Method for cracking hydrocarbon oil

A technology for hydrocarbon oil and cracking conditions, applied in the direction of hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of affecting the distribution of cracked products, catalyst deactivation, etc., and achieve the effect of strong desulfurization capacity and strong heavy oil conversion capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

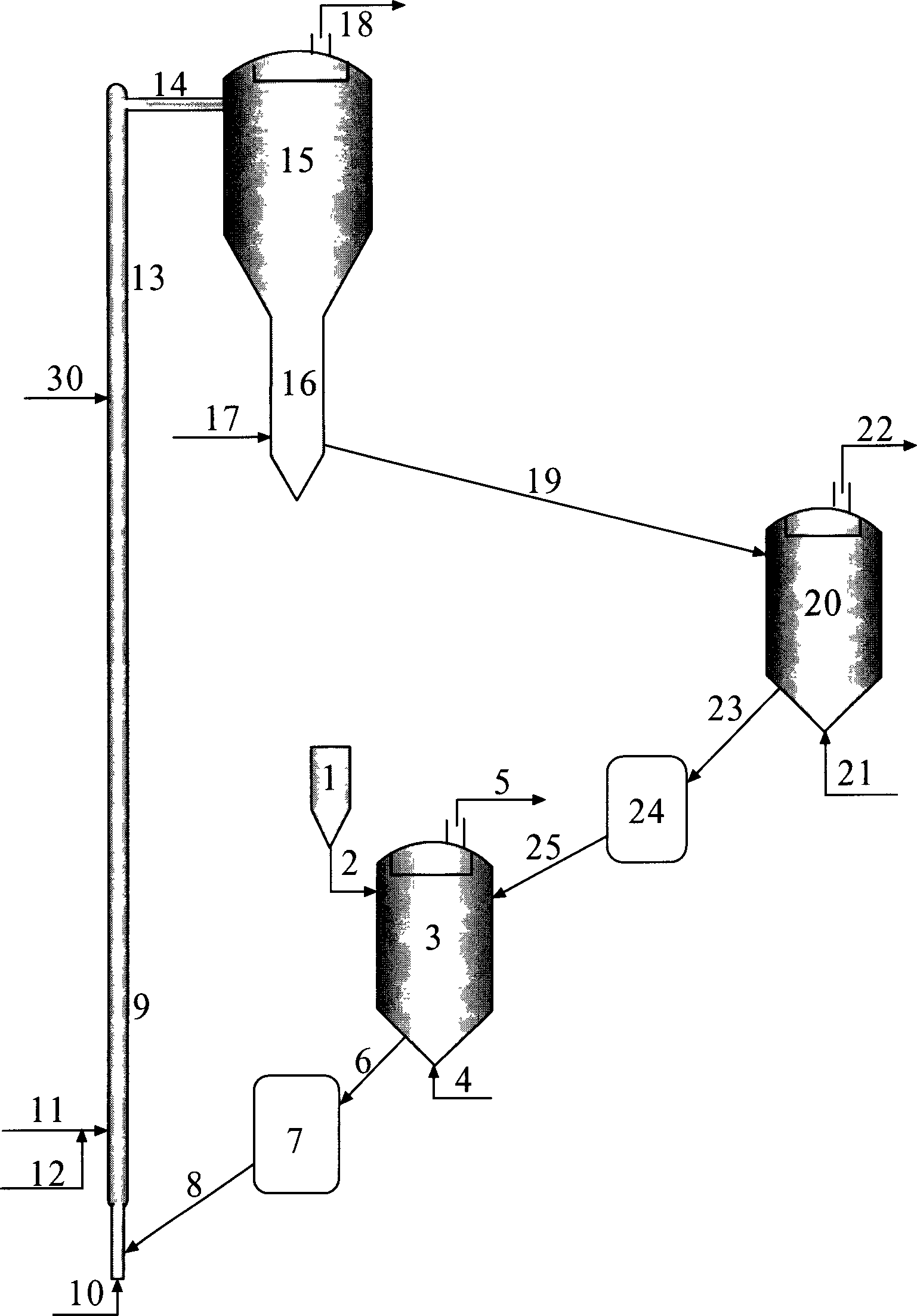

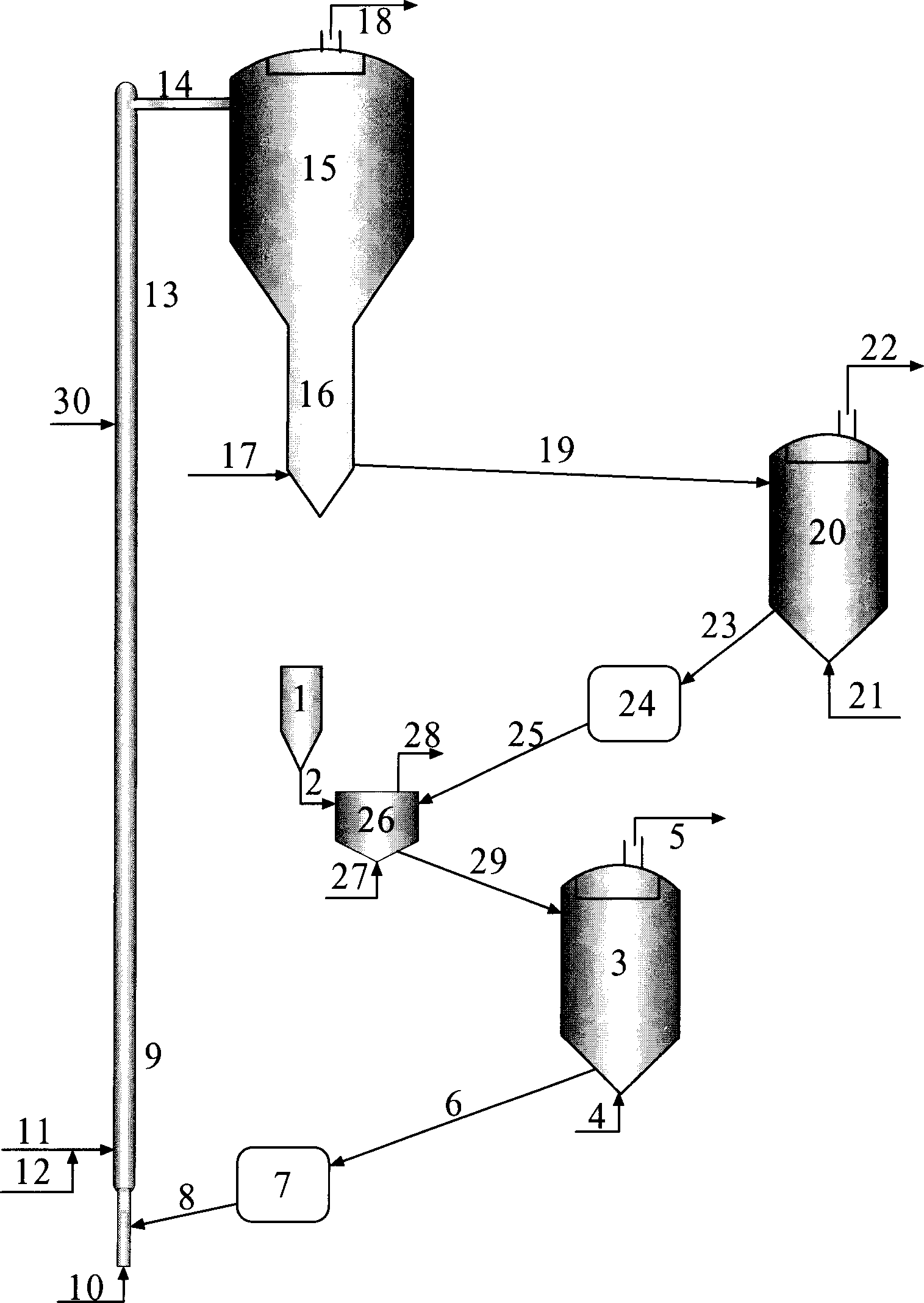

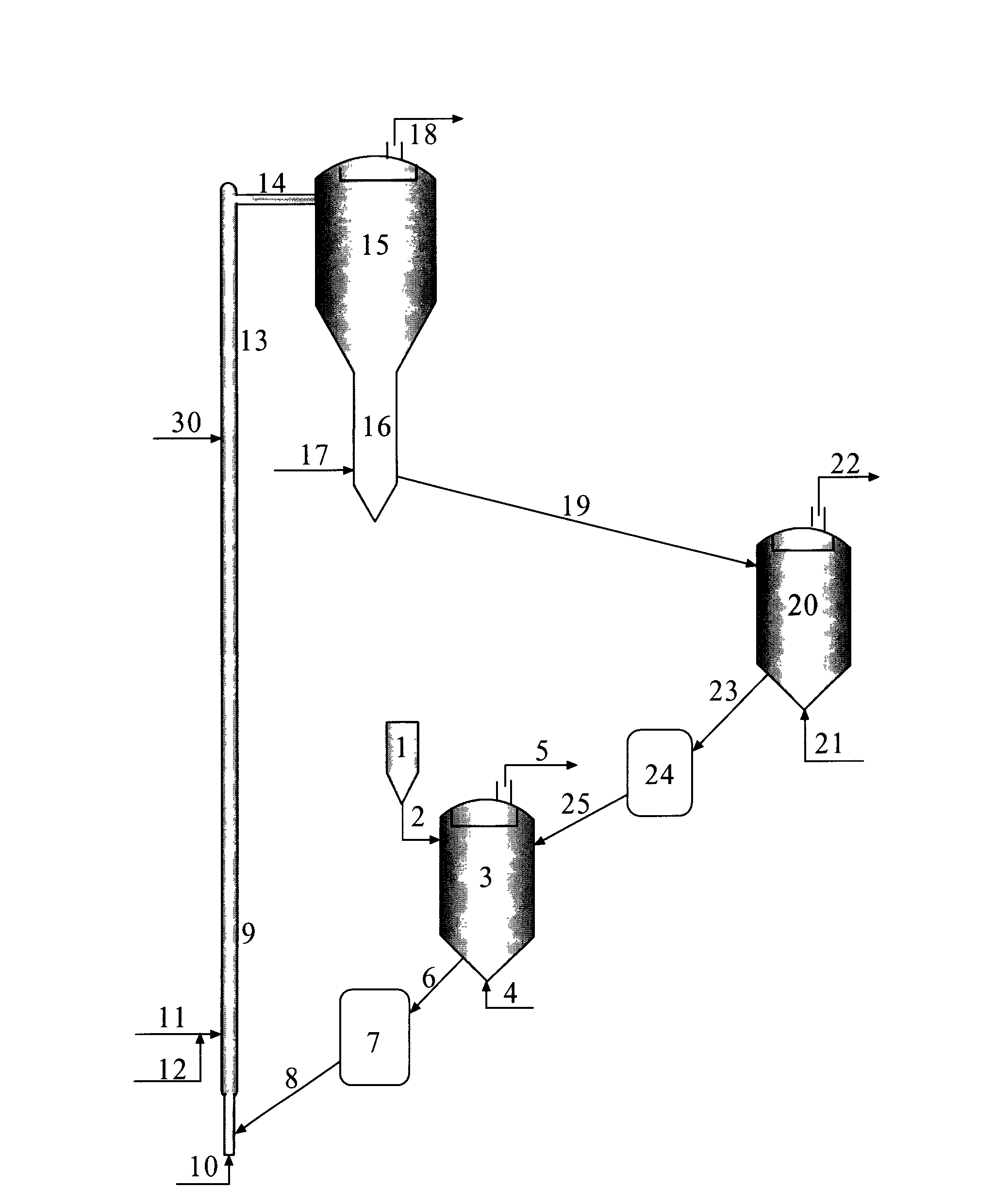

Method used

Image

Examples

preparation example Construction

[0093] The preparation method of the cracking aid is preferably carried out by the preparation method of the cracking aid described in the following preferred embodiments of the present invention.

[0094] The preparation method of the cracking aid described in the preferred embodiment of the present invention comprises contacting the composition containing metal component compound, refractory inorganic oxide and clay, with or without molecular sieve, with an atmosphere