Method for preparing high nitrogen and nickel-less austenitic stainless steel

An austenitic stainless steel and high-nitrogen technology, which is applied in the field of smelting and manufacturing high-nitrogen nickel-free austenitic stainless steel, can solve problems such as difficult claims, and achieve the effects of low production cost, simple requirements for smelting equipment, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First smelt 100kg of Cr-Mn basic steel in an induction furnace, then carry out converter refining, adjust the chemical composition (wt%): C 0.03; Cr 9; Mn 14; Si 0.58; Mo 1.5; P≤0.02; S≤0.02; The rest is iron.

[0026] Mix 12 kg of high-nitrogen ferrochrome alloy containing 63% Cr and 8% N with a particle size of 20 mesh and 3 kg of chromium nitride with a particle size of 80 mesh to prepare high-nitrogen alloy powder.

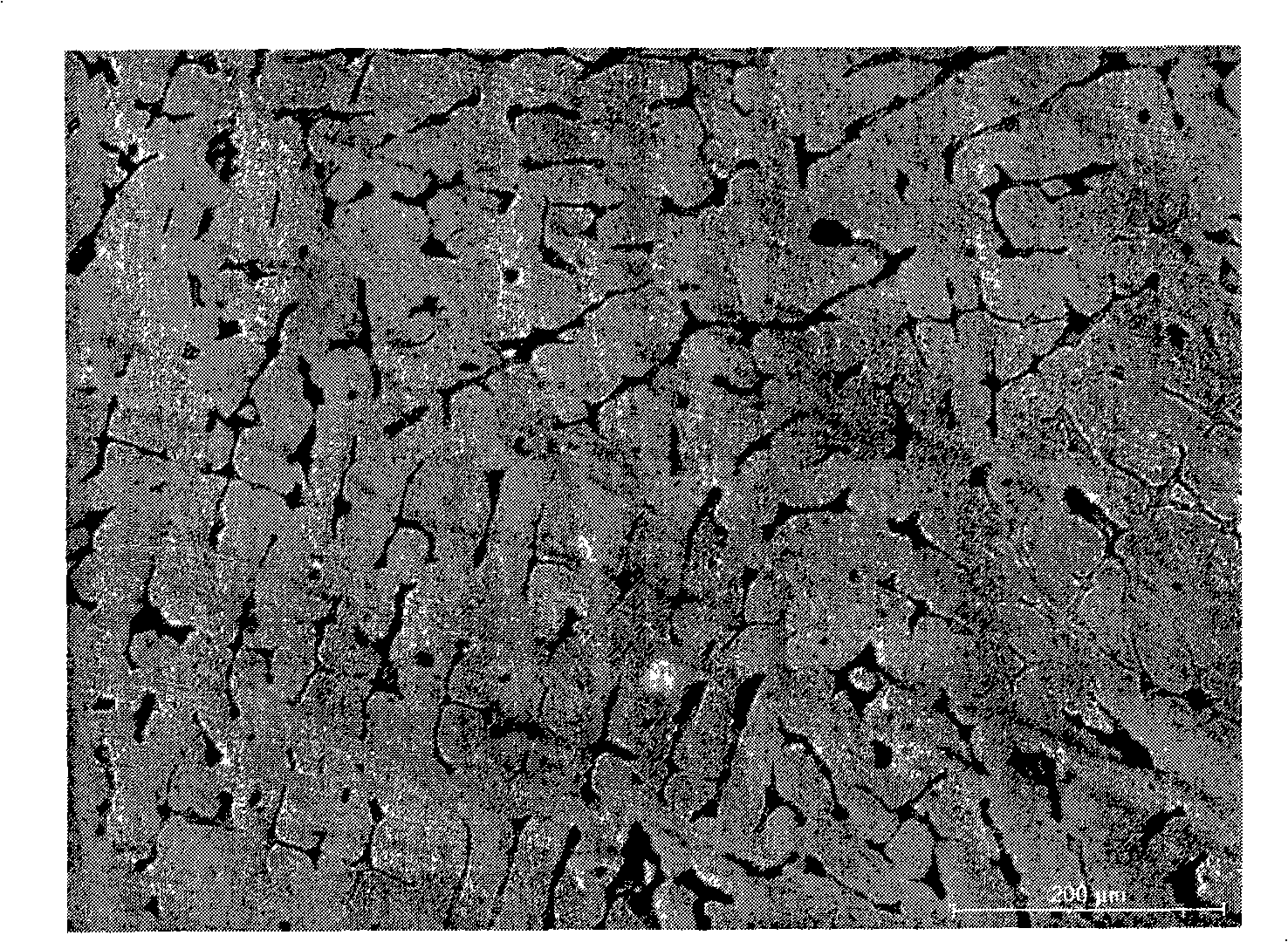

[0027] The Cr-Mn basic molten steel and the prepared high-nitrogen alloy mixed solid are poured into a 20×80mm square crystallizer together, and electromagnetic stirring is performed at the same time to rapidly solidify into a billet. Metallographic examination such as figure 1 As shown, undissolved nitrides and high-temperature ferrite in the form of strips and spheres can be seen.

