Method for preparing lithium battery material by using plant fibers

A plant fiber and electrode material technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of low capacity of negative electrode materials and difficulty in applying new negative electrode materials for lithium-ion batteries, etc., to improve lithium battery performance, rich in processing, and huge applications. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described more fully below with reference to the accompanying drawings, in which preferred embodiments of the invention are shown. However, this invention may be embodied in different forms and should not be construed as limited to only the embodiments set forth herein.

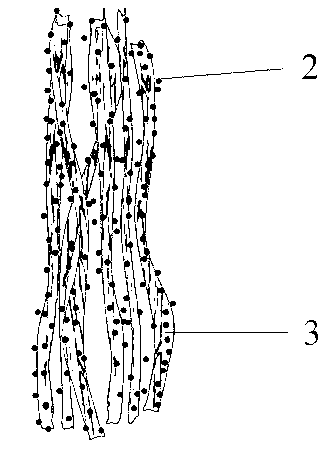

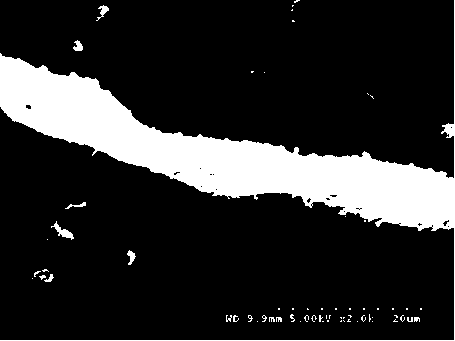

[0019] (1) Cotton fiber is selected as the raw material. The main component of cotton fiber is cellulose. Each cotton fiber is composed of multi-level fiber structure, and there are many pore structures inside. Firstly, the naturally mature fibers are cleaned with deionized water and alcohol, and the cleaning process is supplemented by ultrasonic treatment. The cotton fibers were then dried in a forced air oven at 70°C. Finally, the cotton fibers are crushed into small fiber segments with a length of about 1 mm.

[0020] (2) Through chemical methods, the cotton fiber is purified to remove pectin, gum, metal ions and other substances in the plant fiber. First, the crushed cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com