Nitrogen-doped carbon-coated hollow porous silicon dioxide/cobalt nano composite material and lithium ion battery negative electrode material thereof

A technology of silica and composite materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems that hinder the large-scale application of LIBs anode materials, low initial Coulombic efficiency, and volume expansion effects. It can achieve the effect of enhancing the kinetic process of electrode reaction, shortening electron and ion transport paths, and enhancing rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

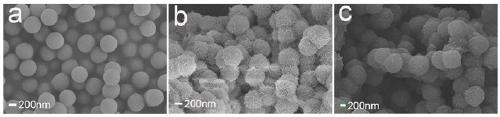

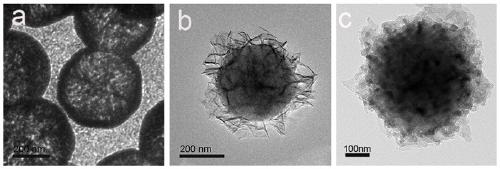

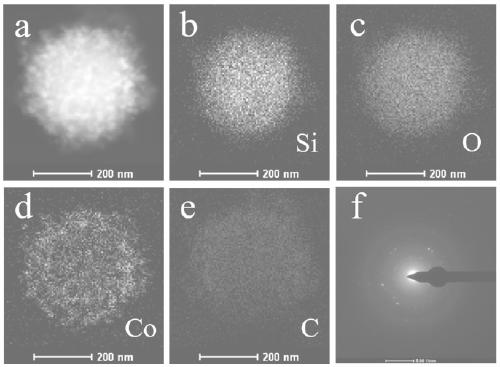

[0027] In this example, the hollow hollow SiO 2 、HSiO 2 / Co and HSiO 2 / Co@NC Composites.

[0028] First, prepare hollow porous silica microspheres: measure and mix 0.4 mL of ammonia water with a mass concentration of 25 % and 0.2 g of resorcinol respectively, and then add 28 mL of a 3:4 volume ratio to the mixed solution. Mix solution of water, ethanol and deionized water, then magnetically stir at room temperature for 30 minutes, then add 0.28 mL of formaldehyde dropwise under stirring to make the reaction more complete, and after stirring for 10 minutes, slowly add 0.4 mL of formaldehyde at a rate of 5 minutes per drop Tetraethyl orthosilicate (TEOS) and 0.1 g cetyltrimethylammonium bromide (CTAB) were added to the mixed solution, and after rapid stirring for 1 h, the solution was transferred to a muffle furnace and heated at 80 Anneal at ℃ for 24 h; centrifuge to separate the solid phase precipitate, wash the precipitate three times with deionized water and absolute eth...

Embodiment 2

[0036] In the present embodiment, with the HSiO that embodiment 1 makes 2 / Co@NC composite material was used as the negative electrode of lithium-ion battery for lithium-ion battery assembly, and the performance of the battery material was tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com