Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Avoid carbon formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

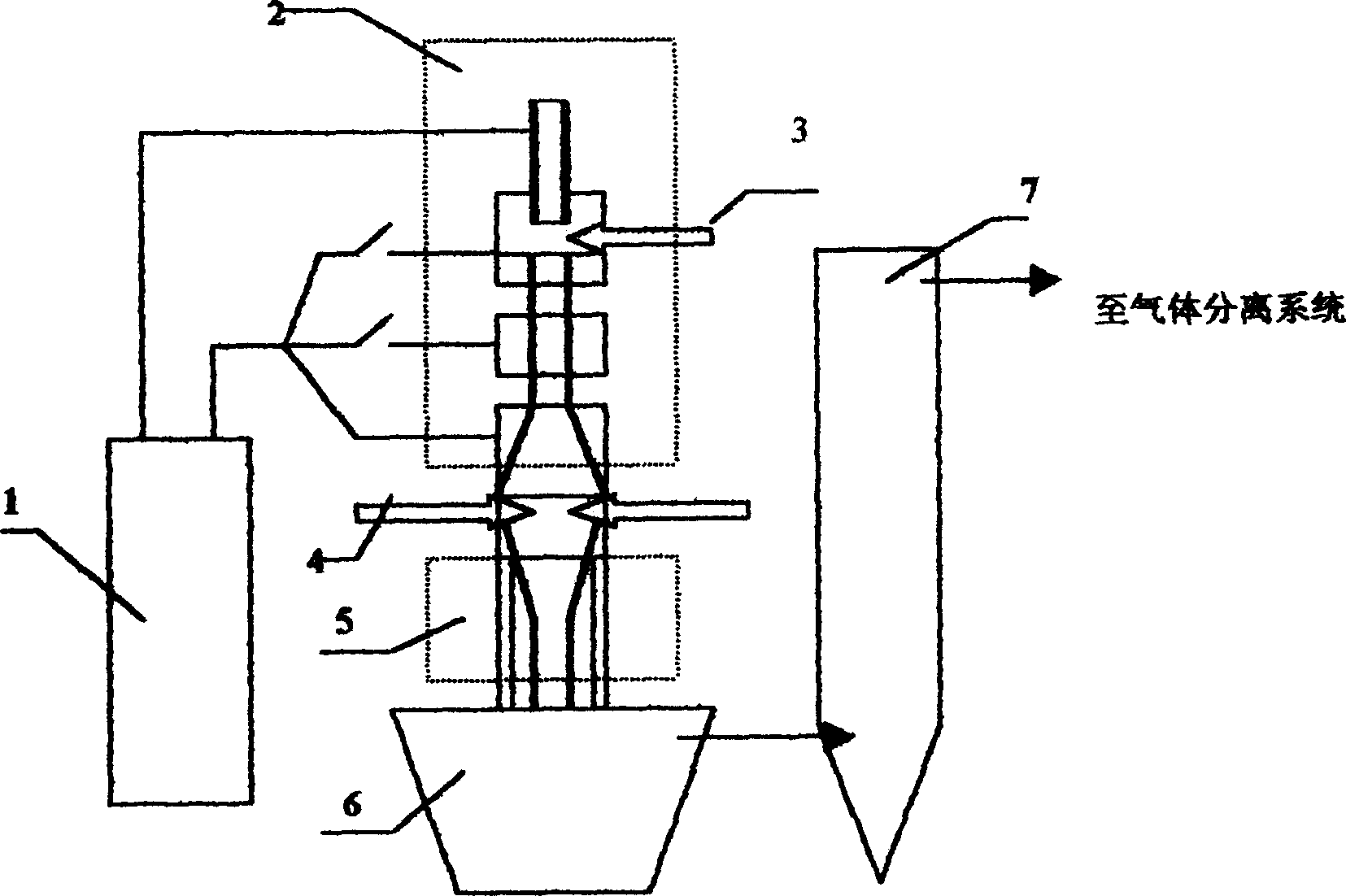

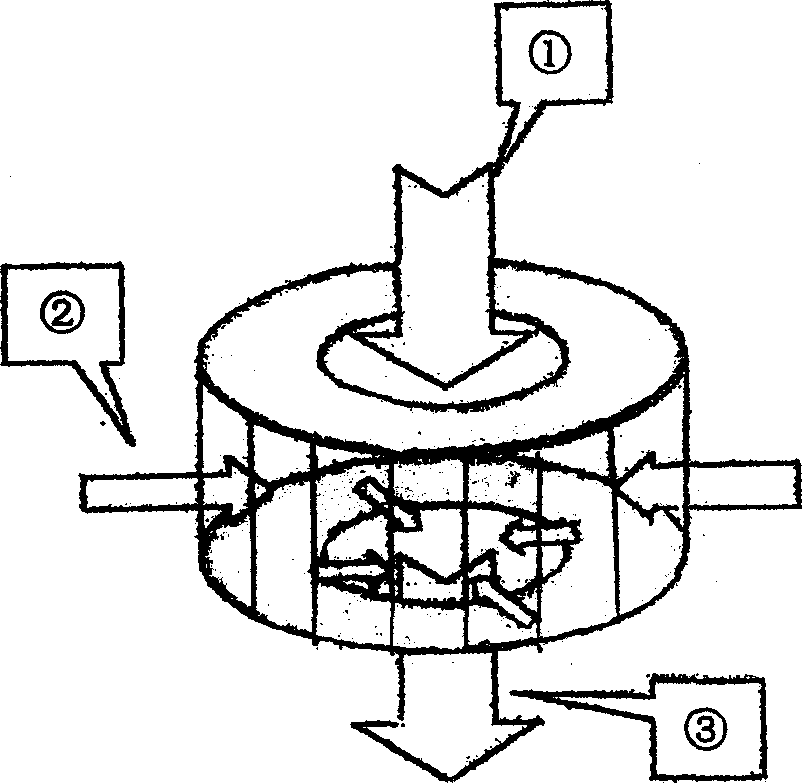

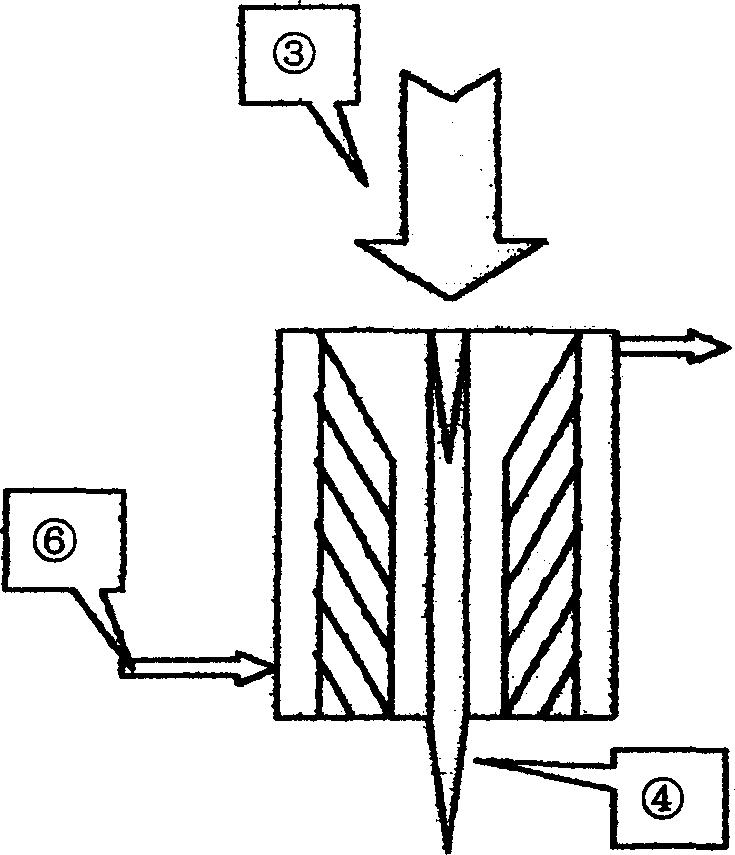

Method for preparing acetylene by hot plasma cracking methane containing gas

InactiveCN1552680AAvoid adverse consequencesIndustrial method improvementHydrocarbon by hydrocarbon crackingPlasma jetPlasma generator

A process for preparing acetylene by using hot plasma to crack the gas containing methane includes such steps as using plasma generator to ionize the argon or N2 or H2 to form a plasma jet, spraying raw gas via a gas inlet ring in reactor, mixing the plasma jet with the raw gas in the reactor, cracking reacting, and quickly cooling the cracked gas in an expansion cavity of cooler to obtain acetylene, carbon black and H2.

Owner:德阳市旌能天然气有限公司 +1

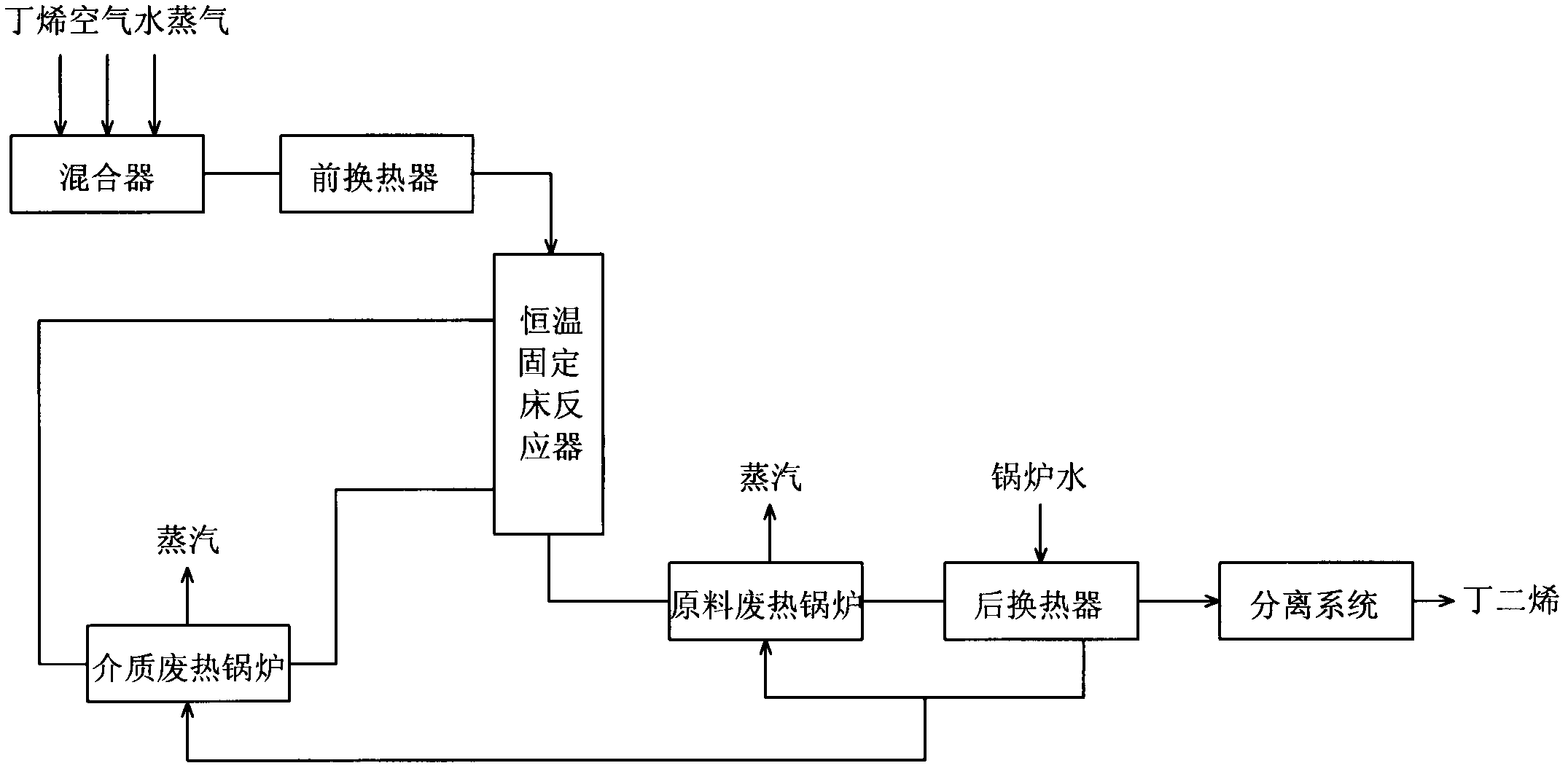

Method for preparing butadiene by oxidization and dehydrogenation of butane using constant-temperature static bed

