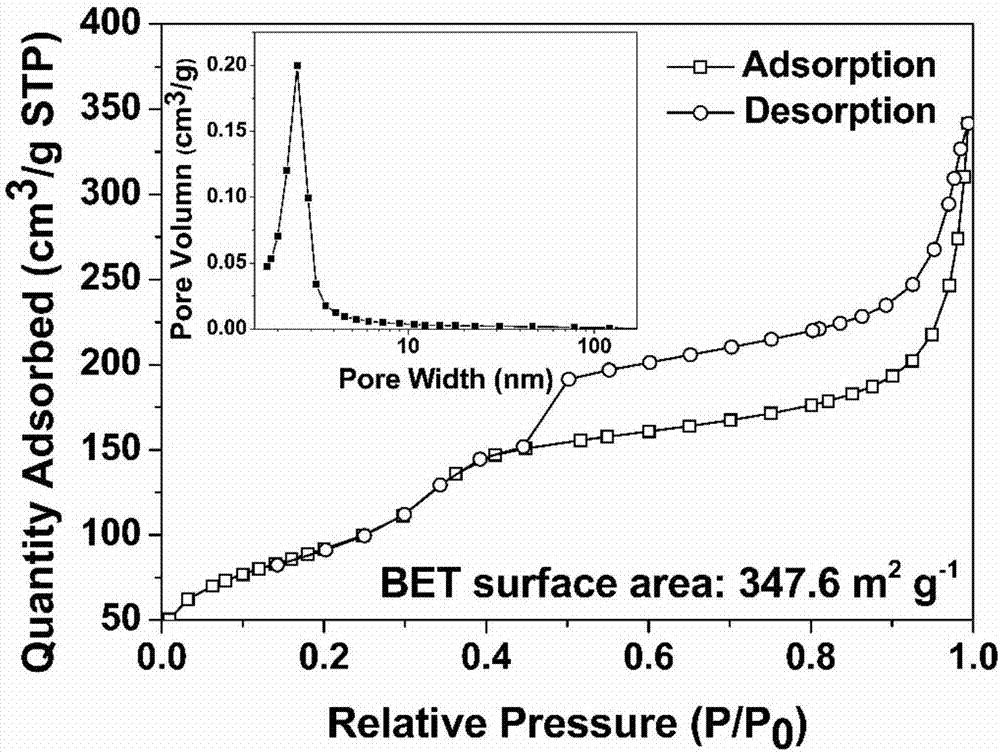

ActiveCN107359338AImprove responseExperiment operation is simpleMaterial nanotechnologyCell electrodesCarbon compositesDodecahedron

The invention disclose a cobaltous oxide / carbon composite hollow nanostructure material of dodecahedron structure and application of the cobaltous oxide / carbon composite hollow nanostructure material in negative electrodes of lithium batteries, and belongs to the technical field of preparation of negative electrode materials for lithium batteries. The method comprises the following specific steps: (1) preparing and purifying an organic frame compound ZIF-67 containing cobalt metal; (2) reacting a dopamine monomer with the organic frame compound ZIF-67 containing cobalt metal to generate a cobalt ion coordinated hollow polymer nanostructure; and (3) under the condition of nitrogen production, carbonizing the hollow polymer nanostructure at the temperature of 500 to 600 DEG C to obtain the hollow nanostructure material. The dimensions of the hollow nanostructure material can be adjusted according to the dimensions of the template metal organic frame compound ZIF-67 nanostructure; in the performance testing process of lithium ion batteries, the hollow nanostructure material, as a negative electrode active material, has preferable cycle performance, rate capacity and stability. Therefore, the cobaltous oxide / carbon composite hollow nanostructure material, as the negative electrode active material, can be of preferable application values and prospects in the field of lithium ion batteries.

Owner:JILIN UNIV

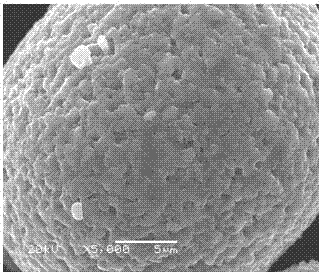

Silver loaded mesoporous silicon oxide coated ternary cathode material, and preparation method and applications thereof

ActiveCN106571455AReduce corrosionImprove conductivityCell electrodesSecondary cellsNickel saltFiltration

The invention relates to a silver loaded mesoporous silicon oxide coated ternary cathode material, and a preparation method and applications thereof. The preparation method comprises the following steps: dissolving lithium salts, nickel salts, cobalt salts, and manganese salts into a uniform medium, wetting the mixture by two chelating agents, adding ammonia liquor, adding a solution of two chelating agents into the inorganic salt uniform medium, heating the mixture under stirring to prepare dry gel; grinding the dry gel into powder, calcining the powder to obtain a ternary material; adding a water solution of the ternary material into tetraethyl orthosilicate, ethanol, and surfactant (cetyl trimethyl ammonium bromide), carrying out centrifugal precipitation, drying the precipitates, calcining the precipitates to obtain a silica-ternary shell-core cathode material; dissolving silver oxide into water to obtain a solution A; dissolving PVP into water to prepare a solution B; dropwise adding the solution B into the solution A to obtain a solution C; adding the silica-ternary shell-core cathode material into the solution C to obtain a solution D; dropwise adding a reducing agent into the solution D, and finally carrying out washing, suction filtration, and drying to obtain the final product. The preparation method is simple, the technological conditions are easy to realize, the energy consumption is low, and the preparation is pollution-free.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

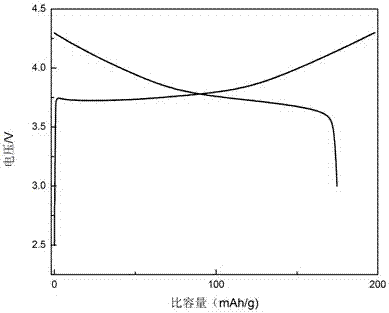

Composite iron trifluoride positive electrode material, preparation method and application

InactiveCN111883770AHigh theoretical capacityLow costMaterial nanotechnologyElectrode manufacturing processesFluid phaseNitrogen gas

The invention discloses a composite iron trifluoride positive electrode material. The composite iron trifluoride positive electrode material is a FeF3.0.33H2O carbon nanohorn composite material synthesized from carbon nanohorns and Fe(NO3)3.9H2O through a liquid-phase synthesis method. The preparation method of the composite material comprises the following steps: dispersing carbon nanohorns subjected to open pore oxidation treatment into ionic liquid, and uniformly dispersing the carbon nanohorns into the ionic liquid through stirring and ultrasonic treatment; then sequentially adding absolute ethyl alcohol and an iron source, and stirring the mixture until reactants are fully and uniformly mixed; putting the reaction solution into a constant-temperature oil bath reactor, carrying out nitrogen protection, and continuously stirring the mixture until the reaction is stopped; diluting the viscous reaction product obtained in the step 3 with acetone, and centrifuging the reaction product;freezing the centrifugal product in the step 4 by using liquid nitrogen, and volatilizing residual acetone to obtain a target product. The invention further discloses application of the composite material to a lithium ion solid-state battery. The material has good conductivity and is suitable for a high-rate system, and the preparation method is simple.