containing reducing gas, said The temperature and time of contact with an atmosphere containing a reducing gas are sufficient to cause the average valence state of the metal component to be lower than its highest oxidation state, said metal being selected from the group IIIA non-aluminum metals of the Periodic Table of the Elements, group IVA metals, VA One or more of group metals, IB group metals, IIB group metals, VB group metals, VIB group metals, VIIB group metals, and VIII group non-noble metals. The conten...

Embodiment 1

[0119] This example illustrates the cracking aid of the present invention and its preparation method.

[0120] Mix kaolin, pseudo-boehmite, and cobalt nitrate aqueous solution with a concentration of 30% by weight, add deionized water, mix well, slowly add hydrochloric acid with a concentration of 36.5% by volume under rapid stirring, and adjust the pH value of the slurry to 2.0, The amount of deionized water was such that the resulting slurry had a solids content of 25% by weight. The amount of kaolin, pseudo-boehmite and cobalt nitrate aqueous solution makes the dry basis weight of kaolin, Al 2 o 3 and Co 2 o 3 The weight ratio is 50.0:45.0:5.0.

[0121] The resulting slurry was spray-dried at a temperature of 150° C. and calcined at 550° C. for 1 hour. The catalyst that obtains is packed in the fixed-bed reduction reactor, under 400 ℃ of temperature, feed hydrogen, the flow rate of hydrogen is 5 milliliters per minute per gram of catalyst, makes hydrogen contact with d...

Embodiment 2

[0123] This example illustrates the cracking aid of the present invention and its preparation method.

[0124] The auxiliary agent was prepared according to the method of Example 1, except that the temperature of the solid and hydrogen contacted was 700° C., and the contact time was 3 hours to obtain the cracking auxiliary agent C2 of the present invention. The composition of additive C2 and the type, distribution, average valence state and the ratio of the average valence state to the highest valence state of the metal components are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com