Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Strong ability to convert heavy oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN1958452AHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

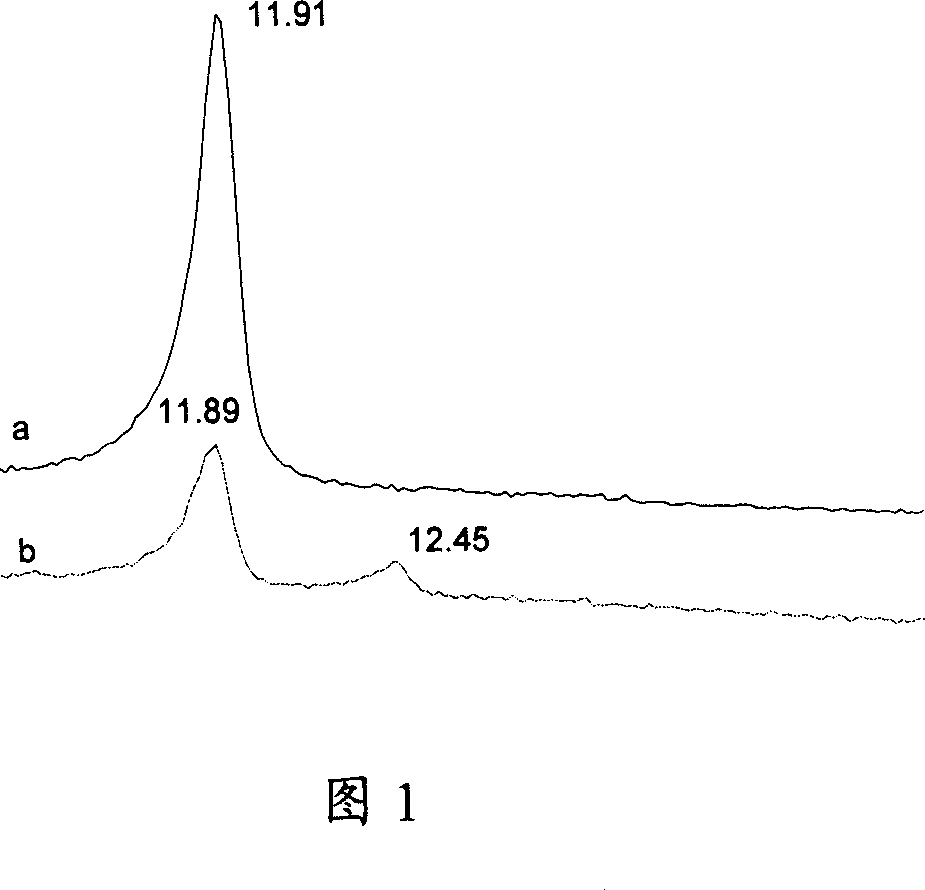

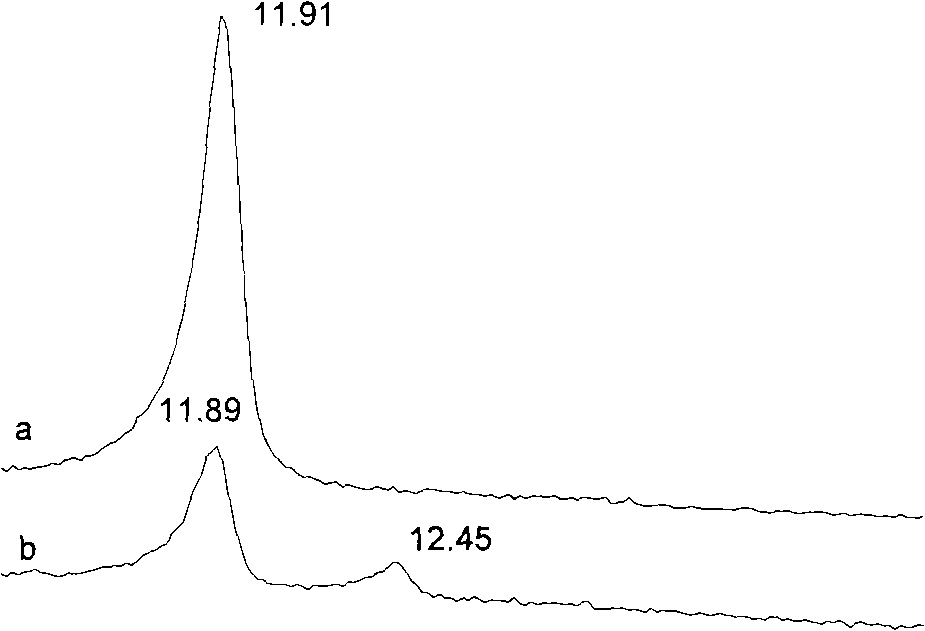

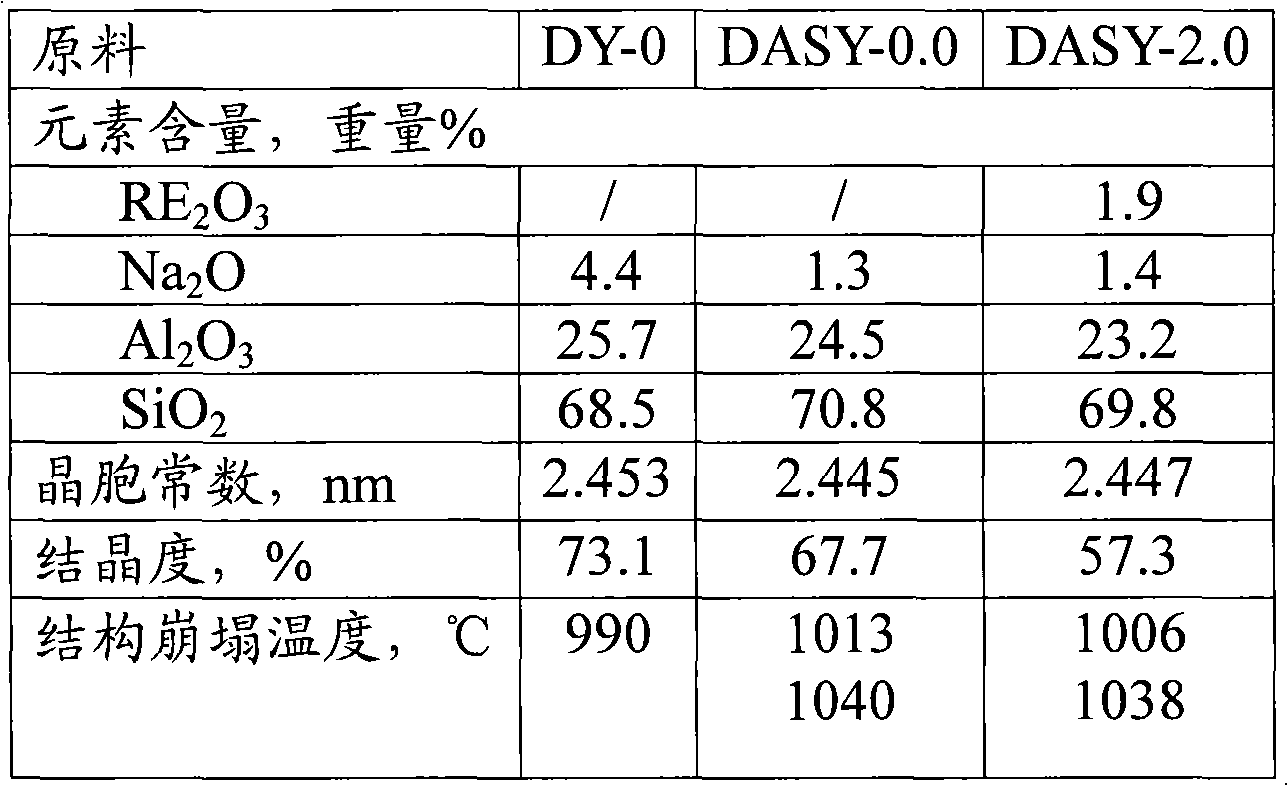

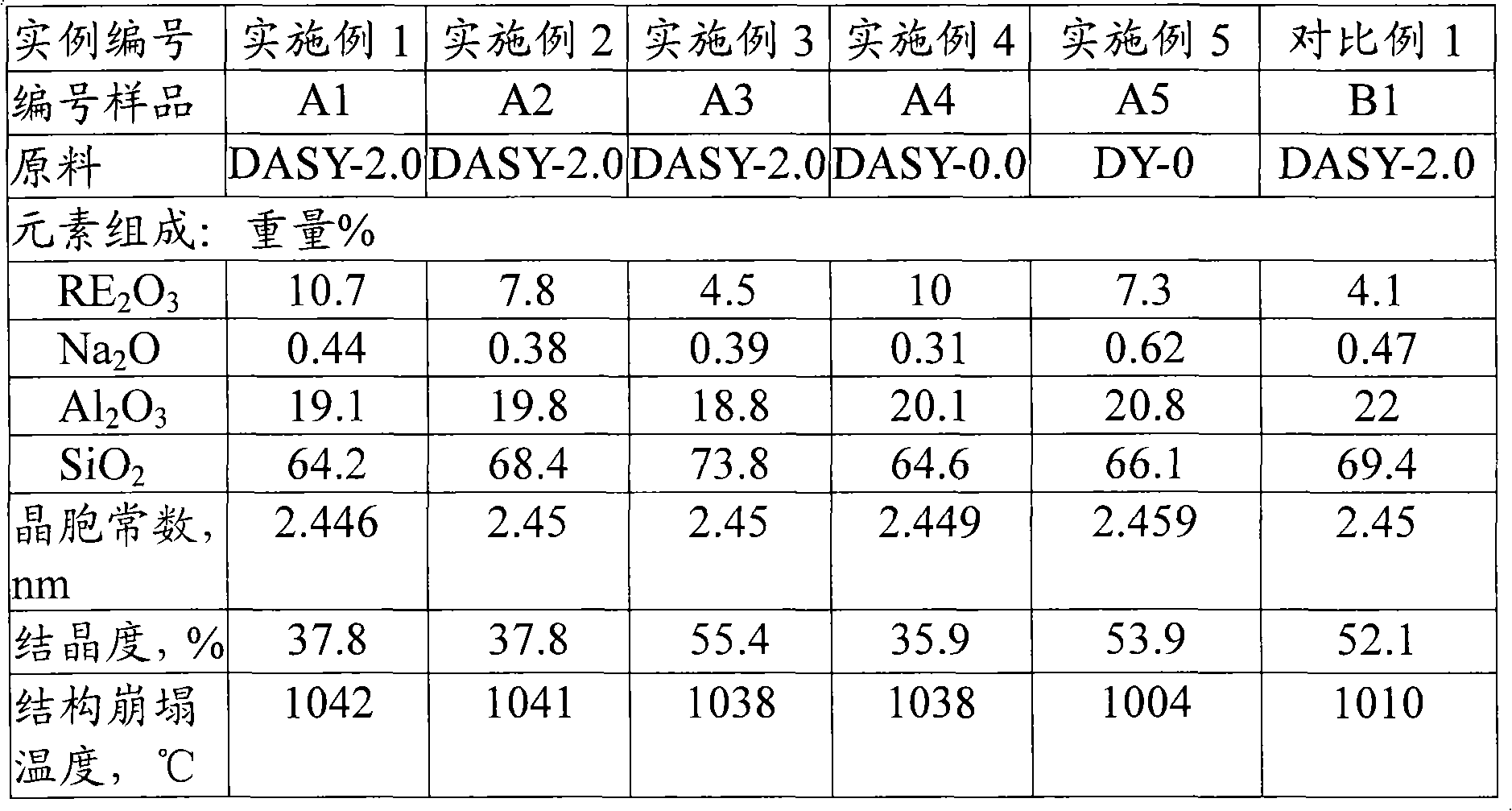

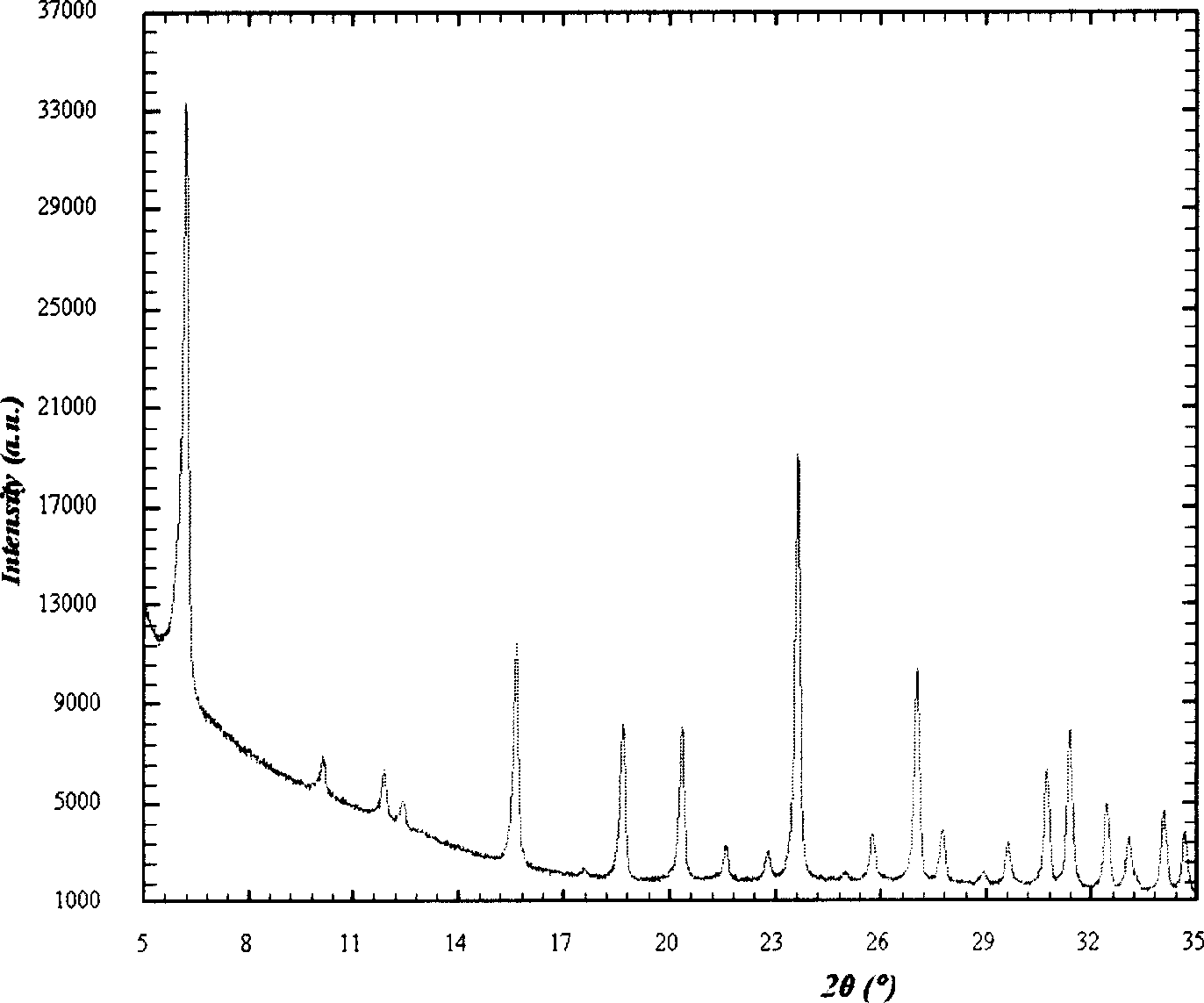

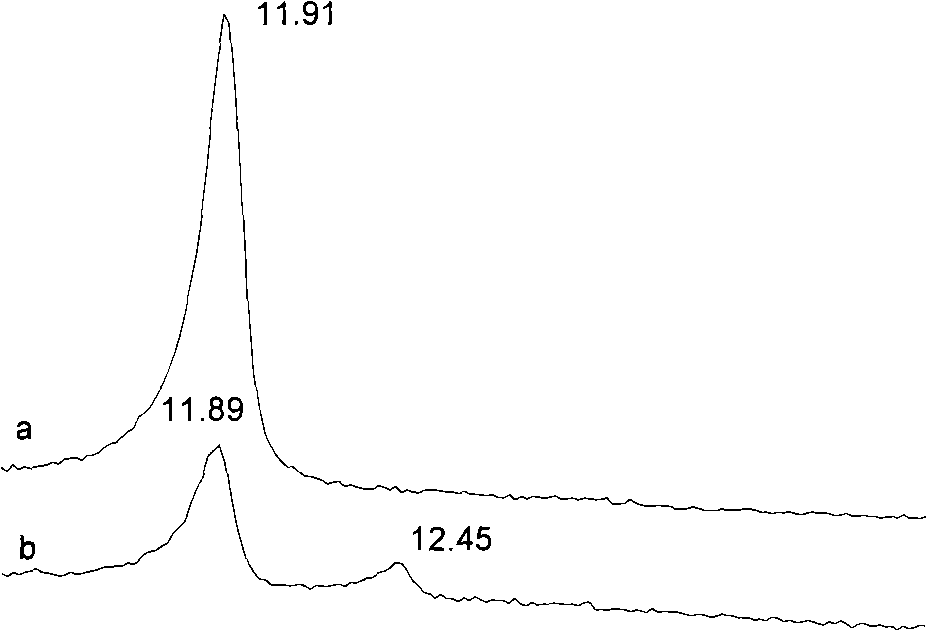

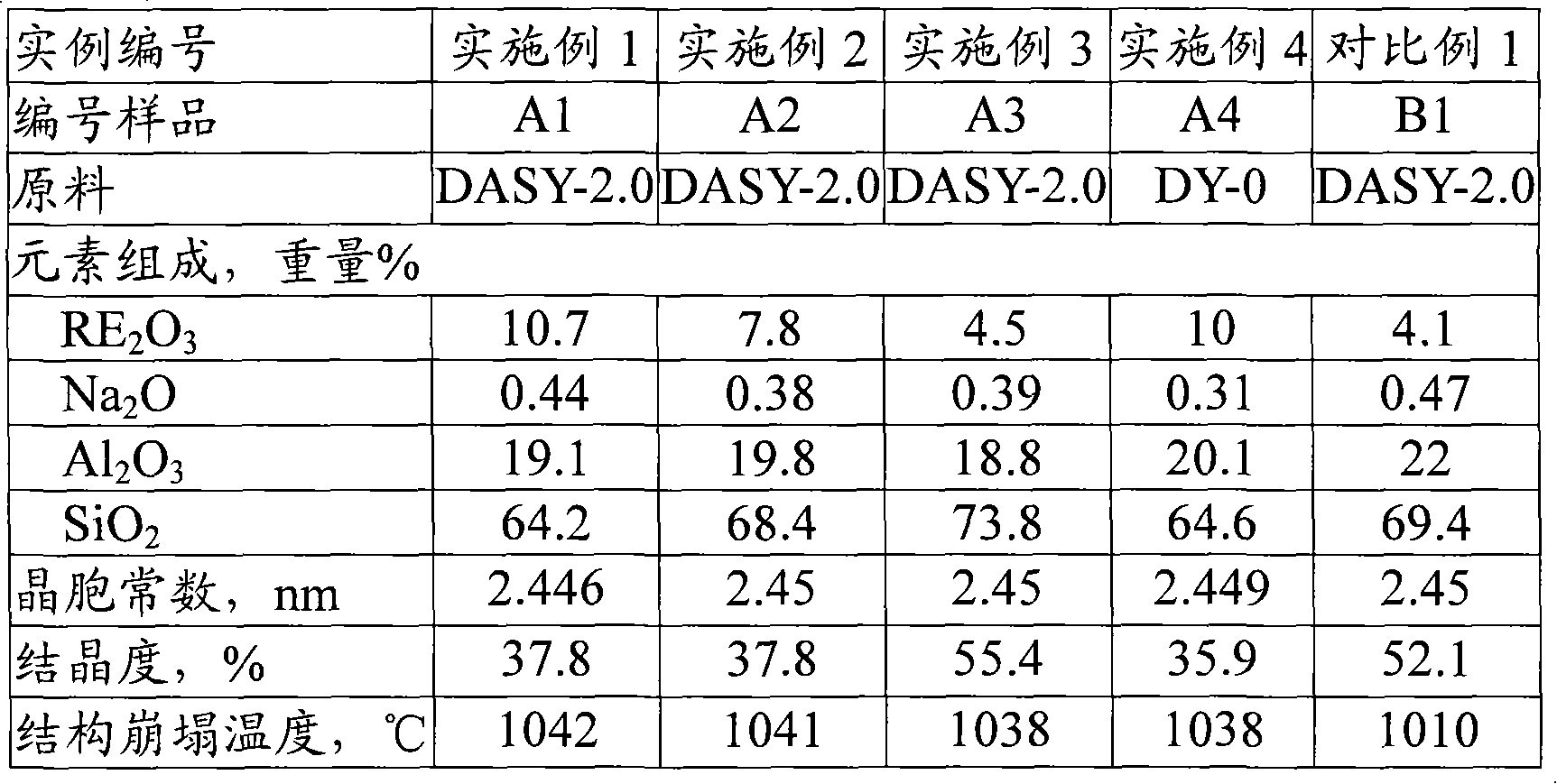

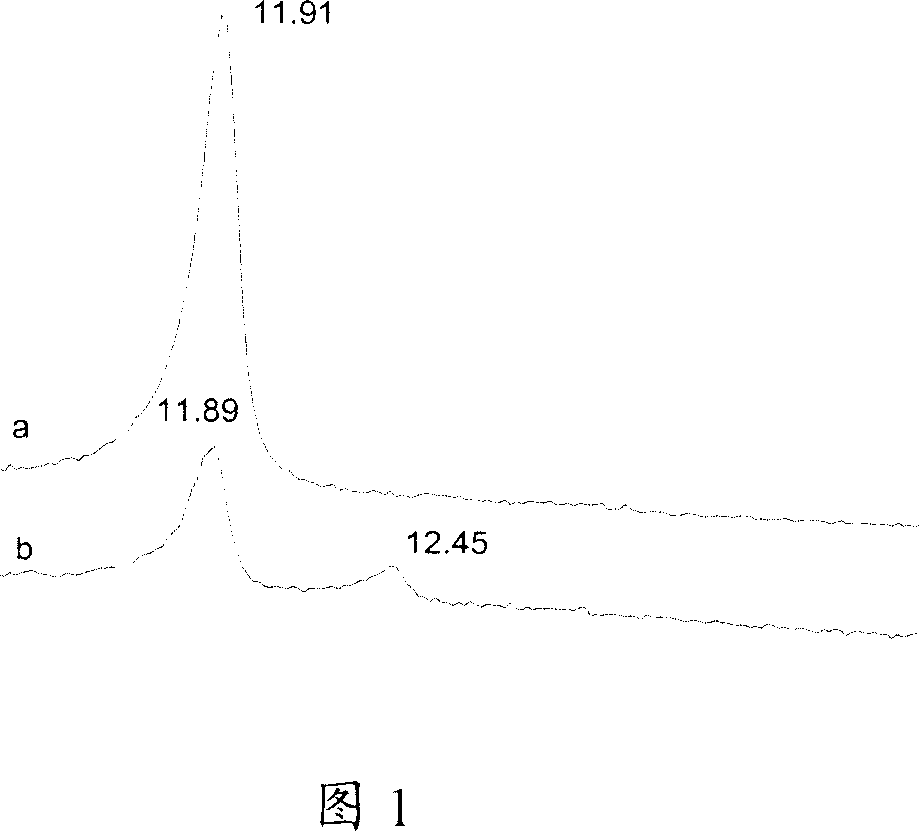

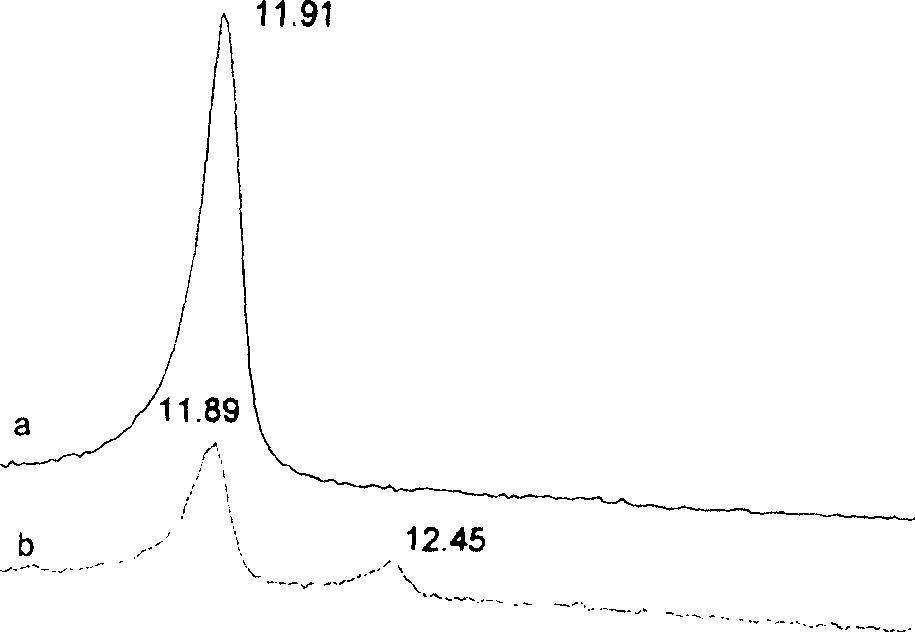

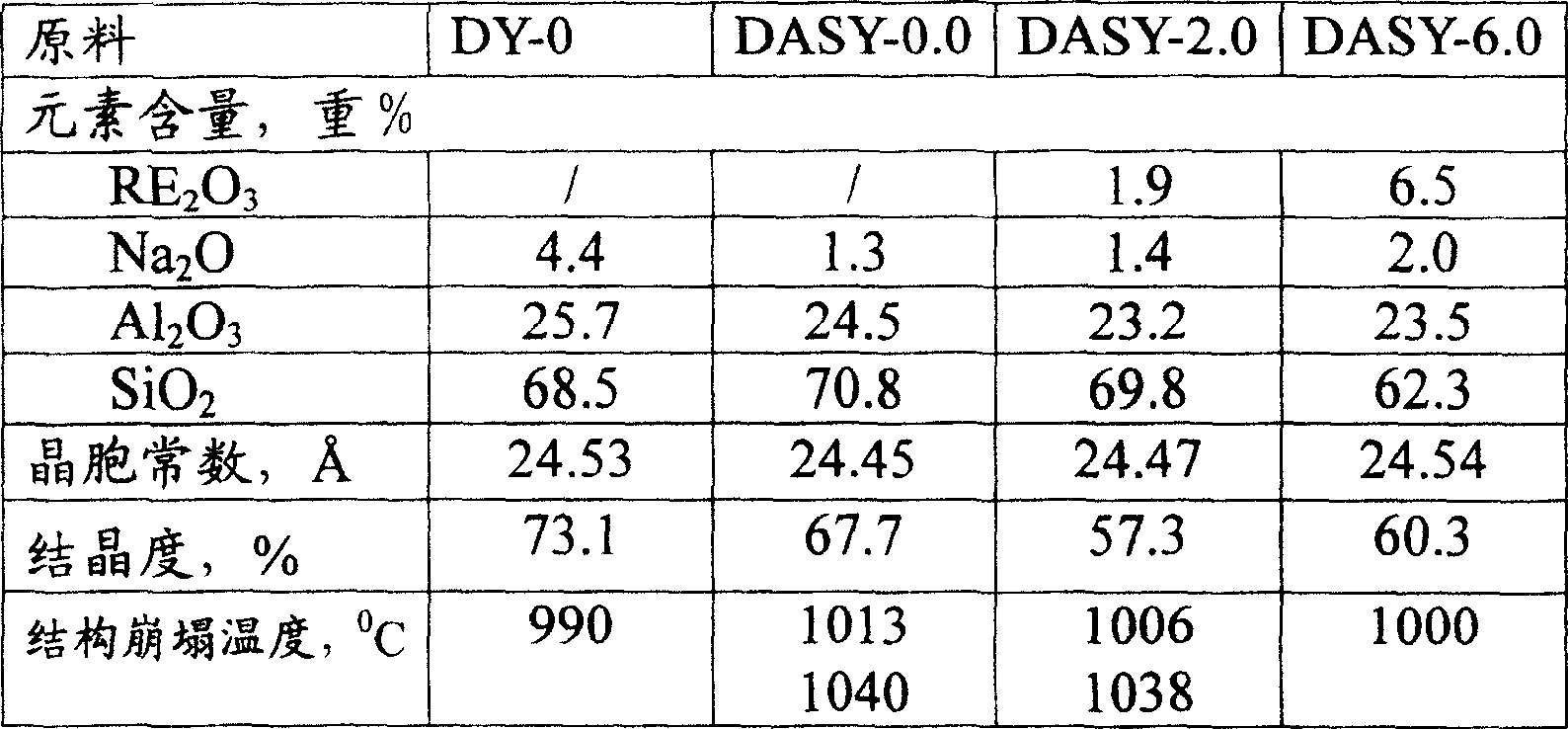

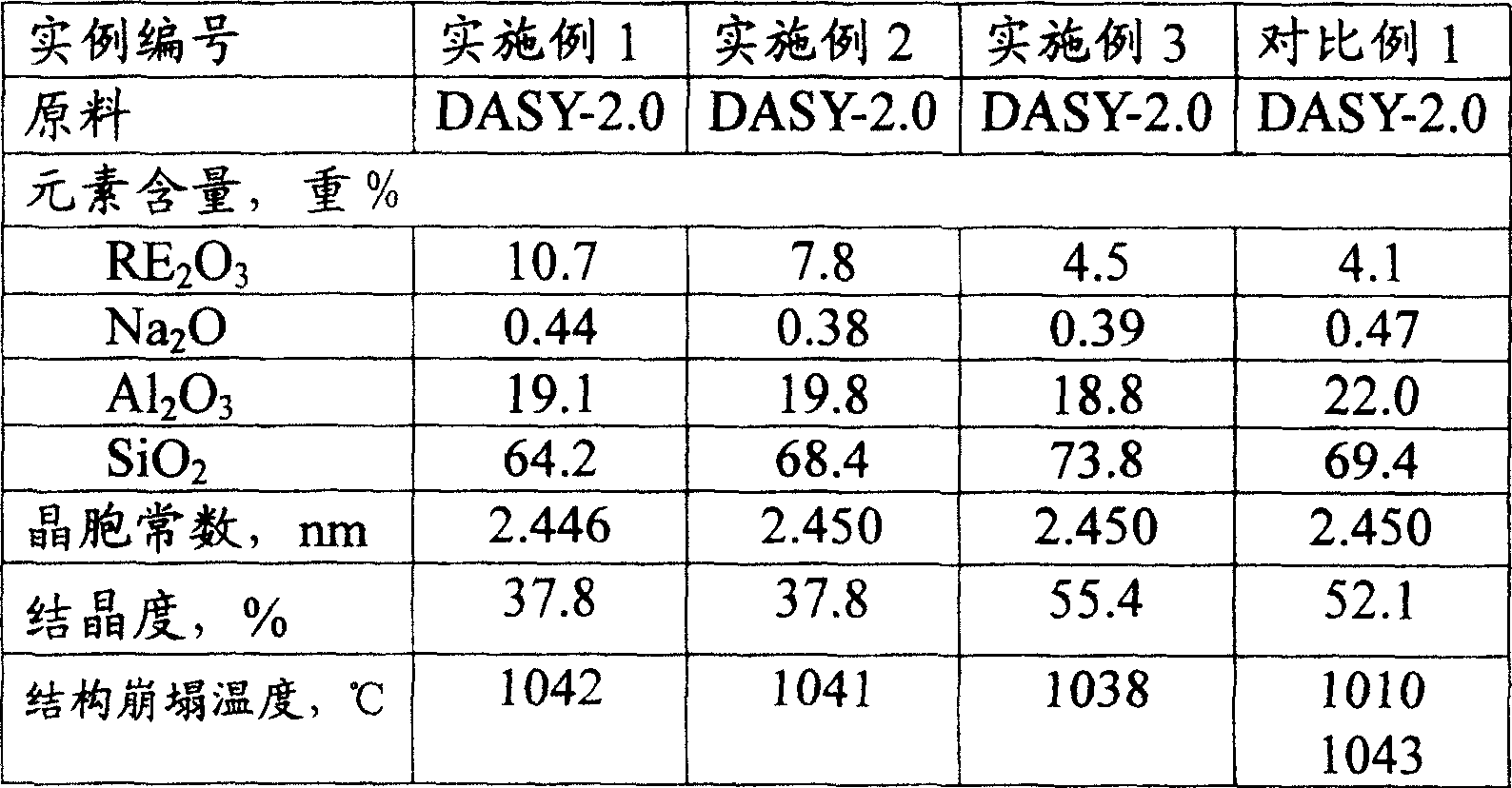

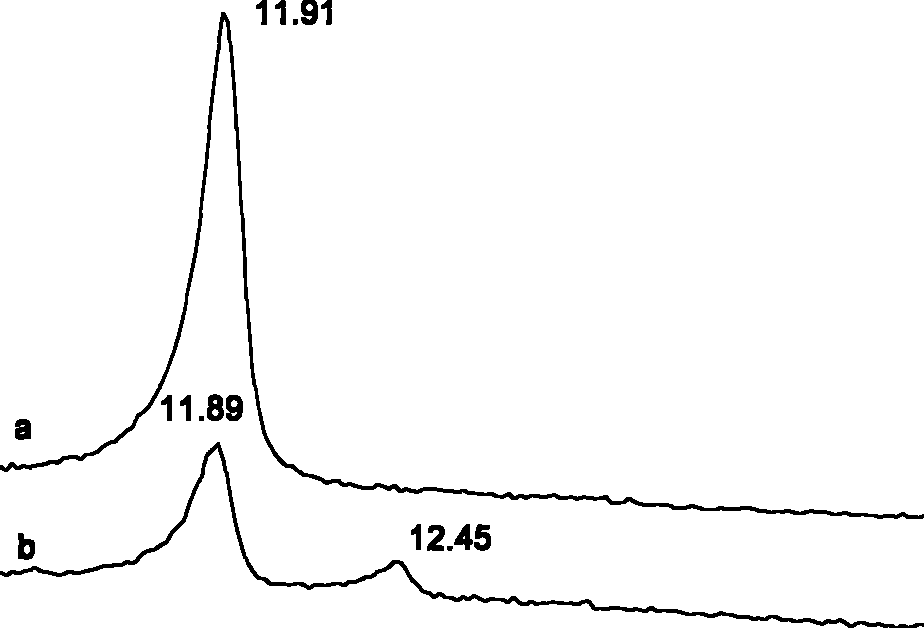

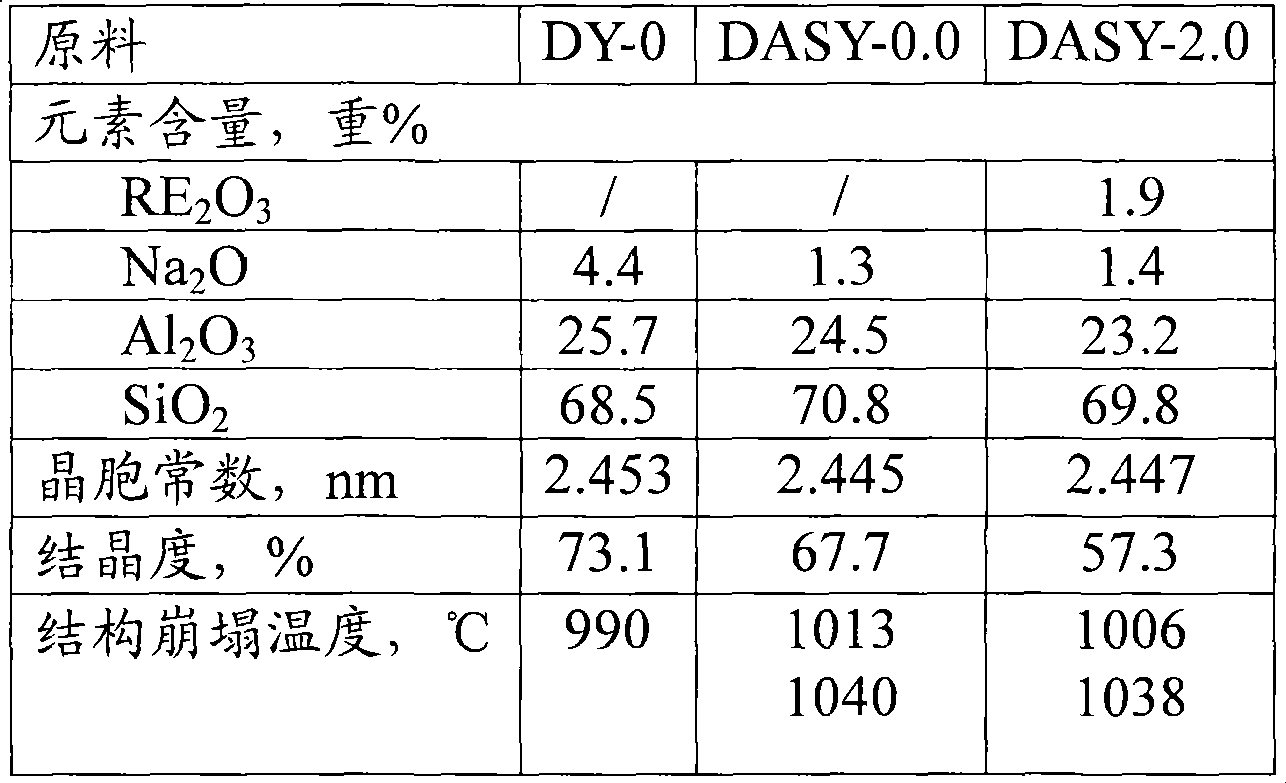

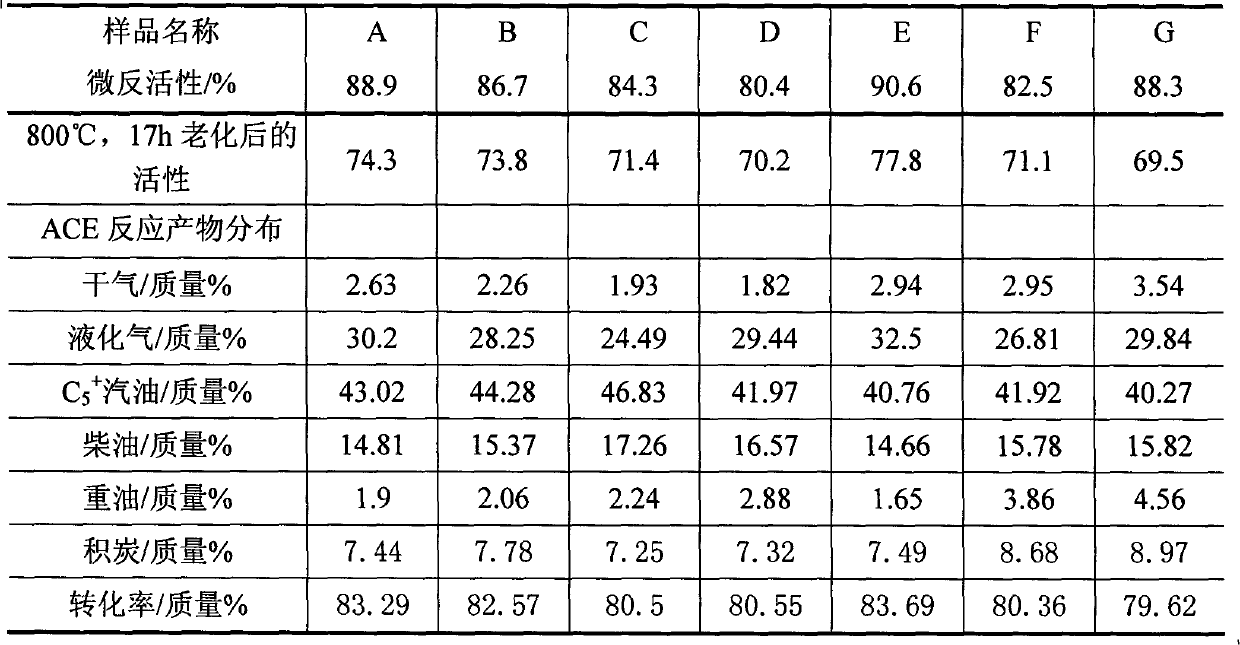

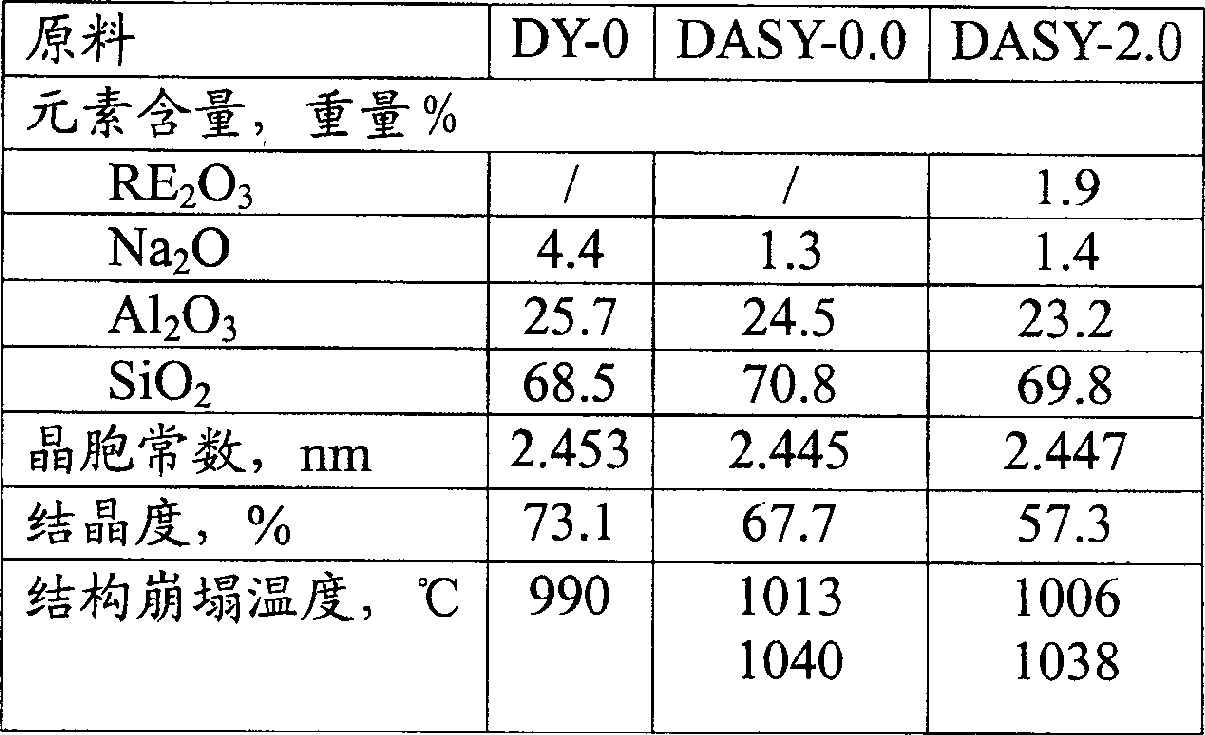

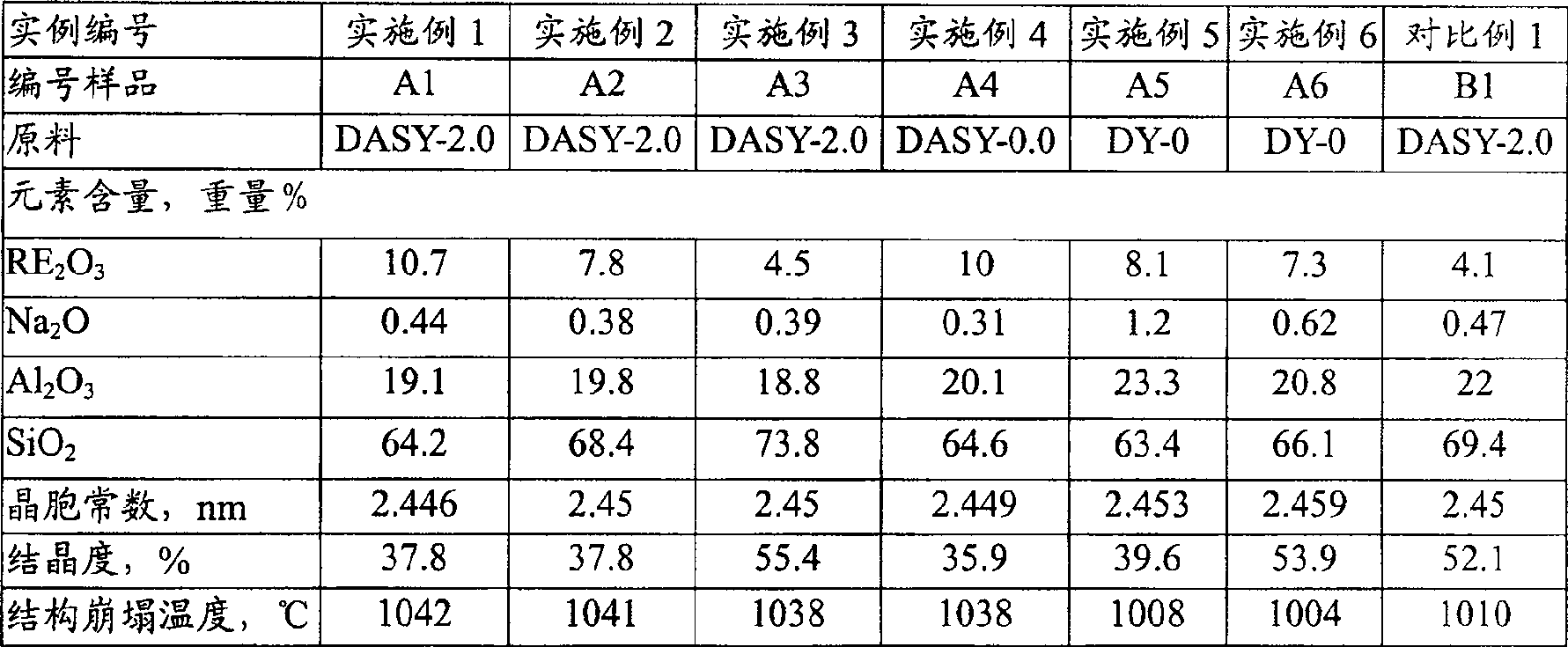

This invention discloses a method for raising rare earth content in super-stable Y-type zeolite. The method comprises: mixing super-stable Y-type zeolite and 0.01-2 N acid solution at a liquid / solid ratio of 4-20 at 20-100 deg.C, treating for 10-300 min, washing, filtering, adding rare earth salt solution for rare earth ion exchange, washing, filtering, and drying to obtain rare earth reinforced super-stable Y-type zeolite. The obtained rare earth reinforced super-stable Y-type zeolite has through pores without any blockage, and has obviously raised rare earth content. Cracking catalyst containing the rare earth reinforced super-stable Y-type zeolite as the active component has high heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparing method thereof

InactiveCN1552801AHigh activityGood activity and stabilityCatalytic crackingRare earthComposite substrate

A catalytic cracking catalyst and its production are disclosed. The catalyst consists of clay 20 - 80m%, silica sol 5 - 30m%, pseudodiaspore 0 - 30%, faujusite with cell parameters of (2.432 - 2.472nm) 5 - 40%, and balanced of ZSM-5 zeolite, beta zeolite and their mixture, oxide selected from Sb, rare earths, Ti, Mg, Zn, P, Sr or their mixture. It uses silica sol as substrate or silica sol and pseudodiaspore as composite substrate to increase macromolecular cracking ability and to improve wearproof performance. It can be produced by non-continuous process or multi-stream continuous process with easy mass production.

