Method for removing microcracks from additive manufacturing nickel-base high-temperature alloy components manufactured by electron beam selective melting

A nickel-based superalloy and additive manufacturing technology, applied in additive manufacturing, additive processing, energy efficiency improvement and other directions, can solve problems such as alloy cracks, and achieve the effect of improving microhardness, good microstructure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

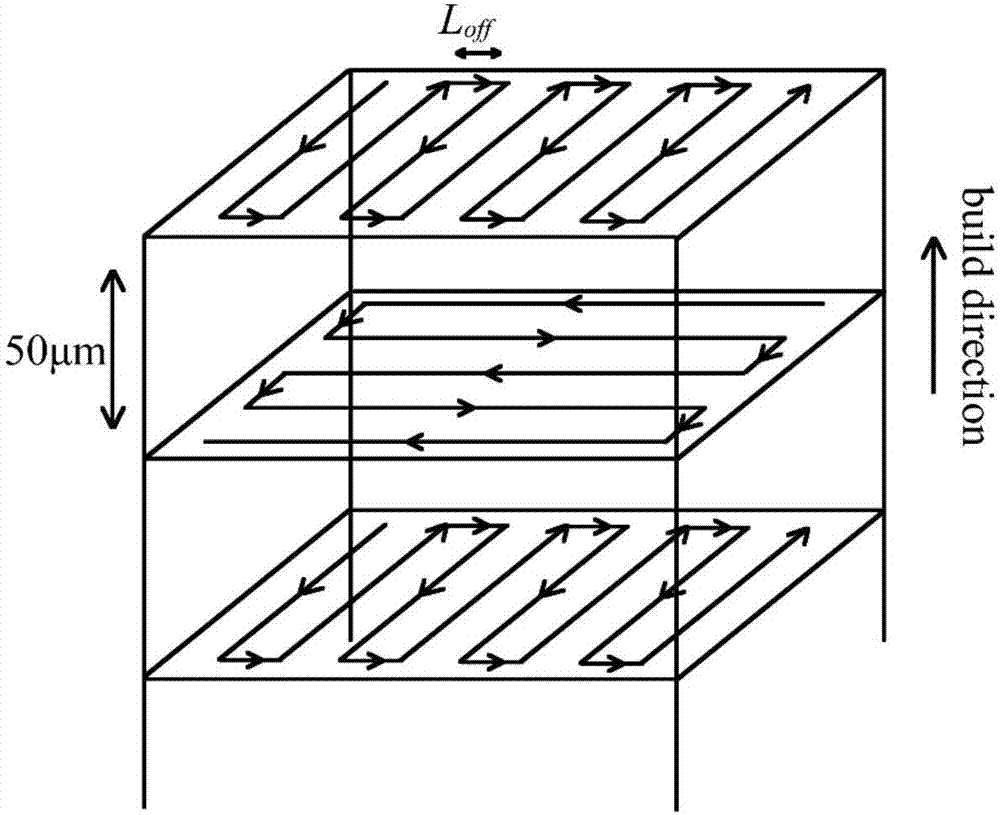

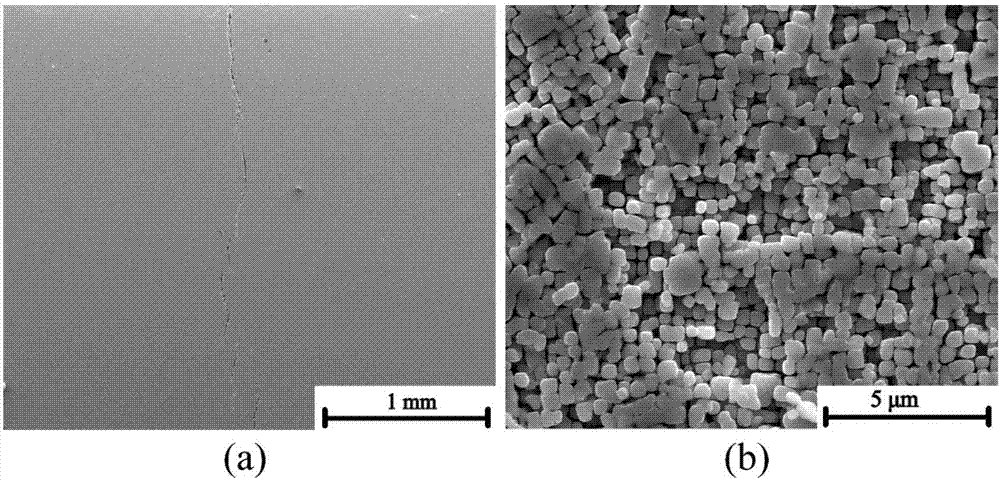

[0024] (1) DZ125 nickel-based superalloy samples were prepared using EBM additive manufacturing equipment, and the forming method was as follows figure 1 . The forming method is to manufacture layer by layer from bottom to top along the vertical direction. The electron beam scanning mode of each layer is serpentine scanning, and the scanning mode of the upper layer is perpendicular to the scanning direction of the next layer. The crack morphology and microstructure photos of DZ125 nickel-based superalloy prepared by EBM are as follows figure 2 . from figure 2 In (a), it can be seen that through EBM forming, there are microcracks inside the DZ125 nickel-based superalloy. from figure 2 (b) It can be seen that the γ' phase in the microstructure of DZ125 nickel-based superalloy has irregular morphology and uneven size distribution.

