Production for synthesizing high-content NaY molecular sieve from kaolin atomized microball

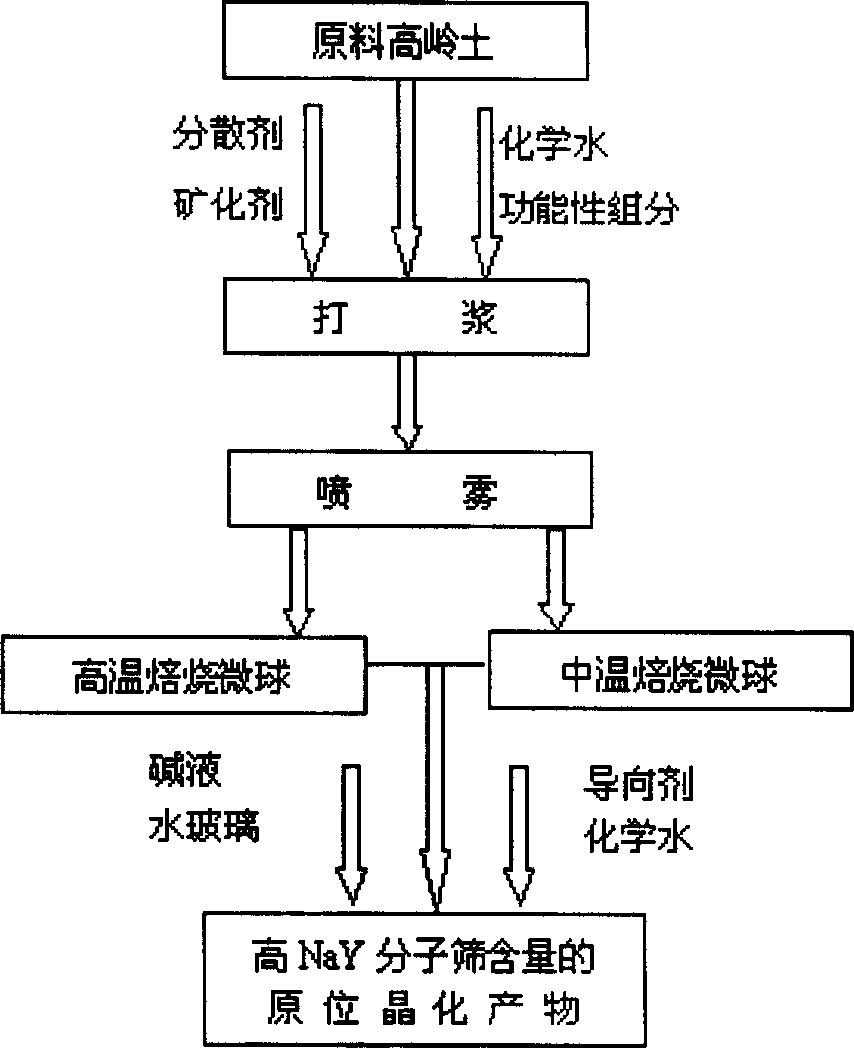

一种喷雾微球、高岭土的技术,应用在分子筛催化剂、分子筛和碱交换化合物、化学仪器和方法等方向,能够解决微球抗磨性差、原料要求很高、晶化产物孔结构不够理想等问题,达到改善孔结构、提高分子筛含量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1500g of kaolin (calcium base), based on the mass of kaolin, 2% of sodium silicate, 12% of silica sol, 1.4% of sodium hydroxide, 2% of starch, 2% of carboxymethyl cellulose, and deionized water were added to prepare The mixed slurry with a kaolin solid content of 33% was spray-dried to obtain 1540 g of kaolin spray microspheres SM1 with a particle size of 20-110 μm.

Embodiment 2

[0035] 1500g of kaolin (calcium base), based on the mass of kaolin, 10% of sodium silicate, 7% of pseudoboehmite, 1.0% of sodium hydroxide, 5% of starch, 2% of graphite powder, and deionized water are added to prepare The mixed slurry with a kaolin solid content of 40% was spray-dried to obtain 1610 g of kaolin spray microspheres SM2 with a particle size of 20-110 μm.

Embodiment 3

[0037] Add 1500g of kaolin (calcium base), based on the mass of kaolin, add 6% sodium silicate, 10% aluminum sol, 1.2% sodium hydroxide, 3% graphite powder, 4% starch, 2% carboxymethyl cellulose, add Deionized water was prepared into a mixed slurry with a kaolin solid content of 47%, and spray-dried to obtain 1532 g of kaolin spray microspheres SM3 with a particle size of 20-110 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com