Owner:中国石油化工集团公司长岭炼油化工有限责任公司

Catalytic cracking catalyst

ActiveCN101285001AHigh yieldStrong ability to convert heavy oilCatalytic crackingAlkaline earth metalLanthanide

The invention relates to cracking catalyst, containing rare earth ultrastable Y-type zeolite and stroma, wherein the stroma contains alumina with additive; the alumina with additive contains the following composition in percentage by weight: 60 to 99.5 percent of alumina and 0.5 to 40 percent of additive; the additive is selected from one or a plurality of compounds containing alkaline earth, lanthanide metal, silicon, gallium, boron or phosphorus elements; the rare earth ultrastable Y-type zeolite is obtained through a method comprising the following steps that: ultrastable Y-type zeolite and an acid solution with the equivalent concentration between 0.01 and 2 N are mixed with the liquid / solid weight ratio of 4 to 20 in the temperature range between 20 and 100 DEG C, stirred for 10 to 300 minutes, washed and filtered; rare earth salt solution is added in to exchange rare earth ions; the solution is washed and filtered after exchange. The catalyst is strong in heavy oil cracking capability, high in light oil yield and low in coke yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst for reducing alkene content in catalytically cracked gasoline

ActiveCN1733363AReduce olefin contentStrong ability to convert heavy oilCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth ions

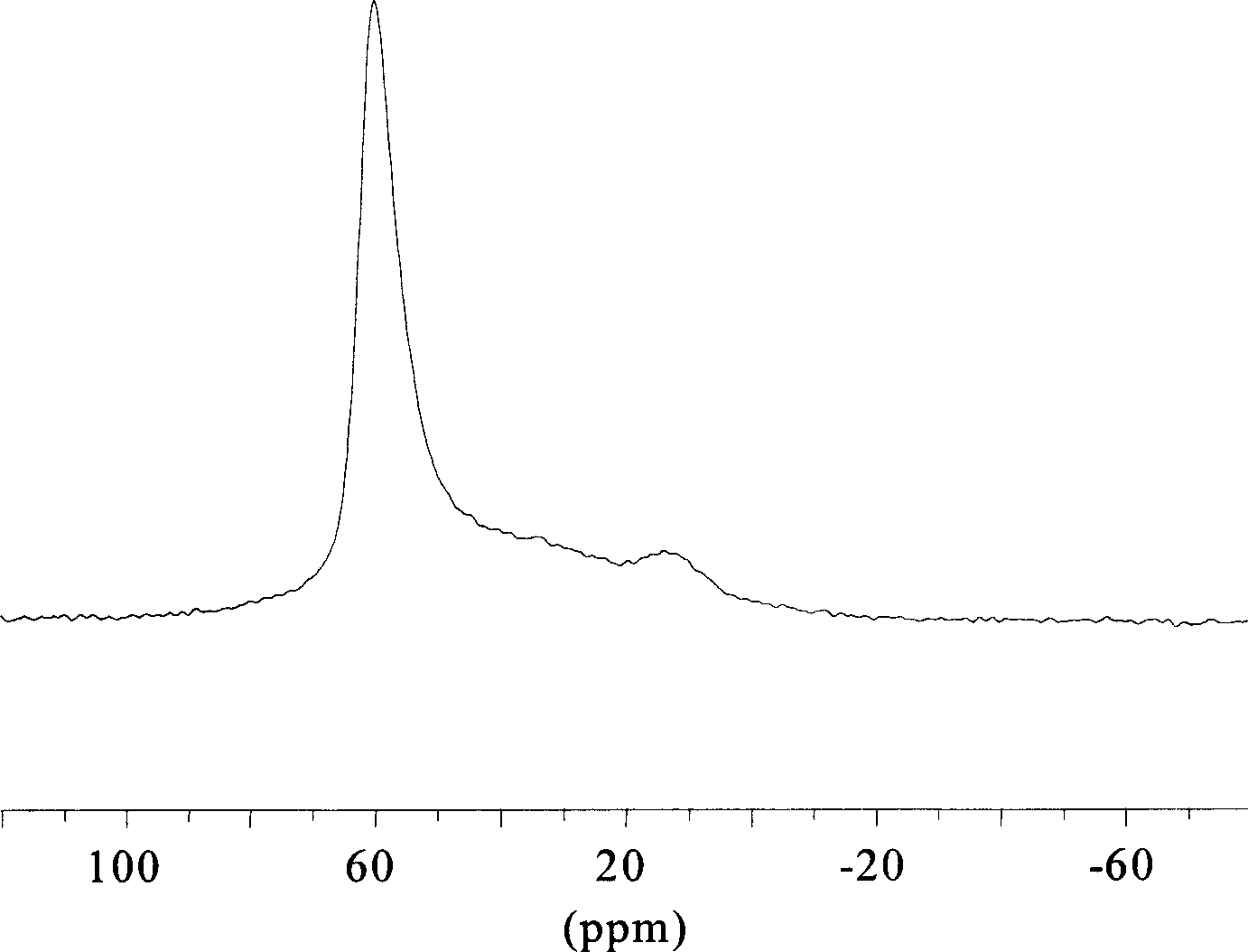

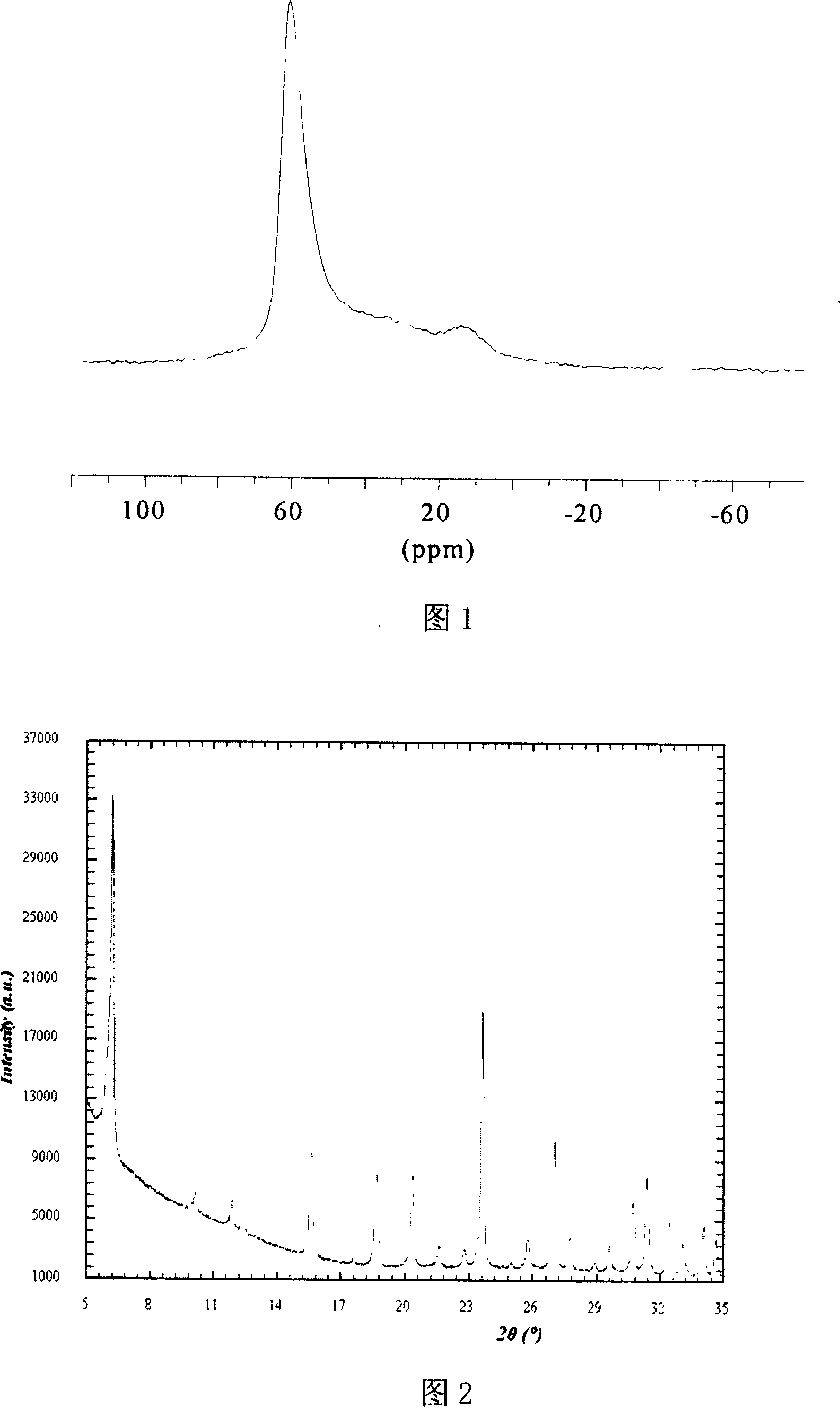

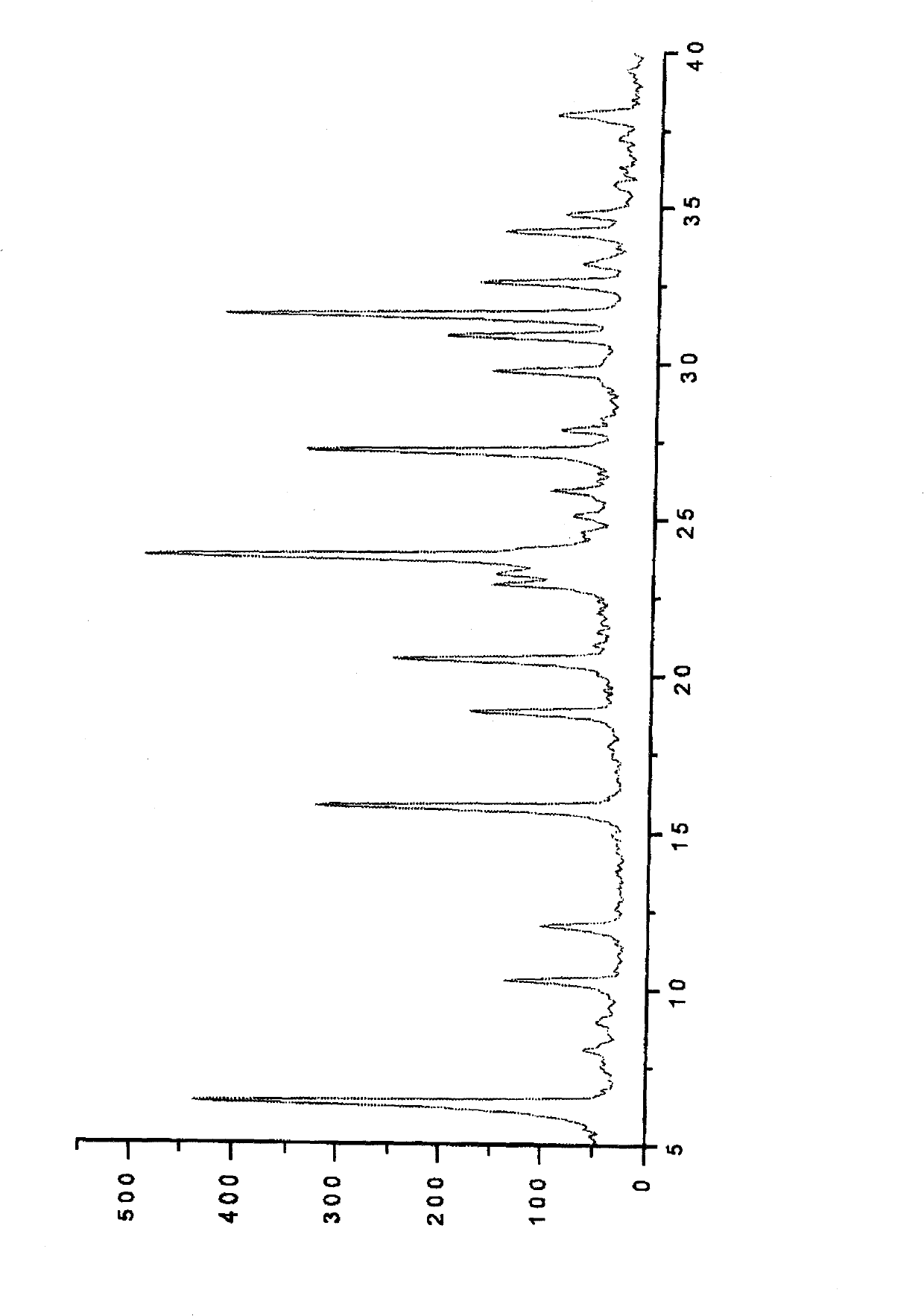

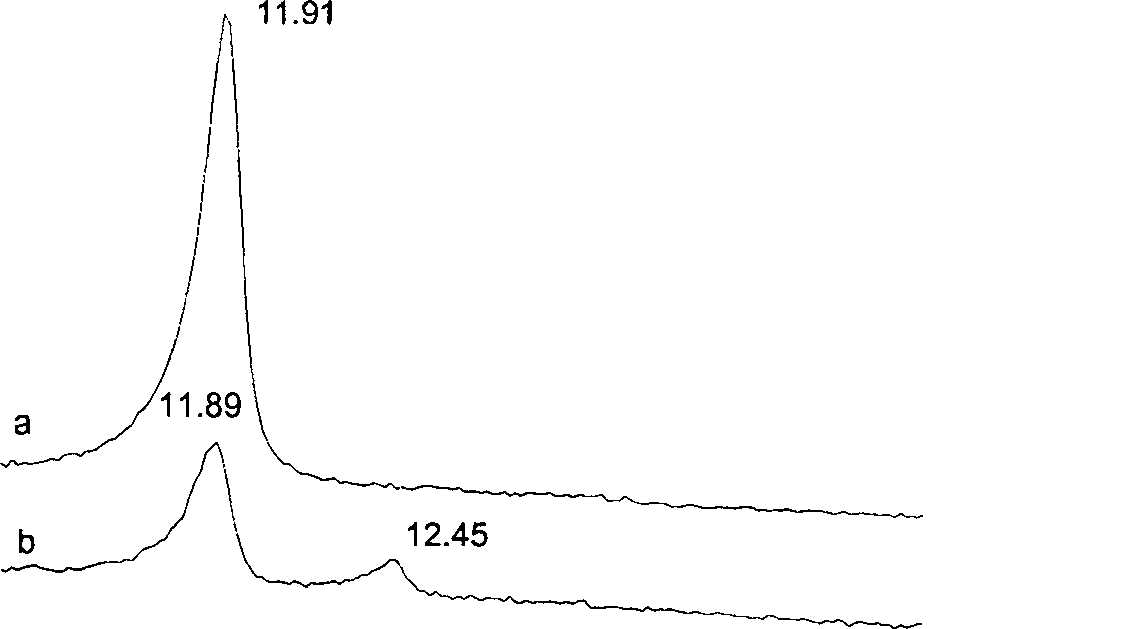

This invention discloses crack catalyst to decrease olefin content in catalytic cracking gasoline, which is characterized in that there is 10~50 w.t% CDY molecular sieve in the catalyst that is prepared by exchanging method of solid-liquid combination; the rare earth content is 12~22 w.t% considering the quantity of rare earth oxide; all rare earth ion is in molecular sieve small cage; there is no peak at 0ppm in 27Al M AS NMR spectrogram. The catalyst can decrease olefin content in catalytic cracking gasoline greatly with well heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN101284243AHigh yieldReduce yieldCatalytic crackingMolecular sieve catalystsRare earth ionsFiltration

A cracking catalyst comprises a rare earth ultra-stable Y-zeolite and a matrix, the matrix comprises a silicon oxide binder, the rare earth ultra-stable Y-zeolite is obtained by the method including the following steps: the ultra-stable Y-zeolite and the acid solution with the equivalent concentration of 0.01N to 2N are mixed within the temperature range of 20 DEG C to 100 DEG C in the liquid-solid weight ratio of 4 to 20; washing and filtration are carried out after stirring for 10 minutes to 300 minutes; rare earth salt solution is then added for carrying out the rare earth ion exchange; and washing, filtration and drying are carried out after the exchange. The catalyst of the invention is used for catalytic cracking of heavy oil, the conversion rate is high, the yield of gasoline is high and the coke yield is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

The present invention relates to a cracking catalyst. Its composition contains (by wt%) 10%-50% of high rare earth ultrastable Y-type molecular sieve, 10%-40% of aluminium oxide adhesive and 10%-70% of clay. The preparation method of described high rare earth ultrastable Y-type molecular sieve includes the following steps: fully mixing ultrastable Y-type zeolite and acid solution whose equivalent concentration is 0.01N-2N according to the solid-liquid ratio of 20:4 at temperature range of 20deg.C-100deg.C, stirring them for 10min-300min, then washing, filtering, adding rare earth salt solution to make rare earth ion exchange, after the exchange washing, filtering and drying so as to obtain the high rare earth ultrastable Y-type molecutar sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN100497175CHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst for reducing alkene content in catalytically cracked gasoline

ActiveCN1322928CReduce olefin contentStrong ability to convert heavy oilCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth ions

Owner:CHINA PETROLEUM & CHEM CORP +1

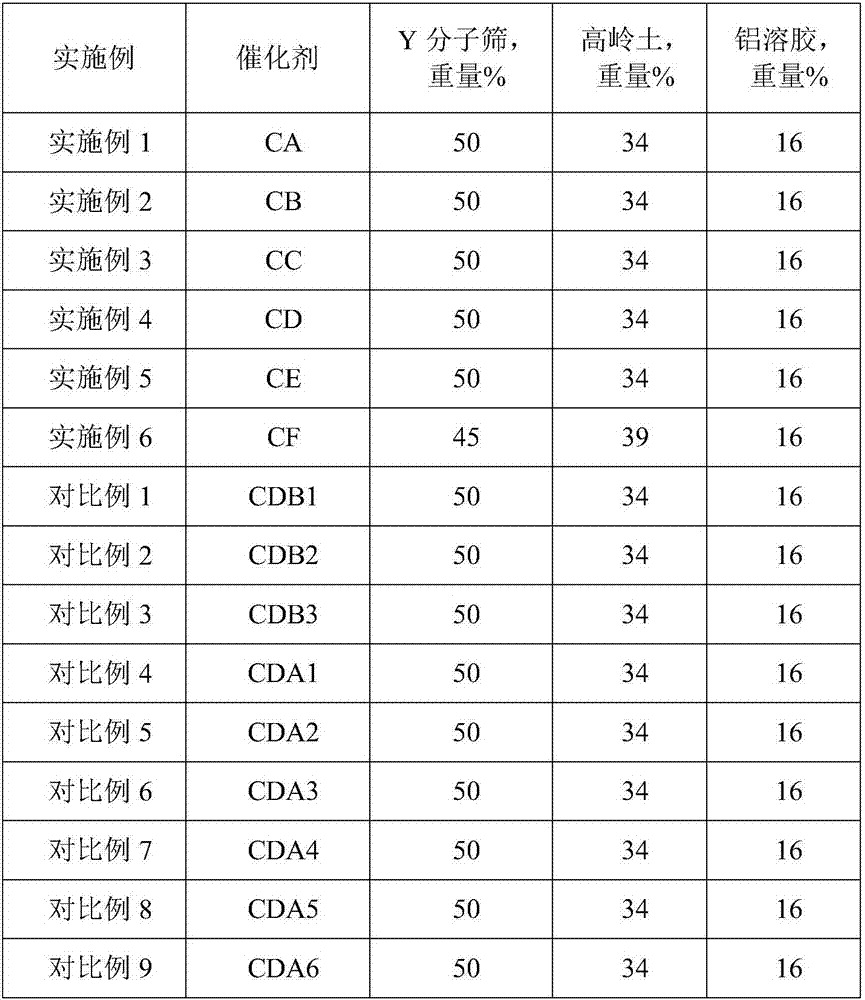

Catalytic cracking catalyst and preparation method thereof

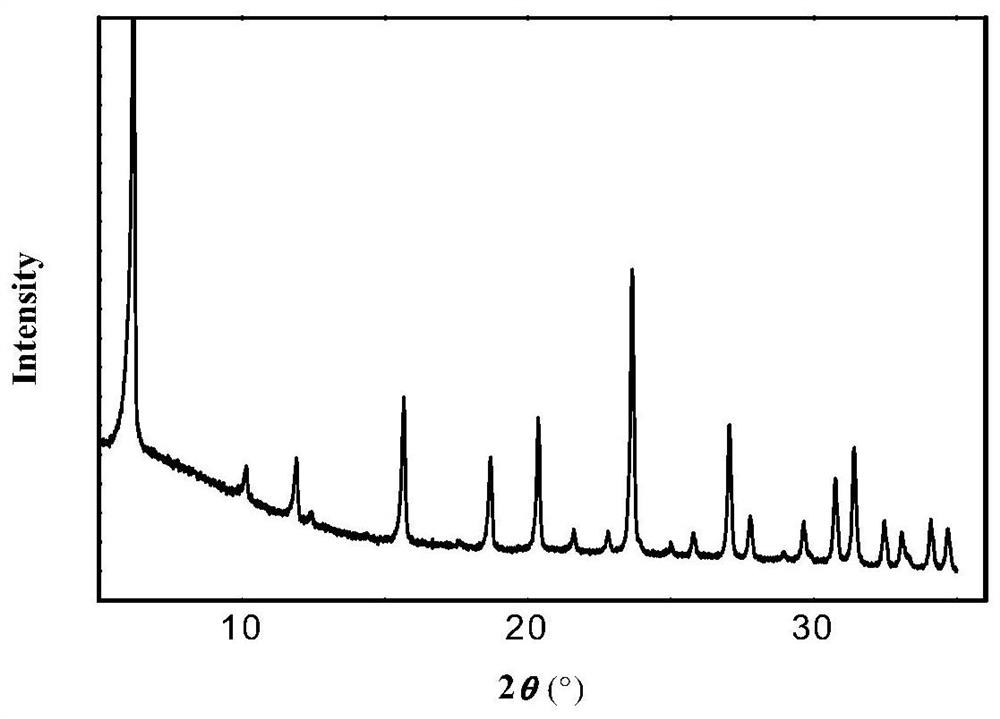

ActiveCN107970974AStrong ability to convert heavy oilHigh gasoline yieldCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