Owner:SIDUS ENERGY TECH LTD

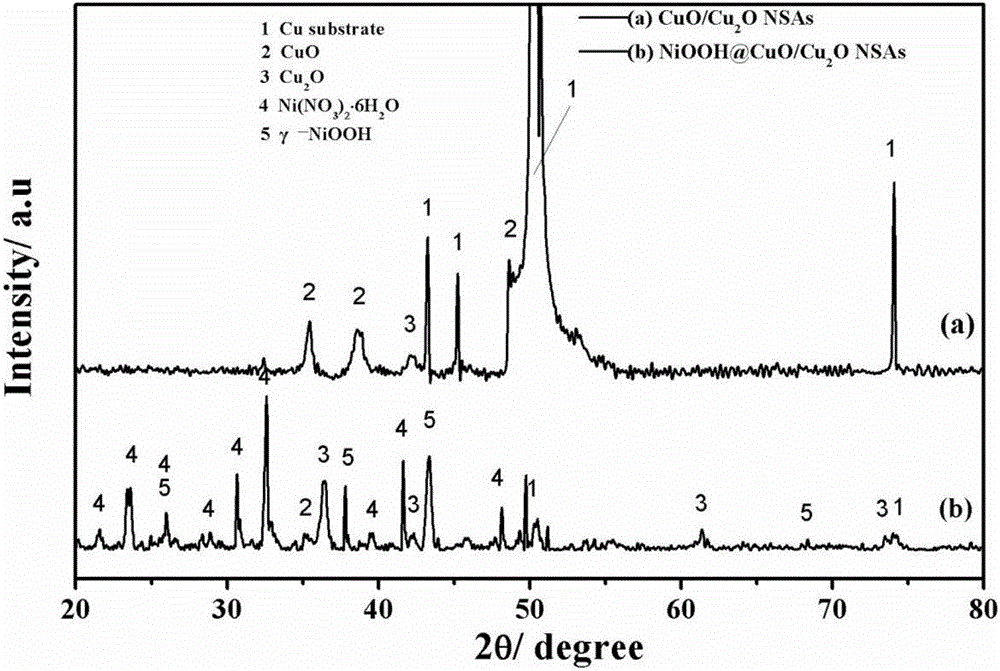

NiOOH@CuO/Cu2O composite nanosheet array film as well as preparation method and application thereof

ActiveCN106158408AHigh theoretical capacityImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHydrothermal deposition

The invention discloses a NiOOH@CuO / Cu2O composite nanosheet array film as well as a preparation method and application thereof. The method comprises the following steps: growing CuO / Cu2O nanosheet arrays vertical to a substrate and in stagger arrangement on the surface of a high-purity copper material by adopting an anode oxidation technology; performing hydrothermal deposition treatment in an aqueous solution of nickel nitrate; and performing in-situ deposition of a nickel oxide hydroxide nano product on the nanosheet arrays to obtain a NiOOH@CuO / Cu2O nanocomposite. The prepared electrode material gives full play to the electrochemical synergism between the CuO / Cu2O nanosheet arrays and NiOOH, and shows ultrahigh specific capacitance property and good cycling stability while the preparation steps are simple and controllable; and therefore, the electrode material is a super capacitor electrode material with practical application value.

Owner:HEFEI UNIV OF TECH

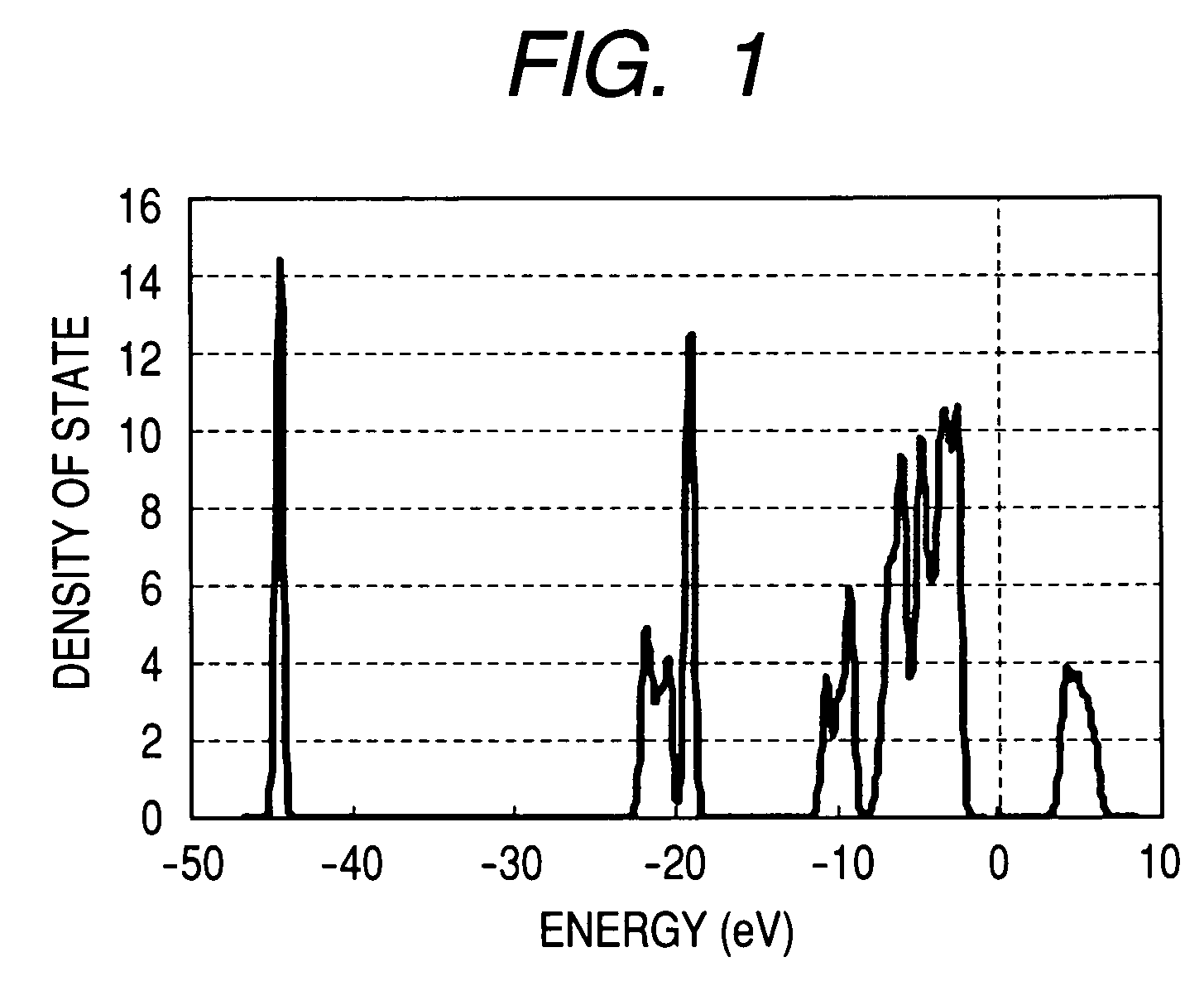

Electrode material for lithium secondary battery, electrode structure employing electrode material, and lithium secondary battery having electrode structure

InactiveUS7378189B2Large capacityExcellent charge and discharge characteristicsSilver accumulatorsAlkaline accumulator electrodesMixed oxideHigh energy

The present invention provides: an electrode material for a lithium secondary battery containing lithium boron mixed oxide having a monoclinic LiBO2 structure and represented by a chemical formula LiB1-xDxO2-yEy (wherein, D represents a substitution element of boron B, E represents a substitution element of oxygen O, 0<x<0.5, and 0≦y<0.1); an electrode structure employing the electrode material; and a lithium secondary battery having the electrode structure. Accordingly, the present invention provides: an electrode material for a lithium secondary battery having a voltage of 3.0 V (vs. Li / Li+) or more, a usable capacity exceeding 200 mAh / g, and a high energy density; an electrode structure employing the electrode material; and a lithium second battery having the electrode structure.