InactiveCN102442874AHigh selectivityExtended service lifeHydrocarbonsHydrocarbon preparationButeneButadiene Dioxide

The invention provides a method for preparing butadiene by oxidization and dehydrogenation of butane using a constant-temperature static bed, which specifically comprises the steps that: the butane, air and water vapor are added into a static mixer according to proportions; mixed raw materials are heated to a certain temperature by a pre-heat exchanger, and then enter a constant-temperature static bed reactor for oxidization and dehydrogenation, wherein the static bed reactor is filled with catalyst, and the temperature of a catalyst bed layer of the reactor is controlled to be constant; after the mixed raw materials are oxidized and dehydrogenated, reaction products enter a post-heat exchanger for heat exchange through a raw material waste heat boiler, the products after heat exchange enter a separating system for separating the butadiene, so that butadiene product is obtained. In comparison with the prior art, the method for preparing butadiene by oxidization and dehydrogenation of butane using the constant-temperature static bed disclosed by the invention reaches a conversion per pass of the butadiene of 75%-85%, and the selectivity of the butadiene of at least 95%. The method can increase the conversion rate of the butane and the yield of the butadiene, reduce the butane and water consumed by the butadiene, greatly lower energy consumption, and decrease sewage discharge.

Owner:SHANDONG HUAMAO NEW MATERIALS

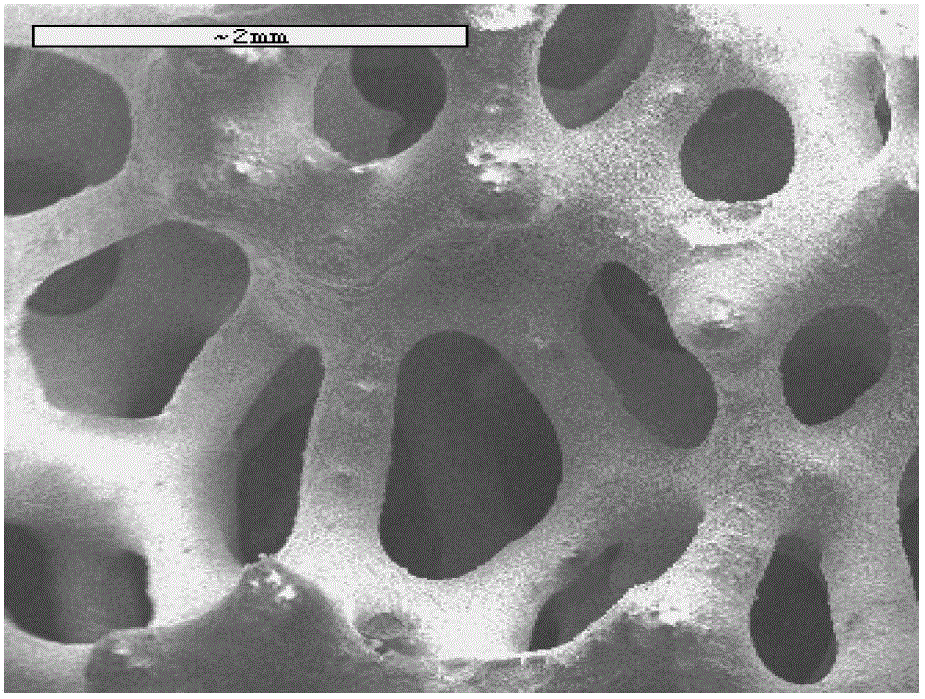

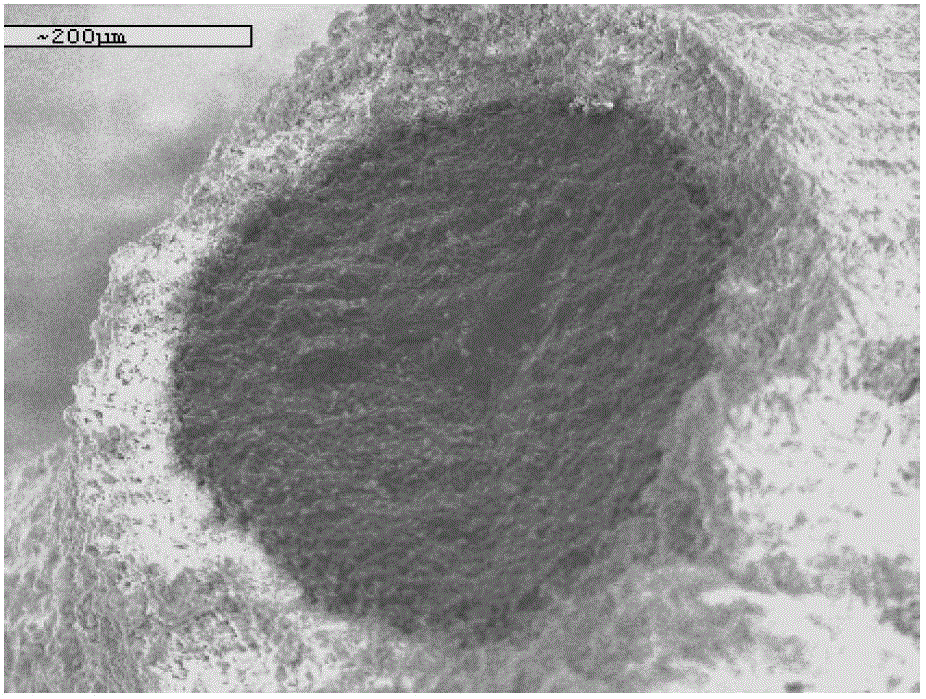

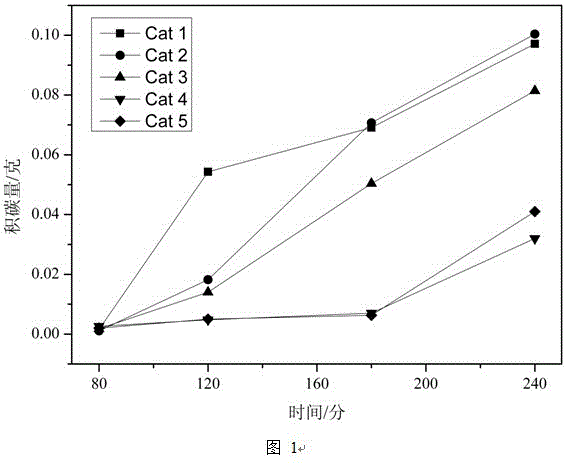

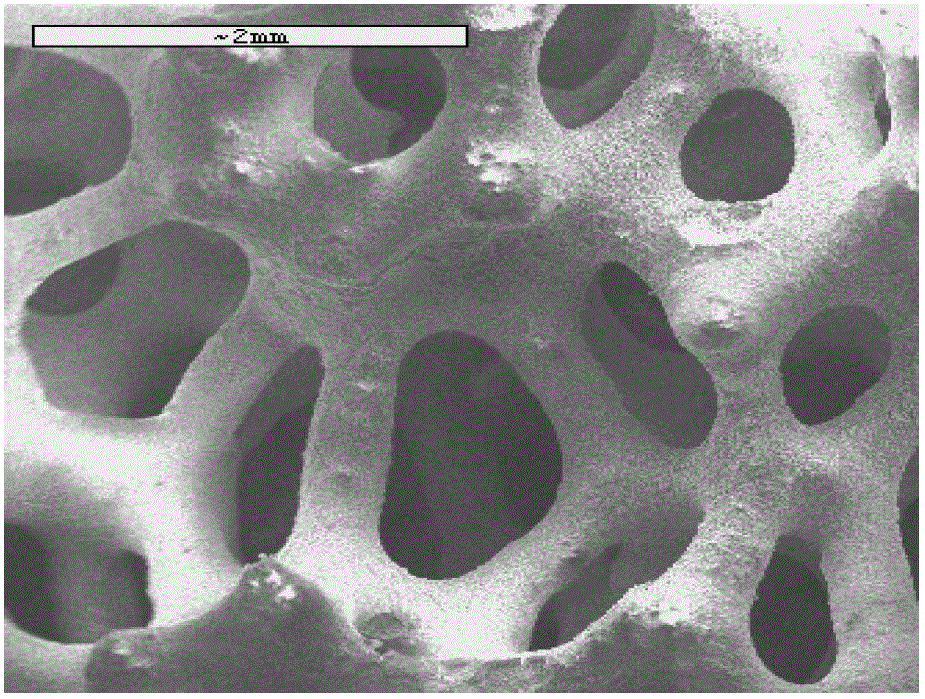

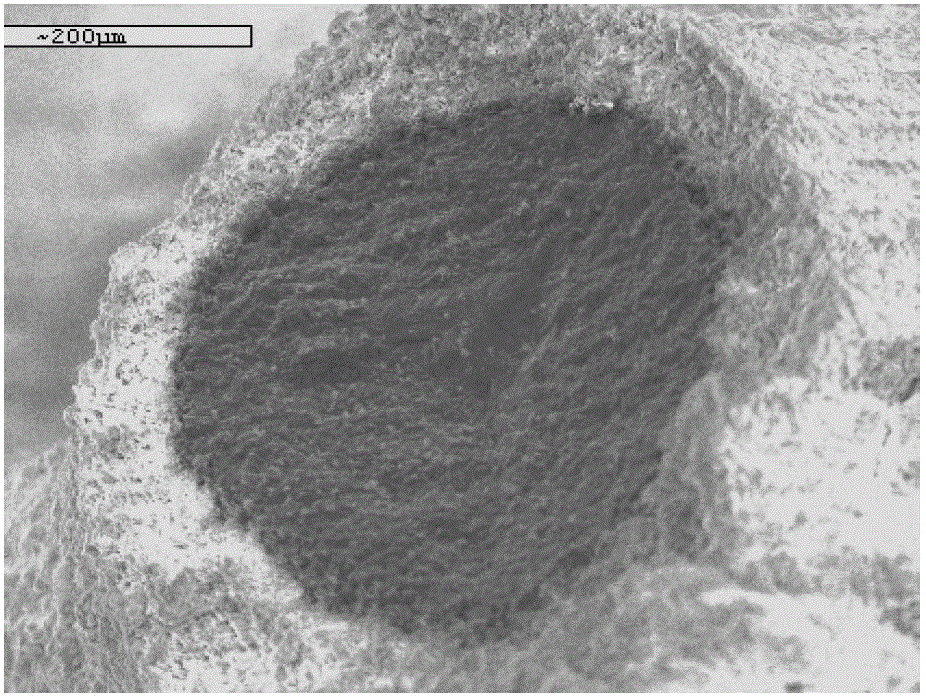

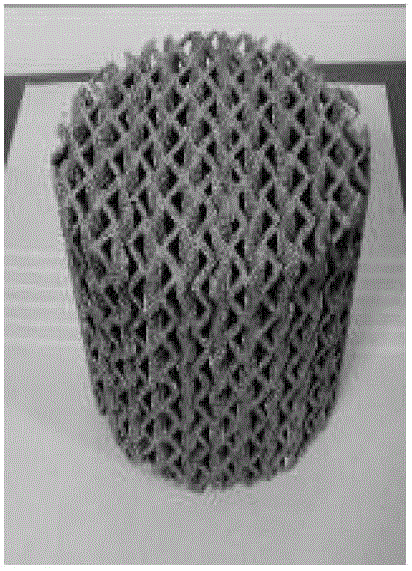

Foam silicon carbide based structured catalyst and application in preparation of butadiene

