Method for improving inoxidizability of cuprammonia-containing ammonia compressor oil

A compressor oil and anti-oxidation technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of short service life and poor anti-oxidation performance of oil products, and achieve excellent viscosity-temperature properties and excellent oxidation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

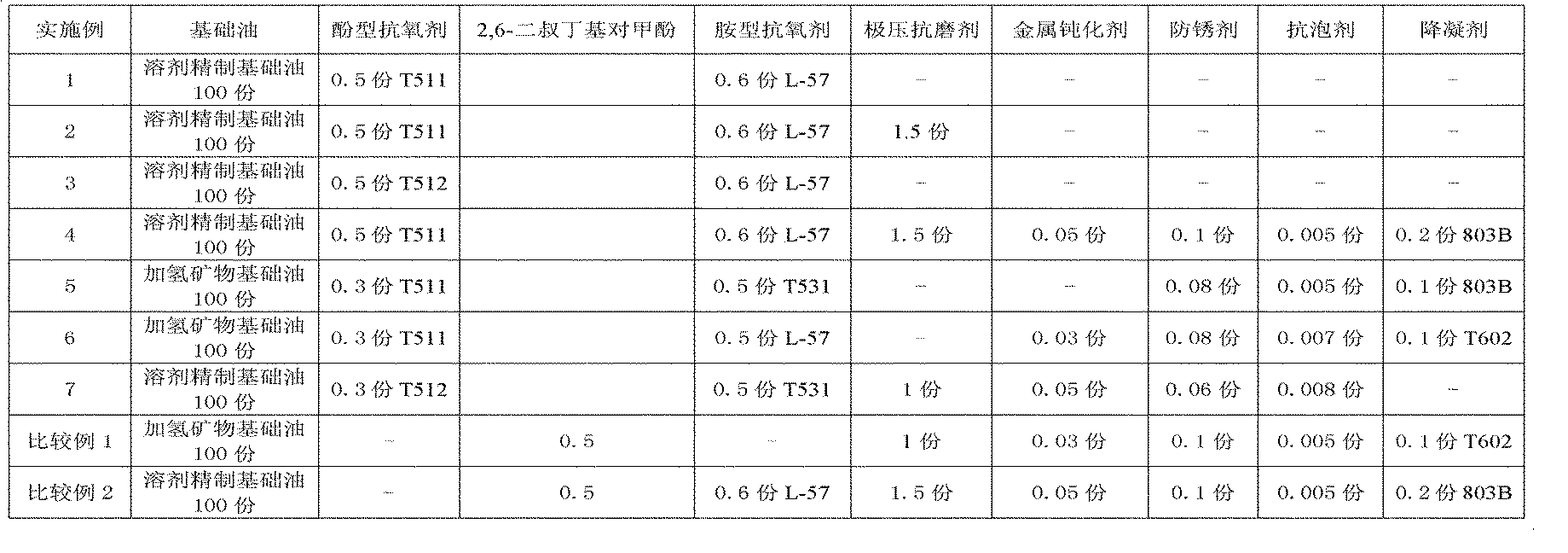

[0019] According to the parts by weight in Table 1, take the required amount of antioxidants, extreme pressure antiwear agents, metal passivators, rust inhibitors, antifoaming agents and pour point depressants respectively and add them to the base oil. ℃, heated and stirred until completely uniform to obtain the screw ammonia compressor oil composition. The type and amount of each component in the composition are specifically shown in Table 1.

[0020] Among them, T511 is 4,4-methylene bis(2,6-di-tert-butylphenol), T512 is 3,5-di-tert-butyl-4-hydroxyphenyl acrylate, and L-57 is alkylated Diphenylamine, T531 is phenyl-α-naphthylamine, T803B is polyalphaolefin, T602 is polyacrylate. The extreme pressure antiwear agent is tricresyl phosphate, the metal passivator is N, N-dialkylaminomethylene benzenetriazole, the rust inhibitor is basic dinonyl naphthalene sulfonate barium, and the antifoaming agent is It is a copolymer of acrylate and ether.