Owner:CANON KK

Negative electrode active material for lithium-ion/sodium-ion battery, negative electrode and battery

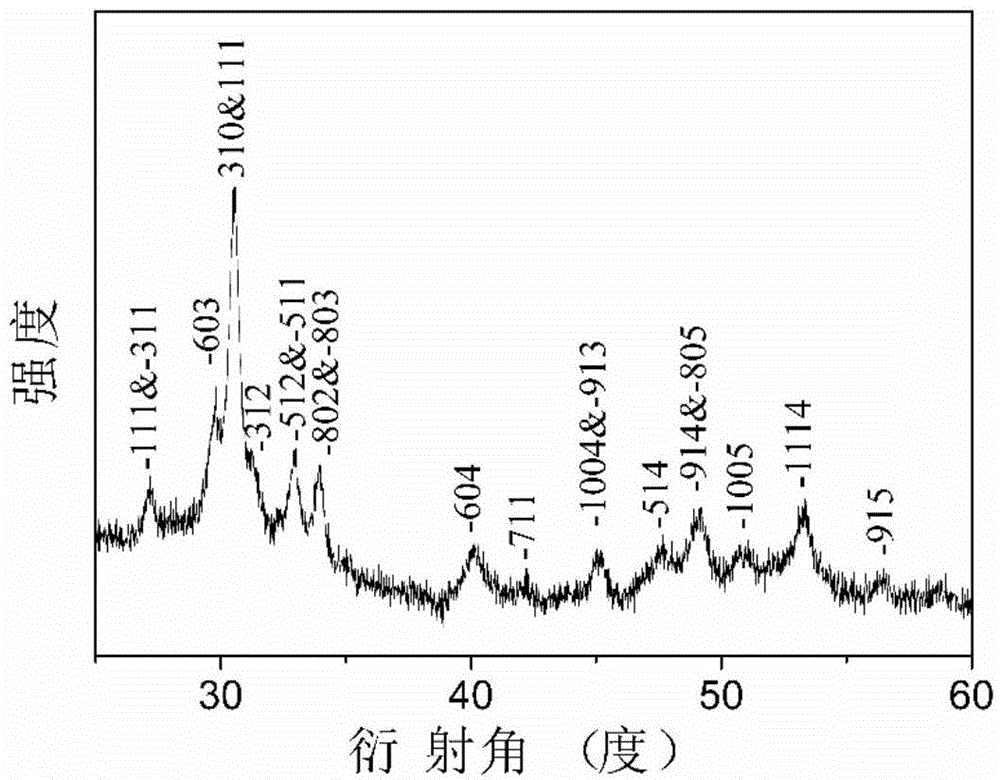

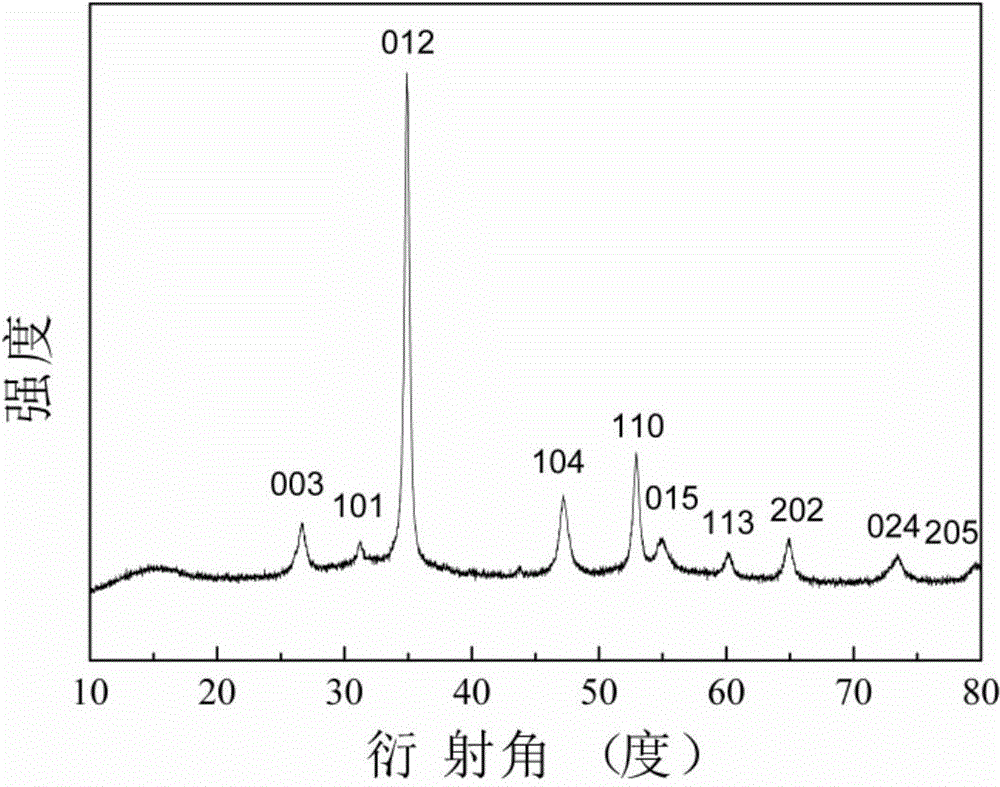

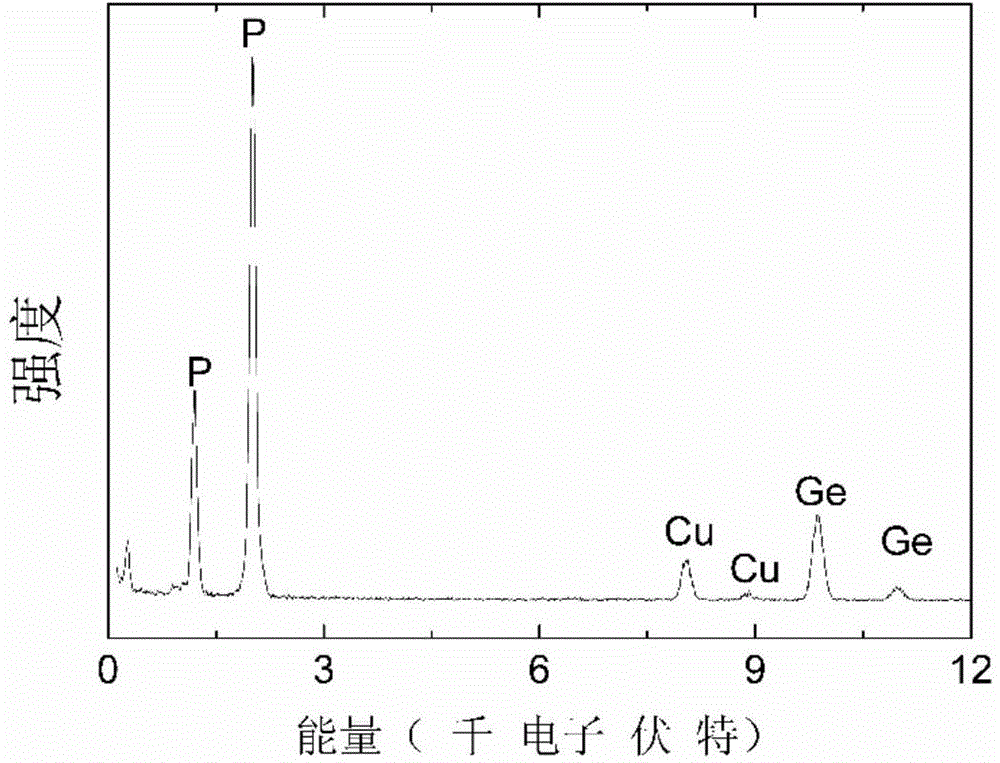

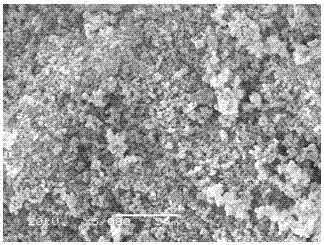

ActiveCN104600299AHigh lithium/sodium storage capacityHigh lithium/sodium storage activityCell electrodesSecondary cellsLithiumCharge discharge

The invention provides a negative electrode active material for a lithium-ion / sodium-ion secondary battery, a negative electrode and a battery, belonging to the technical field of electrochemistry and batteries. The negative electrode active material comprises a phosphorus-germanium compound, or / and a first complex formed by the phosphorus-germanium compound and elementary P or / and elementary Ge, or / and a second complex formed by the phosphorus-germanium compound and conductive components, or / and a third complex formed by the first complex and conductive components. The negative electrode provided by the invention comprises the negative electrode active material. The negative electrode has the advantages of high specific capacity, high initial Coulomb efficiency, small charge-discharge voltage platform difference and good high-current charge-discharge performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for cladding vanadium phosphate on lithium ion battery anode material lithium cobalt nickel manganate

ActiveCN107230771AIncrease capacityImprove protectionElectrode thermal treatmentImpregnation manufacturingPhosphateManganate

The invention discloses a method for cladding vanadium phosphate on lithium ion battery anode material lithium cobalt nickel manganate. The method comprises the following steps: (1) mixing vanadate, phosphate and reducing agent in the deionized water according to the vanadium element, the phosphorus element and the reducing element, regulating pH by using ammonia water, stirring