The invention relates to the catalyst field, particularly to a foam silicon carbide based structured catalyst and its application in preparation of butadiene by oxidative dehydrogenation of butylene. The foam silicon carbide based structured catalyst is the catalyst for preparation of butadiene by oxidative dehydrogenation of butylenes, and takes foam silicon carbide with a three-dimensional interconnected pore structure as the carrier. A ferrite catalyst with a spinel structure is loaded on the carrier surface as the main active component, and one or over two of alpha-Fe2O3, gamma-Fe2O3 and Fe3O4 are loaded on the carrier surface as the secondary active components, thus forming the structured catalyst. The structured catalyst can be processed into a plurality of complex configurations like wall flow type, parallel channel type, static hybrid type, granules and the like. The foam silicon carbide based structured catalyst provided by the invention can convert butylene into butadiene through oxidative dehydrogenation, thus reinforcing heat transfer and mass transfer, improving butadiene yield, prolonging the catalyst life, and reducing the energy consumption and material consumption of the reaction process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

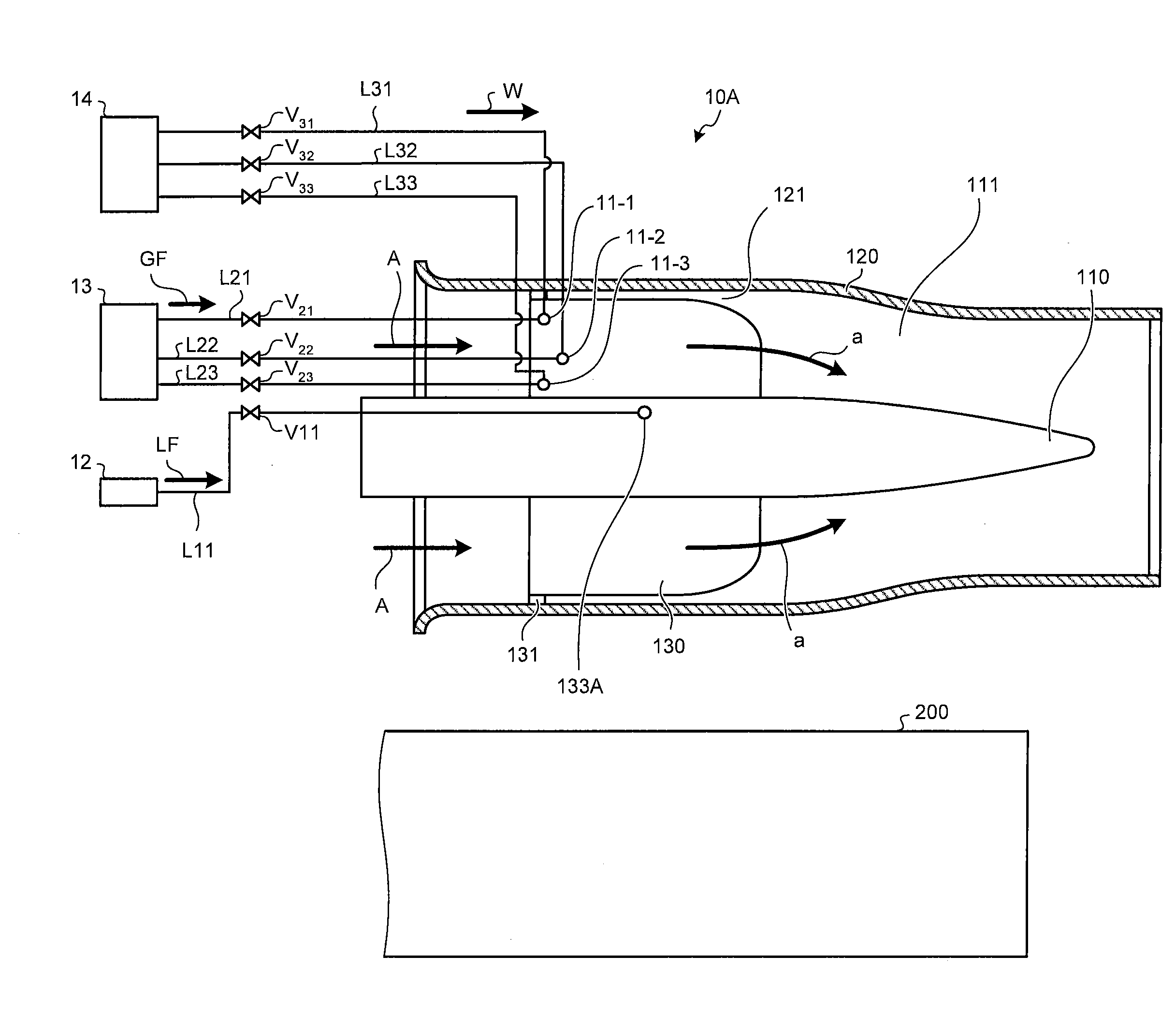

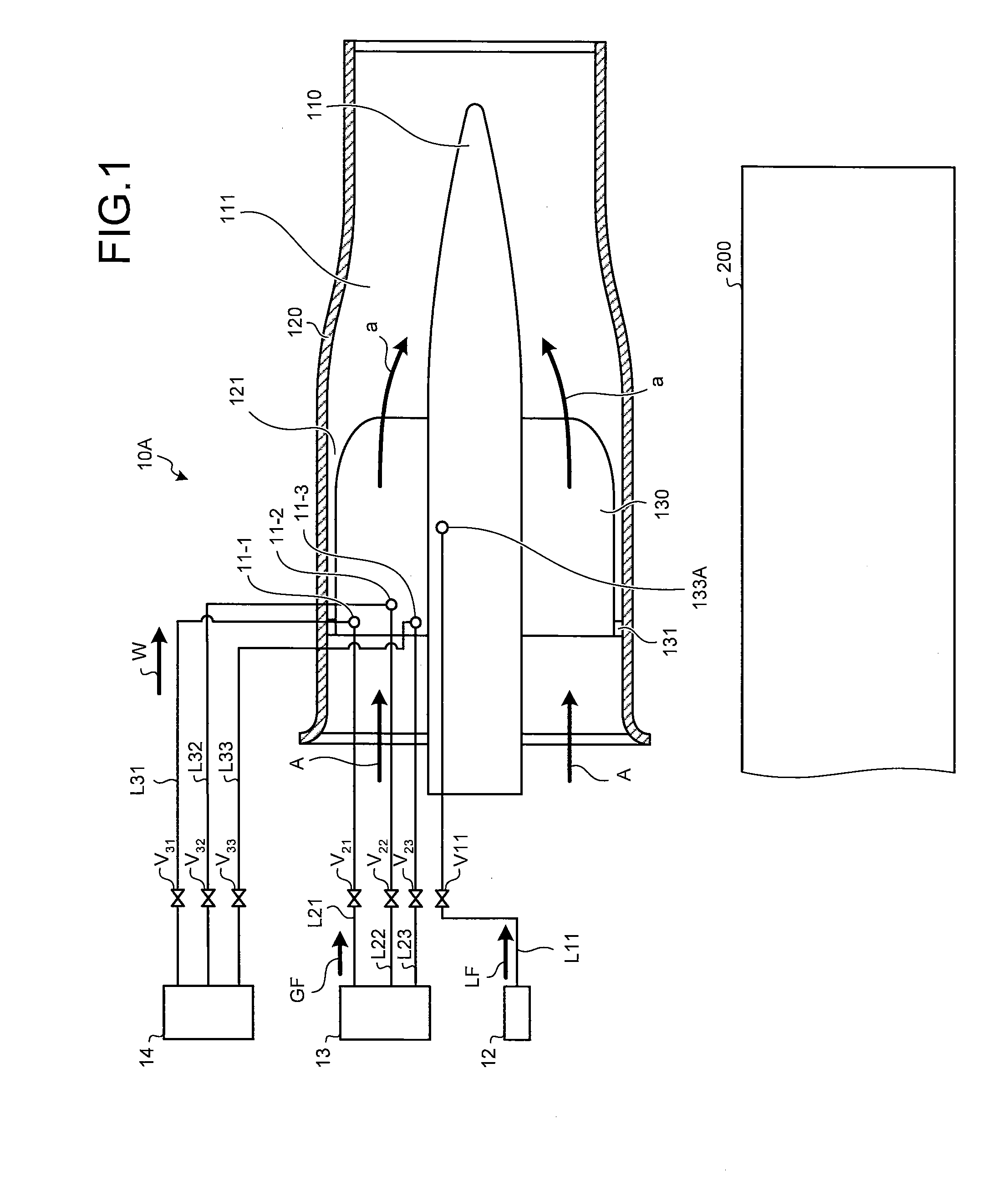

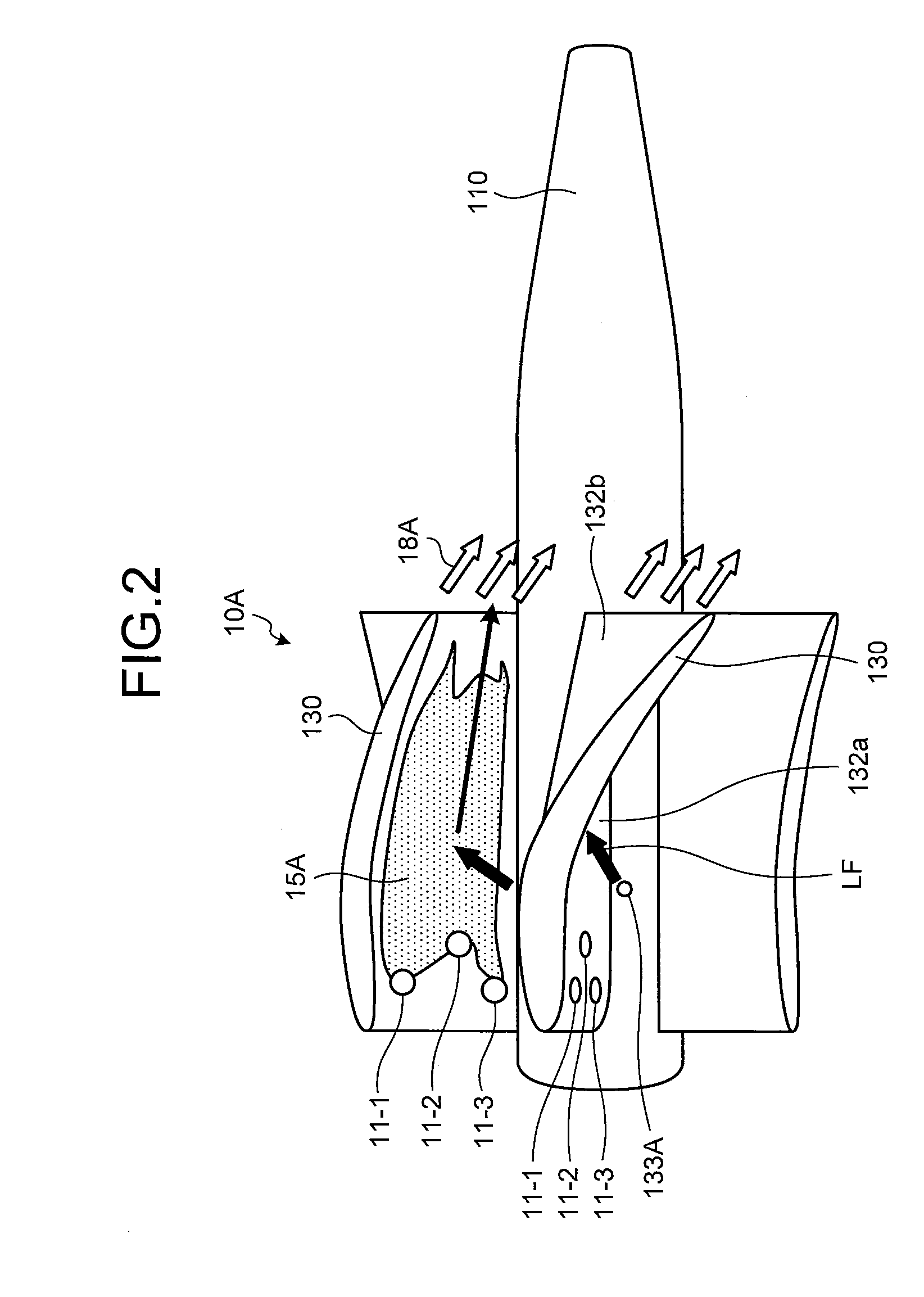

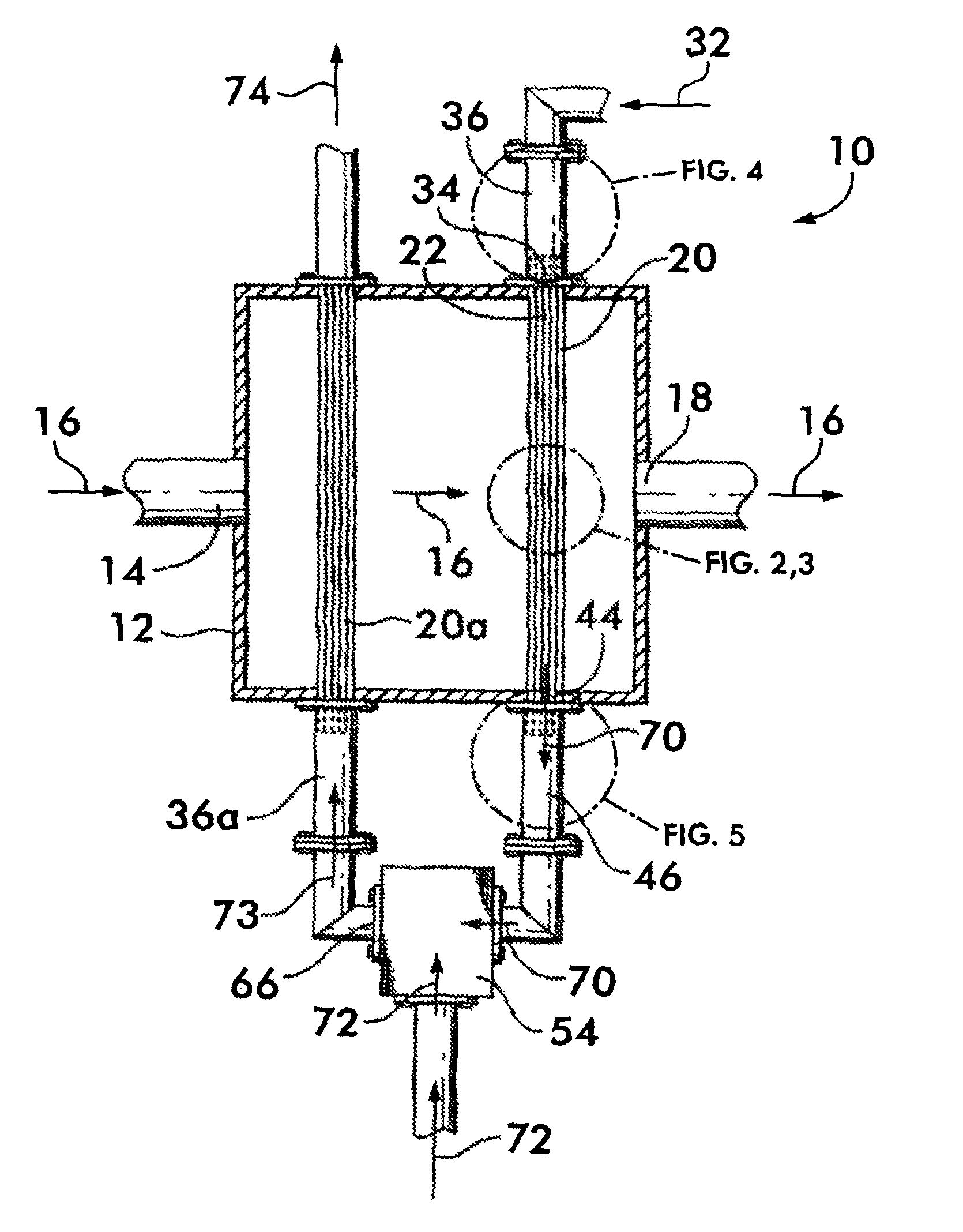

Combustion burner

ActiveUS20100269508A1Reduce NOxReduce temperatureTurbine/propulsion fuel supply systemsContinuous combustion chamberEngineeringNozzle