[0025] (2) By changing the EBM preparation parameters, that is, changing the electron beam scanning rate v, scanning current I and scanning l...

Embodiment 2

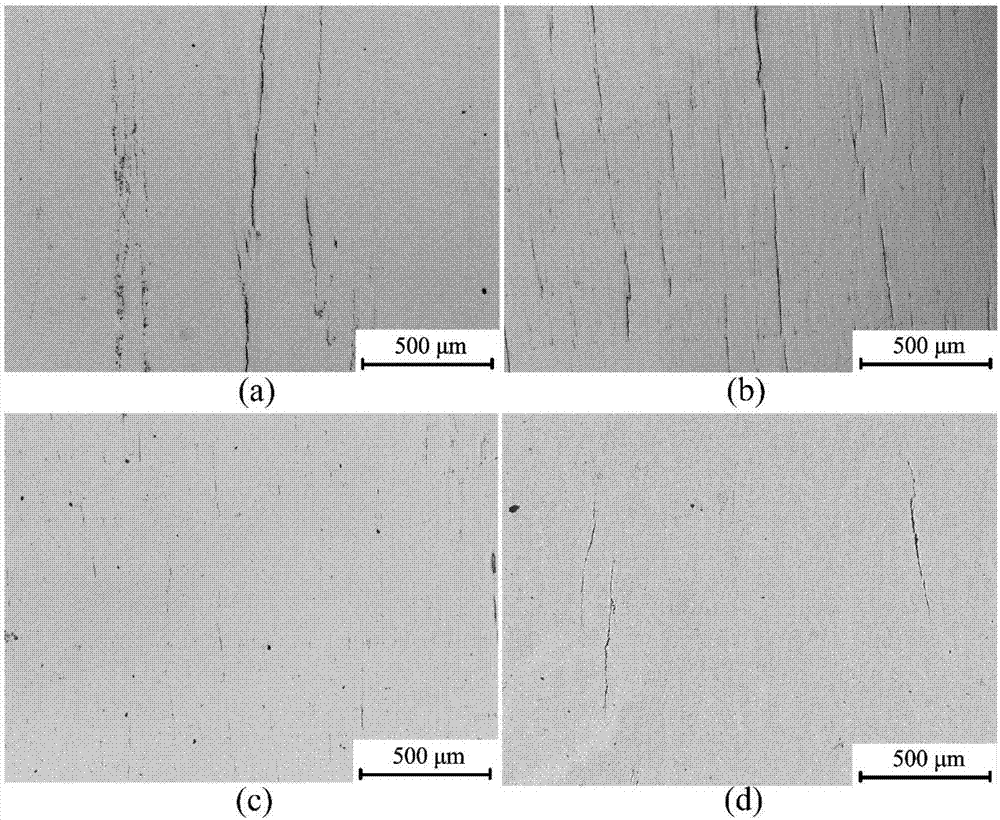

[0032] (1) take image 3 (c) and the EBM preparation parameters in Table 1c, the crack morphology and microstructure of the DZ125 sample after 1220 ° C, 2 h hot isostatic pressing are as follows Figure 4 (c)(d). from Figure 4 (c) It can be seen that after HIP treatment, the cracks are obviously eliminated. It shows that the process has a significant effect on eliminating cracks. from Figure 4 (d) It can be seen that the γ' morphology has a growing tendency after HIP treatment, and the size distribution is uneven, indicating that the process will affect the microstructure, so subsequent heat treatment is required to adjust the microstructure.

[0033] (2) After 1220°C, 15min solution treatment, and 860°C, 18h aging treatment, the crack morphology and microstructure photos are as follows Figure 5 (c)(d). from Figure 5 It can be seen from (c) that after this treatment process, the purpose of eliminating microscopic cracks in the EBM-formed nickel-based superalloy can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com