to obtain a uniform solution, reacting for 20-48h at 160-240 DEG C; filtering, washing, drying to obtain the vanadium phosphate; (2) adding the lithium cobalt nickel manganate ternary anode material and the vanadium phosphate in a high-speed mixer, wherein the vanadium phosphate mass in the obtained mixture is 1%-10% of the total mass of the mixture; stirring under a condition of 500-2000rmp to obtain a uniform product; and (3) sintering at 200-400 DEG C in an non-oxidation atmosphere, and keeping temperature for 1-5h, cooling to obtain the vanadium phosphate clad lithium ion battery anode material lithium cobalt nickel manganate. By using method disclosed by the invention, the capacity and the cyclic performance of the lithium ion battery are effectively improved.

Owner:湖南恒创睿能新能源科技有限公司

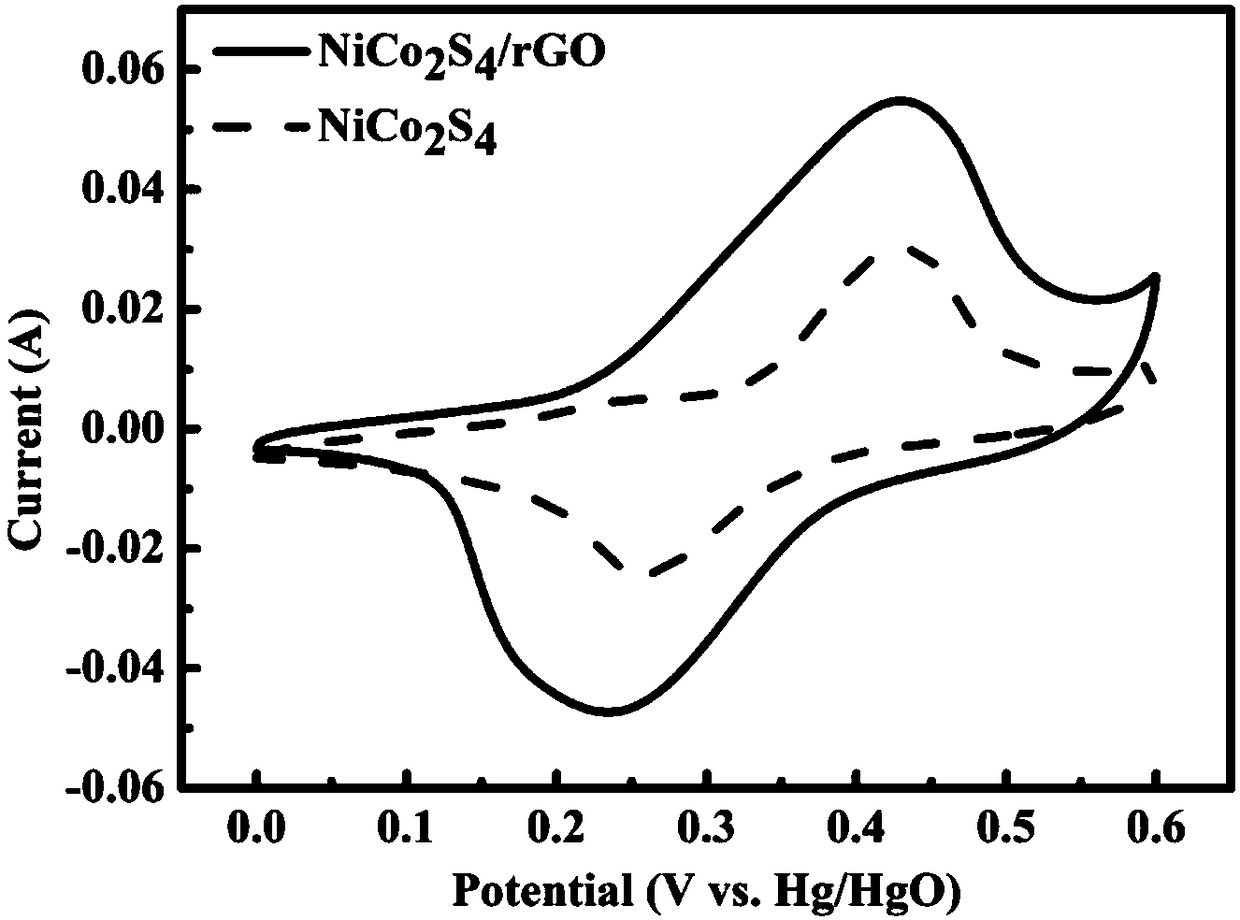

Preparation method of cobaltous sulfide nickel/graphene composite gel and application

InactiveCN108257794AMultiple growth sitesUnique three-dimensional network structureHybrid capacitor electrolytesHybrid/EDL manufactureNickel saltAlcohol

The invention discloses a preparation method of cobaltous sulfide nickel / graphene composite gel. The following preparation raw materials are employed: graphene oxide (GO), cobalt salt, nickel salt, thioacetamide and 95wt% of ethyl alcohol and the like. The preparation method comprises: graphene oxide and ethyl alcohol are fixed and ultrasonic preparation is carried out to obtain a graphene oxide alcoholic solution; and in-situ growth of a cobaltous sulfide nickel microsphere on a graphene oxide sheet is carried out by a one-step hydrothermal method to obtain cobaltous sulfide nickel / graphene composite gel. According to the invention, the cost is low; and the preparation process is simple. The prepared cobaltous sulfide nickel / graphene composite gel has excellent electrochemical performanceand can be used as a positive electrode material of an asymmetric super capacitor.

