Tributyl phosphate organic phase regeneration treatment method

A technology of tributyl phosphate and a treatment method is applied in the treatment field of organic phase regeneration of tributyl phosphate, and can solve the problems of difficult control, affecting the separation of zirconium and hafnium, and difficulty in phase separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

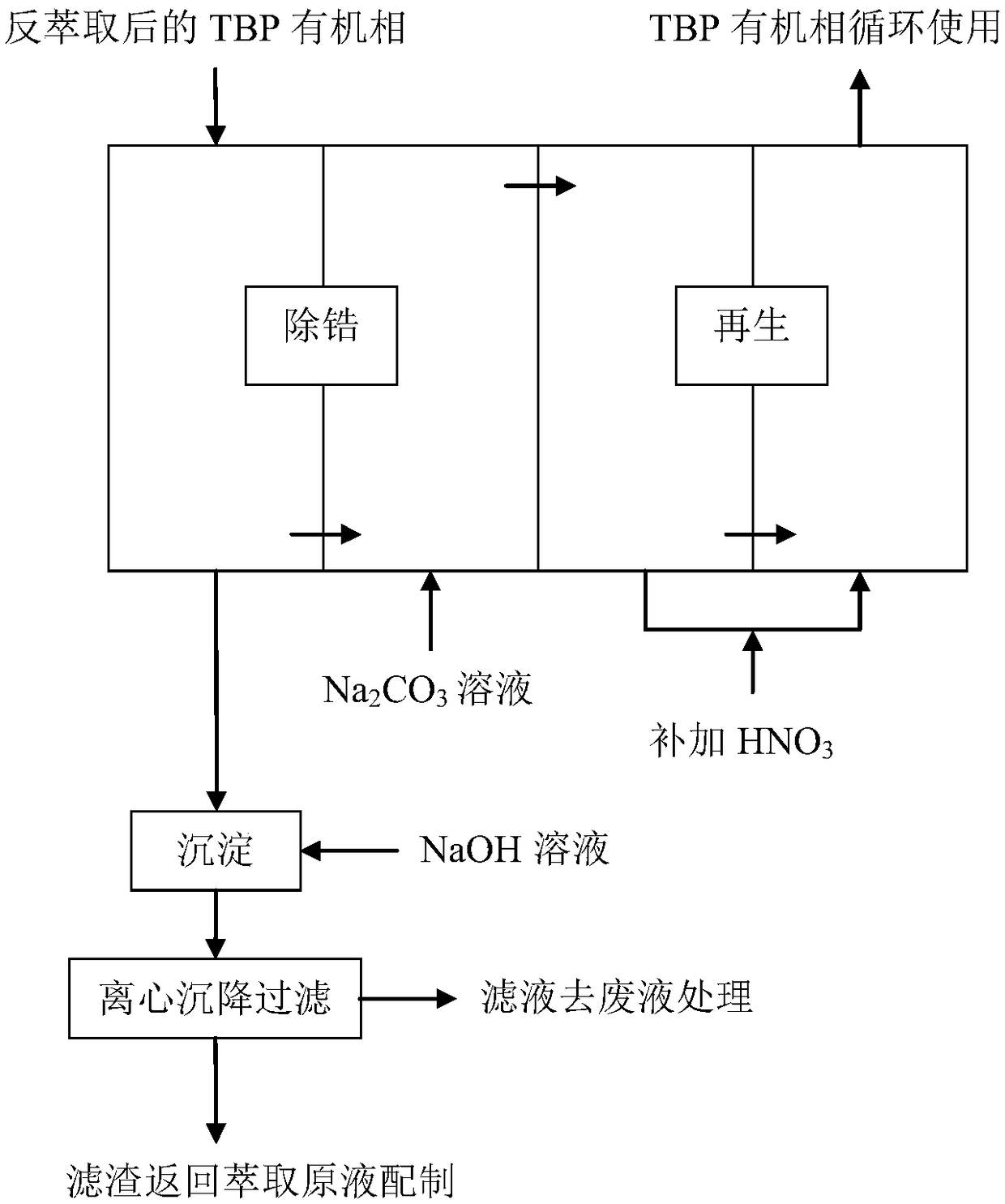

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] Such as figure 1 As shown, a treatment method for the regeneration of the organic phase of tributyl phosphate of the present invention is applied to the regeneration of the organic phase of tributyl phosphate extracted and separated by zirconium and hafnium, comprising the following steps:

[0042] The first step: organic phase alkali washing to remove zirconium

[0043] After the organic phase of tributyl phosphate is used for the extraction and separation of zirconium and hafnium, a certain amount of zirconium remains, which affects the recycling of the organic phase;

[0044] Add the organic phase of tributyl phosphate with the problem of zirconium retention to the first stage of the zirconium removal section of the two-stage countercurrent contact mixing clarifier at a flow rate of 800L / h;

[0045] At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com