High silicon aluminium ratio small crystal NaY molecular sieve

A high-silicon-aluminum ratio, molecular sieve technology, applied in crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of difficult removal of cesium ions, low silicon utilization rate, etc., and achieve good structural stability and stability. Catalytic activity, low cost of raw materials, and effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Take 10.53g of sodium hydroxide solid (produced by Beijing Chemical Plant, with a purity of 99%) and dissolve it in 30.95g of water. After cooling to room temperature, add 2.22g of sodium metaaluminate (produced by Tianjin Jinke Fine Chemical Research Institute, Al 2 O 3 The content is 45wt%, Na 2 The O content is 41wt%) to prepare a high-alkali sodium metaaluminate solution. Then add 36.73g water glass (produced by Beijing Red Star Sodium Alkaline Plant, SiO 2 The content is 28.83wt%, Na 2 The content of O is 8.84wt%), and the directing agent is prepared by stirring and aging at 40°C for 4 hours after uniform mixing.

[0060] Place 14.21g of water in the beaker, control the liquid temperature in the beaker to 60°C, and add 12.79g of 50wt% Al at the same time under rapid stirring 2 (SO 4 ) 3 (Produced by Nanzhao Huaxin Chemical Co., Ltd., purity 99%) solution and 31.91g water glass. After stirring uniformly, add 1.90g of the above-mentioned directing agent, the pH of the ge...

Embodiment 2

[0067] The source of each raw material and the preparation of the directing agent are the same as in Example 1.

[0068] The beaker containing 13.47g of water was kept at a constant temperature of 50°C, and 12.66g of 50wt% Al was added at the same time under rapid stirring. 2 (SO 4 ) 3 After stirring the solution and 31.55g of water glass evenly, 4.40g of the above-mentioned directing agent was added, and the pH of the gel was 12.8. In the above process, the material in the beaker is always kept at 50°C. After stirring uniformly, put it into a stainless steel reactor, shake and crystallize at 60°C for 4 hours, then heat up to 100°C for static crystallization for 36 hours, then filter, wash and dry to obtain NaY molecular sieve product.