Owner:HUAQIAO UNIVERSITY

Lithium-ion battery anode material, non-aqueous electrolyte lithium-ion battery and preparation method of non-aqueous electrolyte lithium-ion battery

PendingCN109904441AHigh theoretical specific capacityImprove safety performanceFinal product manufactureCell electrodesIonLithium electrode

The invention provides a lithium-ion battery anode material. A general formula of a compound of the lithium-ion battery anode material is M<x>Ti<2+xy-5x>Nb<10+x(4-y)>O<29>, wherein M denotes metal ions, x denotes the atomic weight of M in the compound, y denotes the valence state of the metal ions, and the relations that 0<x<=10, 0<y<=5, 2+xy-5x>=0, and 10+x(4-y)>=0 are met. The invention furtherprovides a non-aqueous electrolyte lithium-ion battery and a preparation method thereof. The lithium-ion battery anode material has high theoretical specific capacity, and high safety performance, andhas the advantages of high reversible specific capacity, high coulomb efficiency, excellent cycle performance and the like.

Owner:AAC TECH PTE LTD

Method for preparing lithium battery material by using plant fibers

ActiveCN103066294AImprove lithium battery performanceAdequate responseCell electrodesFiberMicro nano

The invention discloses a method for preparing a lithium battery material by using plant fibers. According to the method, the lithium ion battery electrode material is produced through the processes of pulverization, purification, loading of lithium ion battery active substances and carbonization by using plant fibers as the raw material. Based on the scheme disclosed by the invention, the composite material with a micro-nano mosaic structure can be prepared conveniently, and the raw materials have wide sources. According to the method, a support is provided for improving lithium ion battery production technology and developing novel lithium ion battery materials, and is beneficial for the development of the lithium ion battery industry is facilitated.