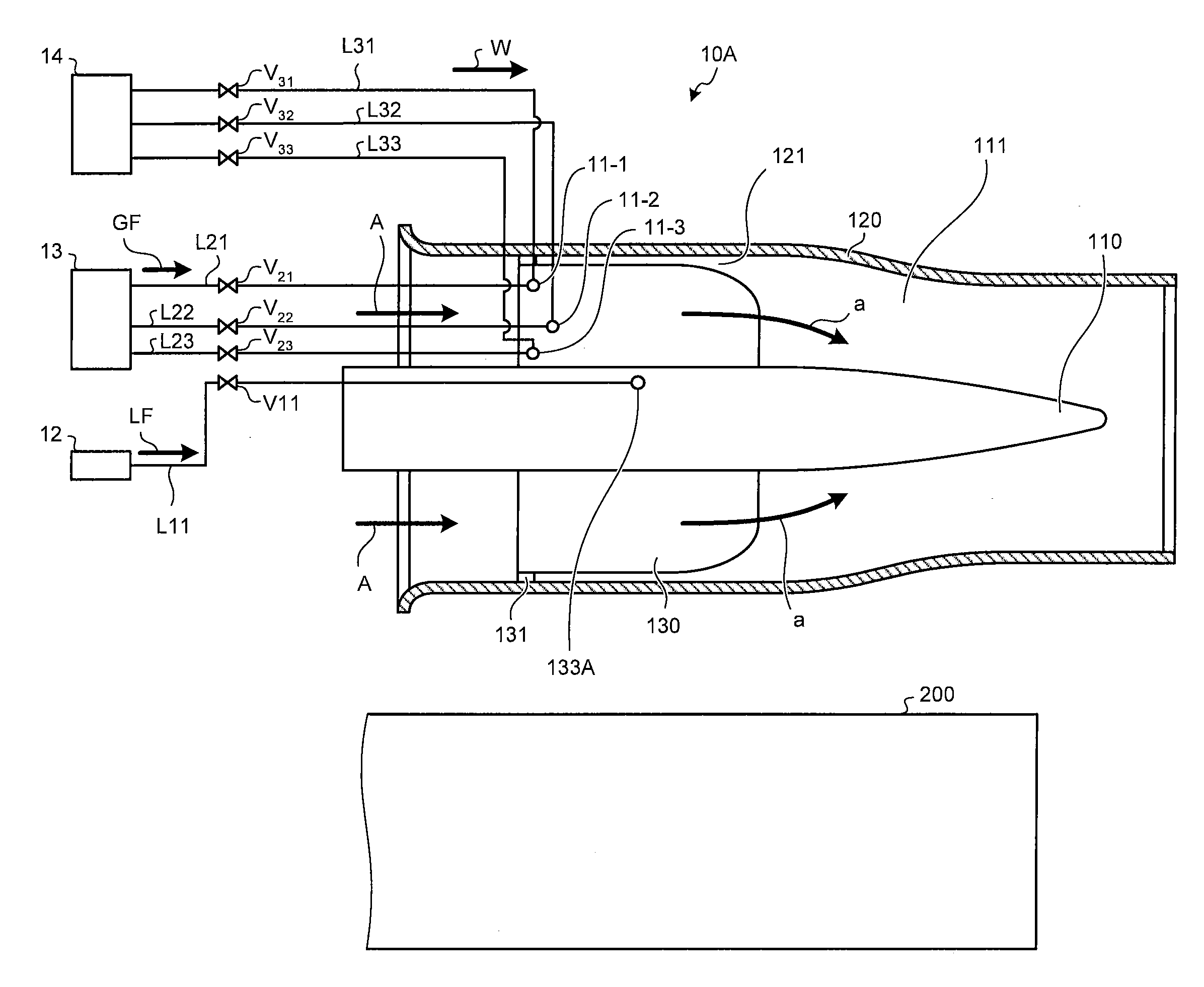

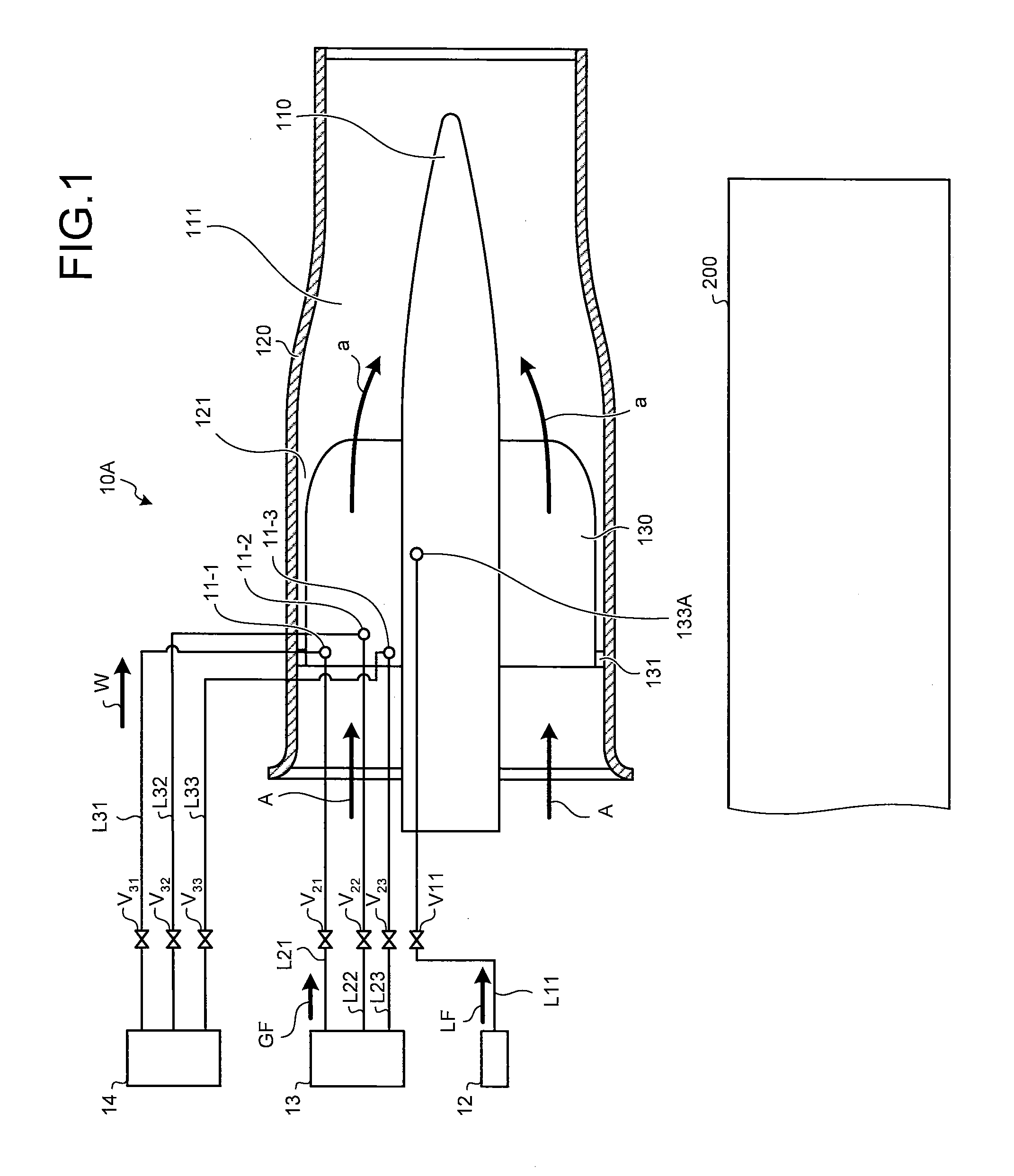

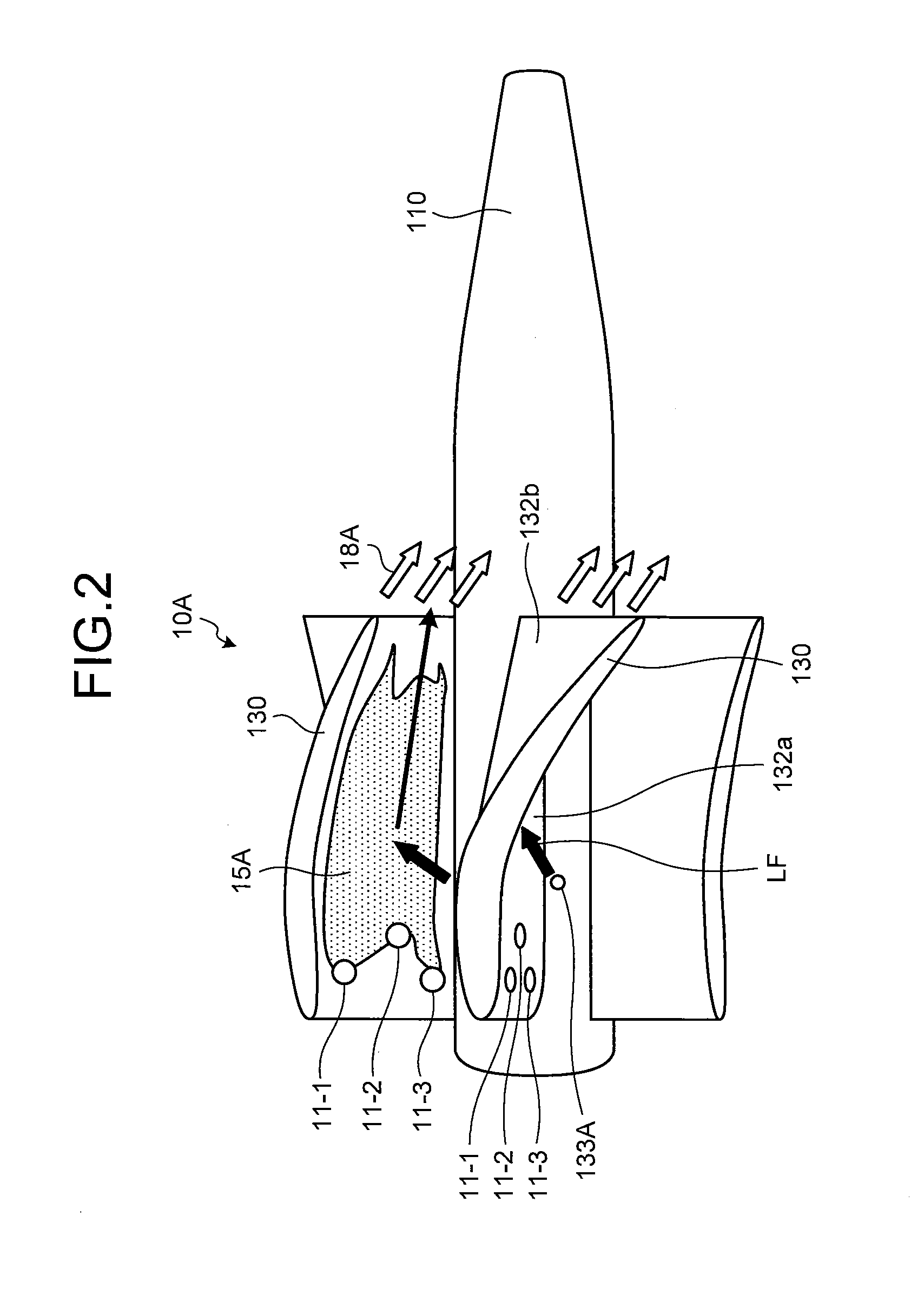

A combustion burner 10A according to one embodiment of the present invention includes: a fuel nozzle 110; a burner tube 120 forming the air passage 111 between the burner tube 120 and the fuel nozzle 110; swirler vanes (swirler vanes) 130 arranged in a plurality of positions in the circumferential direction on the external circumferential surface of the fuel nozzle 110, each extending along the axial direction of the fuel nozzle 110, and gradually curving from upstream toward downstream; and a liquid fuel injecting hole 133A from which a liquid fuel is injected to a surface of each of the swirler vanes 130. The combustion burner 10A also includes multi-purpose injecting holes 11-1 to 11-3 as a cooling unit that cools a part of a vane pressure surface 132a of the swirler vane 130 on which the liquid fuel LF hits. Water is injected through the multi-purpose injecting holes 11-1 to 11-3 to form a water film 15A on the vane pressure surface 132a, whereby a combustion temperature is reduced and formation of carbon deposit is prevented.

Owner:MITSUBISHI POWER LTD

Formula of multifunction fuel and its production process

InactiveCN1513954ALow costWide range of raw materialsLiquid carbonaceous fuelsChemical reactionSecondary component

An environment protection type multifunctional fuel is prepared from 7 primary components including light hydrocarbon, light oil, gasoline, diesel oil, etc and 20 secondary components including sodium hydroxide, water alcohol, hydrogen peroxide, etc. which are divided into 4 groups which take part in chemical reactions to generate cosolvent, oxygen increaser, combustion aid, smoke reducing agent, etc.

Owner:张云

Fuel oil cleaner and use for environmental protection fuel oil

A detergent for fuel oil and its application in environment protection type fuel oil are disclosed. Said detergent contains the component A which is composed of ethanediol ether, diethanediol ether, triethanediol ether and polyether, and the component B which is just the C3-C18 emtrol. Said environment protection type fuel oil contains said detergent, gasoline or diesel oil or similar lipohydrocarbon, and octane number or cetane number increaser.

