Catalytic cracking catalyst

A cracking catalyst and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low conversion rate of heavy oil, low gasoline yield, low rare earth content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

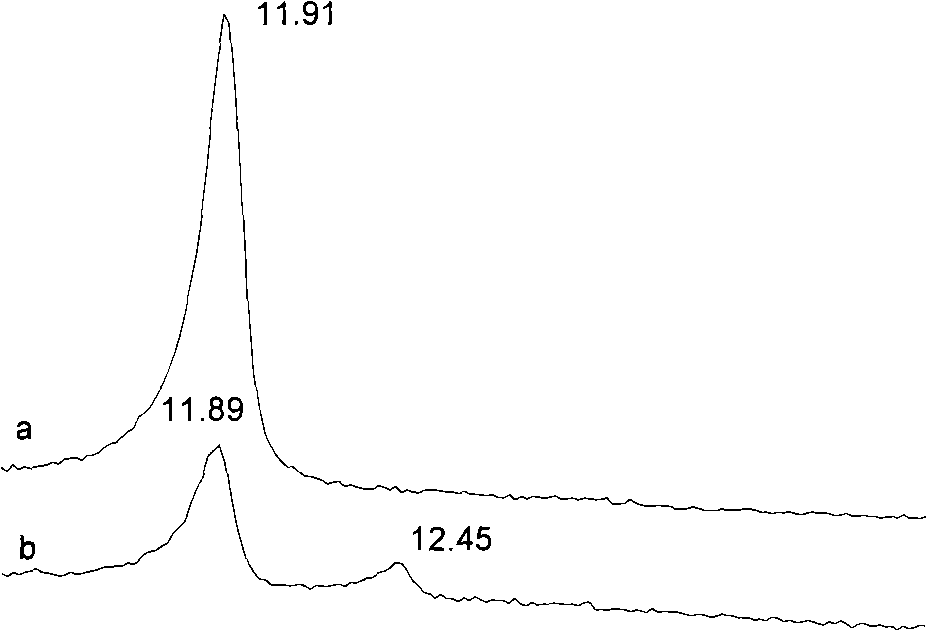

Image

Examples

preparation example Construction

[0035] The catalyst of the present invention can be prepared according to any existing method, for example, according to the method described in Chinese patent, CN1552801A with application number 200610112581.3. The preparation method comprises the steps of mixing the rare earth Y molecular sieve and the matrix, beating, spray drying, washing, filtering and drying. Spray drying, washing, filtering and drying are prior art, and the present invention has no special requirements.

[0036] The catalyst of the invention is suitable for catalytic cracking of hydrocarbon oil, especially for heavy oil catalytic cracking. The hydrocarbon oil is one or more of atmospheric residual oil, vacuum residual oil, vacuum gas oil, atmospheric gas oil, straight-run gas oil, propane light / heavy deasphalted oil and coker gas oil.