Owner:FUZHOU UNIV

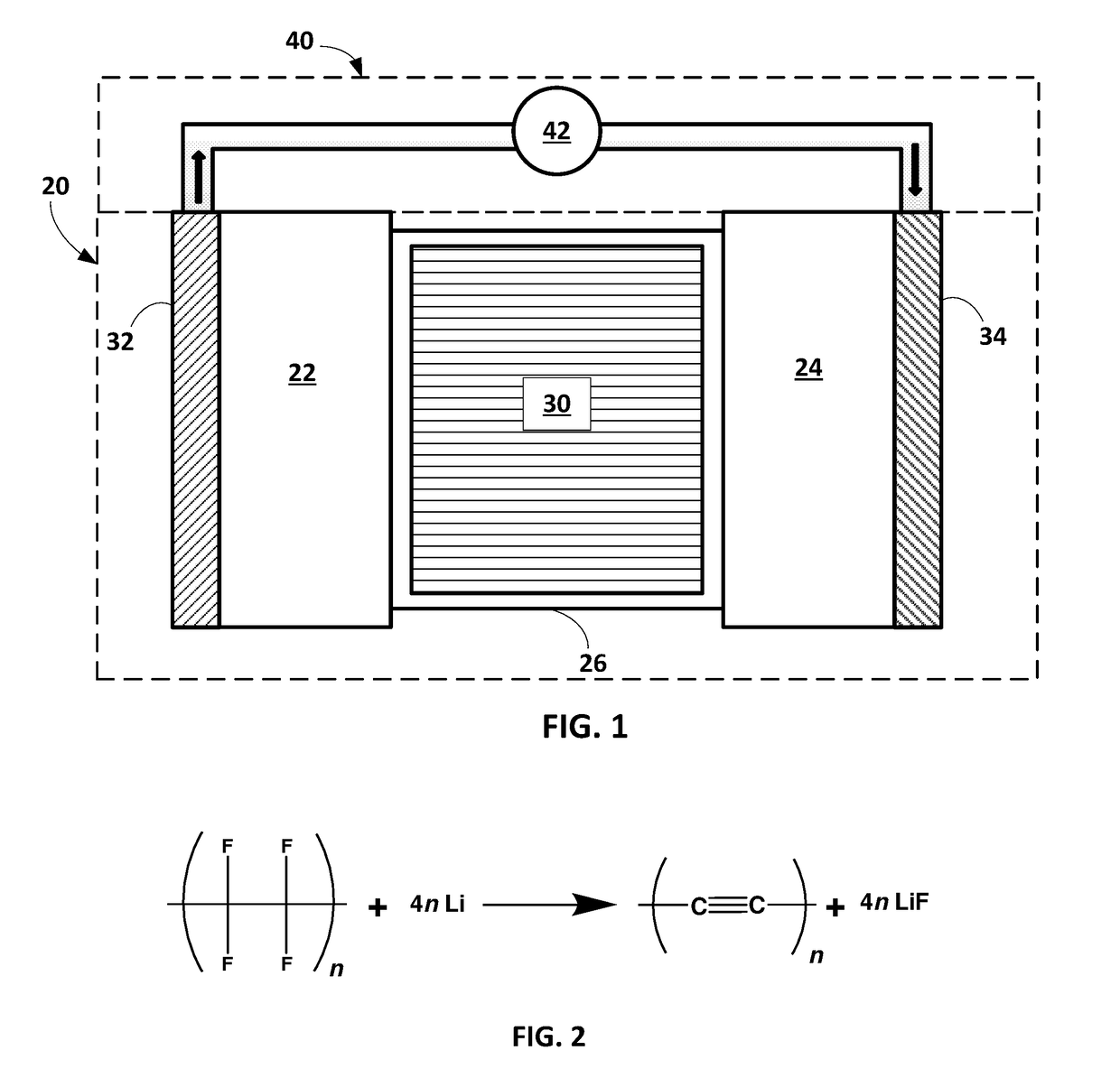

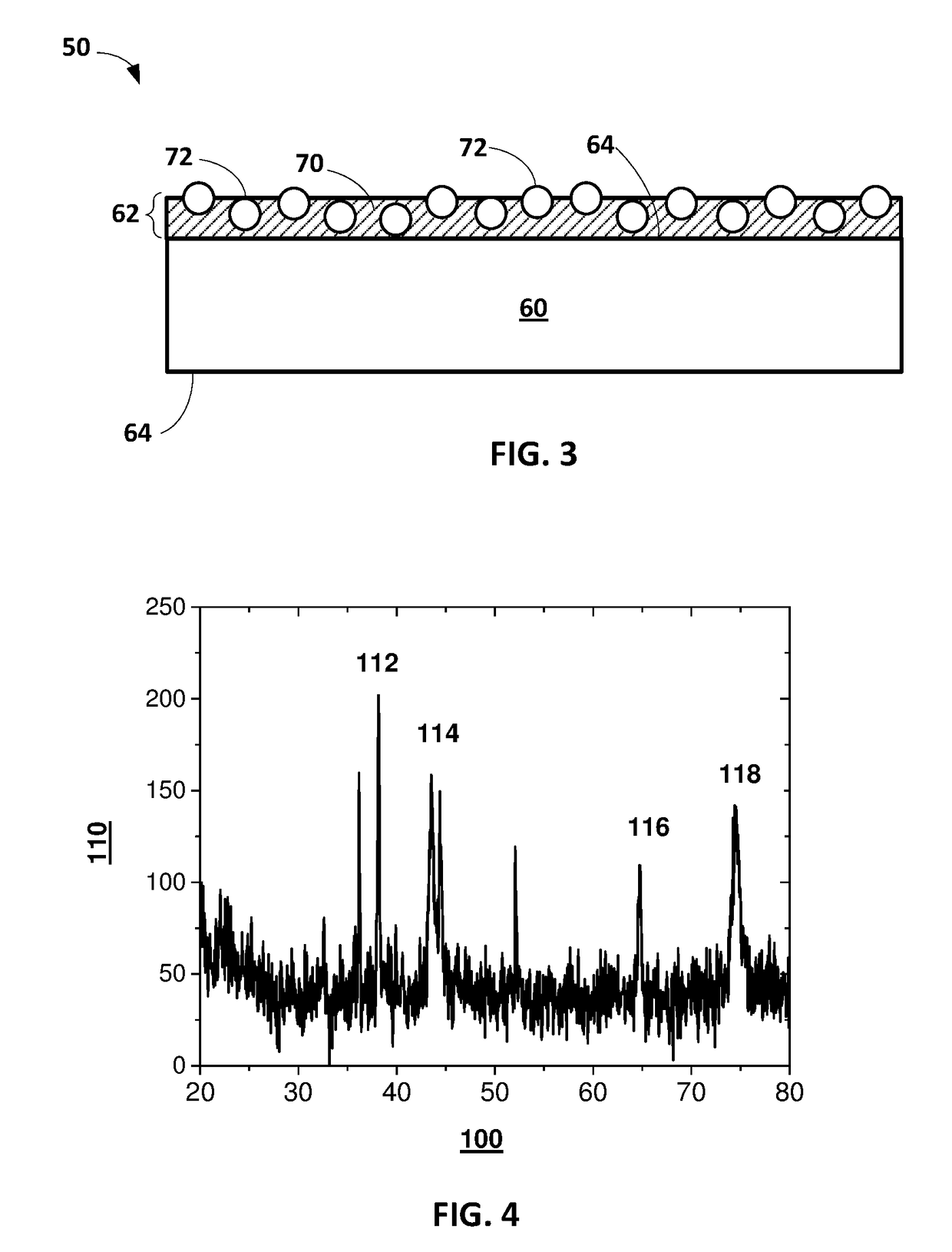

Methods of applying self-forming artificial solid electrolyte interface (SEI) layer to stabilize cycle stability of electrodes in lithium batteries

ActiveUS20190067675A1High charge capacityLow cycle efficiencyNegative electrodesElectrolyte accumulators manufactureMetalLithium metal

A method of making a negative electrode for an electrochemical cell includes applying a fluoropolymer via a deposition process to one or more surface regions of an electroactive material. The electroactive material may be selected from the group consisting of: lithium metal, silicon metal, silicon-containing alloys, and combinations thereof. The fluoropolymer reacts with lithium to form a composite surface layer on the one or more surface regions that comprises an organic matrix material having lithium fluoride particles distributed therein. Electrochemical cells including such negative electrode are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