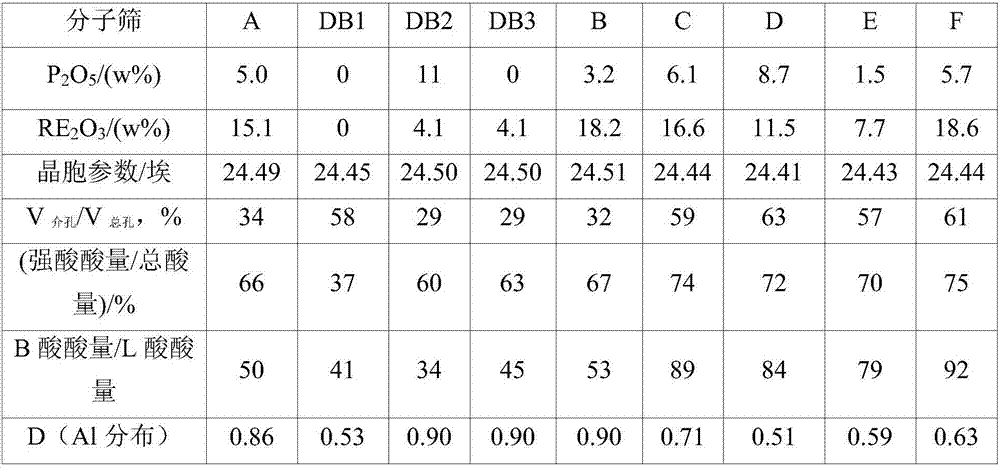

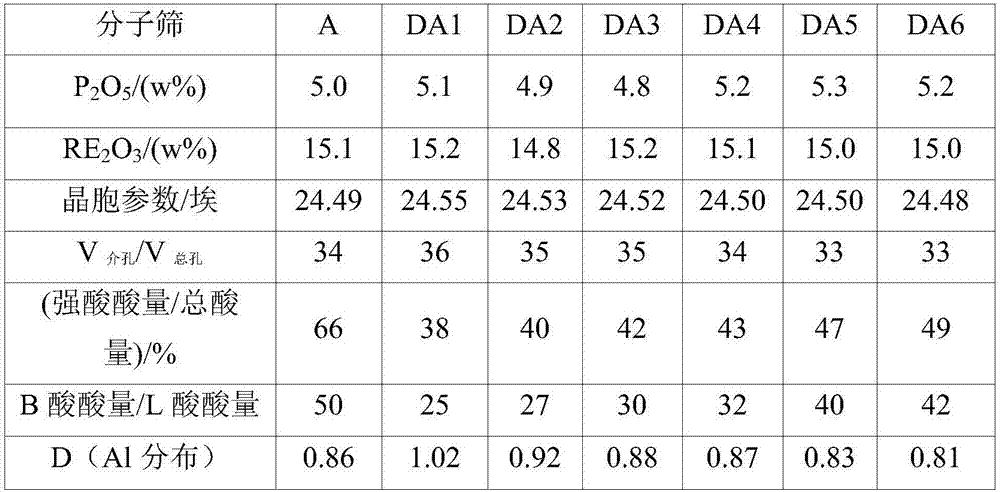

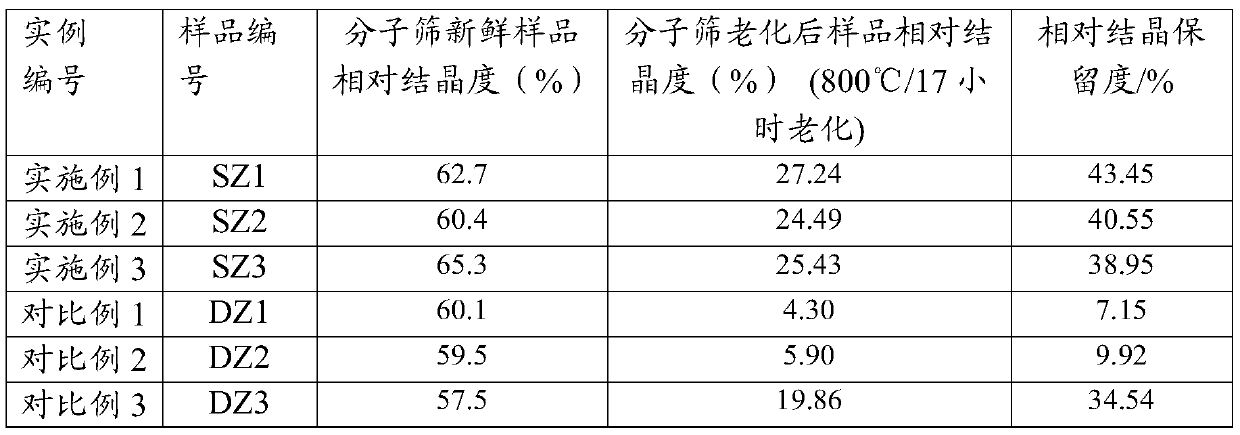

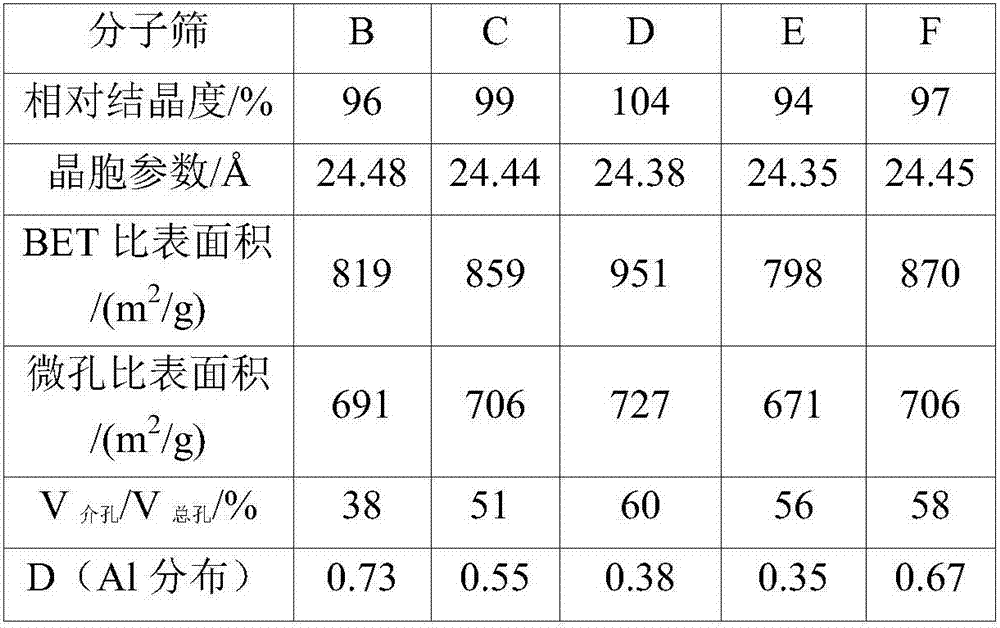

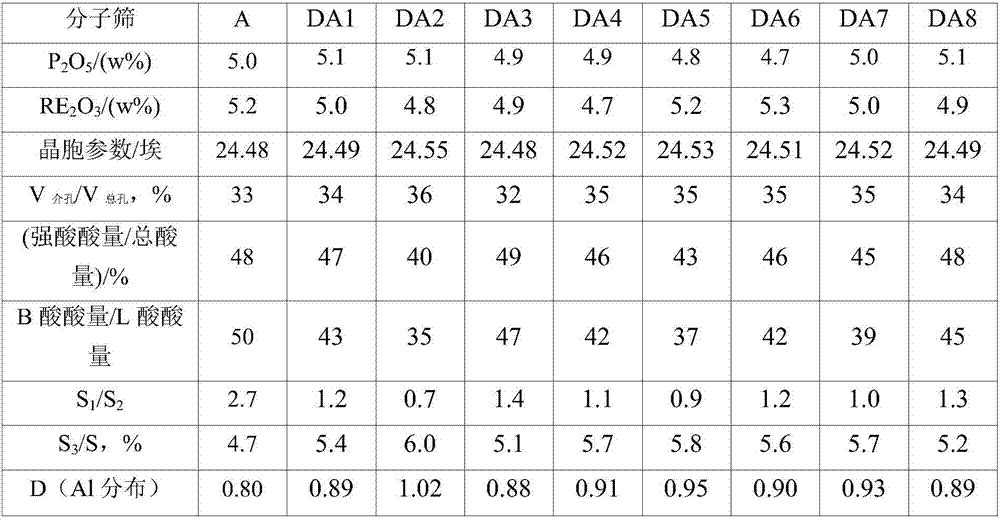

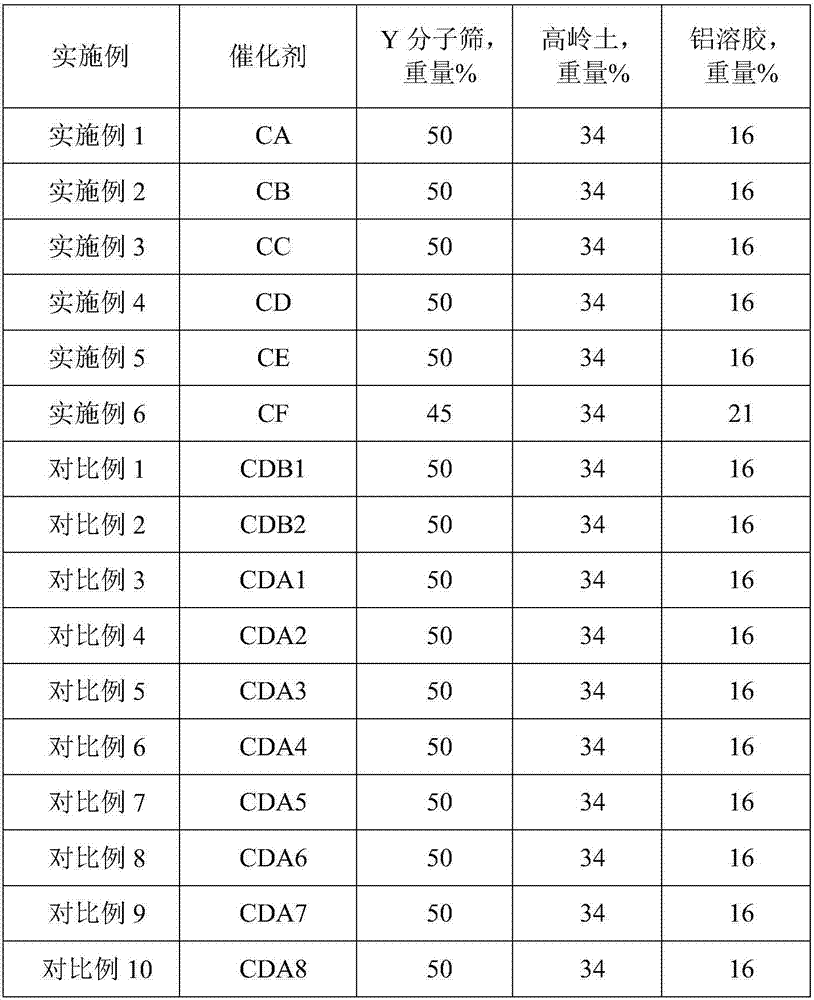

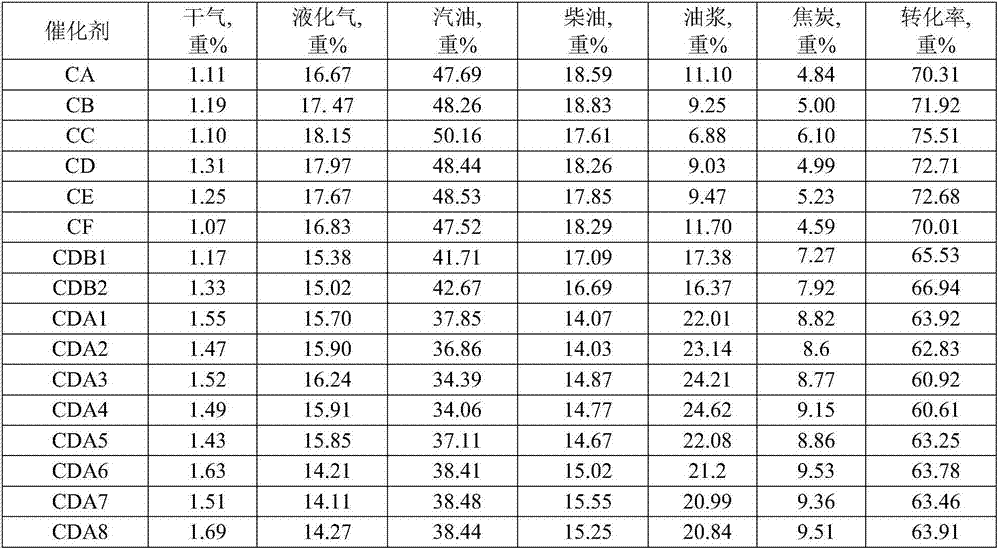

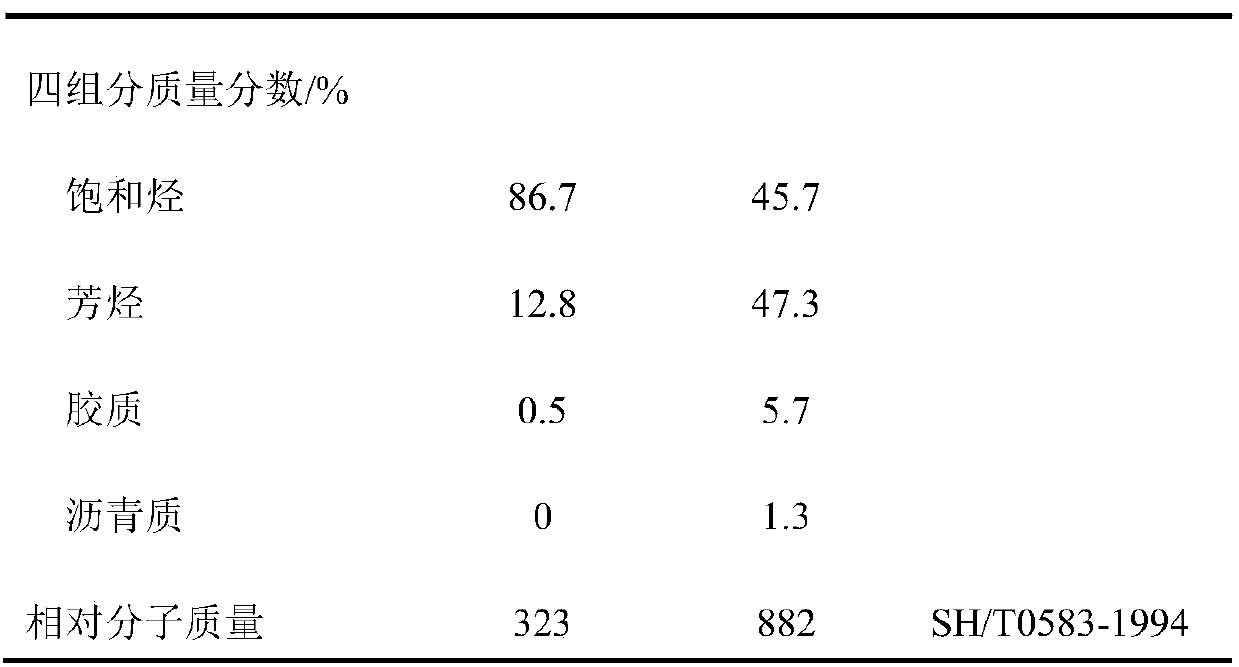

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalytic cracking catalyst comprises, 25 to 75 wt% of a Y molecular sieve containing phosphorus and rare earth, 10 to 30 wt% of an inorganic oxide binder and 15 to 65 wt% of natural mineral matters, wherein the Y molecular sieve containing phosphorus and rare earth has a cell parameter of 24.35 to 24.55 angstroms; the phosphorus content of the molecular sieve is 0.3 to 10.0 wt% in terms of P<2>O<5> and on the basis of the dry base weight of the molecular sieve; the rare earth content of the molecularsieve is 0.5 to 19 wt% in terms of RE<2>O<3> and on the basis of the dry base weight of the molecular sieve; the distribution parameter D of Al in the molecular sieve is no less than 0.4 and no more than 0.9; the mesopore volume of the molecular sieve accounts for 25 to 65% of total pore volume; the amount of strong acids in the molecular sieve accounts for 65 to 78% of total acid amount; and a ratio of the amount of the acid B to the amount of the acid L is 21 to 98. The catalytic cracking catalyst provided by the invention has the advantages of excellent heavy oil conversion capability, higher gasoline yield and lower coke yield when applied to catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

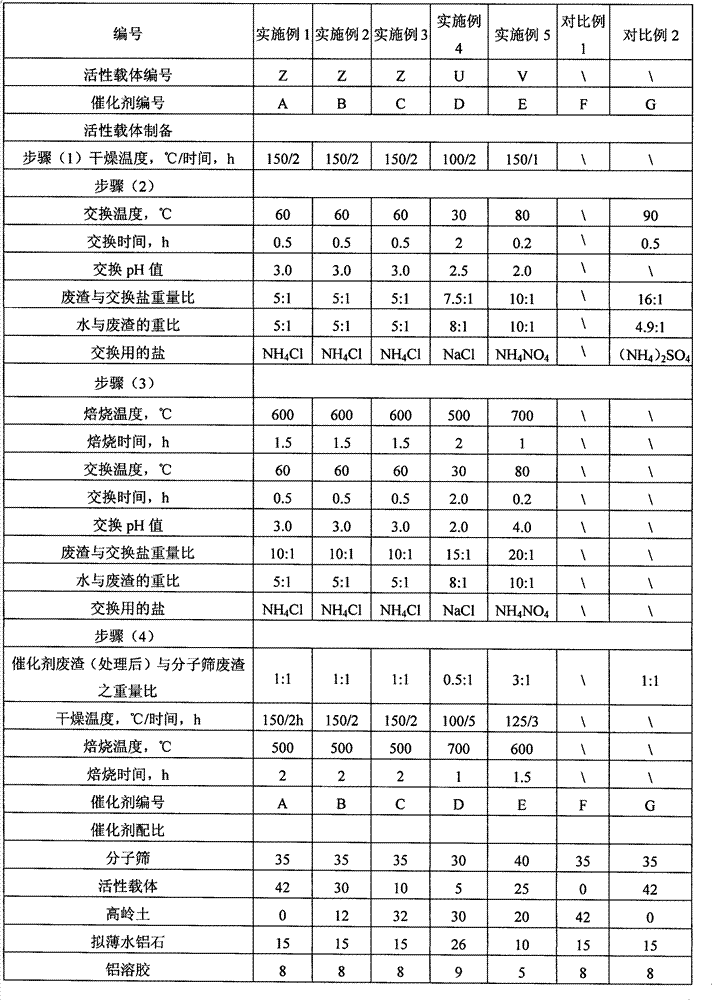

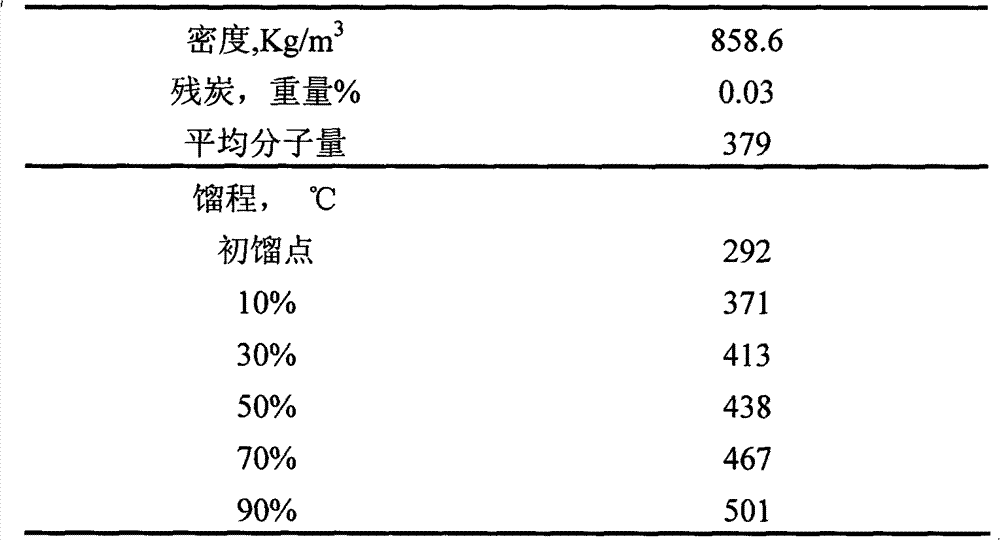

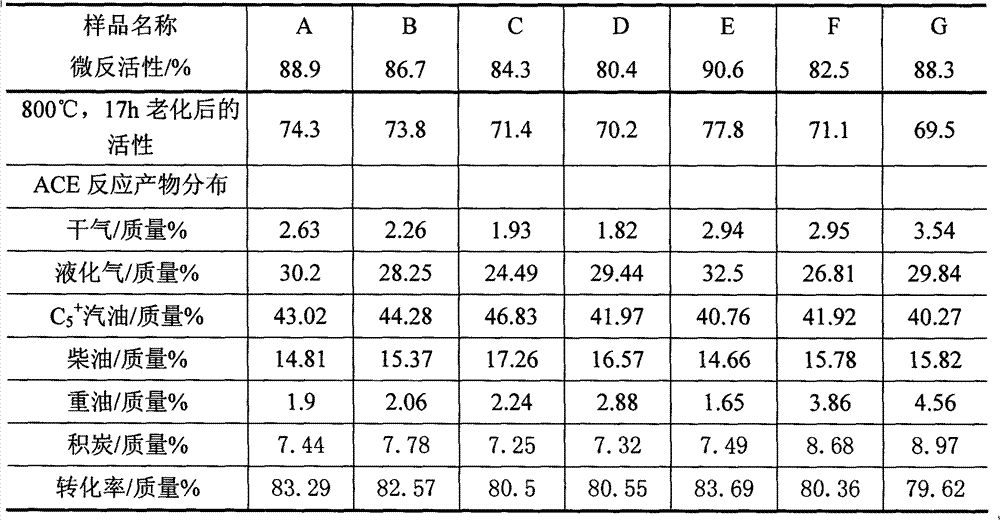

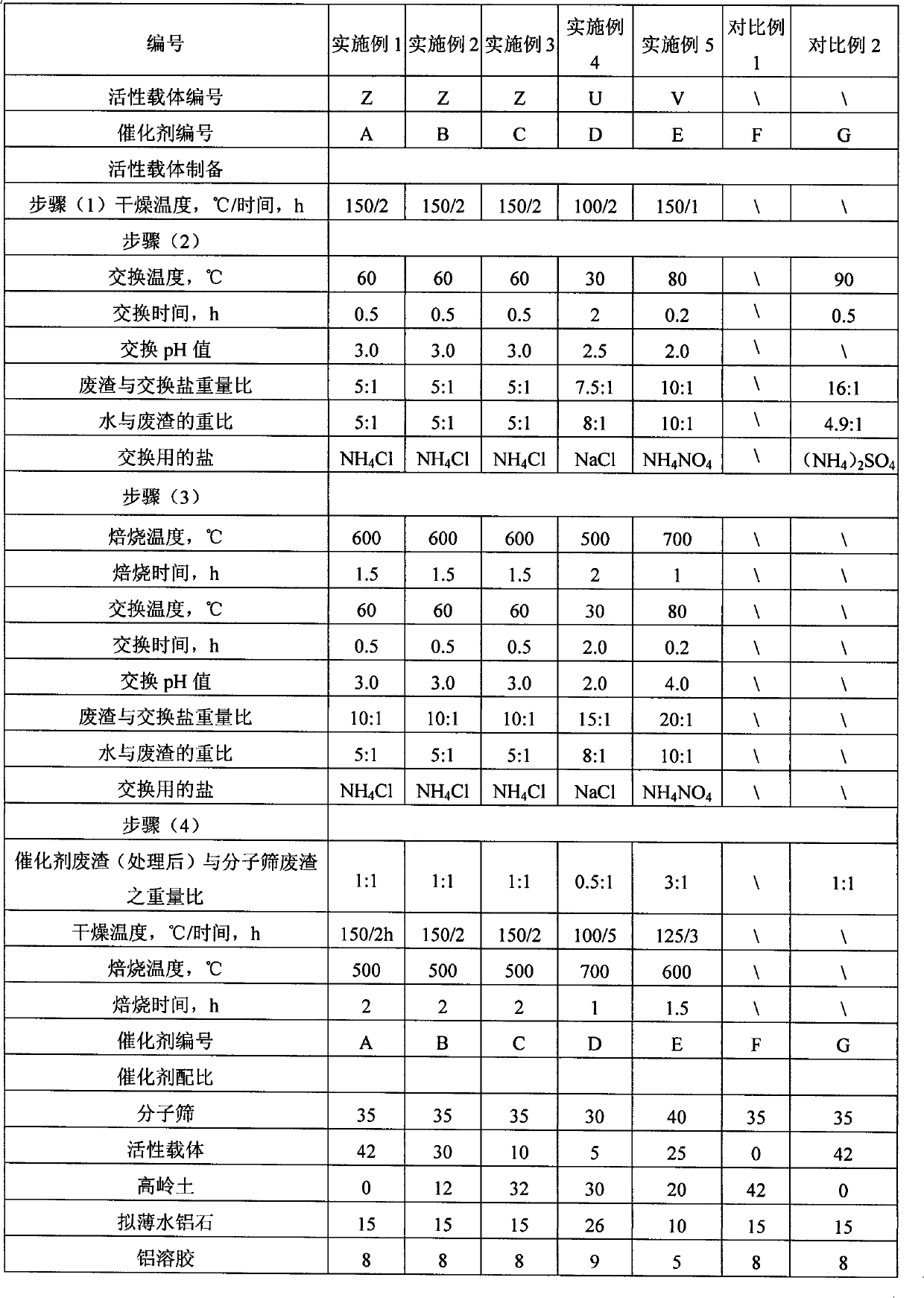

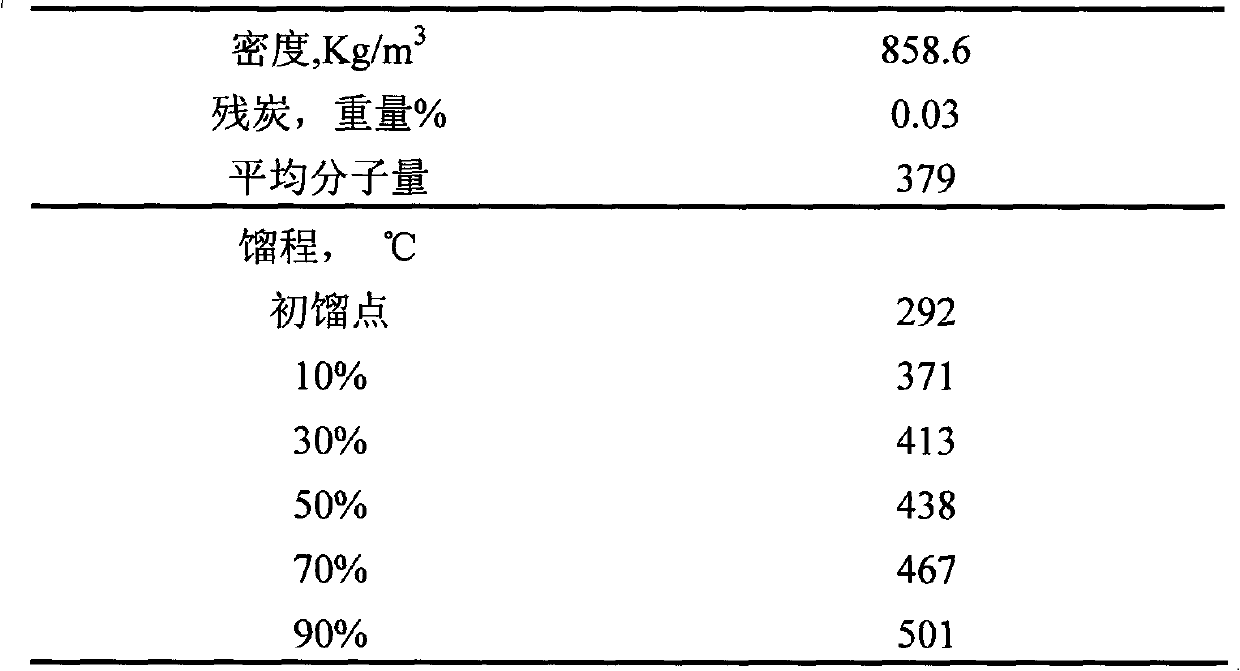

Method for utilizing residues of catalyst production

ActiveCN102896000AOvercoming the disadvantages of poor direct exchangeIdeal for removing impuritiesCatalyst carriersCatalytic crackingMolecular sieveIon exchange

The invention discloses a method for utilizing residues of catalyst production, comprising the following steps: (1) drying catalyst residues; (2) contacting the material obtained by the step (1) with an ammonium salt solution or alkali metal saline solution to conduct ion exchange and washing, then filtering; (3) roasting the material obtained by the step (2) at 450-750 DEG C, then exchanging, washing and filtering; and (4) mixing the material obtained by the step (3) with molecular sieve residues and water and beating, filtering, drying, and then roasting at 500-700 DEG C to obtain an active carrier; and carrying out beating and spray drying on the active carrier, ultrastable Y-type molecular sieve, alumina binder and clay to obtain a cracking catalyst. The obtained catalytic cracking catalyst has the advantages of high cracking activity, high active stability, and low yields of dry gas and coke.