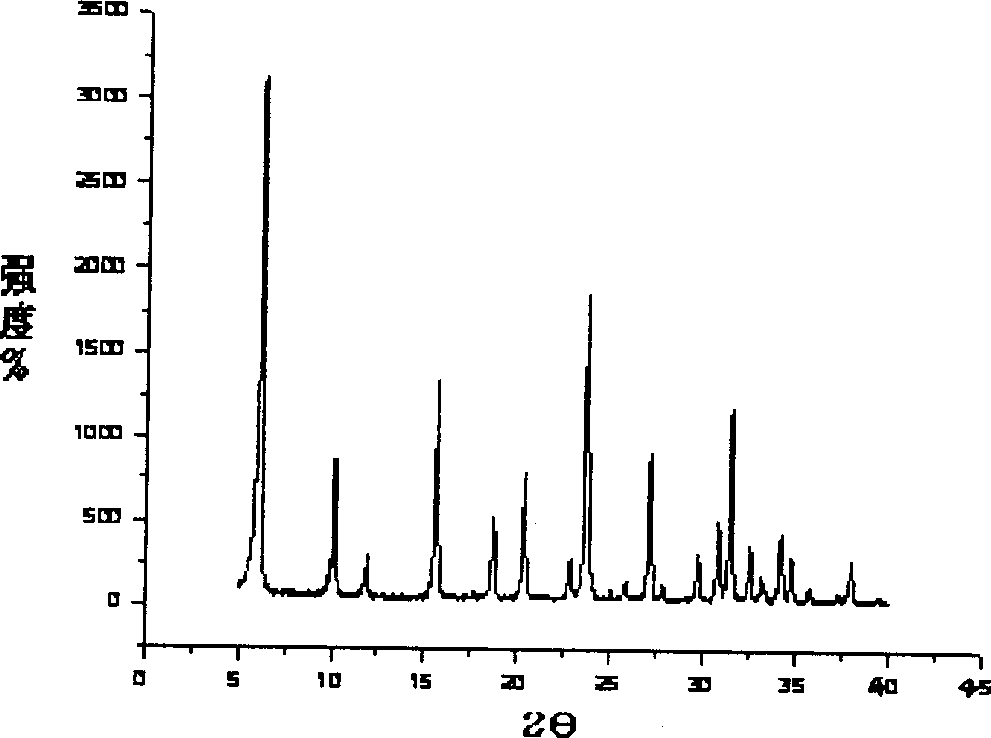

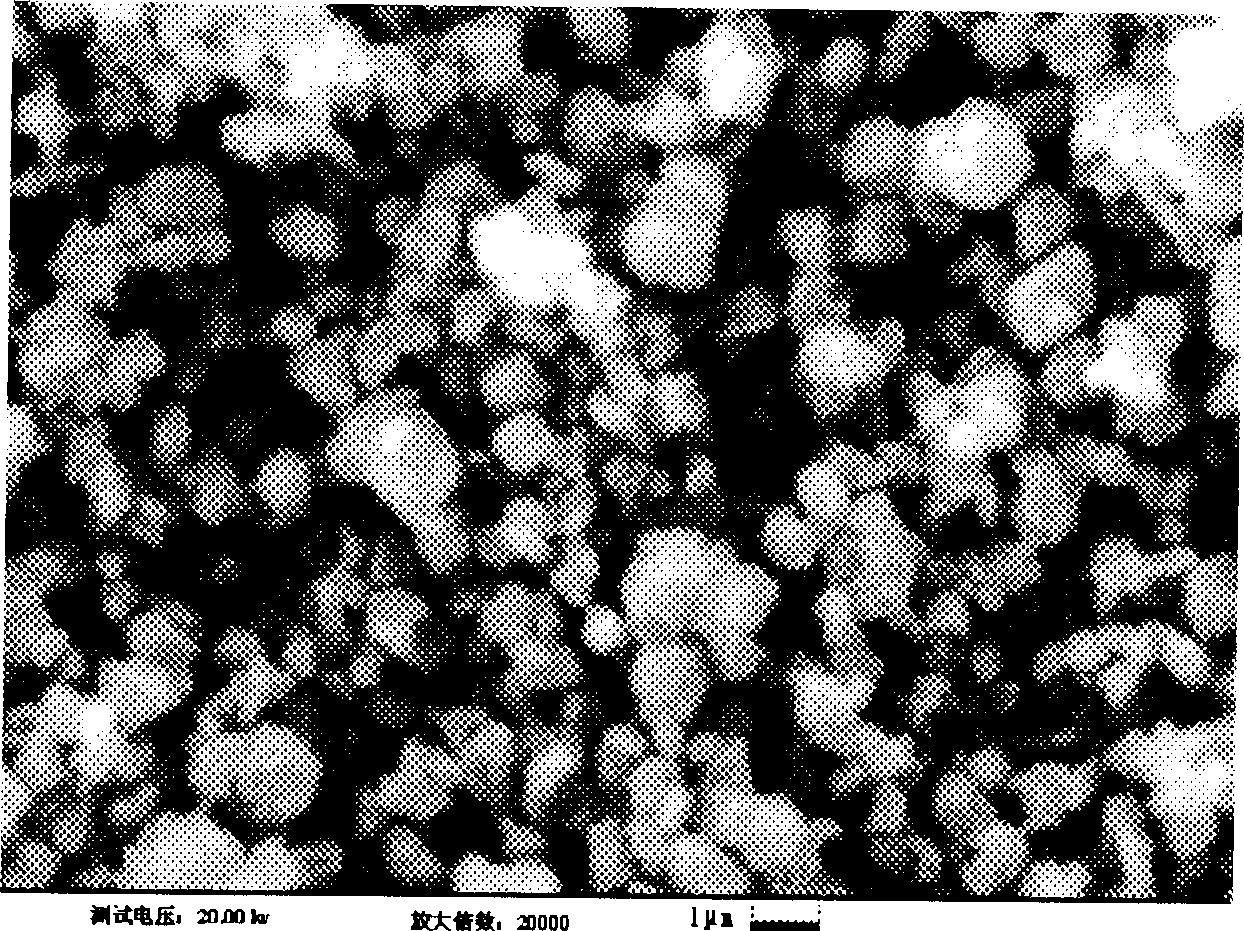

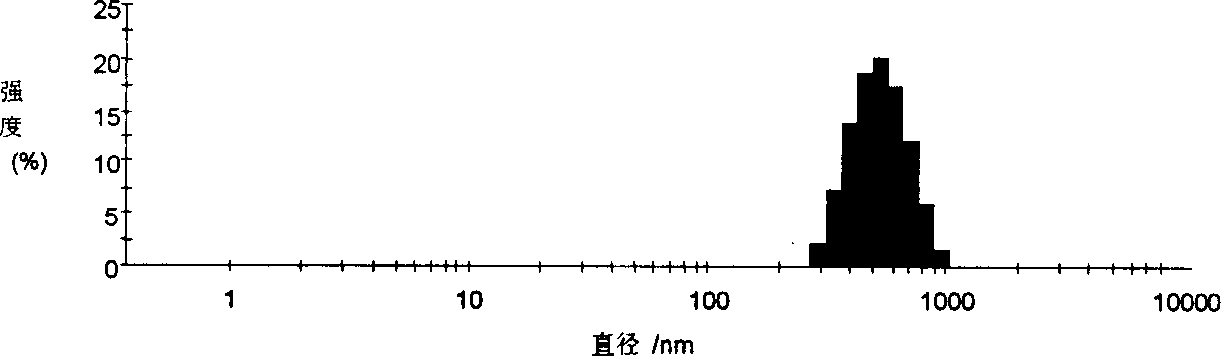

[0069] XRD measured the ratio of silicon to aluminum of the NaY molecular sieve product was 6.2, the relative crystallinity was 98%, the average grain size was 488 nanometers, and the BET specific surface area was 750m. 2 / g.

Embodiment 3

[0071] The source of each raw material and the preparation of the directing agent are the same as in Example 1.

[0072] The constant temperature of the beaker containing 14.21g of water was 60℃, and 12.79g of 50wt% Al was added at the same time under rapid stirring. 2 (SO 4 ) 3 After stirring the solution and 31.91g of water glass, add 4.31g of the above-mentioned directing agent, and the pH of the gel is 12.8. During the above process, the material in the beaker is always kept at 60°C. After stirring uniformly, put it into a stainless steel reactor, stir and crystallize at 60°C for 4 hours, then heat to 100°C for static crystallization for 36 hours, then filter, wash and dry to obtain NaY molecular sieve product.

[0073] XRD measured the ratio of silicon to aluminum of the NaY molecular sieve product was 6.3, the relative crystallinity was 98%, the average grain size was 510 nanometers, and the BET specific surface area was 743m. 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com