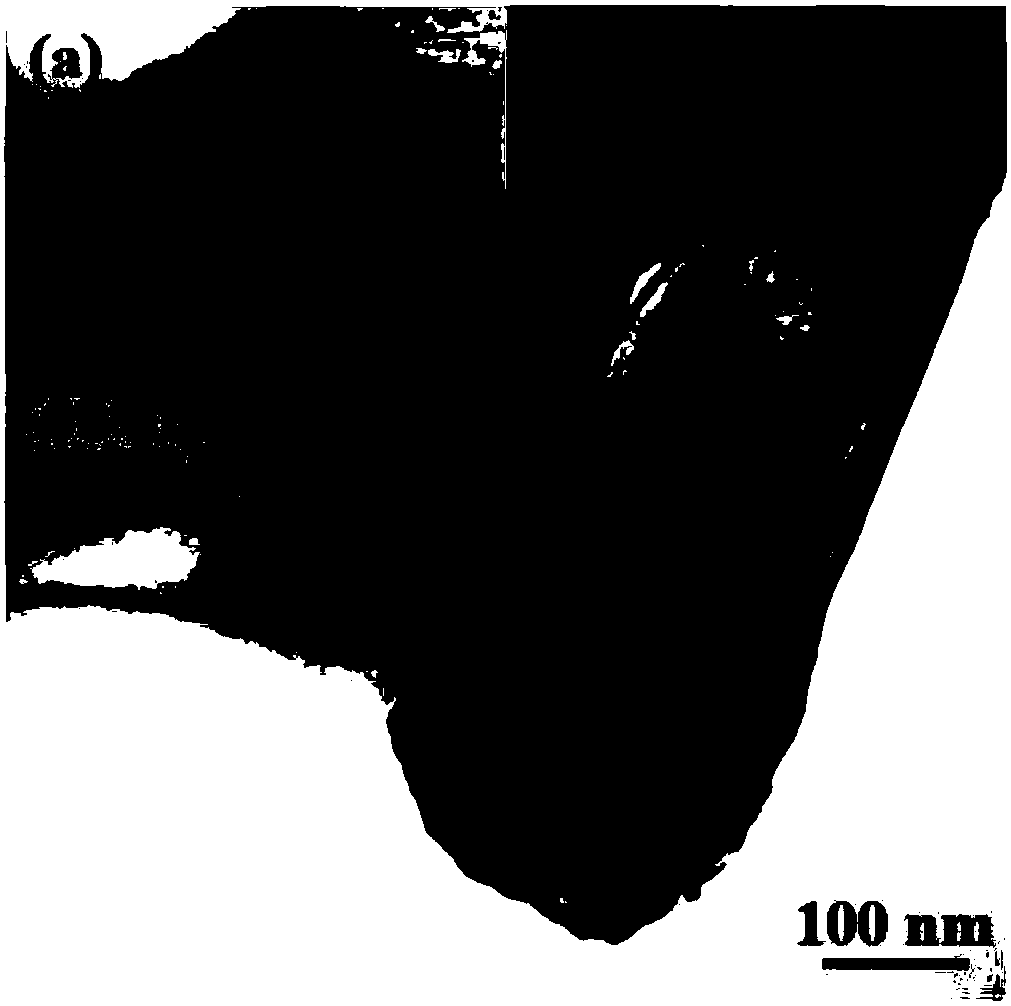

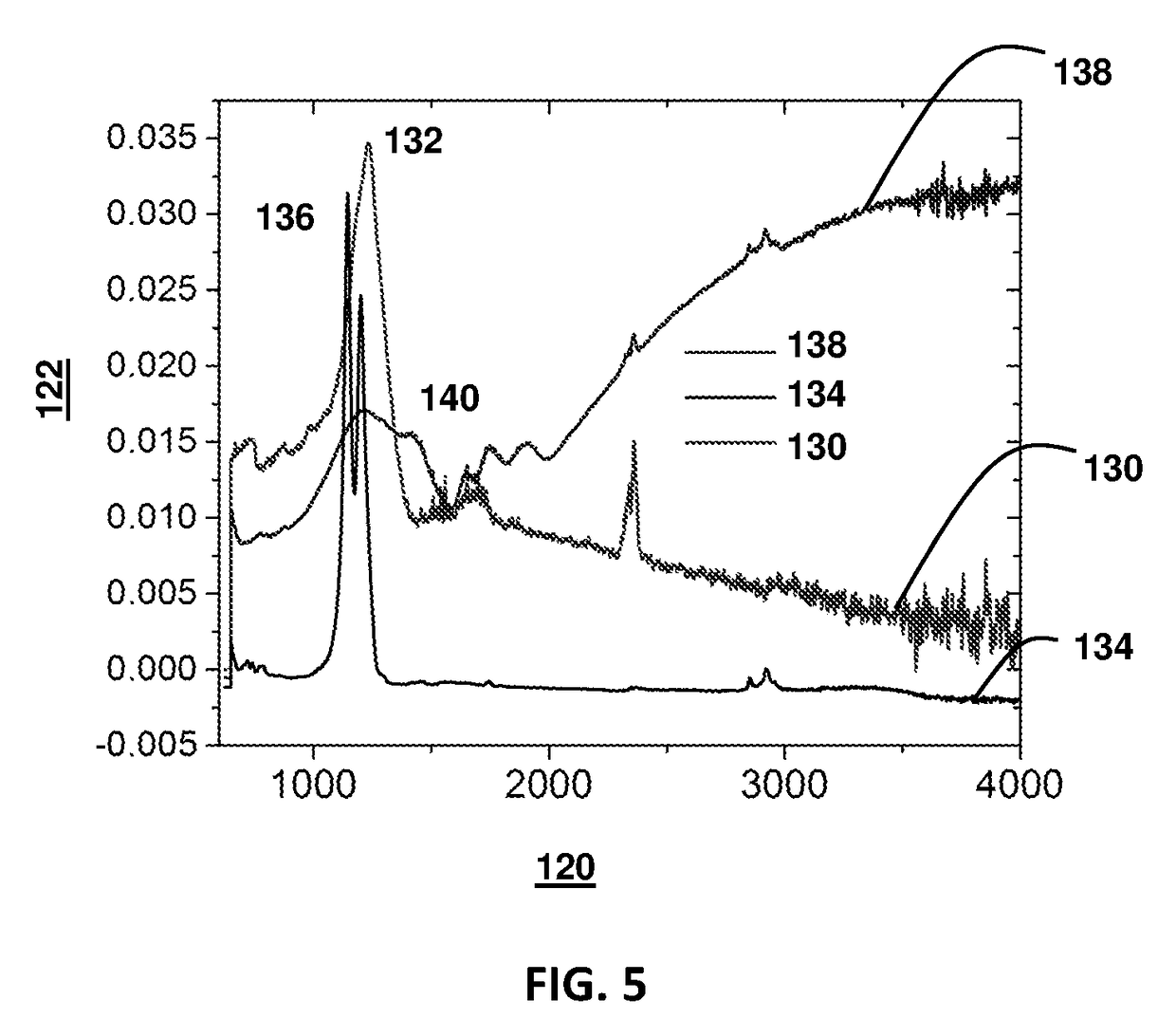

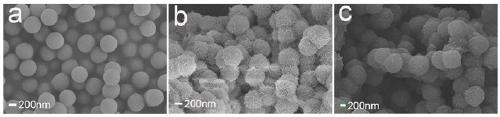

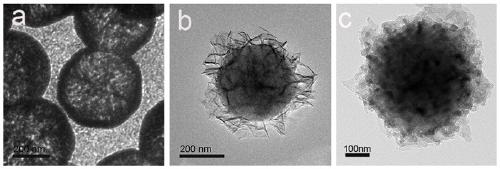

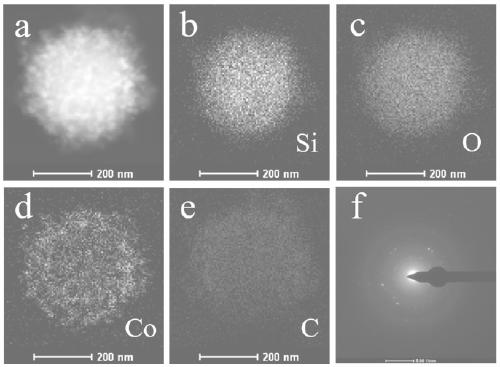

Nitrogen-doped carbon-coated hollow porous silicon dioxide/cobalt nano composite material and lithium ion battery negative electrode material thereof

ActiveCN111446440AShorten the transmission pathIncrease migration rateMaterial nanotechnologyNegative electrodesNanocompositeMaterials science

The invention relates to a nitrogen-doped carbon-coated hollow porous silicon dioxide / cobalt nano composite material and a lithium ion battery negative electrode material thereof. The preparation method of the nitrogen-doped carbon-coated hollow porous silicon dioxide / cobalt nano composite material comprises the following steps: by taking tetraethyl silicate as a silicon source, cobalt acetylacetonate as a cobalt source, dopamine hydrochloride as a carbon source and N,N-dimethylformamide as a solvent, reacting under a hydrothermal condition, and sequentially preparing hollow-hollow porous silicon dioxide spheres, a hollow-hollow porous silicon dioxide / cobalt composite material and a nitrogen-doped carbon-coated hollow-hollow porous silicon dioxide / cobalt nano composite material. The composite material prepared by the invention is prepared by a step-by-step growth step, has excellent cycling stability and rate capability as a lithium ion battery negative electrode, and is low in manufacturing cost, simple in process, low in equipment requirement and environment-friendly.