Owner:朴万成

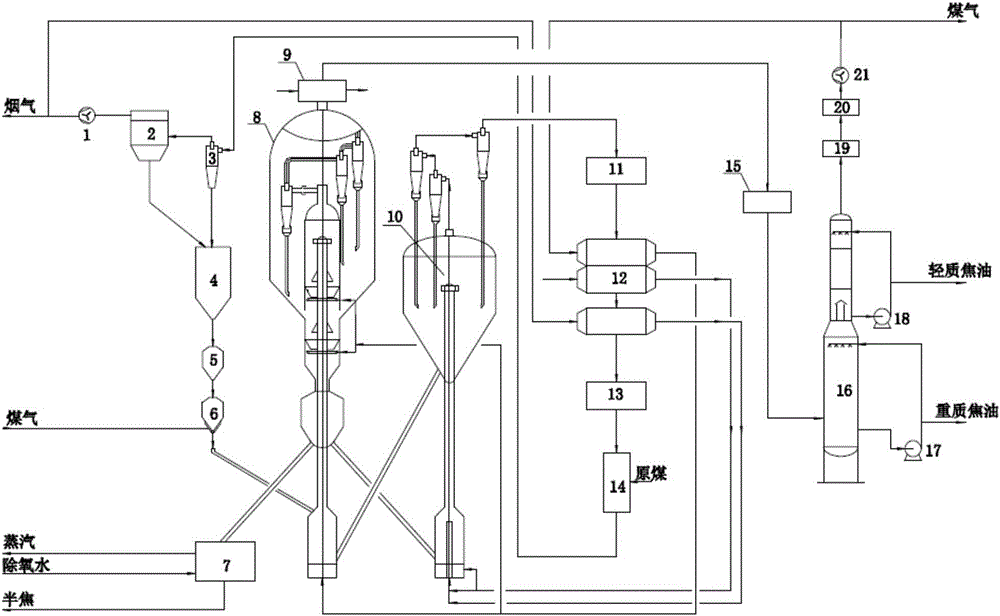

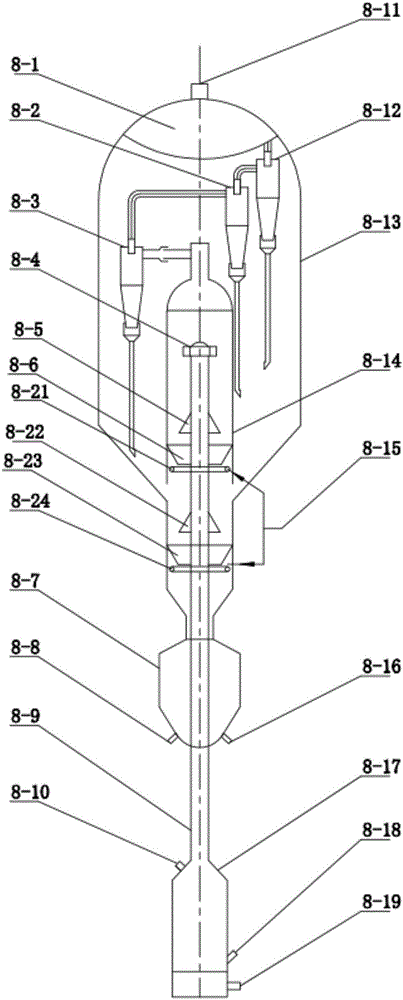

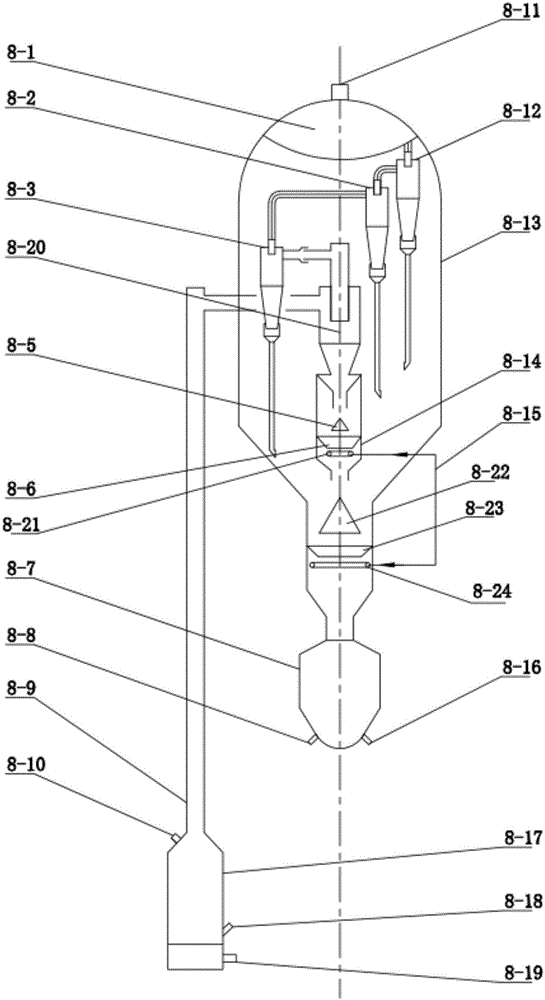

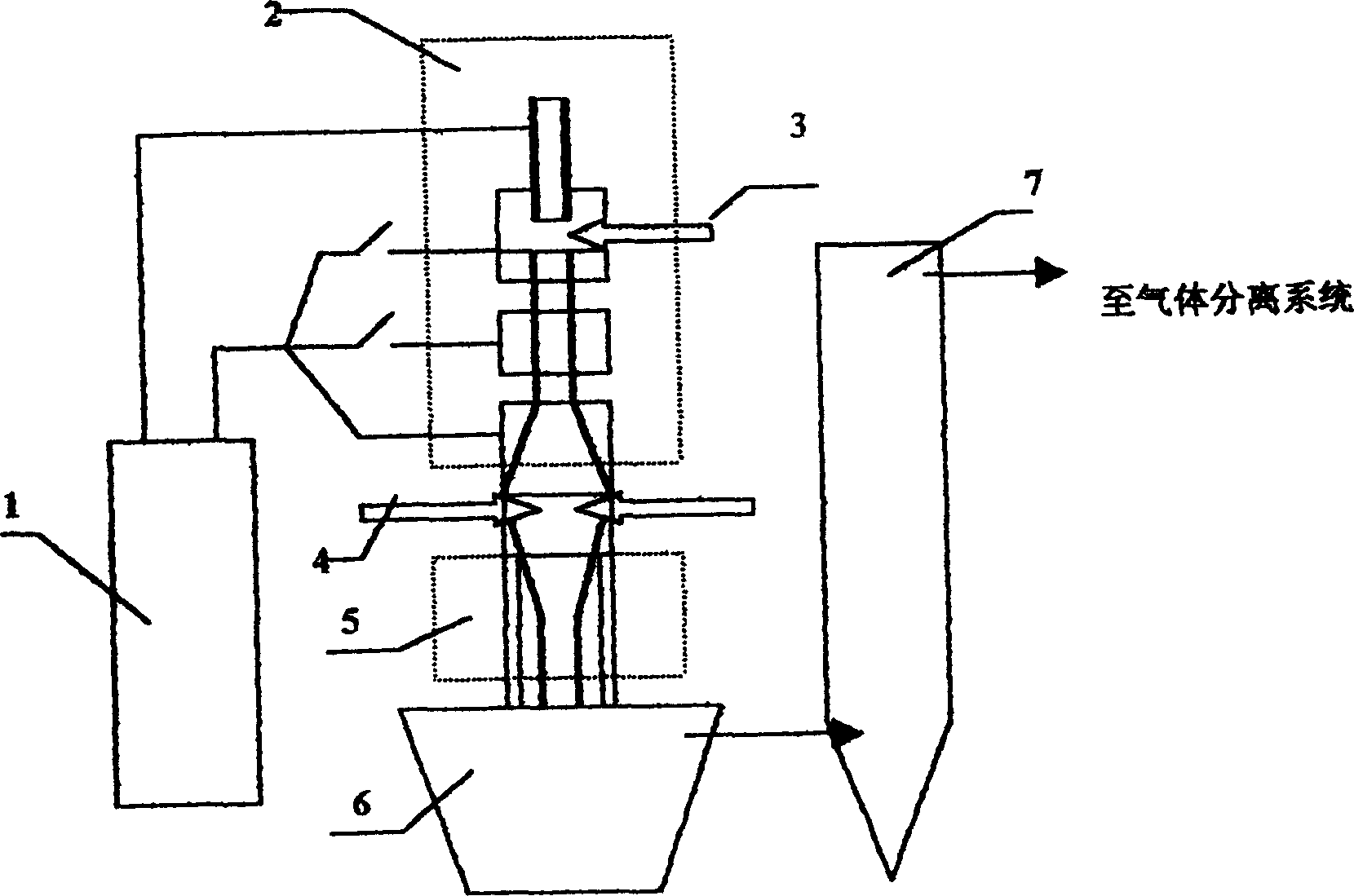

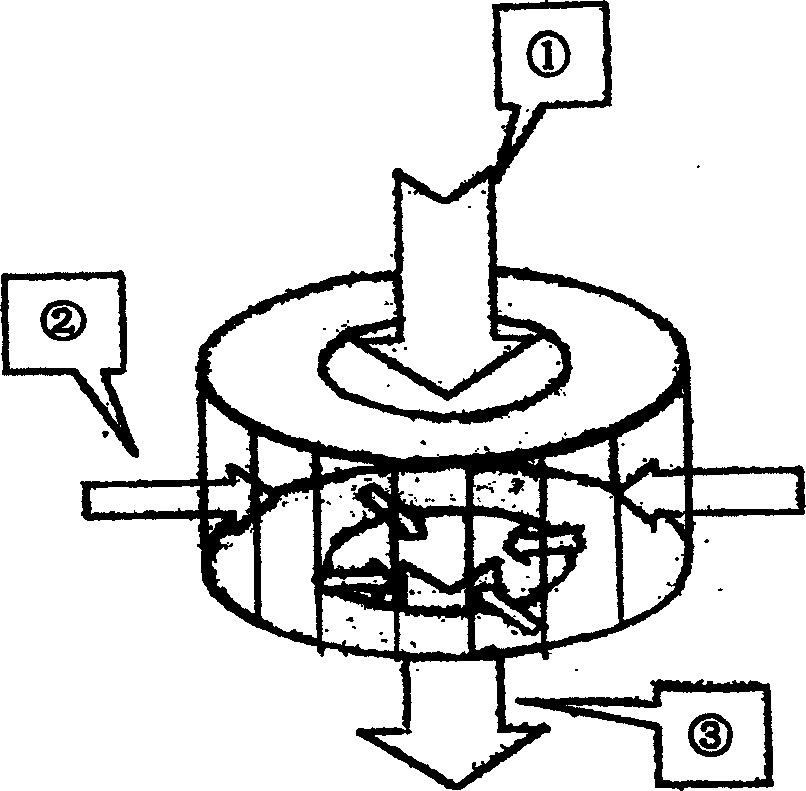

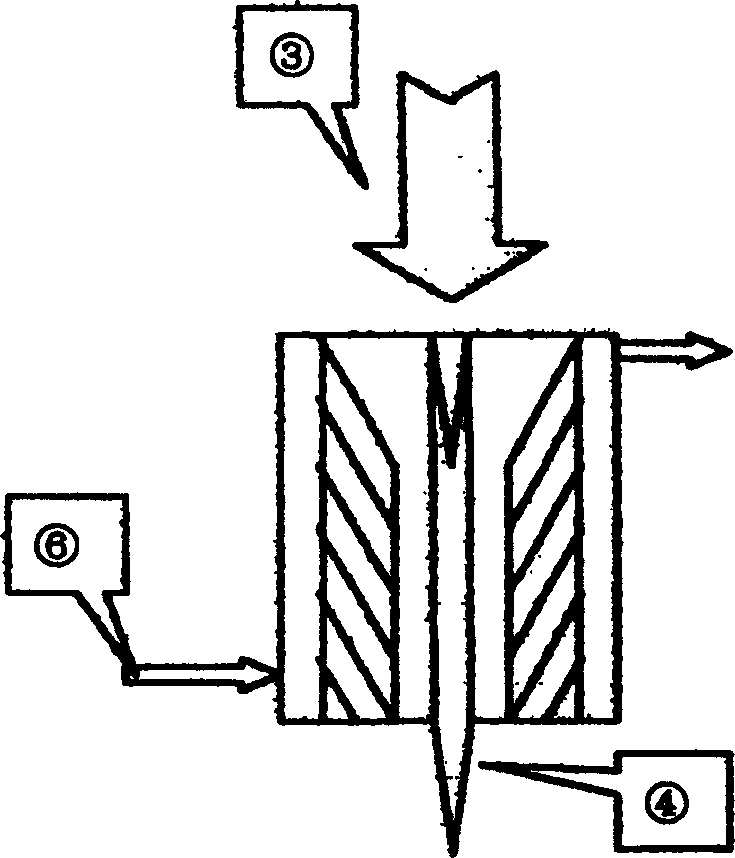

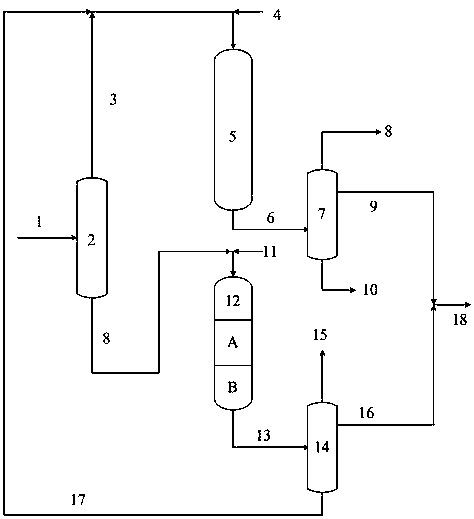

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

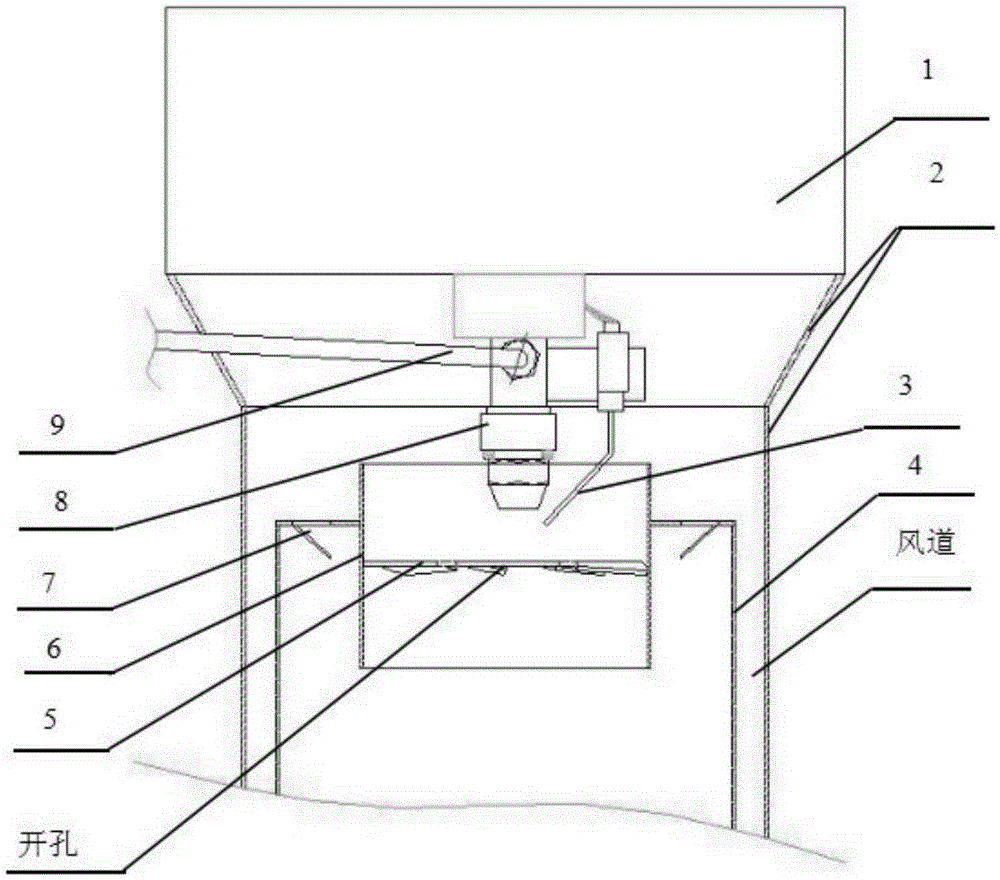

Double-cyclone combustor with primary air distribution structure

InactiveCN105402724AImprove blending effectImprove combustion efficiencyLiquid fuel burnerCycloneCombustion chamber