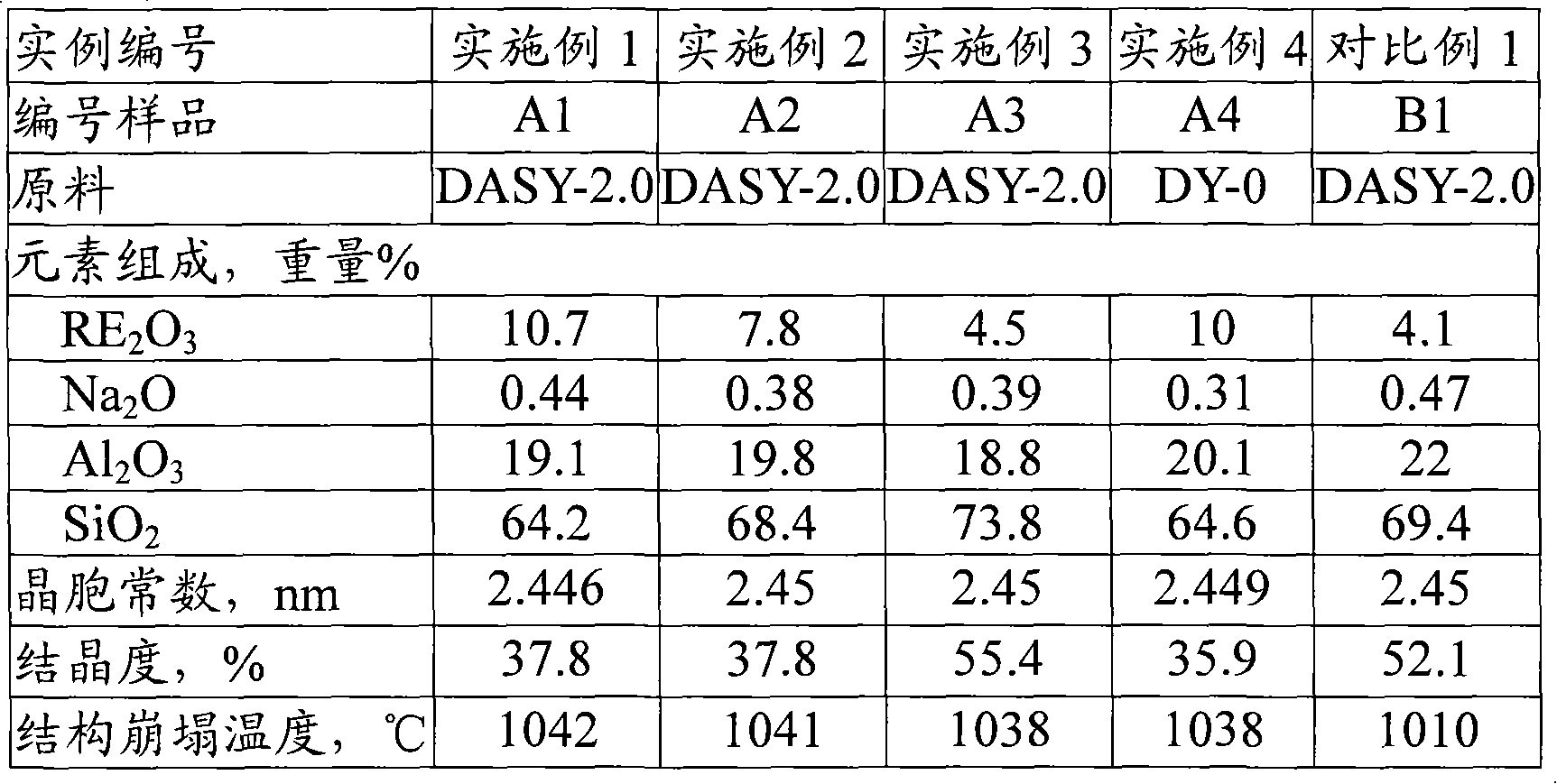

Embodiment 1

[0043] Take 500 grams of DASY2.0 (dry basis), add it to 5 liters of 0.2N oxalic acid aqueous solution and stir to mix evenly, raise the temperature to 95°C and keep it for 1 hour, then filter, wash with water, take out the filter cake, and place it in 5 liters of decationized water , add 160ml RECl 3 Solution (RE in solution 2 o 3 content is 319g / L), stirred, heated up to 92°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A1, and its physical properties are shown in Table 2 .

[0044] Preparation of silica sol: 2 liters of water glass solution with a silica concentration of 155g / l and 1 liter of dilute acidified aluminum sulfate solution (free acid concentration is 148g / l, alumina content is 20g / l) are simultaneously introduced into the rapid mixer reaction , to obtain silica sol.

[0045] Preparation of kaolin and silica sol slurry: add 465 grams of kaolin...

Embodiment 2

[0049] Take 500 grams of DASY2.0 (dry basis), add it to 5 liters of 0.1N oxalic acid aqueous solution, stir to mix evenly, raise the temperature to 95°C and keep it for 1 hour, filter, wash with water, take out the filter cake, and place it in a 5 liter decationization water and add 160ml RE(NO 3 ) 3 Solution (solution concentration: in RE 2 o 3 Calculated as 319g / L), stirred, heated up to 92°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was designated as A2, and its physical properties are shown in Table 2.

[0050] Silica sol preparation: 2 liters of silica concentration is the water glass solution of 155g / l and 1 liter of dilute acidified aluminum sulfate solution (free acid is 148g / l, aluminum oxide content is 20g / l) and introduces rapid mixer reaction simultaneously, to obtain silica sol.

[0051] Preparation of kaolin and silica sol slurry: add 465 grams of kaolin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com