Method for preparing dual-molecular-sieve-containing cracking catalyst by using in-situ crystallization

A cracking catalyst and bimolecular sieve technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, catalytic cracking, etc., can solve the problems that the preparation of in-situ crystallization has not been published, and the pellet catalyst cannot meet the requirements of fluidized operation, etc. , to achieve the effect of rich catalyst pores and strong conversion ability of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

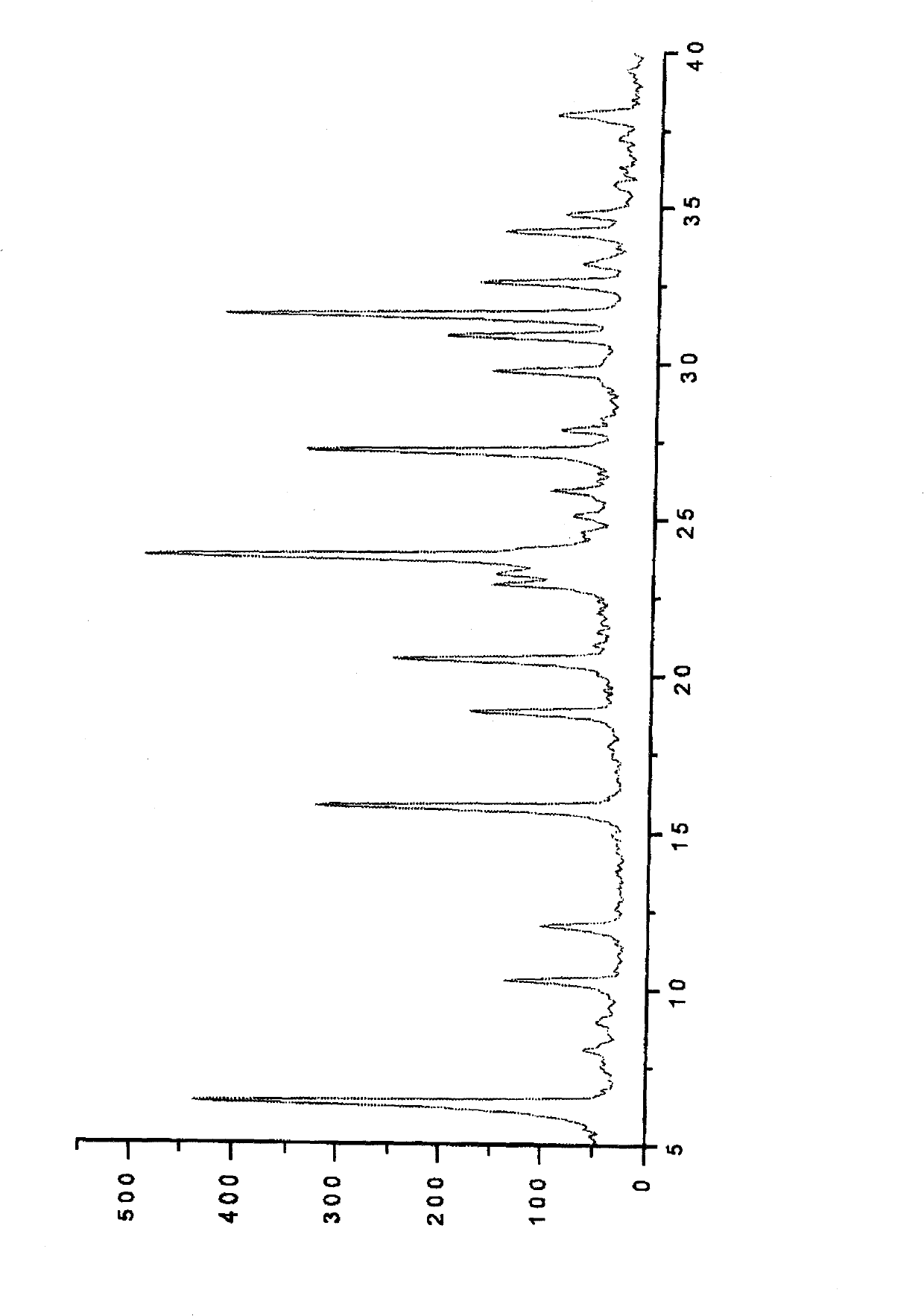

Image

Examples

Embodiment 1

[0029] With 80 grams of NaZSM-5 molecular sieve (industrial product, Leshan Runhe Catalytic New Material Co., Ltd., silicon-aluminum ratio 30), 80 grams of NaY molecular sieve (same as above, silicon-aluminum ratio 5.0, crystallinity 90%), 800 grams of kaolin and 3 liters of water Add to beating in the gel-forming kettle for 30 minutes, add 400 milliliters of silica sol (same as above, SiO 2 25% by weight) after continuing beating for 30 minutes, use a high-shear mixing emulsifier (MBE-100L type, manufactured by Shanghai Environmental Protection Equipment General Factory) beating and homogenizing after 30 minutes in the laboratory with a small spray dryer (LPG-5 type, Changzhou Jianda Drying Equipment Co., Ltd.) is made into the microsphere of embodiment 1, and its average particle diameter is 65 microns.

[0030] Roast the microspheres at 200° C. for 2 hours to dehydrate in a calciner system with an air pump at a pressure of 0.05 MPa, then turn off the air pump and open the ...

Embodiment 2

[0037] Add 40 grams of HZSM-5 molecular sieve (same as above, silicon-aluminum ratio of 50), 40 grams of HY molecular sieve (same as above, silicon-aluminum ratio of 6.5, crystallinity 80%), 850 grams of kaolin and 3 liters of water into the gelling kettle for beating for 30 minutes, Add 200 ml aluminum sol (same as above, SiO 2 20% by weight), 150 grams of pseudo-boehmite (industrial product, Shanxi Aluminum Plant of Aluminum Corporation of China, solid content 65% by weight) and 25 milliliters of hydrochloric acid (chemically pure, Beijing Chemical Reagent Company, 33% by weight) continue beating for 40 Minutes later, beating and homogenizing with a high-shear mixing emulsifier (same as above) after 30 minutes, the microspheres of embodiment 2 were made on a small spray dryer (same as above) in the laboratory, and its average particle diameter was 62 microns.

[0038] Roast the microspheres at 300° C. for 1 hour to dehydrate in a roasting furnace system with an air pump at ...

Embodiment 3

[0043] 40 g NH 4 ZSM-5 molecular sieve (the same, silicon-aluminum ratio 50) and 40 grams of rare earth ZSM-5 molecular sieve (the same, silicon-aluminum ratio 30, rare earth oxide 2.0% by weight), 40 grams of NH 4 Y molecular sieve (same as above, silicon-aluminum ratio 5.0, crystallinity 90%), 40 grams of rare earth USY molecular sieve (same as above, 2.0 weight percent of rare earth oxide), 850 grams of kaolin and 3 liters of water are added to the gelling kettle for beating for 30 minutes, and 400 ml Sodium silicate (same as above) continues beating after 40 minutes, with high-shear mixing emulsifying machine (same as above) beating homogeneously after 30 minutes, the microsphere of embodiment 3 is made on the small-sized spray drier (same as above) in laboratory, its The average particle diameter is 64 microns.

[0044] Roast the microspheres at 350° C. for 1 hour to dehydrate in a calciner system with an air pump at a pressure of 0.06 MPa, then turn off the air pump and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com