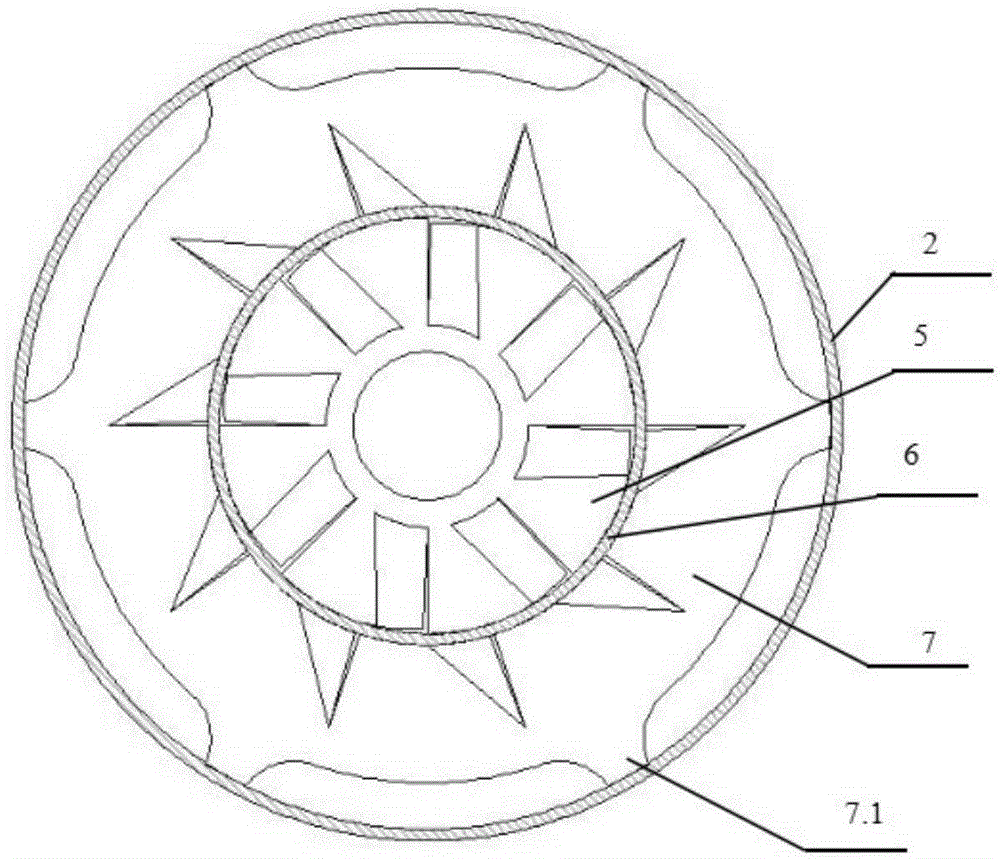

The invention discloses a double-cyclone combustor with a primary air distribution structure; and the double-cyclone combustor consists of a fan, an outer cylinder, an ignition mechanism, an inner cylinder, a cyclone piece, an oil nozzle and an oil way. The double-cyclone combustor is characterized in that cyclone piece blades are set as an inner cyclone blade and an outer cyclone blade; an air stabilizing cylinder penetrating through the inner cylinder along the axis of the inner cylinder is arranged at the top of the inner cylinder; the outer cyclone blade coats the air stabilizing cylinder, and is connected with the outer cylinder through support legs; the inner cyclone blade is arranged in the air stabilizing cylinder; a hole is formed in the center of the inner cyclone blade; and the oil nozzle is positioned rightly above the hole of the inner cyclone blade. The double-cyclone combustor has the following beneficial effects: the fuel and air mixing effect is intensified to improve the combustion efficiency; cyclone air currents are formed in a combustion chamber to form rotating flame so as to improve the combustion stability; and the carbon formation on the wall surface of the combustion chamber is prevented.

Owner:YUNNAN AEROSPACE IND

Combustion burner

ActiveUS20140000264A1Avoid carbon formationInhibition formationTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorEngineering

A combustion burner 10A according to one embodiment of the present invention includes: a fuel nozzle 110; a burner tube 120 forming the air passage 111 between the burner tube 120 and the fuel nozzle 110; swirler vanes (swirler vanes) 130 arranged in a plurality of positions in the circumferential direction on the external circumferential surface of the fuel nozzle 110, each extending along the axial direction of the fuel nozzle 110, and gradually curving from upstream toward downstream; and a liquid fuel injecting hole 133A from which a liquid fuel is injected to a surface of each of the swirler vanes 130. The combustion burner 10A also includes multi-purpose injecting holes 11-1 to 11-3 as a cooling unit that cools a part of a vane pressure surface 132a of the swirler vane 130 on which the liquid fuel LF hits. Water is injected through the multi-purpose injecting holes 11-1 to 11-3 to form a water film 15A on the vane pressure surface 132a, whereby a combustion temperature is reduced and formation of carbon deposit is prevented.

Owner:MITSUBISHI POWER LTD

Low-lead aviation gasoline and production method thereof

ActiveCN104673410ABoost Octane IndexImprove securityLiquid carbonaceous fuelsAviationCombustion chamber

The invention belongs to the technical field of aviation fuel, and discloses a low-lead aviation gasoline and a production method thereof. The low-lead aviation gasoline comprises the following components in percentage by volume: 25%-60% of front-fraction alkylate oil, 18%-60% of super fraction alkylate oil, 10%-22% of methylbenzene, 3%-14% of dimethylbenzene, 10%-21% of carbon-5 and less than 0.53ml / l of lead tetraethyl. These components are mixed under a stirring condition; the isopentane content in the obtained low-lead aviation gasoline reaches 0.5%-22%; the content of isooctane reaches 20%-80%; and the motor octane number is greater than 99.5. The front-fraction alkylate oil and the super fraction alkylate oil are obtained by rectifying alkylate oil; the octane number index in the aviation gasoline is effectively improved; components with relatively much colloid are eliminated; carbon formation in a combustion chamber of an aircraft engine is avoided; and the security of the aircraft is improved.