Owner:CHINA PETROLEUM & CHEM CORP +1

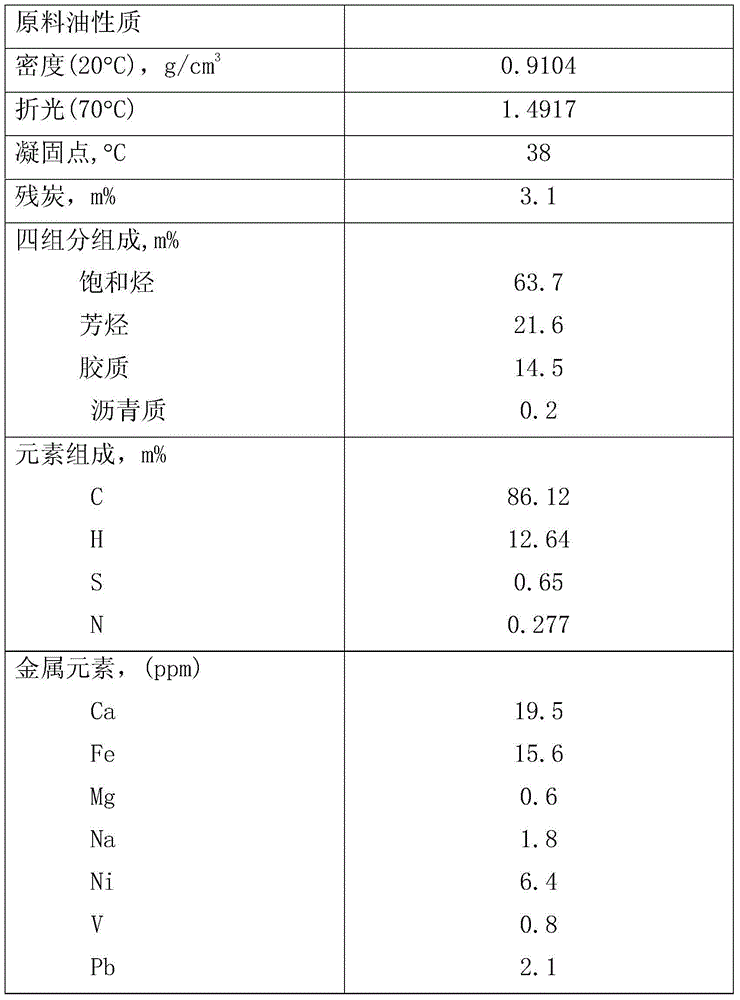

Method for cracking hydrocarbon oil

ActiveCN1600839AStrong desulfurization abilityStrong ability to convert heavy oilHydrocarbon oil crackingChemistryProduct gas

This method aims at cracking hydrocarbon oil, under cracking condition, raw material hydrocarbon oil contactes with catalyst, which is already contacted with reducing gas atmosphere. Then proceeded are procedures of: separating cracking produced from catalyst, regenerating catalyst, said catalyst being contacted with reducing gas atmosphere. In above-said procedures, the catalyst is a mixture of cracking-aid agent and catalytic-cracking catalyst, wherein: said cracking-aid agent comprising a metal component and a carrier; the contact temp. for catalyst, contactint with reducing gas atmosphere being 100-900 deg.C, with contacting time being at least 1 second, the volume of reducing gas atmosphere is that: each ton of metal-contd. cracking catalyst, at one minute contact is not less than 0.03 m3 of reducing gas, the pressure in the reactor being 0.1-0.5 mega Pa.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dual-molecular-sieve-containing cracking catalyst by using in-situ crystallization

ActiveCN102886275AStrong ability to convert heavy oilRich in channelsCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A method for preparing dual-molecular-sieve-containing cracking catalyst by using in-situ crystallization is characterized by mixing 1 to 10 % by weight of a ZSM-5, 1 to 10 % of by weight of a Y molecular sieve, 1 to 15 % by weight of a binder and the balance being kaolin, pulping and atomizing to prepare microballoons with an average particle size of 50 to 80 microns; vacuum calcinating and dehydrating under 0.01 to 0.1 MPa and 150 to 500 DEG C for 0.5 to 4 hours, and calcinating under 500 to 900 DEG C for 1 to 10 hours, adding a sodium silicate solution with a solid / liquid ratio of 1 : 1-5; adjusting a pH value of the slurry to 12-14 with a sodium hydroxide solution; hydrothermally crystallizing 20 to 60 % by weight of a NaY molecular sieve with a silica-alumina ratio of 4.5 to 5.8 respectively under 50 to 100 DEG C for 0.5 to hours and under 80 to 130 DEG C for 15 to 40 hours; and hydrothermally exchanging for 1 to 3 times with a rare earth salt solution and an ammonium salt solution and calcinating under 400 to 750 DEG C for 1 to 4 hours for 1 to 2 times to prepare a catalyst with less than or equal to 1.0 % by weight of Na2O and 2 to 12 % by weight of rare earth oxide, wherein the catalyst contains the ZSM-5 molecular sieve and the Y molecular sieve, and has advantages of strong conversion capability of heavy oil, large liquid yield and high octane number of gasoline.