Owner:YANGZHOU UNIV

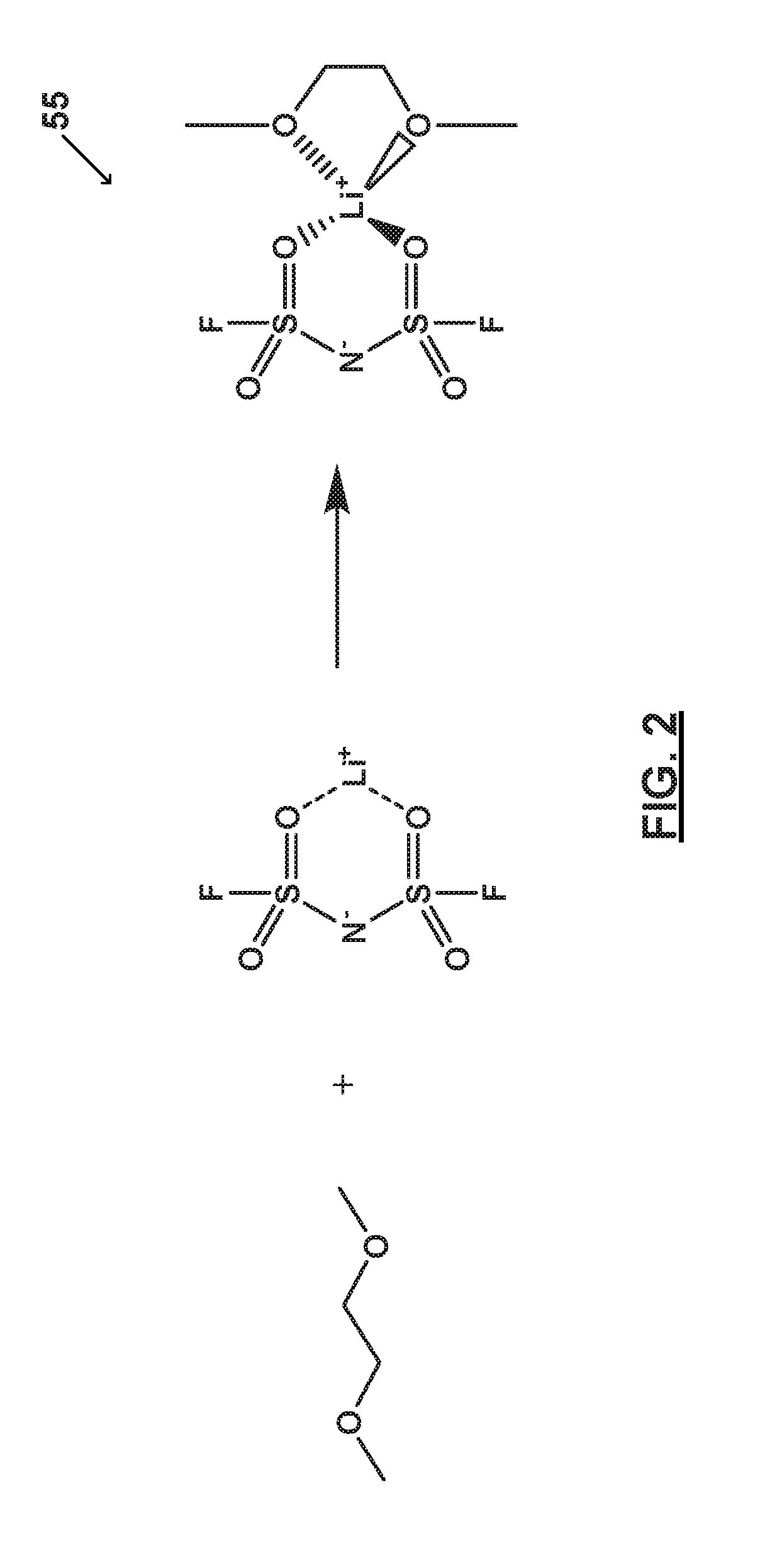

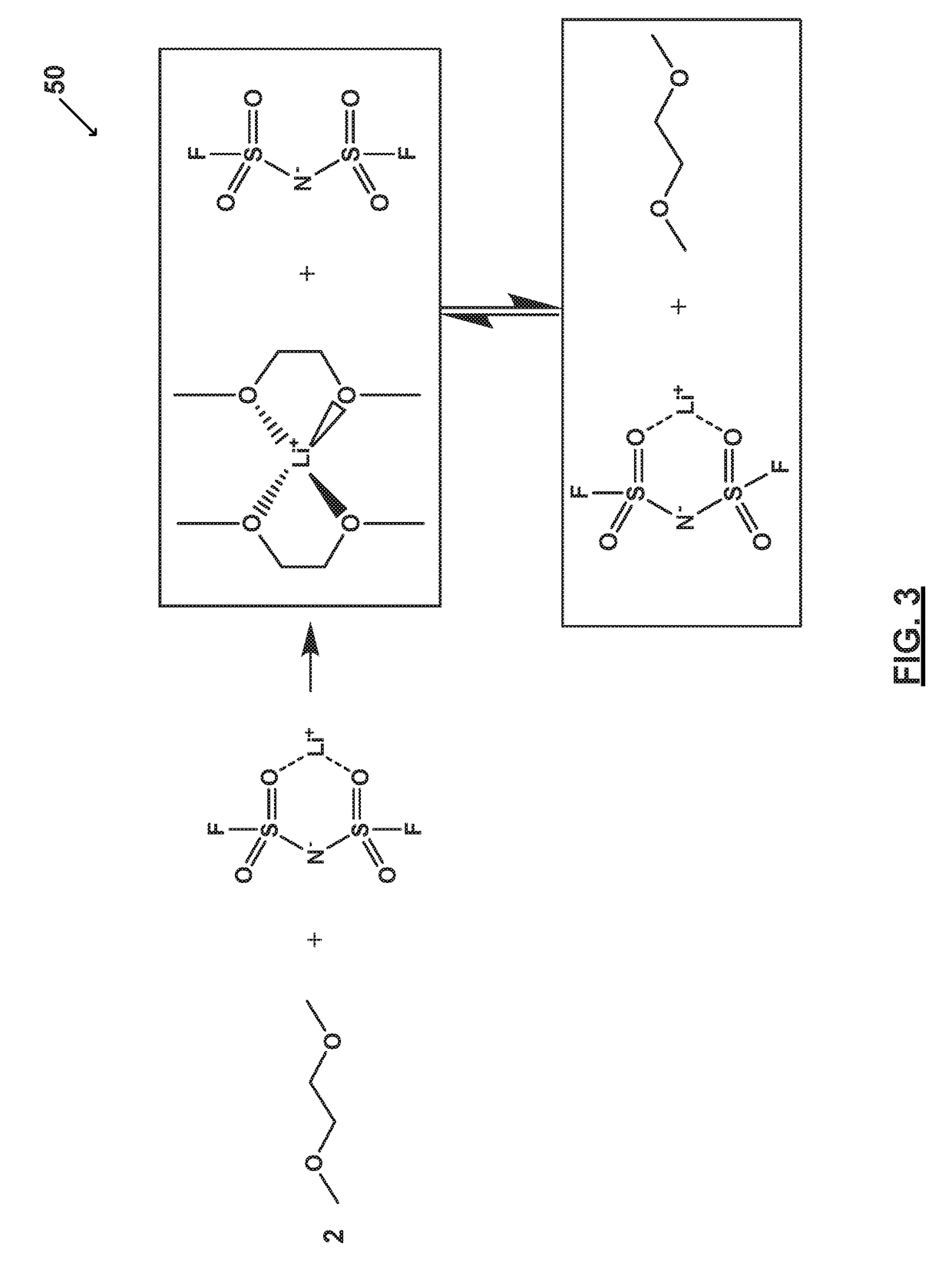

Ether-based electrolyte system improving or supporting anodic stability of electrochemical cells having lithium-containing anodes

ActiveUS20190058211A1Improve long-term performanceCapacity drop rapidlyFinal product manufactureElectrolyte accumulators manufactureLithiumImide

A highly-concentrated electrolyte system for an electrochemical cell is provided, along with methods of making the highly-concentrated electrolyte system. The electrolyte system includes a bound moiety having an ionization potential greater than an electron affinity and comprising one or more salts selected from the group consisting of: lithium bis(fluorosulfonyl)imide (LiFSI), sodium bis(fluorosulfonyl)imide (NaFSI), potassium bis(fluorosulfonyl)imide (KFSI), and combinations thereof bound to a solvent comprising dimethoxyethane (DME). The one or more salts have a concentration in the electrolyte system of greater than about 4M, and a molar ratio of the one or more salts to the dimethoxyethane (DME) is greater than or equal to about 1 to less than or equal to about 1.5. The one or more salts binds to the dimethoxyethane (DME) causing the electrolyte system to be substantially free of unbound dimethoxyethane (DME) and unbound bis(fluorosulfonyl)imide (FSI−).

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com