Owner:DONGYING HUAYA GUOLIAN AVIATION FUEL CO LTD

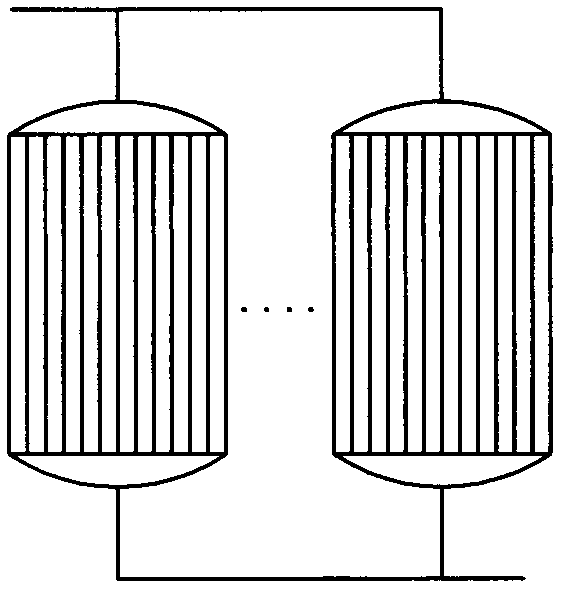

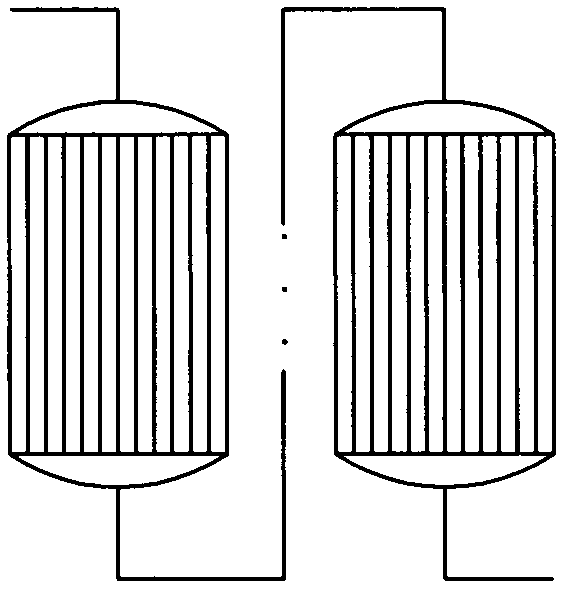

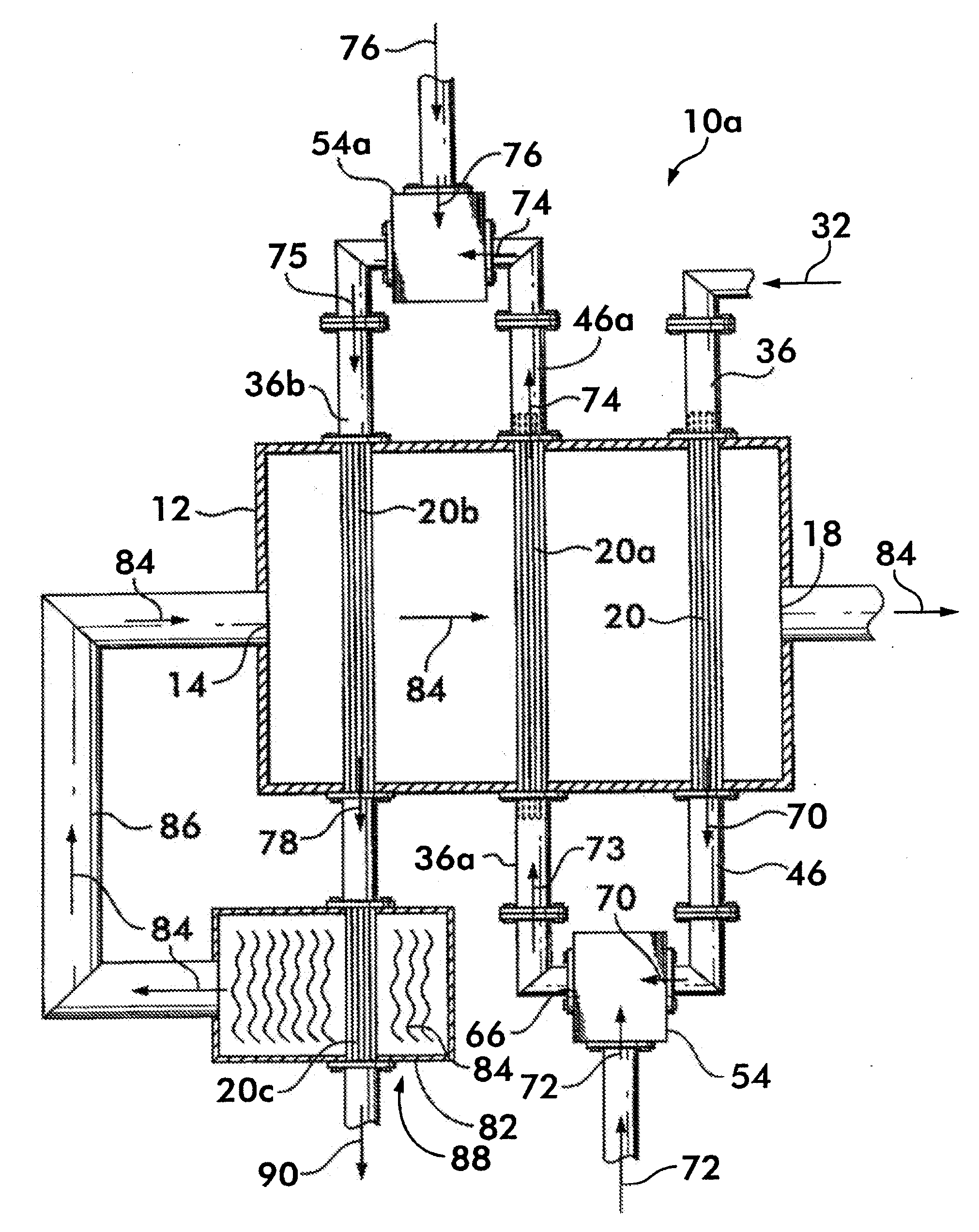