Owner:REZEL CATALYSTS CORP

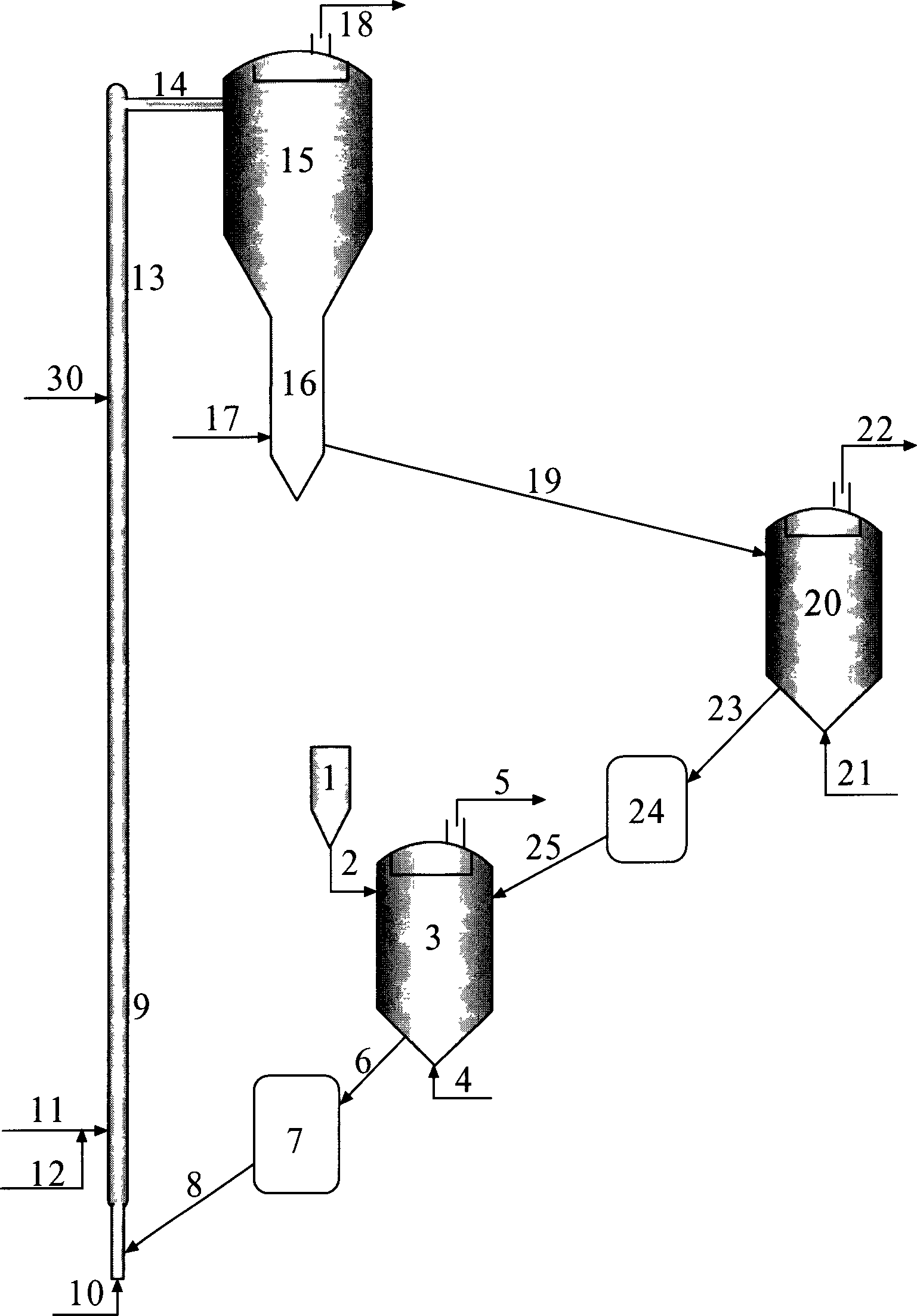

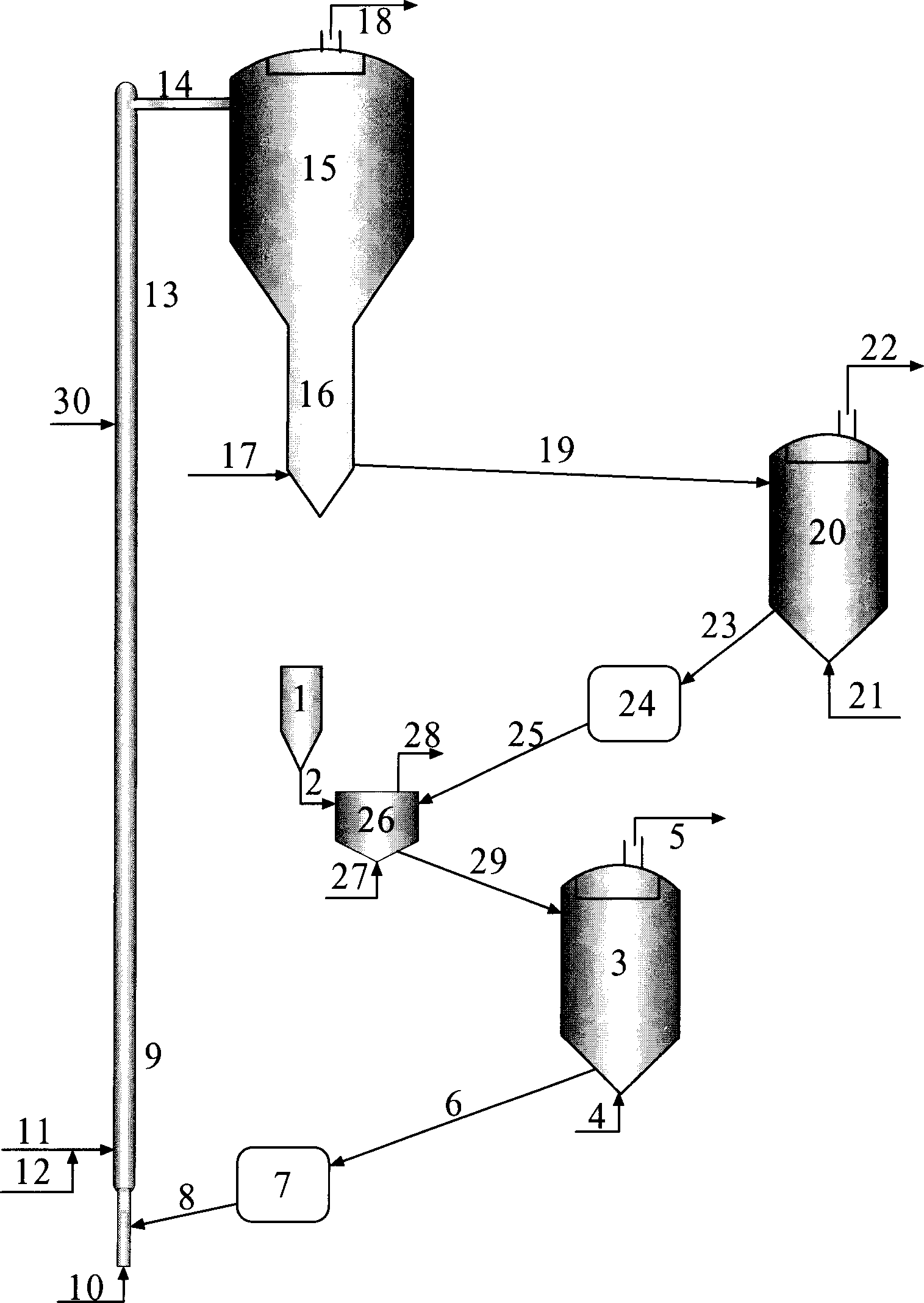

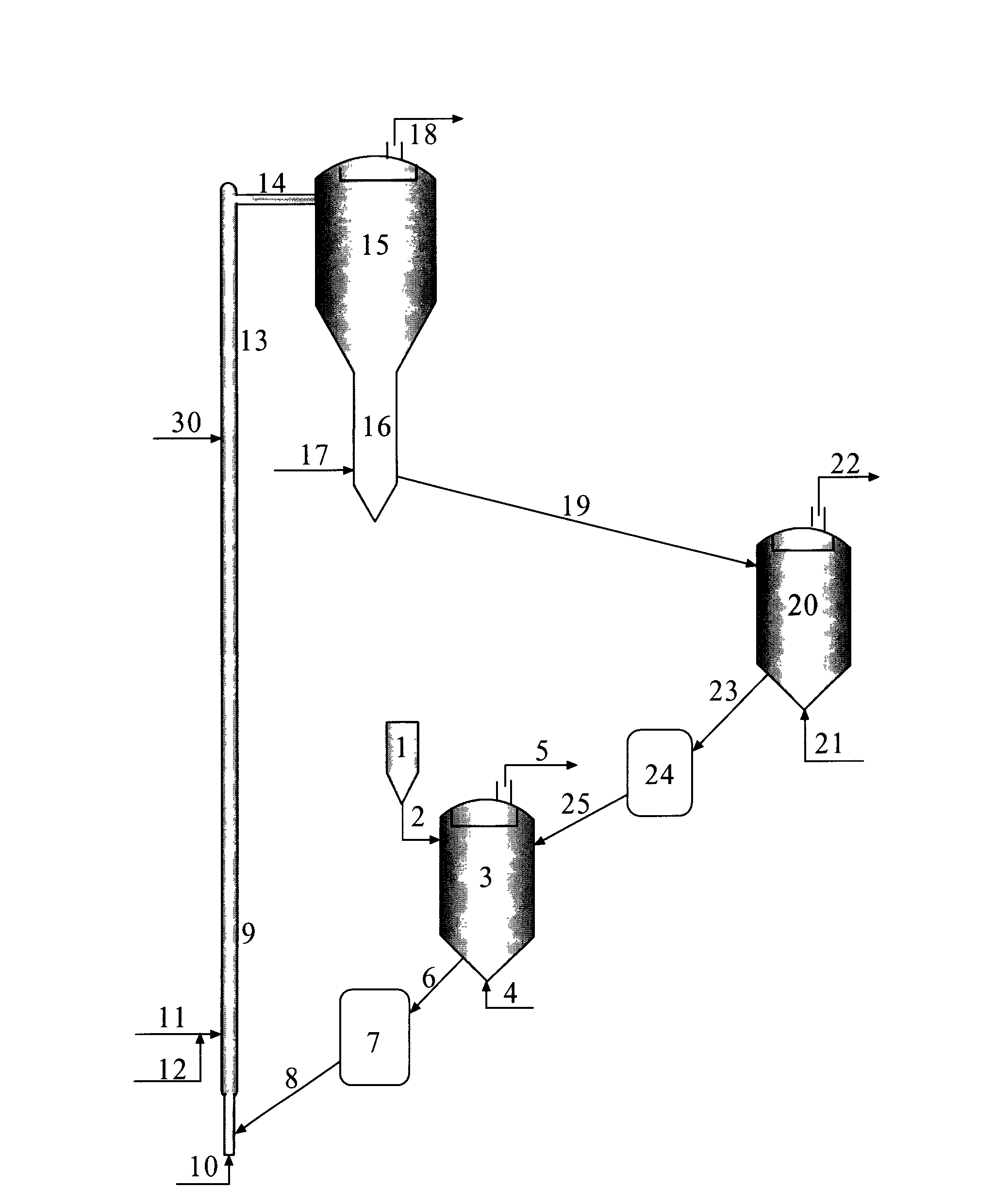

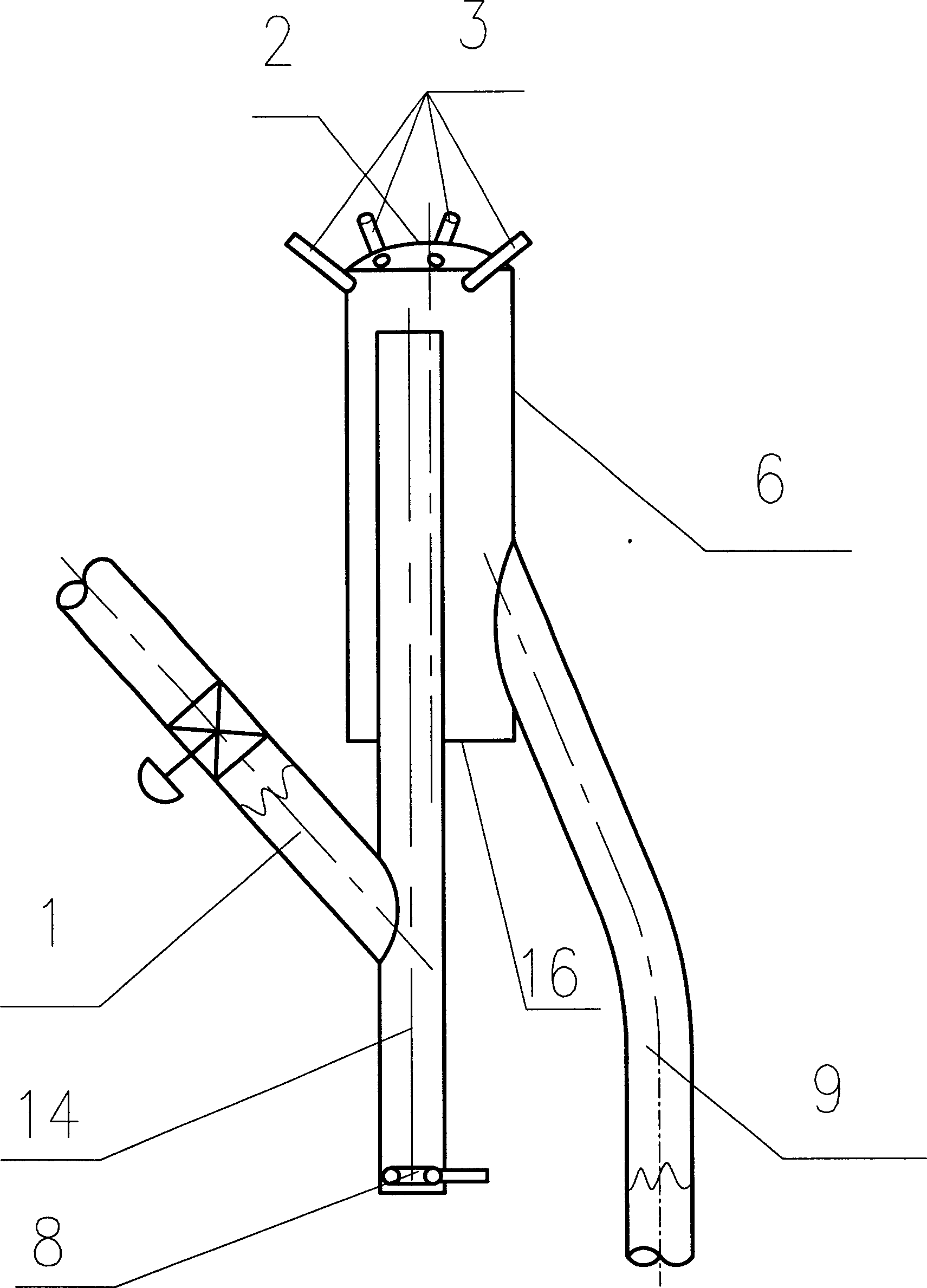

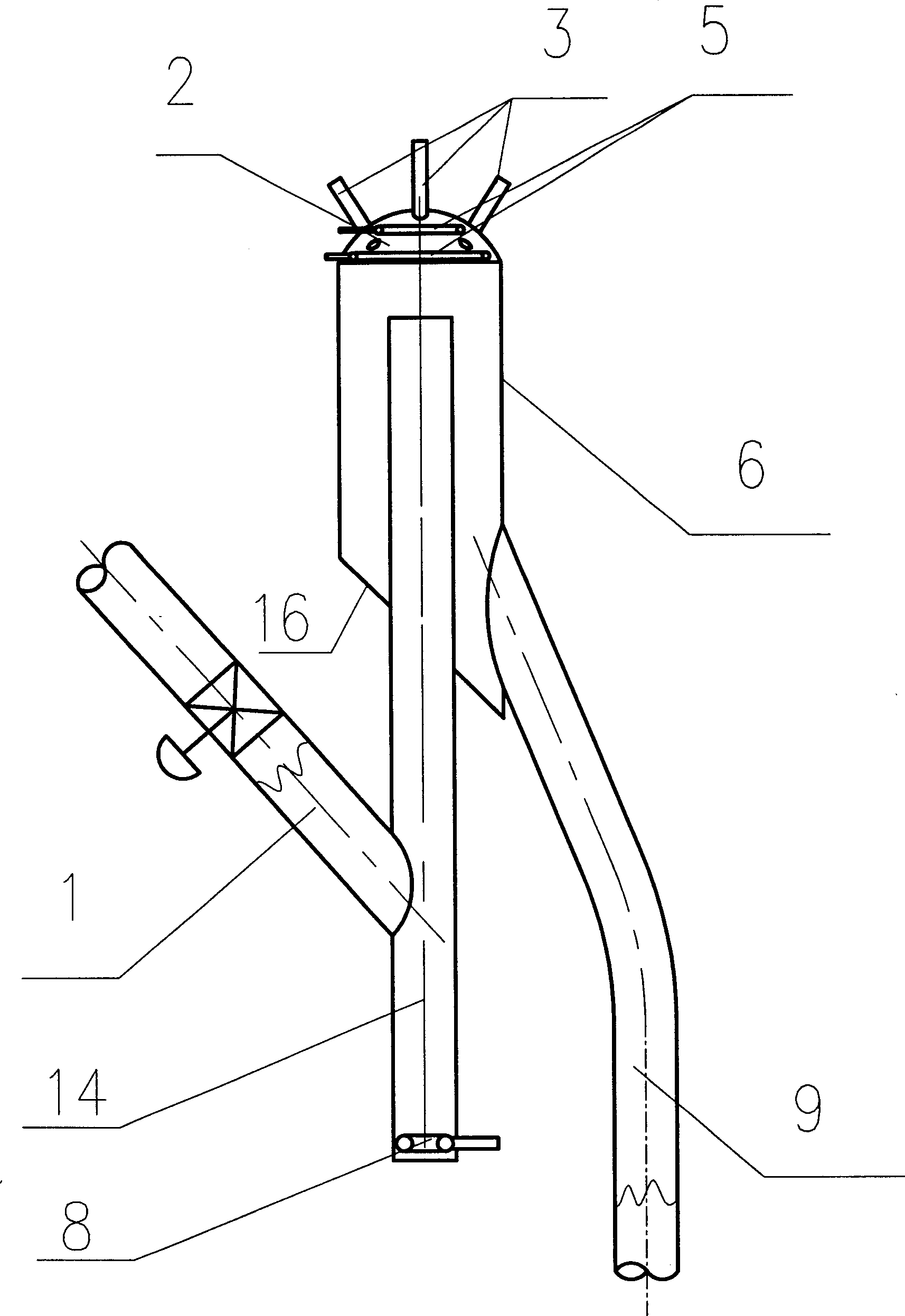

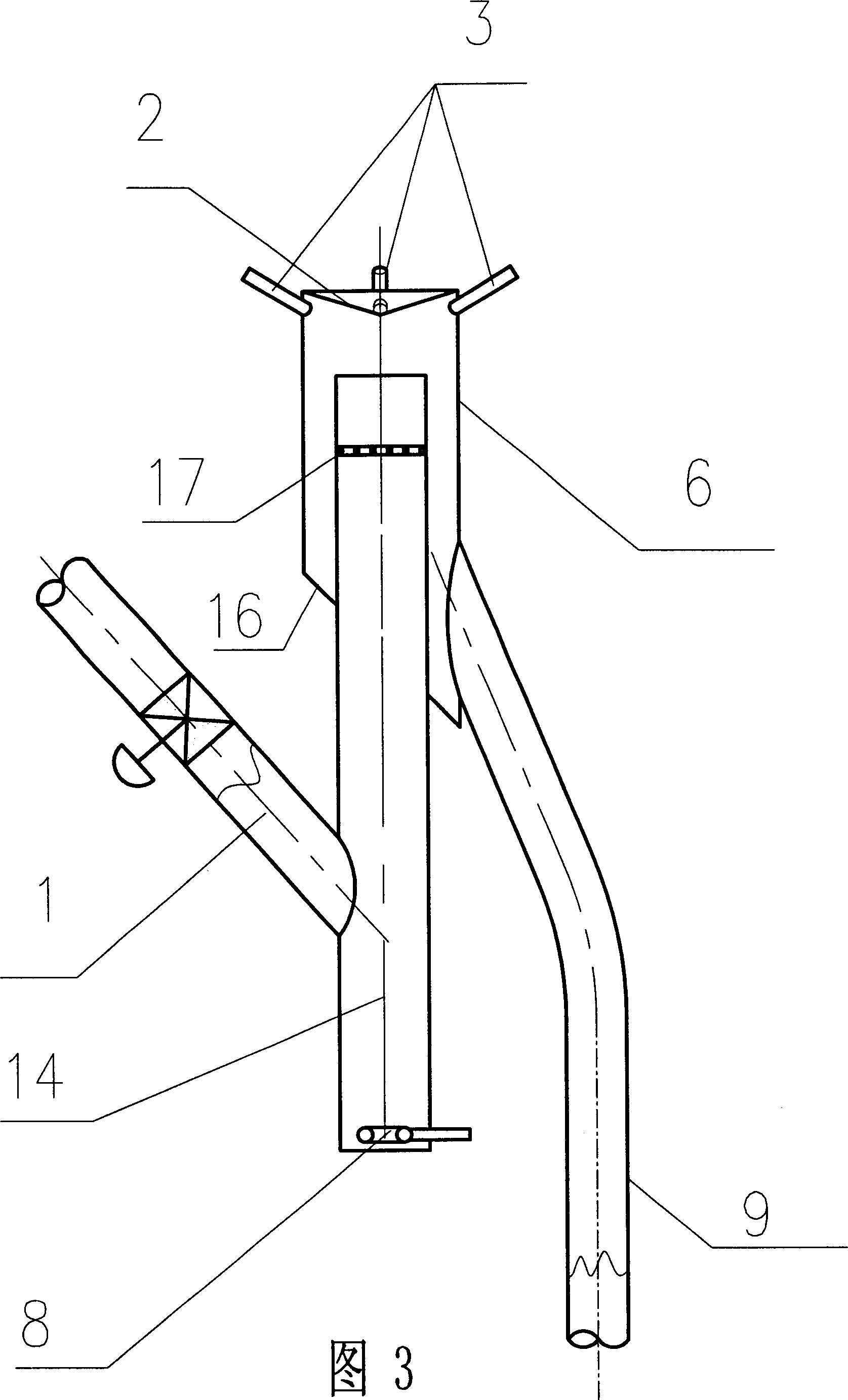

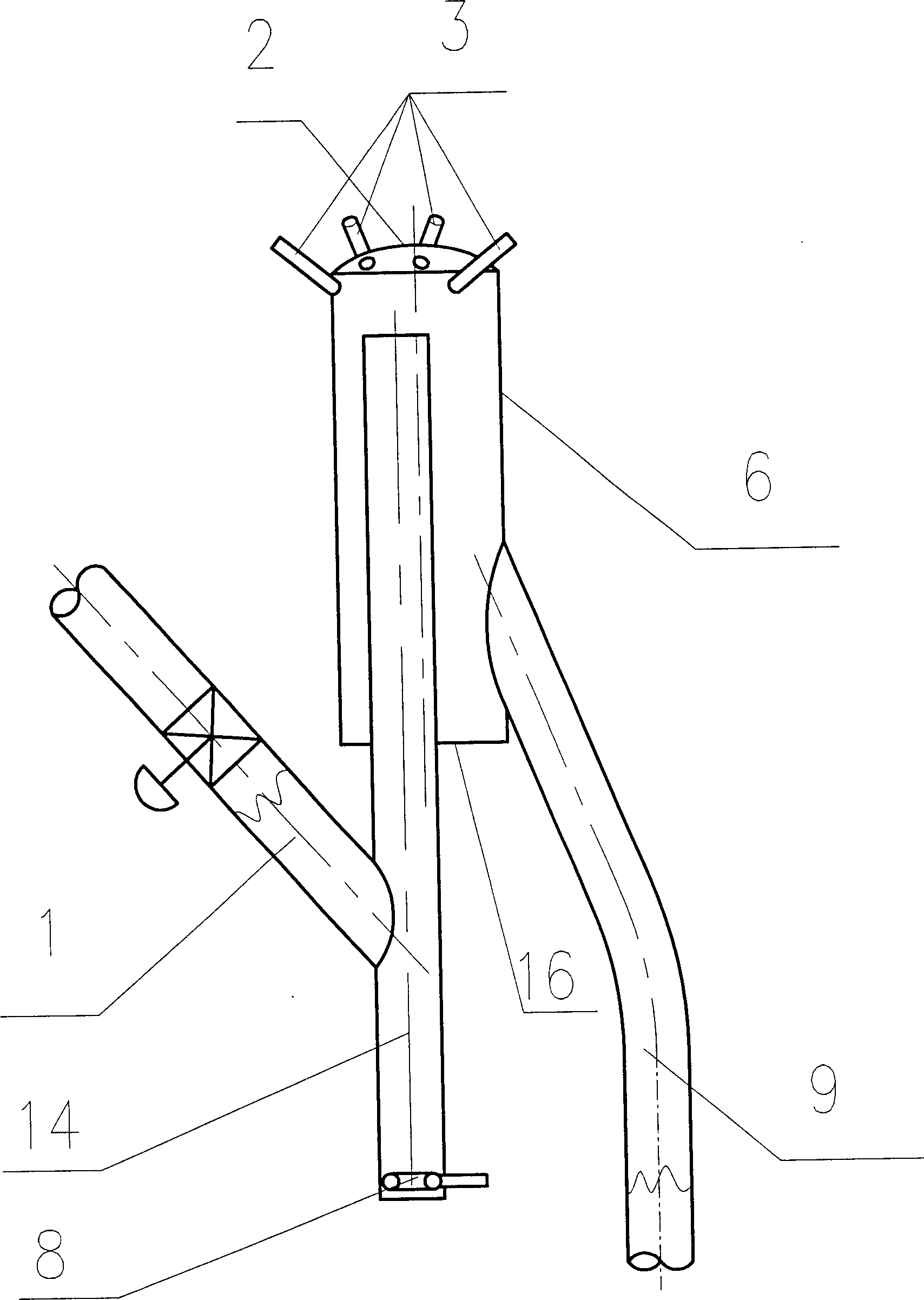

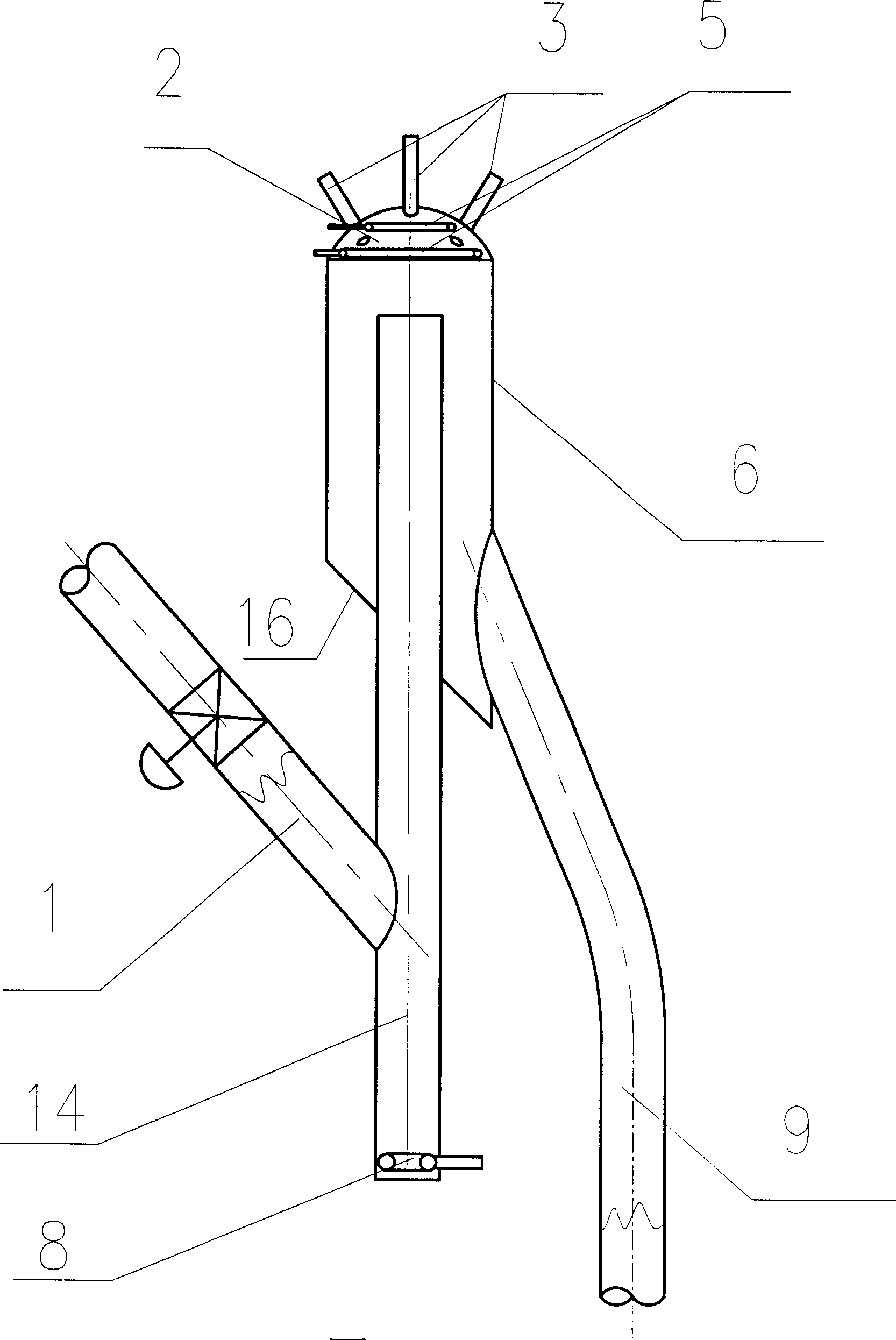

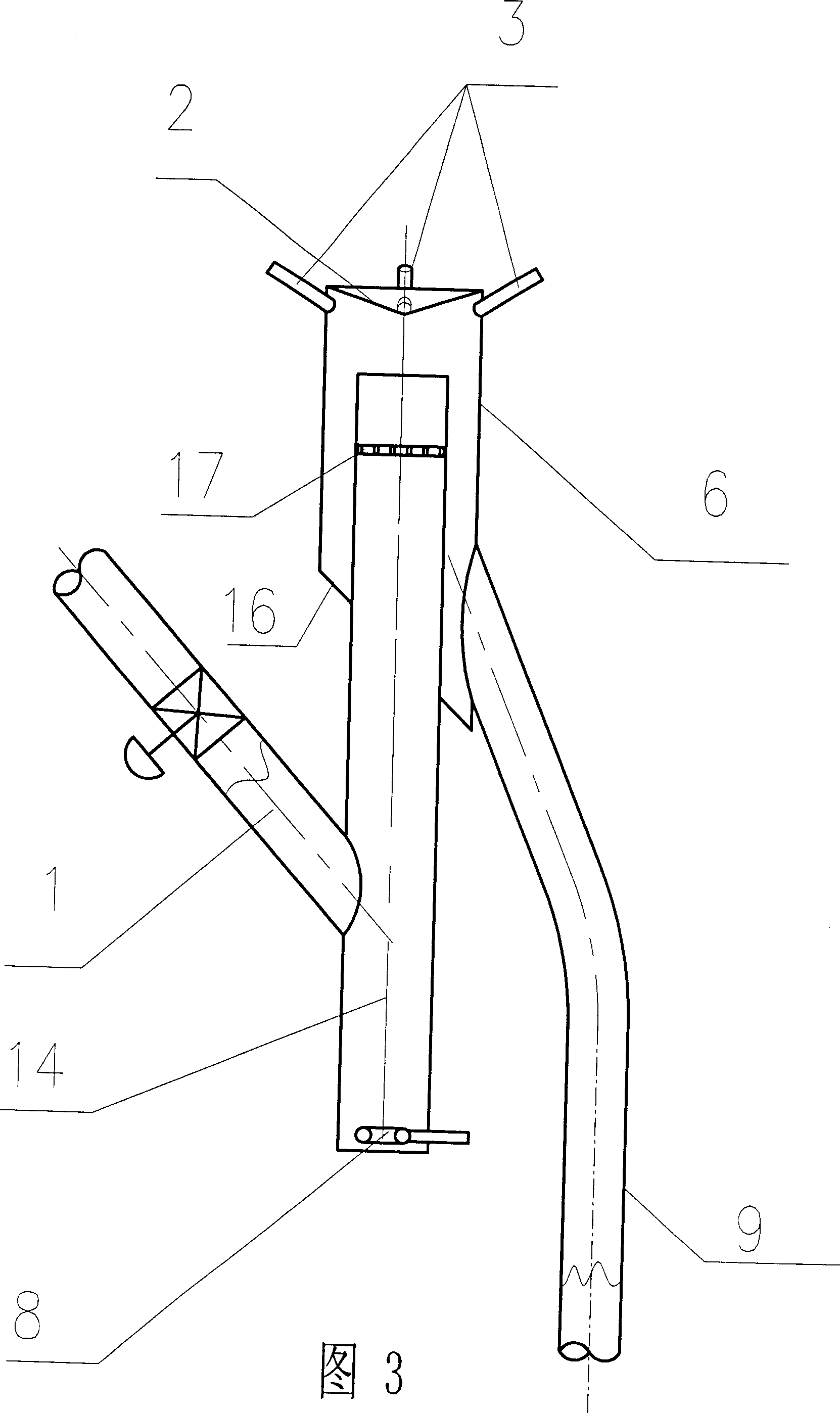

Descending catalytic cracking reactor

InactiveCN1552800AImprove atomization effectUniform particle sizeCatalytic crackingDistributorRaw material

A descending catalytic cracker consists of a regenerating agent duct, a top cover, raw material nozzles, an outer shell, a pre-lift medium distributor, a descending reacting pipe, and a catalyst pre-lift pipe, of which the upper opening is located in the outer shell and the lower portion is communicated with the regenerating agent duct. The pre-lift medium distributor is arranged at the bottom of the catalyst pre-lift pipe. The upper portion of the outer shell is closely connected with the periphery of the top cover. The descending reacting pipe is communicated with the outer shell at its sidewall or bottom, or through two symmetrically arranged bypass pipes. The raw material nozzles are arranged on the top cover and / or the upper portion of outer shell sidewall, above the upper opening of the catalyst pre-lift pipe.

Owner:CHINA PETROLEUM & CHEM CORP +1

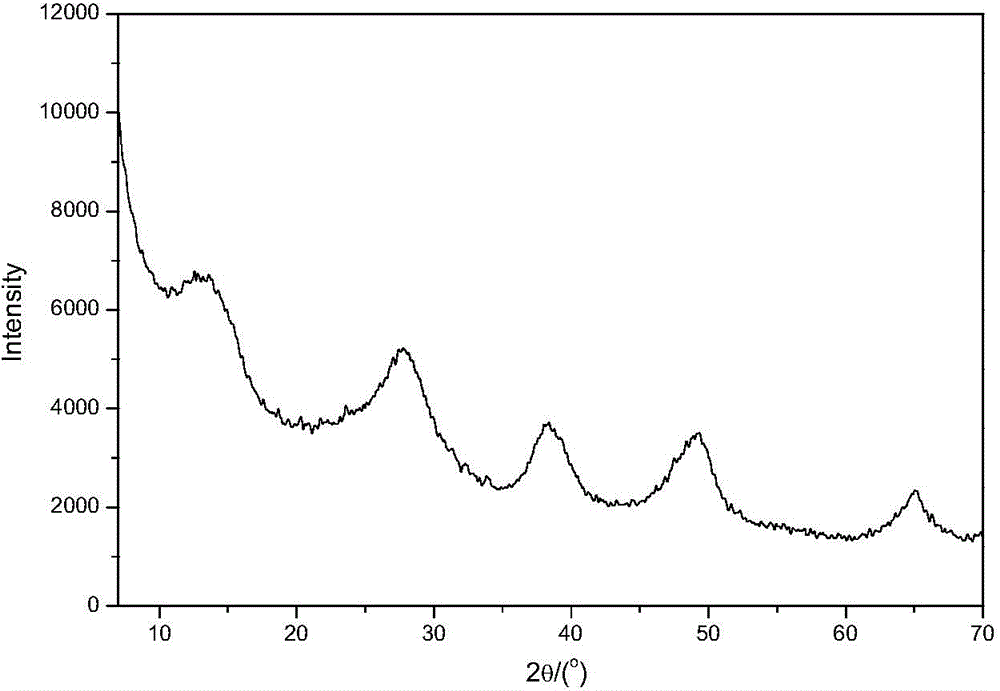

Mesoporous catalytic material containing phosphorus, magnesium and rare earth

ActiveCN104588071ARegulates and improves acid centersAdjust and improve the situationCatalytic crackingMolecular sieve catalystsTO-18Rare earth

The invention provides a mesoporous catalytic material containing phosphorus, magnesium and rare earth. The material is characterized in that the material has a pseudo-boehmite phase structure; the anhydrous compound composition of the material is, in terms of the weight of oxides, (0-0.2)Na2O.(40-85)Al2O3.(10-55)SiO2.(0.5-10)P2O5.(0.5-5)MgO.(0.5-5)RE2O3; the specific surface area of the material is 200 to 500 m2 / g; the total pore volume is 0.5 to 1.5 cm3 / g; and the average pore size is 8 to 18 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing modified kaolin with mixed acid

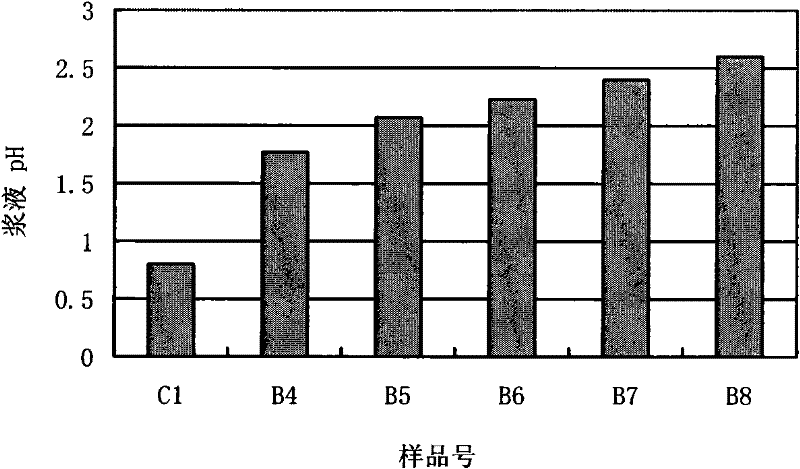

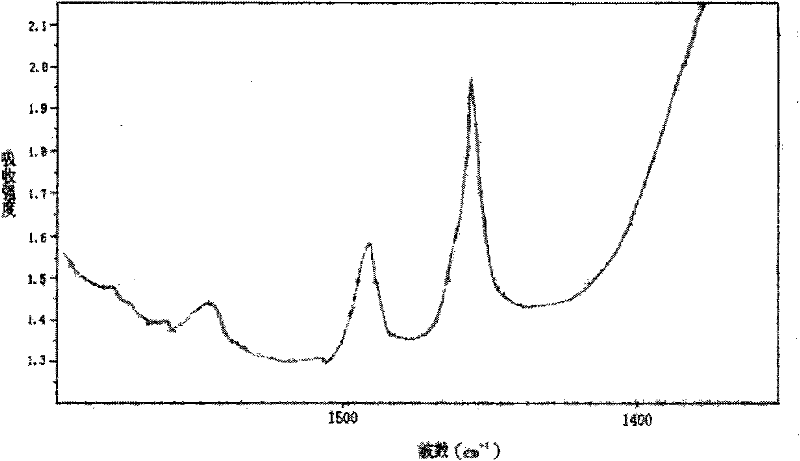

ActiveCN102188964AReduce the ratioRegulating pHCatalytic crackingMolecular sieve catalystsOrganic acidSlurry

The present invention relates to a method for modifying kaolin. The method comprises the following steps: calcined kaolin, applied aluminum source and an acid solution are added to a container in a stirring state; a mixed slurry is obtained after a uniform stirring process, and substances in the mixed slurry are subjected to a reaction through heating the mixed slurry to obtain a new slurry; and the new slurry can be used as raw materials for preparing a catalytic cracking catalyst with no filtering. The method is characterized in that the acidic solution is a mixed acid system comprising inorganic acid and organic acid. The modified kaolin has developed middle / large pore volumes, a favorable hydrothermal stability and certain L acid characteristics. A catalyst prepared from the modified kaolin slurry has a high heavy oil conversion capability.