Embodiment 2

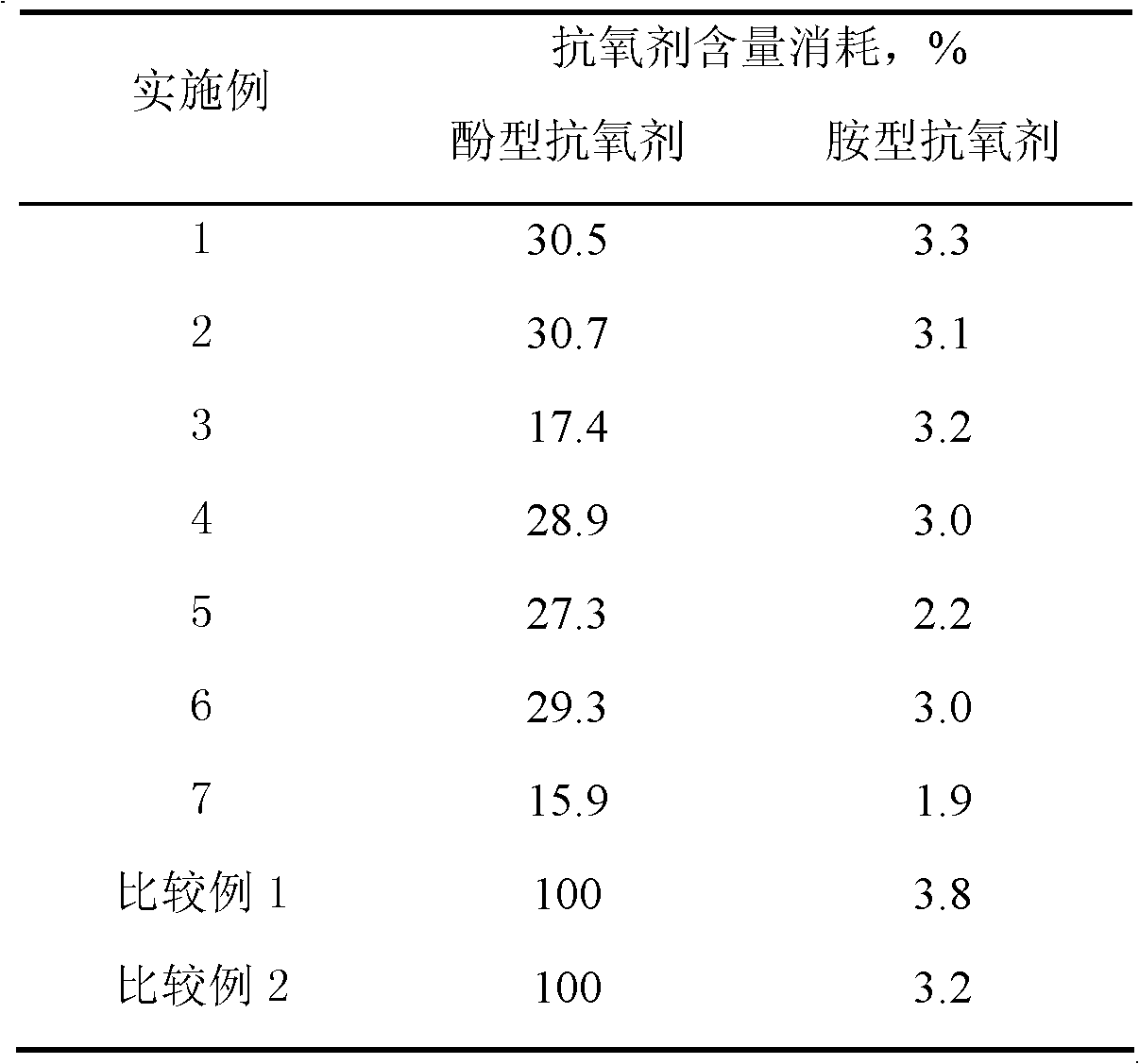

[0022] The antioxidant test of the compositions of [Examples 1-7]. The test conditions are: 100 ml of test oil and cuproammonia solution, the test temperature is 50°C, the compressed air with a gauge pressure of 19.6kPa is introduced, the mixture of test oil and cuproammonia solution is stirred, and the pressure and temperature are maintained for 6 hours. The test results are shown in Table 2.

[0023] Other properties of the test oil, viscosity-temperature, anti-foam, oil-water separation, extreme-pressure anti-wear and anti-rust and anti-corrosion properties, were not affected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com