Antimony sulfide negative electrode material with micro-nano structure for sodium-ion battery and preparation method of antimony sulfide negative electrode material

A sodium-ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problems of low capacity and poor cycle performance of sodium-ion battery negative electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

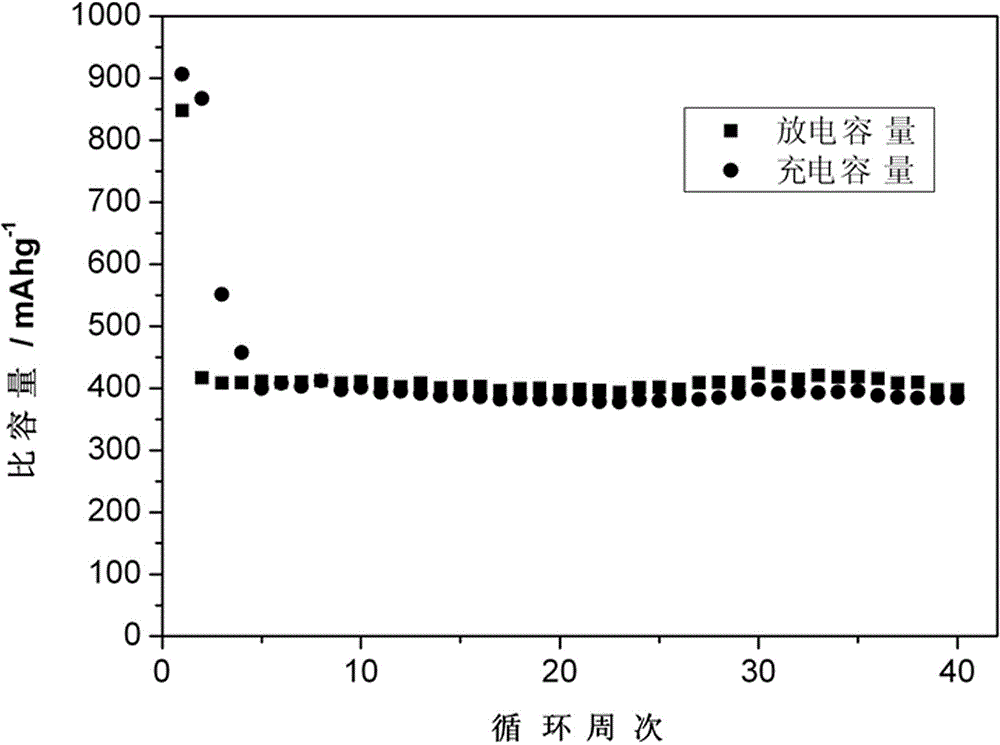

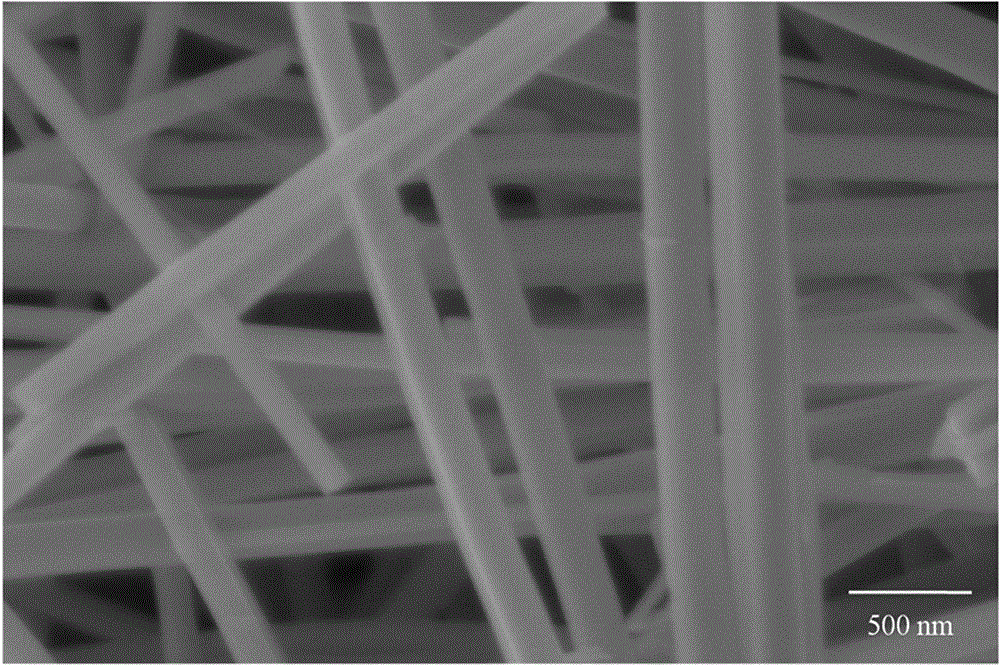

[0028] Example 1: Preparation of antimony sulfide nanowires by hydrothermal method and its electrochemical sodium storage performance

[0029] Add a certain amount of antimony trichloride to 60 mL of deionized water, and stir for several minutes to form a white turbid solution, add 60 mL of ethylene glycol, continue magnetic stirring for several minutes, then add a certain amount of sodium borohydride and sulfur powder respectively , and then transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal reactor, seal the reactor, and keep the temperature at 120-240°C for several hours. After the reactor was cooled to room temperature, the product was centrifuged, washed, and vacuum-dried to obtain antimony sulfide nanowires (attached figure 2 ). The negative electrode made of antimony sulfide nanowires has an initial discharge capacity of 850 mAh / g at a current density of 100 mA / g, and after 40 cycles, the capacity still maintains 90% of the capacity of the sec...

Embodiment 2

[0030] Embodiment 2: Synthesis of antimony sulfide microtubes by hydrothermal method

[0031] Dissolve antimony potassium tartrate in deionized water, stir well, then add thiourea, wait for it to mix evenly, then transfer the mixed solution to a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal it, and place it at 160-240 °C Keep warm for several hours. After the reactor was cooled to room temperature, the product was centrifuged, washed, and vacuum-dried to obtain antimony sulfide microtubes (see attached image 3 ).

Embodiment 3

[0032] Example 3: Precipitation method to prepare spherical micro-nano structure antimony sulfide particles

[0033] Dissolve antimony chloride in ether and stir magnetically. After fully stirring, a uniform solution is formed. Then add sodium sulfide to the solution and let it stand for several hours. The precipitate is formed and precipitated. After the precipitate is centrifuged, cleaned and dried in vacuum, Obtain spherical micro-sodium grade antimony sulfide particles (see attached Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com