Owner:PETROCHINA CO LTD

Catalyst suitable for two-stage catalytic cracking reaction, and preparation method and application thereof

ActiveCN102294261AImprove distribution and propertiesStrong ability to convert heavy oilCatalytic crackingMolecular sieve catalystsContact timeAlkane synthesis

A catalyst suitable for a two-stage catalytic cracking reaction, and a preparation method and application thereof. The catalyst is characterized by comprising five-member ring micropores, twelve-member ring micropores and mesopores in a pore volume ratio of 1:9-11:4-6 in a structure, and by being prepared from 2-12wt% of ZSM-5 molecular sieve, 20-45wt% of rare earth Y molecular sieve, 5-15wt% of aluminium sol calculated by Al2O3 and 10-30wt% of pseudo-boehmite, 0.5-5wt% of pore forming agent and the balance of kaolin into microballoons with an average particle size of 50-70mum, through slurryand spray moulding. During beating, 5-30wt% of hydrochloric acid, calculated by dry basis, is added into the pseudo-boehmite, and maintained at 40-90 DEG C for 0.1-2 h; and the rare earth Y molecularsieve contains 1-16wt% of oxidized rare earth and has a crystal cell of 2.450-2.470 nm. When applied to a catalytic cracking apparatus, in which a second stage reaction temperature is 10-35 DEG C lower than that of the first stage and an oil agent contact time of a second stage reaction is 3-6 times longer than that of the first stage, the catalyst has advantages of low oil slurry yield, high light hydrocarbon liquid yield and low sulfur and alkene in gasoline fraction.

Owner:REZEL CATALYSTS CORP

Catalytic cracking catalyst

ActiveCN101284243BHigh yieldReduce yieldCatalytic crackingMolecular sieve catalystsRare earth ionsFiltration

A cracking catalyst comprises a rare earth ultra-stable Y-zeolite and a matrix, the matrix comprises a silicon oxide binder, the rare earth ultra-stable Y-zeolite is obtained by the method including the following steps: the ultra-stable Y-zeolite and the acid solution with the equivalent concentration of 0.01N to 2N are mixed within the temperature range of 20 DEG C to 100 DEG C in the liquid-solid weight ratio of 4 to 20; washing and filtration are carried out after stirring for 10 minutes to 300 minutes; rare earth salt solution is then added for carrying out the rare earth ion exchange; and washing, filtration and drying are carried out after the exchange. The catalyst of the invention is used for catalytic cracking of heavy oil, the conversion rate is high, the yield of gasoline is high and the coke yield is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

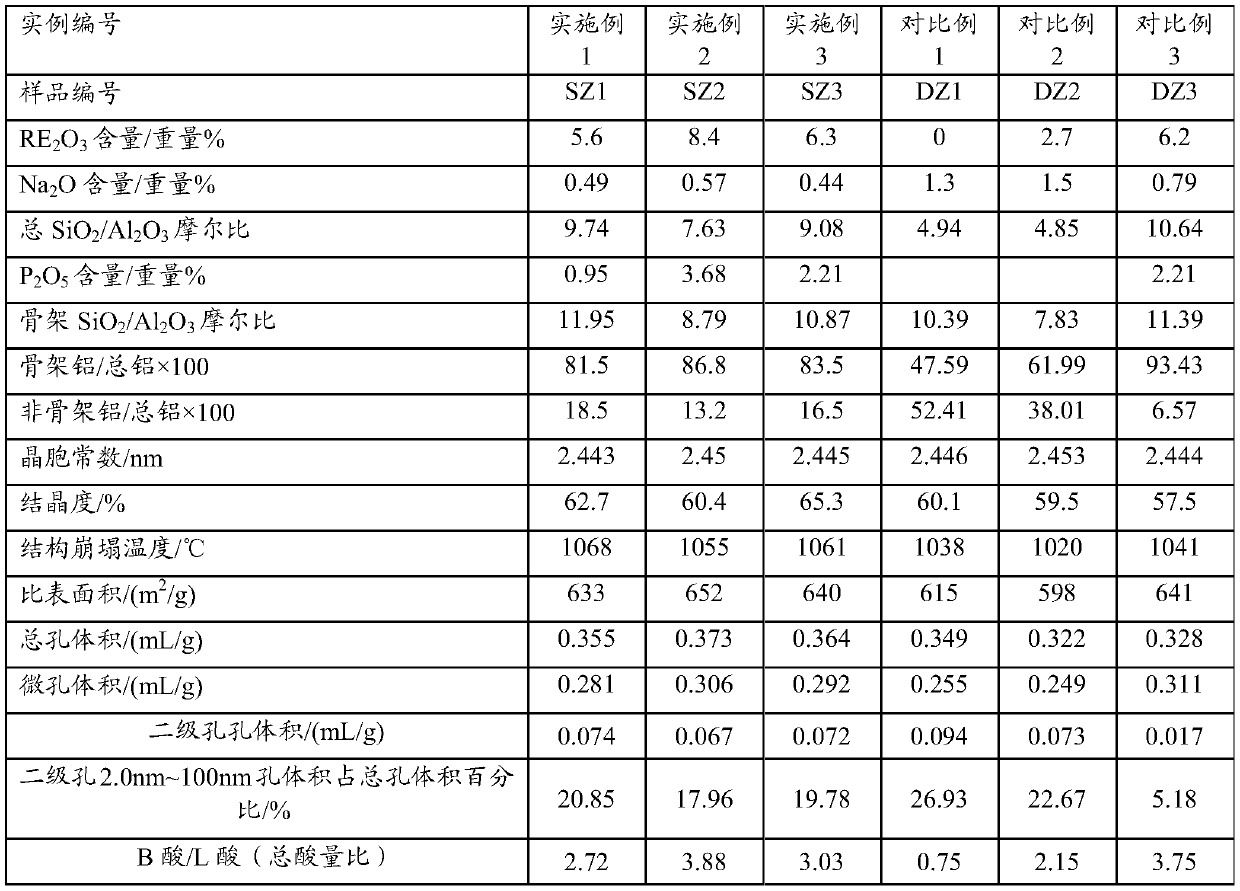

High-stability modified Y-type molecular sieve and preparation method thereof

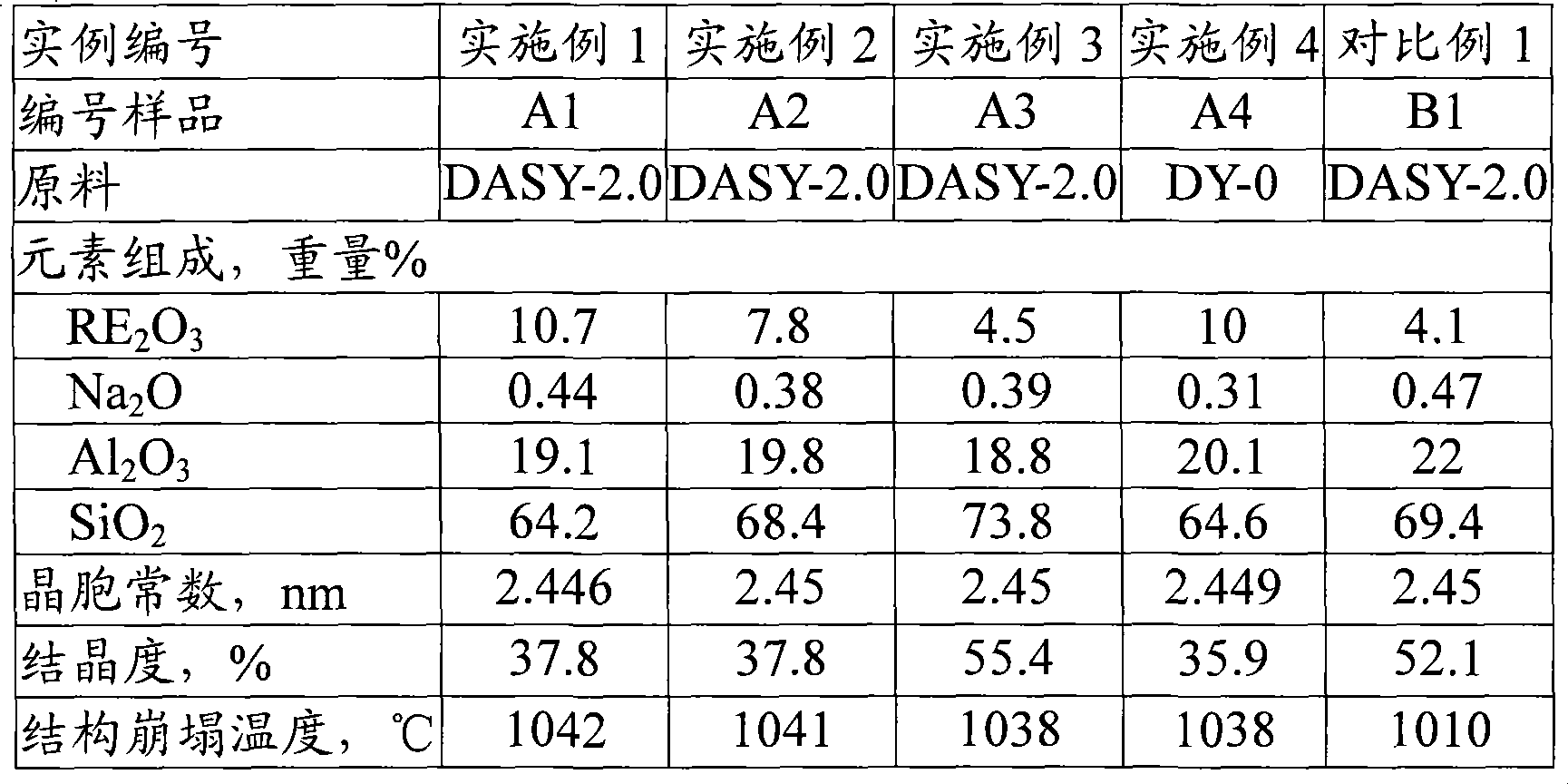

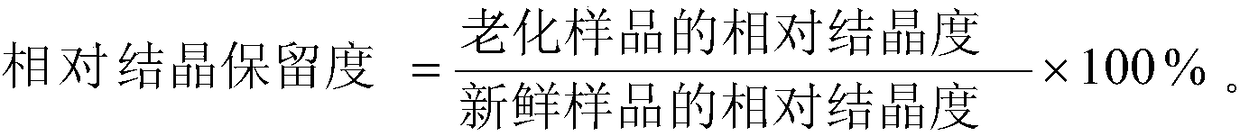

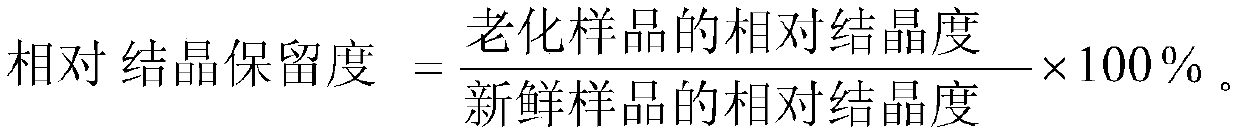

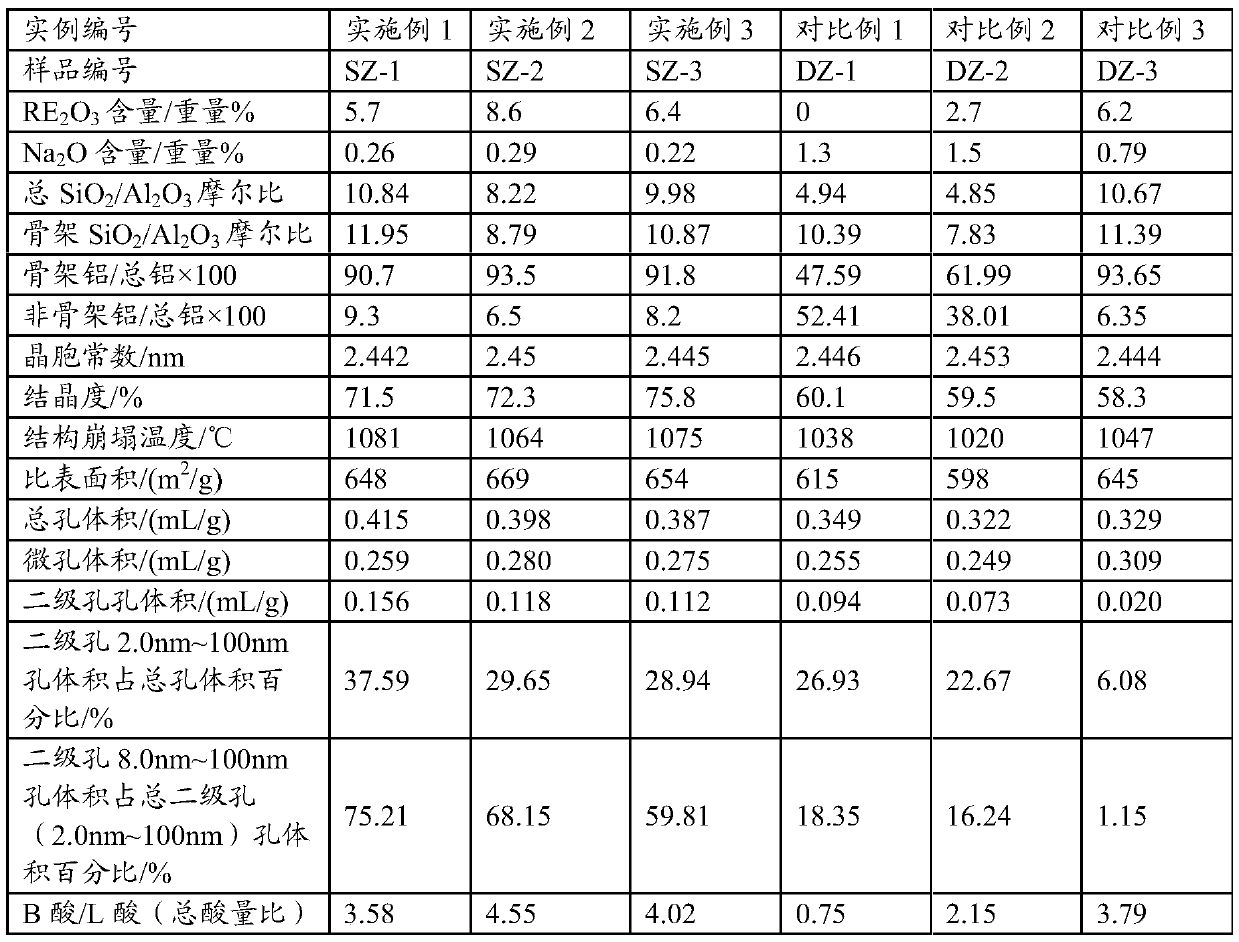

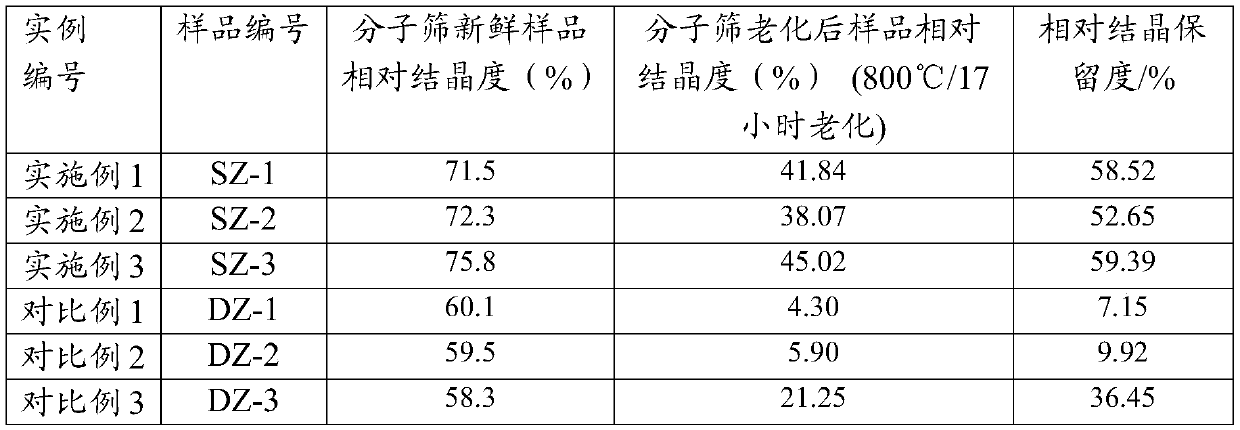

ActiveCN108455625AHigh thermal and hydrothermal stabilityImprove transformation activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

The invention relates to a high-stability modified Y-type molecular sieve and a preparation method thereof, wherein the modified Y-type molecular sieve contains 5-12 wt% of RE2O3 and 0.1-0.7 wt% of Na2O, and has the total pore volume of 0.33-0.39 mL / g, the pore volume of the secondary pores with the pore size of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the non-framework aluminum content is not more than 20% of the total aluminum content, the lattice collapse temperature is not below 1050 DEG C, and the pyridine adsorption infrared methoddetermination results show that a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: ion exchange, modification treatment at a certain temperature under water vapor conditions, and reaction with silicon tetrachloride. According to the present invention, the modified Y-type molecular sieve has advantages of high heavy oil conversion activity, low coke selectivity, high diesel yield, high liquefied gas yield, high light-oil yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst comprising layered clays and a process for cracking hydrocarbon oils using the same

InactiveUS6908544B2Strong ability to crack heavy oilIncrease conversionsCatalytic crackingMolecular sieve catalystsSlurryFuel oil

The present invention relates to a cracking catalyst comprising layered clays and a process for cracking hydrocarbon oils using said catalyst. Said catalyst is prepared by the process comprising the following steps: mixing and slurrying an expandable clay, a modifier component, pseudo-boehmite and water for 0.1-10 h to obtain a slurry, aging the slurry at 50-85° C. for 0.1-10 h, then drying and forming the slurry to obtain a formed material, water washing and aging the solid, and finally drying and calcining the solid, and said modifier being one or more selected from the group consisting of hydroxyl polymers of silicon, aluminum, zirconium or titanium, and substances comprising one or more of said hydroxyl polymers. Said process for cracking hydrocarbon oils comprises contacting a hydrocarbon oil with a catalyst under the cracking conditions, said catalyst being the aforesaid cracking catalyst comprising layered clays or a mixture of at least 1% by weight of said cracking catalyst comprising layered clays and a prior cracking catalyst. The catalyst according to the present invention has an improved ability to convert heavy oils. The process according to the present invention for cracking hydrocarbon oils has higher conversion of hydrocarbon oils and higher yield of light oils.

Owner:CHINA PETROLEUM & CHEM CORP +1

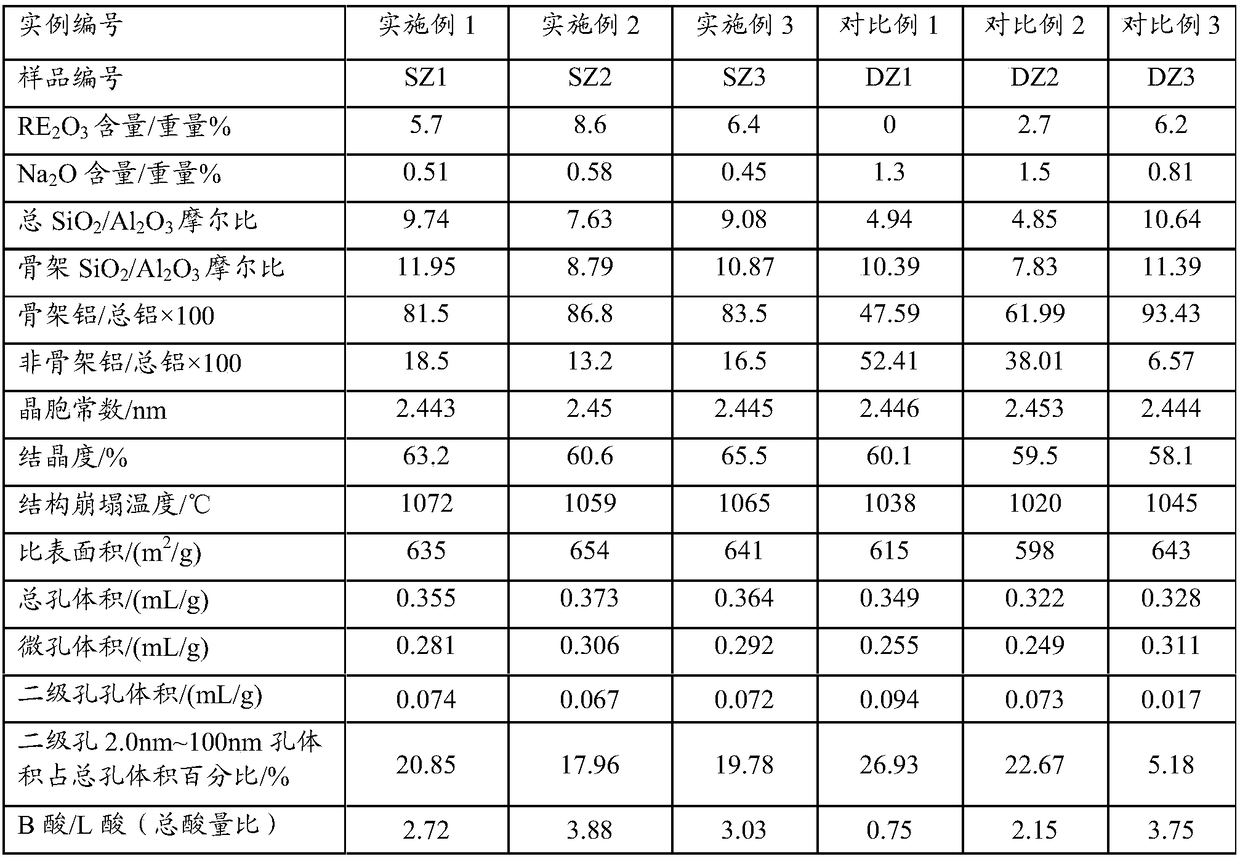

Hydrocarbon catalytic cracking catalyst and its preparation method

InactiveCN1478860AHigh cracking performance and isomerization performanceGood light oil yieldCatalytic crackingMolecular sieve catalystsMolecular sieveHydrocarbon

A catalyst for catalytic cracking of hydrocarbons contains carrier, adhesive, active cracking component and active isomerizing component. It features that said active isomerizing component is composed of modified HZSM-5 molecular sieve with high Si / Al ratio and small grain modified Y-type molecular sieve. Its advantages are high output rate of light oil, and high octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP