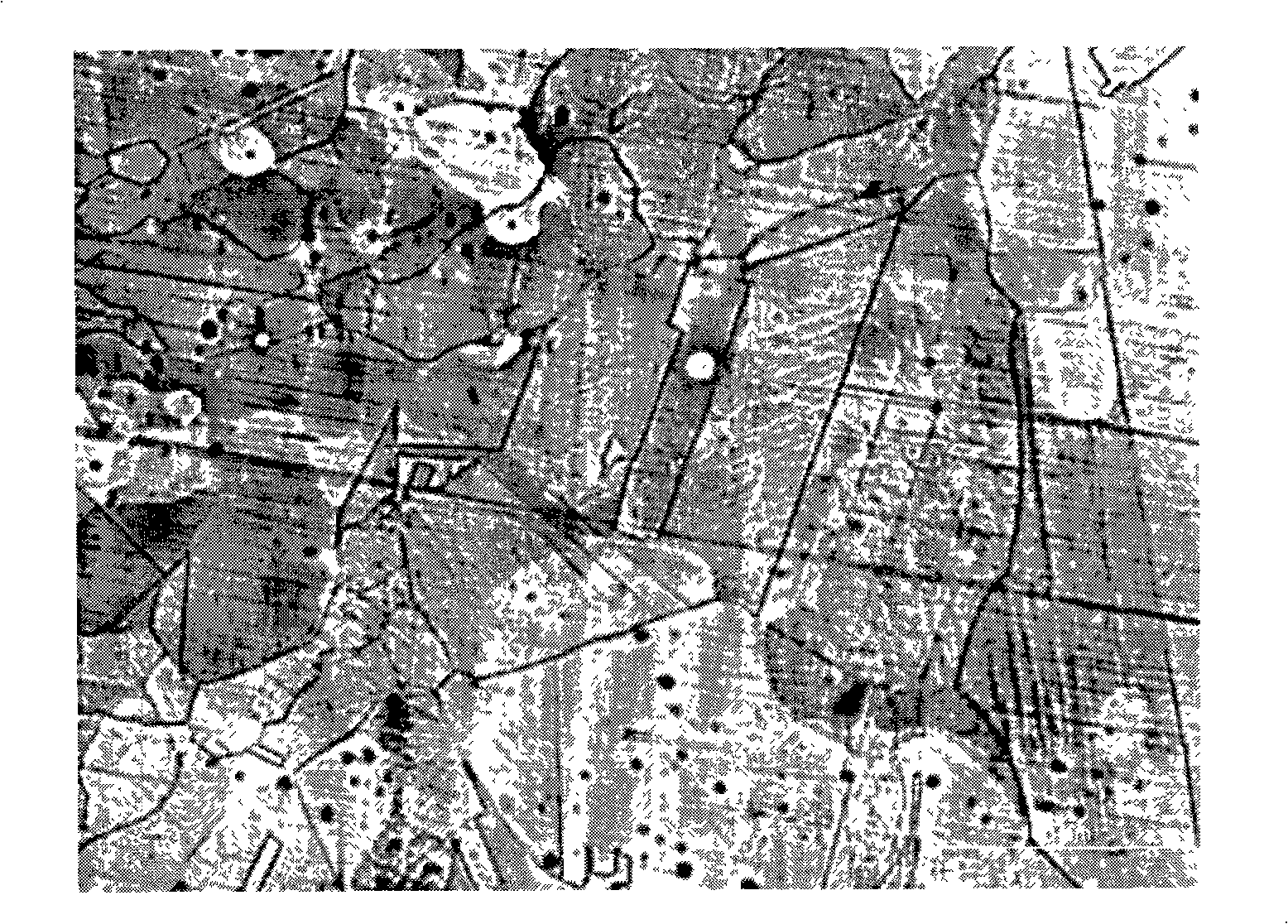

[0028] The steel billet is heated to 1200°C and rolled into a plate for solution treatment, and the solution temperature is 1000°C. Its metallographic examination as ...

Embodiment 2

[0030] Refining 100kg of Cr-Mn base steel, adjusting the chemical composition (wt%): C 0.03; Cr12; Mn18; Si 0.58; Mo 1.5; P≤0.02; S≤0.02; Control molten steel temperature: 1650°C.

[0031] Add 15 kg of high-nitrogen ferrochrome alloy powder (50 mesh, 63% Cr, 8% N) plated with Cr in molten steel, and after electromagnetic stirring for 30 seconds, quickly pour into an ingot mold with high cooling capacity, quickly solidify into a steel ingot, and then Hot rolling and solution treatment were performed as described above. Composition inspection (wt%): C0.045; Cr 21; Mn 15; Si 0.42; N 0.93; Mo1.2; The microstructure is a single-phase austenite with a face-centered cubic lattice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com