Recovery treatment device and method for methanol-containing alkaline resin desorption liquid

A basic resin, recycling and treatment technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control and other directions, can solve the problems of high cost and high energy consumption, and achieve low equipment cost, low energy consumption, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

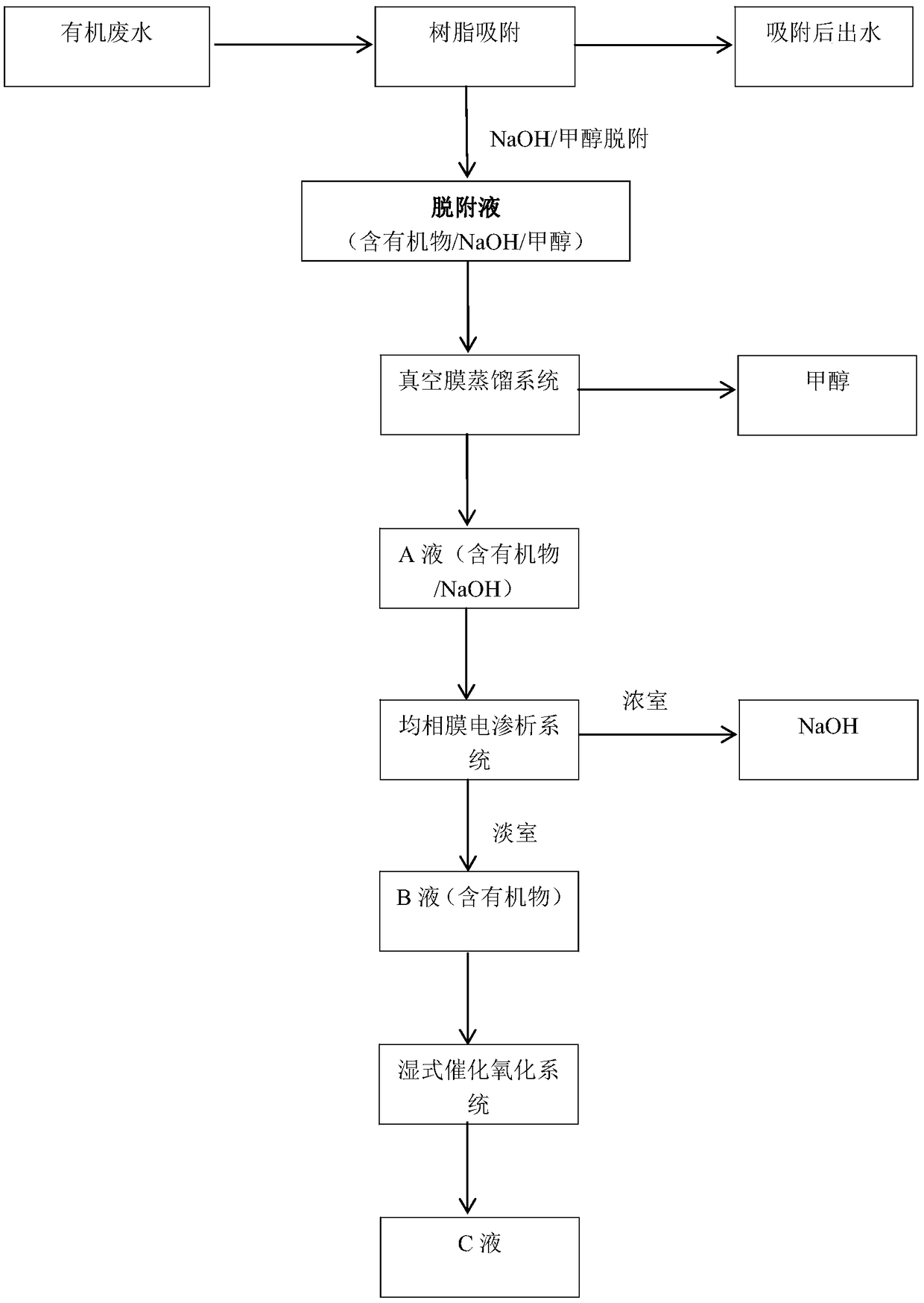

[0044] The recycling and processing device of a methanol-containing alkaline resin desorption liquid used in this embodiment includes a vacuum membrane distillation system connected in sequence for separating methanol in the basic resin desorption liquid, and a vacuum membrane distillation system for separating sodium hydroxide. Homogeneous membrane electrodialysis systems, and wet catalytic oxidation systems for treating organic pollutants.

[0045] The content of methanol in the desorption liquid used in this embodiment is 10%, the content of sodium hydroxide is 6%, and the COD is 10000mg / L.

[0046] like figure 1 Shown, a kind of recovery processing method that contains methanol basic resin desorption liquid, comprises the following steps:

[0047] (1) Use a vacuum membrane distillation system to separate methanol in the basic resin desorption solution:

[0048] The methanol-containing alkaline resin desorption liquid flows into the vacuum membrane distillation system, wh...

Embodiment 2

[0055] The recycling and processing device of a methanol-containing alkaline resin desorption liquid used in this embodiment includes a vacuum membrane distillation system connected in sequence for separating methanol in the basic resin desorption liquid, and a vacuum membrane distillation system for separating sodium hydroxide. Homogeneous membrane electrodialysis systems, and wet catalytic oxidation systems for treating organic pollutants.

[0056] The content of methanol in the desorption liquid used in this embodiment is 40%, the content of sodium hydroxide is 0.5%, and the COD is 25000mg / L.

[0057] like figure 1 Shown, a kind of recovery processing method that contains methanol basic resin desorption liquid, comprises the following steps:

[0058] (1) Use a vacuum membrane distillation system to separate methanol in the basic resin desorption solution:

[0059] The methanol-containing alkaline resin desorption liquid flows into the vacuum membrane distillation system, ...

Embodiment 3

[0066] The recycling and processing device of a methanol-containing alkaline resin desorption liquid used in this embodiment includes a vacuum membrane distillation system connected in sequence for separating methanol in the basic resin desorption liquid, and for separating sodium hydroxide The homogeneous membrane electrodialysis system, and the wet catalytic oxidation system for the treatment of organic pollutants.

[0067] The content of methanol in the desorption liquid used in this embodiment is 60%, the content of sodium hydroxide is 3%, and the COD is 50000mg / L.

[0068] like figure 1 Shown, a kind of recovery processing method that contains methanol basic resin desorption liquid, comprises the following steps:

[0069] (1) Use a vacuum membrane distillation system to separate methanol in the basic resin desorption solution:

[0070] The methanol-containing alkaline resin desorption liquid flows into the vacuum membrane distillation system, which uses a microporous me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com