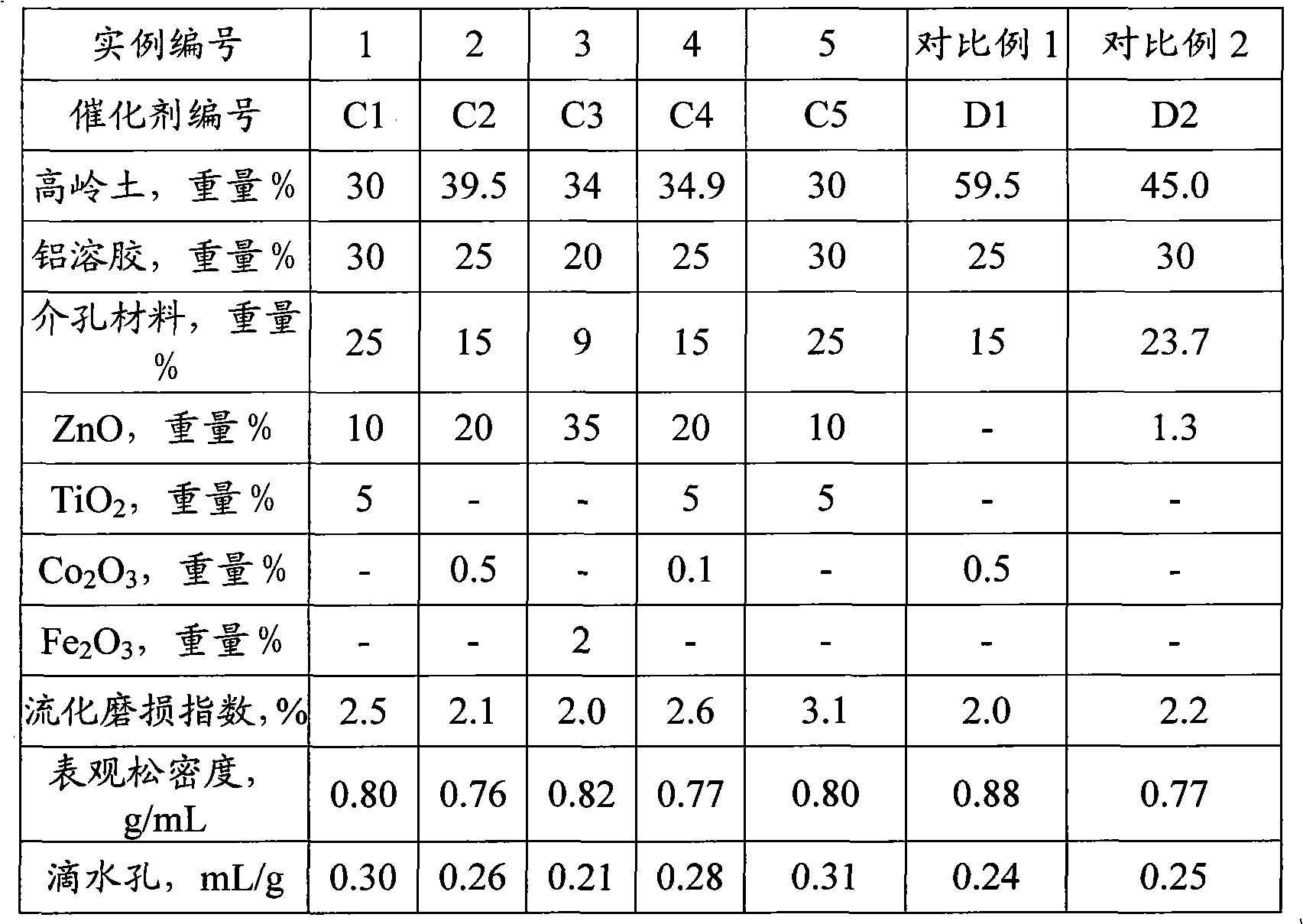

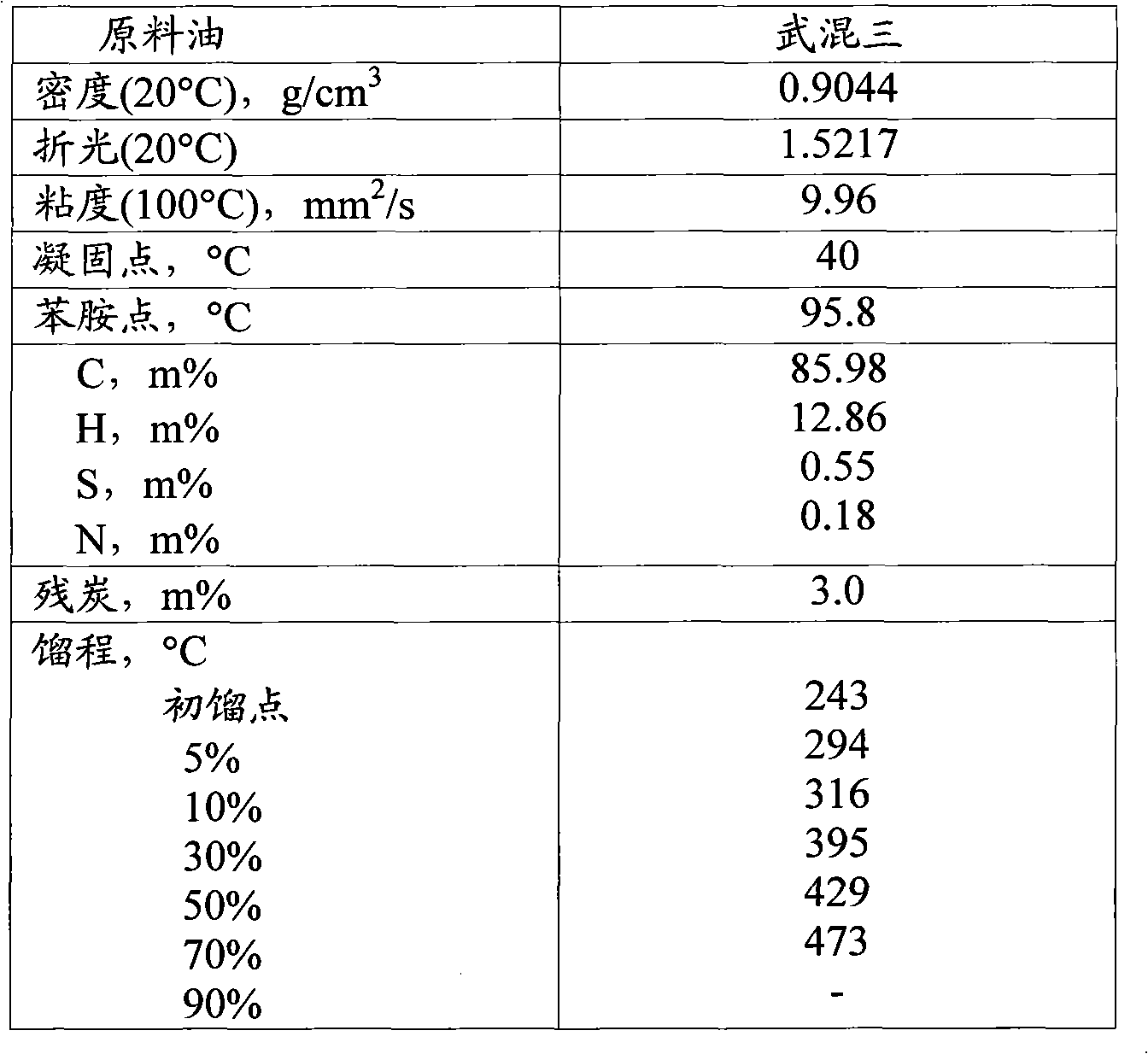

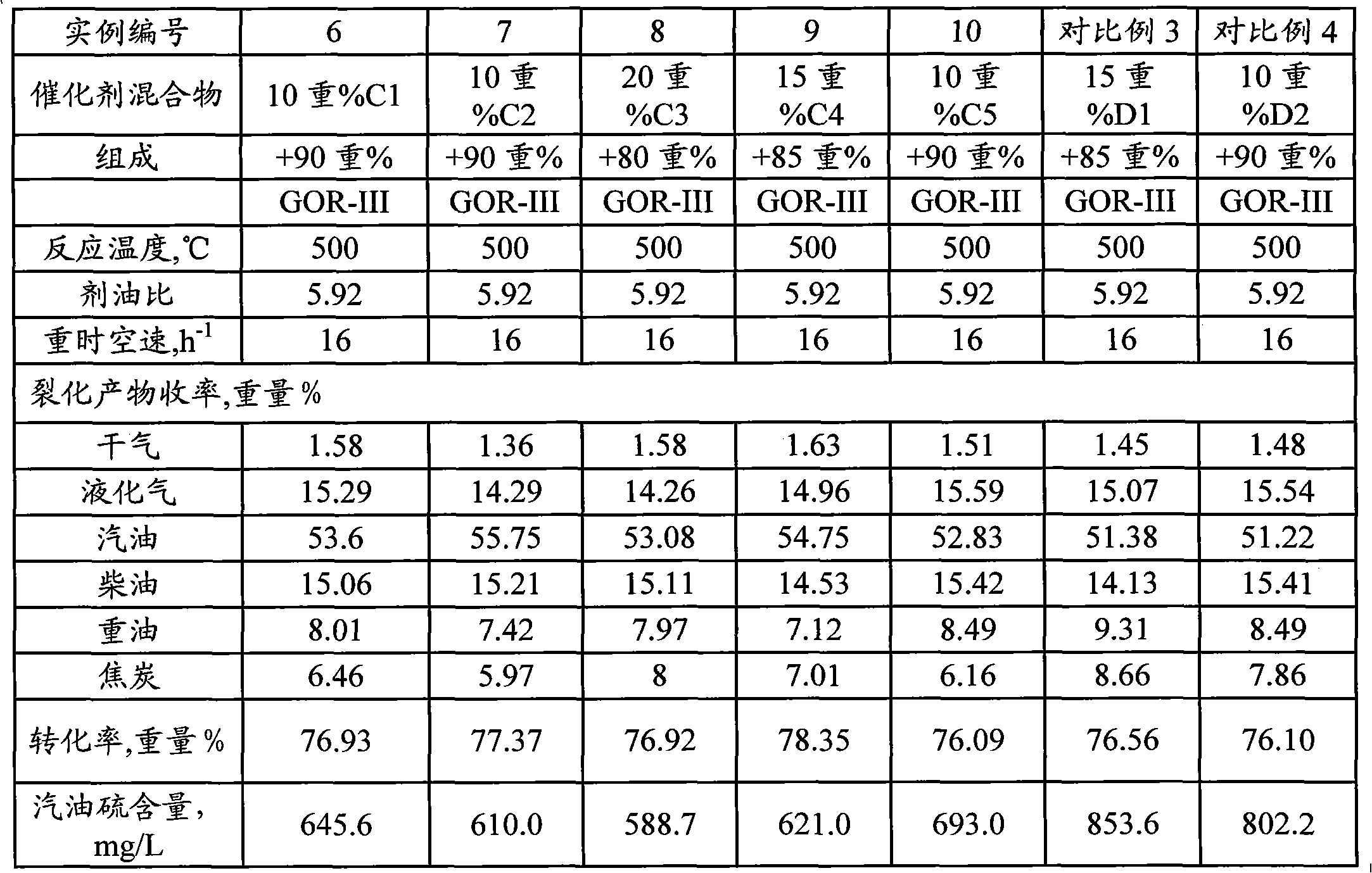

A kind of sulfur reducing additive of hydrocarbon oil cracking product and its preparation and application

ActiveCN102274721AStrong ability to convert heavy oilStrong sulfur reduction performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsSulfur

The invention relates to a desulfurization additive for a product obtained by hydrocarbon oil cracking and preparation and application thereof. The additive contains the following components in percentage by weight: 3-40 percent of mesoporous material, 5-50 percent of zinc component in zinc oxide terms, 5-80 percent of clay, 10-50 percent of caking agent in oxide terms and 0.1-10 percent of metal(s), except for zinc, in oxide terms; and the metal(s) except for the zinc is(are) one or a plurality of lanthanide metal, Ti, Co, Ni, Fe, Mn, Ga and Zr. The preparation method of the additive comprises the following steps of: (1) mixing the mesoporous material and deionized water, adding a zinc-containing compound, mixing and pulping, and mixing and pulping the obtained slurry and a compound of the metals except for the zinc; (2) mixing the slurry obtained in the step (1) and the clay; (3) mixing the slurry obtained in the step (2) and the caking agent; and (4) carrying out spray drying on the slurry obtained in the step (3), and roasting. The additive provided by the invention has higher conversion rate and desulfurization performance and high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Descending catalytic cracking reactor

InactiveCN1272405CImprove atomization effectUniform particle sizeCatalytic crackingDistributorRaw material

A descending catalytic cracker consists of a regenerating agent duct, a top cover, raw material nozzles, an outer shell, a pre-lift medium distributor, a descending reacting pipe, and a catalyst pre-lift pipe, of which the upper opening is located in the outer shell and the lower portion is communicated with the regenerating agent duct. The pre-lift medium distributor is arranged at the bottom of the catalyst pre-lift pipe. The upper portion of the outer shell is closely connected with the periphery of the top cover. The descending reacting pipe is communicated with the outer shell at its sidewall or bottom, or through two symmetrically arranged bypass pipes. The raw material nozzles are arranged on the top cover and / or the upper portion of outer shell sidewall, above the upper opening of the catalyst pre-lift pipe.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ultra-stable Y-type molecular sieve containing phosphorus and rare earth and preparation method thereof

ActiveCN108452828BHigh crystallinityHigh thermal and hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveHeat stability

An ultra-stable Y-type molecular sieve containing phosphorus and rare earth and a preparation method thereof. The Y-type molecular sieve contains 4 to 11 wt% rare earth, 0.05 to 10 wt% phosphorus, 0.1 to 0.7 wt% sodium oxide, and has a pore volume of 0.33 to 0.39 mL / g, the volume of 2-100nm pores accounts for 15-30% of the total pore volume, the unit cell constant is 2.440-2.455nm, non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is greater than 1050°C, and the B acid content The ratio to the amount of L acid is not less than 2.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earth, roasting it for 4.5-7 hours in an atmosphere of 350-480°C and 30-90 volume % water vapor, phosphorus modification treatment and mixing with silicon tetrachloride gas. Contact reaction steps. The Y-type molecular sieve has good hydrothermal stability, high heavy oil cracking activity, good coke selectivity, and high yields of heavy oil converted into gasoline, liquefied gas and total liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107970976AStrong conversion abilityHigh gasoline yieldMolecular sieve catalystsMolecular sieveGasoline

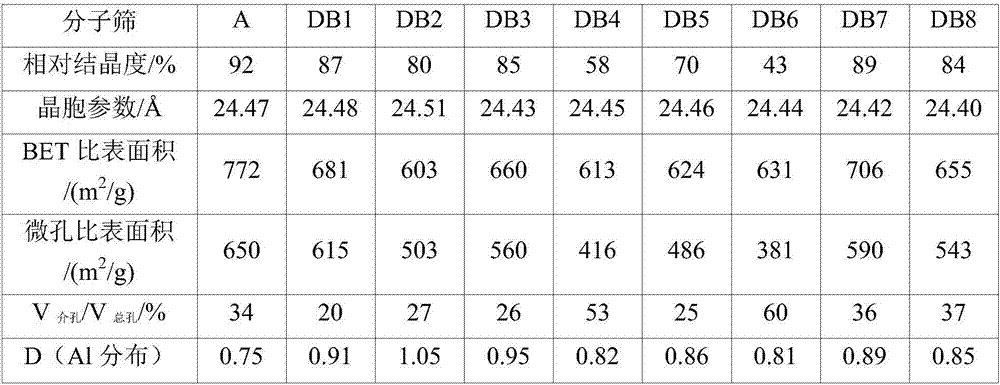

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalytic cracking catalyst comprises, on the basis of dry base weight, 25 to 75 wt% of a Y molecular sieverich in mesopores, 10 to 30 wt% of an inorganic oxide binder and 15 to 65 wt% of natural mineral matters, wherein the Y molecular sieve rich in mesopores has a cell parameter of 24.35 to 24.55 angstroms and relative crystallinity of no less than 92%; the distribution parameter D of Al in the molecular sieve is no less than 0.3 and no more than 0.8; the micropore specific area of the molecular sieve is 650 to 800 m<2> / g; and the mesopore volume of the molecular sieve accounts for 25 to 65% of total pore volume. The catalytic cracking catalyst provided by the invention has the advantages of excellent heavy oil conversion capability and higher gasoline yield when applied to catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

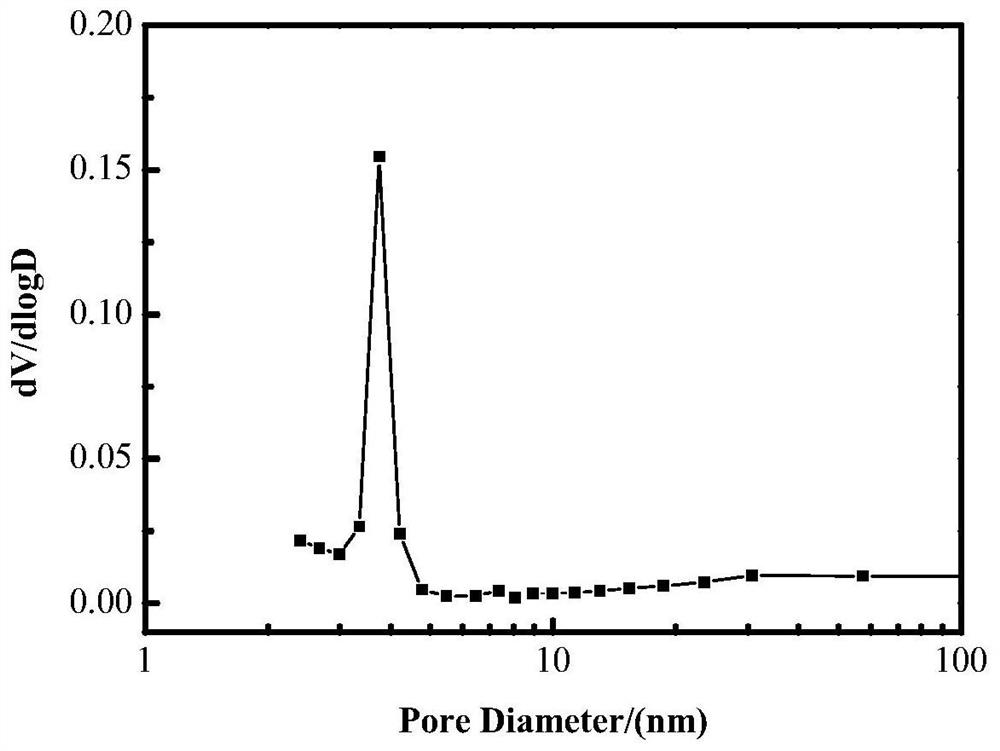

Catalytic cracking catalyst containing rare earth Y-type molecular sieve

PendingCN113318777AStrong ability to convert heavy oilHigh yieldCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

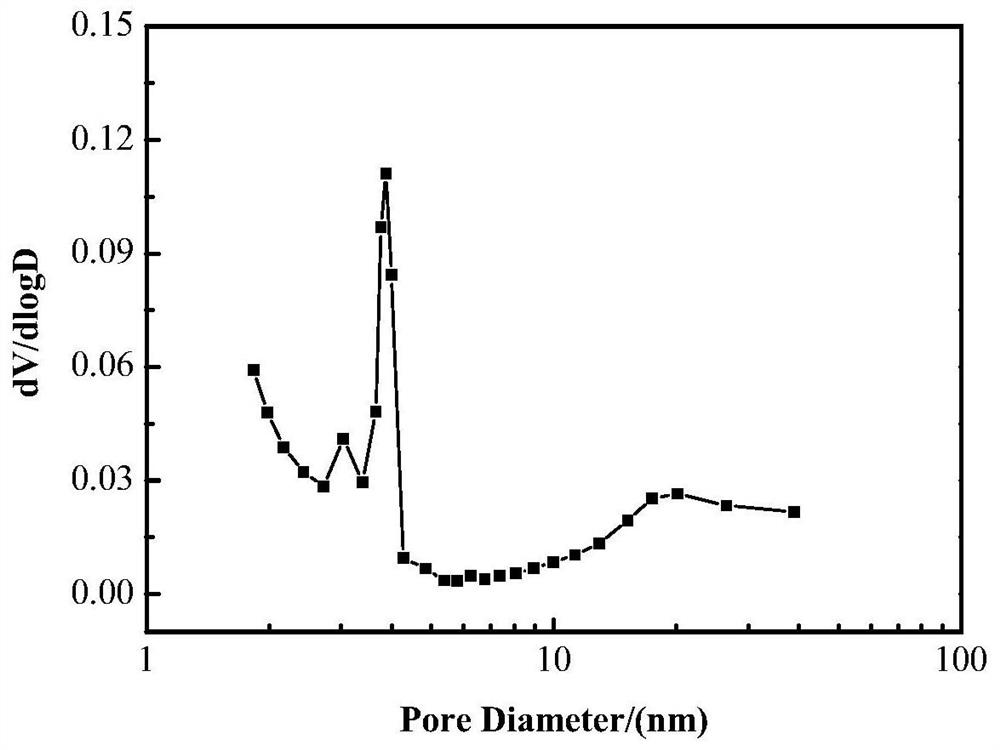

The invention provides a catalytic cracking catalyst containing a rare earth Y-type molecular sieve. The catalyst contains the rare earth Y-type molecular sieve, an inorganic oxide binder and a natural mineral substance, and is characterized in that the rare earth Y-type molecular sieve at least has mesoporous pore size distribution at 2-3 nm, 3-4 nm and 10-30 nm, and in a BJH pore size distribution spectrogram, the ratio of the peak area of 2-3 nm pore size distribution to the peak area of the total pores is greater than 0.1, and the ratio of the peak area of 10-30 nm pore size distribution to the peak area of the total pores is greater than 0.2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for utilizing residues of catalyst production

ActiveCN102896000BOvercoming the disadvantages of poor direct exchangeIdeal for removing impuritiesCatalyst carriersCatalytic crackingMolecular sieveIon exchange

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN100537029CHigh gasoline yieldHigh yieldMolecular sieve catalystsMolecular sieveRare earth ions

A cracking catalyst, containing 10% to 50% by weight of high rare earth ultra-stable Y-type molecular sieve based on dry basis, 10% to 40% by weight of alumina binder based on alumina and 10% by weight to 70% by weight of clay; the high-rare-earth ultra-stable Y molecular sieve is obtained by steps including the following method: ultra-stable Y-type zeolite and an acid solution with an equivalent concentration of 0.01N to 2N at a liquid-solid ratio of 4 to 20 at 20 Fully mix at a temperature range of ℃ to 100 ℃, stir for 10 minutes to 300 minutes, wash and filter, then add a rare earth salt solution to perform rare earth ion exchange, wash, filter and dry after the exchange. The catalyst of the invention is used for catalytic cracking of heavy oil, and has high gasoline yield and high conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN107970971AStrong ability to convert heavy oilHigh yieldCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst contains (calculated as the dry base weight) 25-75 wt% of a phosphorus-containing and rare earth-containing Y molecular sieve, 10-30 wt% of an inorganic oxide binder, and 15-65 wt% of natural minerals, wherein the unit cell parameter of the phosphorus-containing and rare earth-containing Y molecular sieve is 24.35-24.55 angstrom, the phosphorus content of the molecular sieve is 0.3-10 wt%, the rare earth content of the molecular sieve is 0.5-19 wt%, the Al distribution parameter D of themolecular sieve is more than or equal to 0.4 and is less than or equal to 0.9, the volume of the mesopores of the molecular sieve accounts for 20-65% of the total pore volume, the amount of the strong acid of the molecular sieve accounts for 20-60% of the total acid amount, and a ratio of the acid B to the acid L is 20-100. According to the present invention, the catalytic cracking catalyst has advantages of excellent heavy oil conversion capability, high gasoline yield, high liquefied gas yield and low coke yield in the catalytic cracking of heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of heavy oil catalytic cracking catalyst

ActiveCN110523430AStrong ability to convert heavy oilImprove conversion abilityCatalytic crackingMolecular sieve catalystsMolecular sieveMicrosphere

The invention provides a preparation method of a heavy oil catalytic cracking catalyst. A synthesis method comprises the specific steps that kaolin is beaten, and subjected to spray drying to form microspheres, then high-temperature roasting and low-temperature roasting are conducted respectively to obtain roasted kaolin spheres and metakaolin spheres, the roasted kaolin spheres are subjected to alkali treatment and then mixed with a guiding agent and alkali liquor, after hydrothermal crystallization is conducted for a period of time, the metakaolin spheres subjected to acid treatment are added for continuing crystallization, and filtering, washing with water and drying are conducted to obtain NaY molecular sieve microspheres. According to the preparation method, under the situation that the molecular sieve crystallinity degree is not decreased, the utilizing rate of a silicon source is increased without additionally adding the silicon source, the silica-alumina ratio of a molecular sieve is greater than 5.5, a composite material has a good hole structure, and the catalytic cracking catalyst prepared through modification has the good heavy oil conversion capacity.

Owner:PETROCHINA CO LTD

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and its preparation method

ActiveCN108452831BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveWater vapor

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and a preparation method thereof. The Y-type molecular sieve has a rare earth content of 5 to 12% by weight, a sodium content of no more than 0.5% by weight, and a total pore volume of 0.36 to 0.48 mL. / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, the non-framework aluminum content accounts for less than 10% of the total aluminum content, the lattice collapse temperature is higher than 1060°C, B acid The ratio of the amount to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. A step of. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com