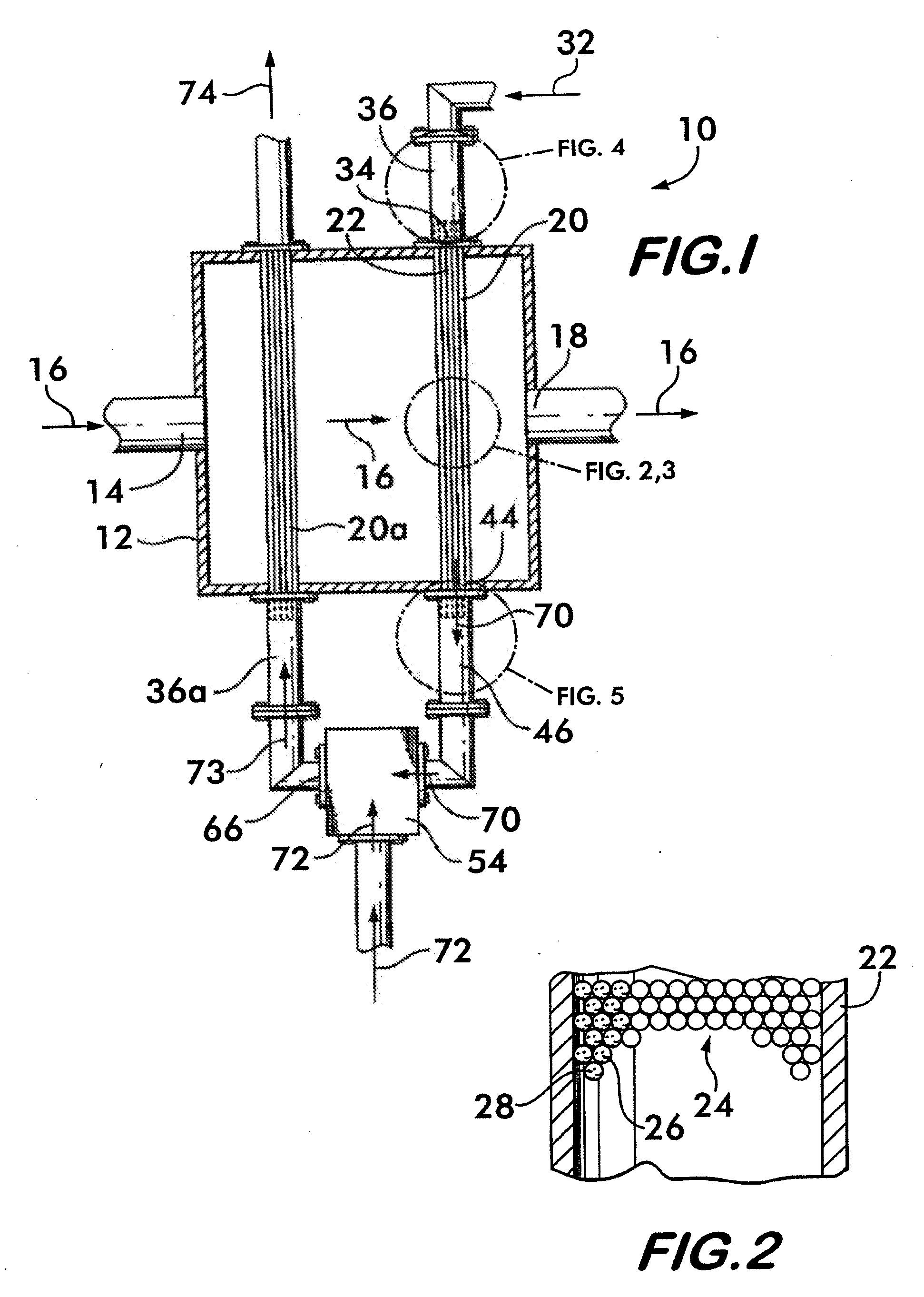

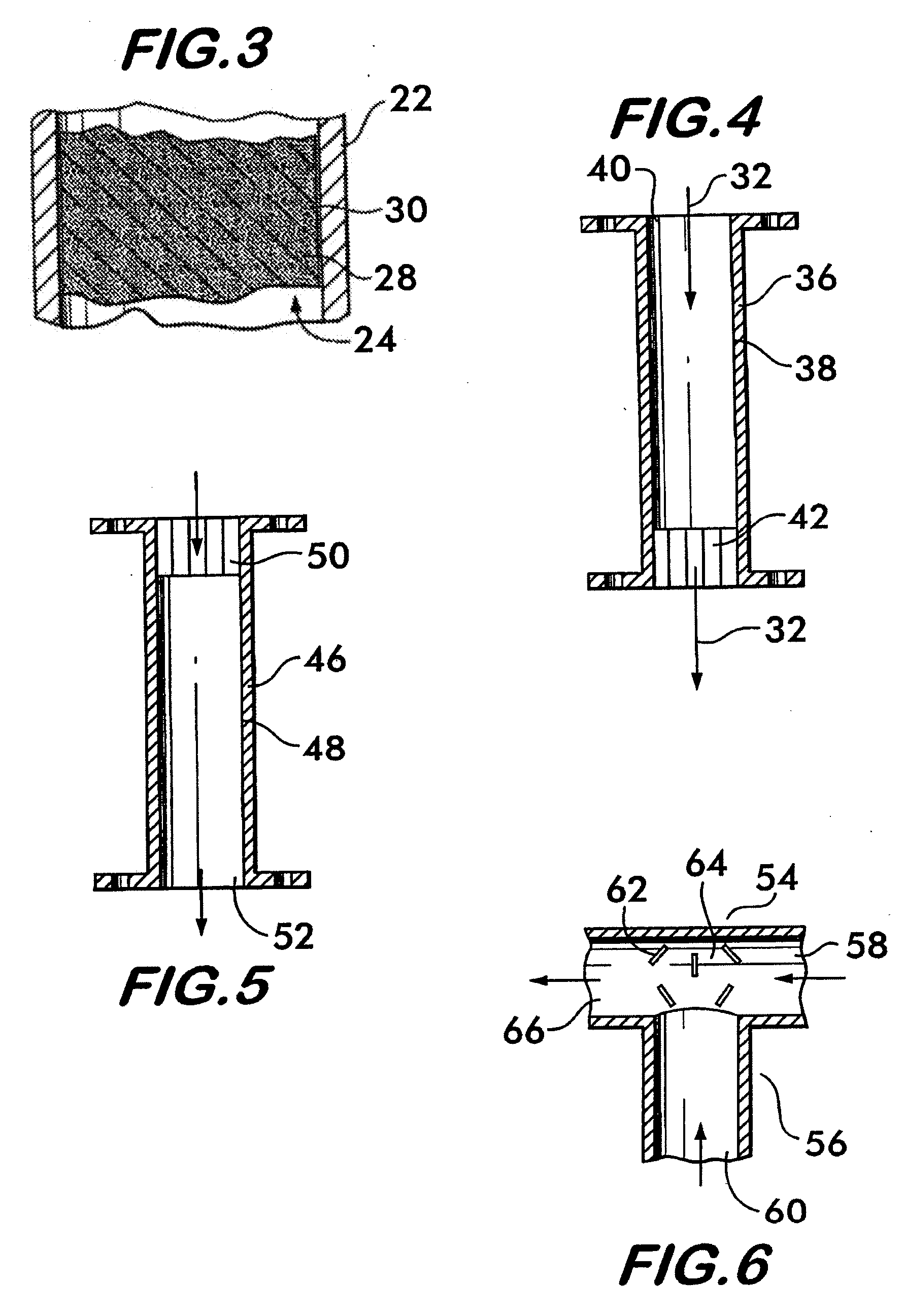

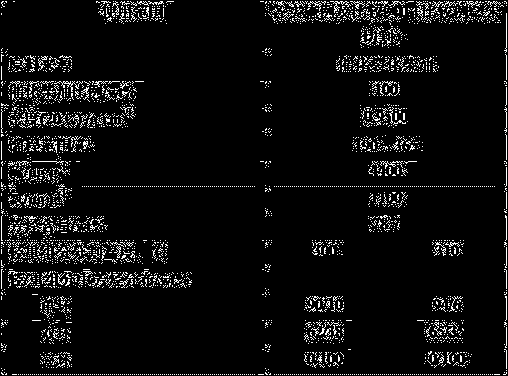

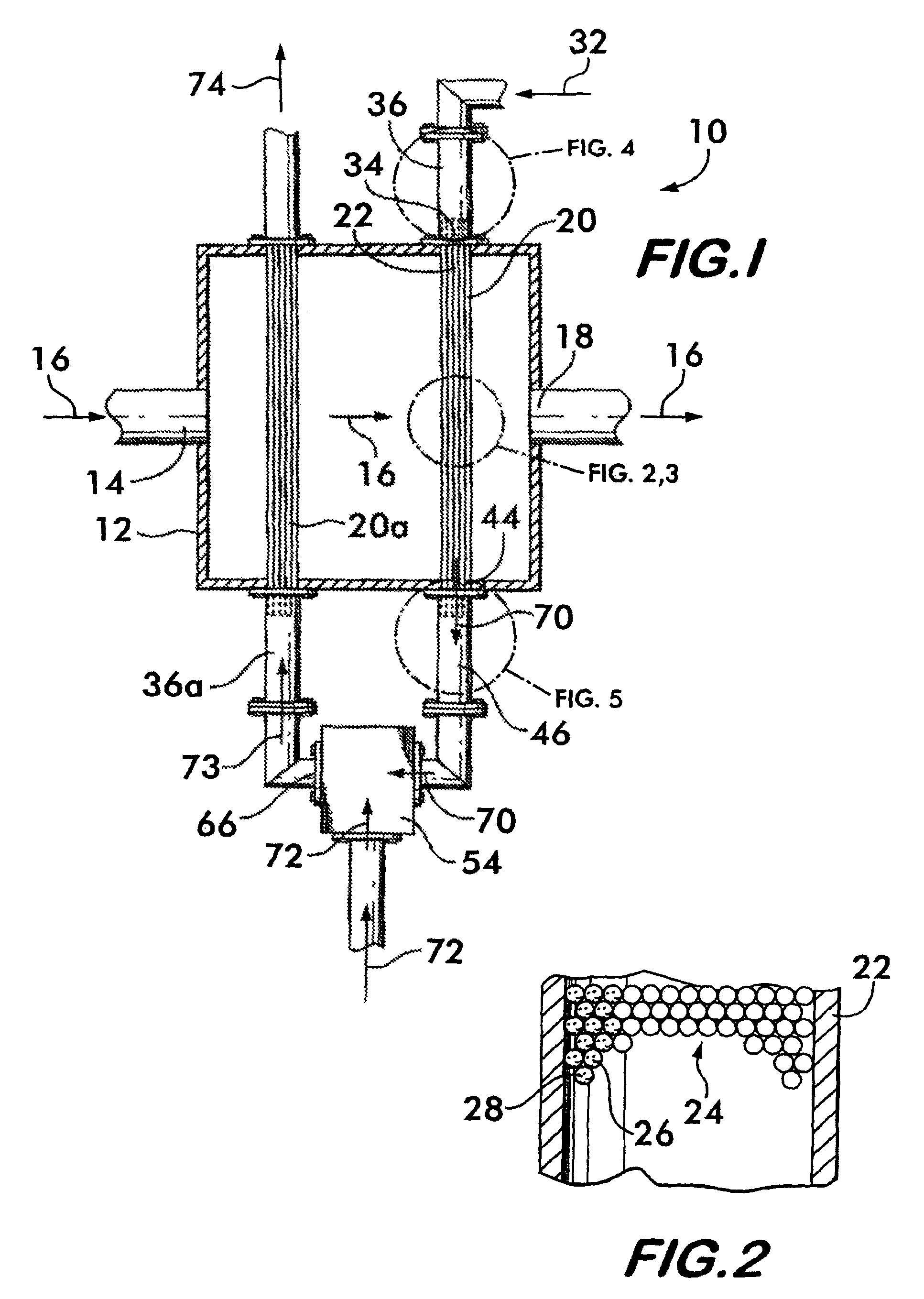

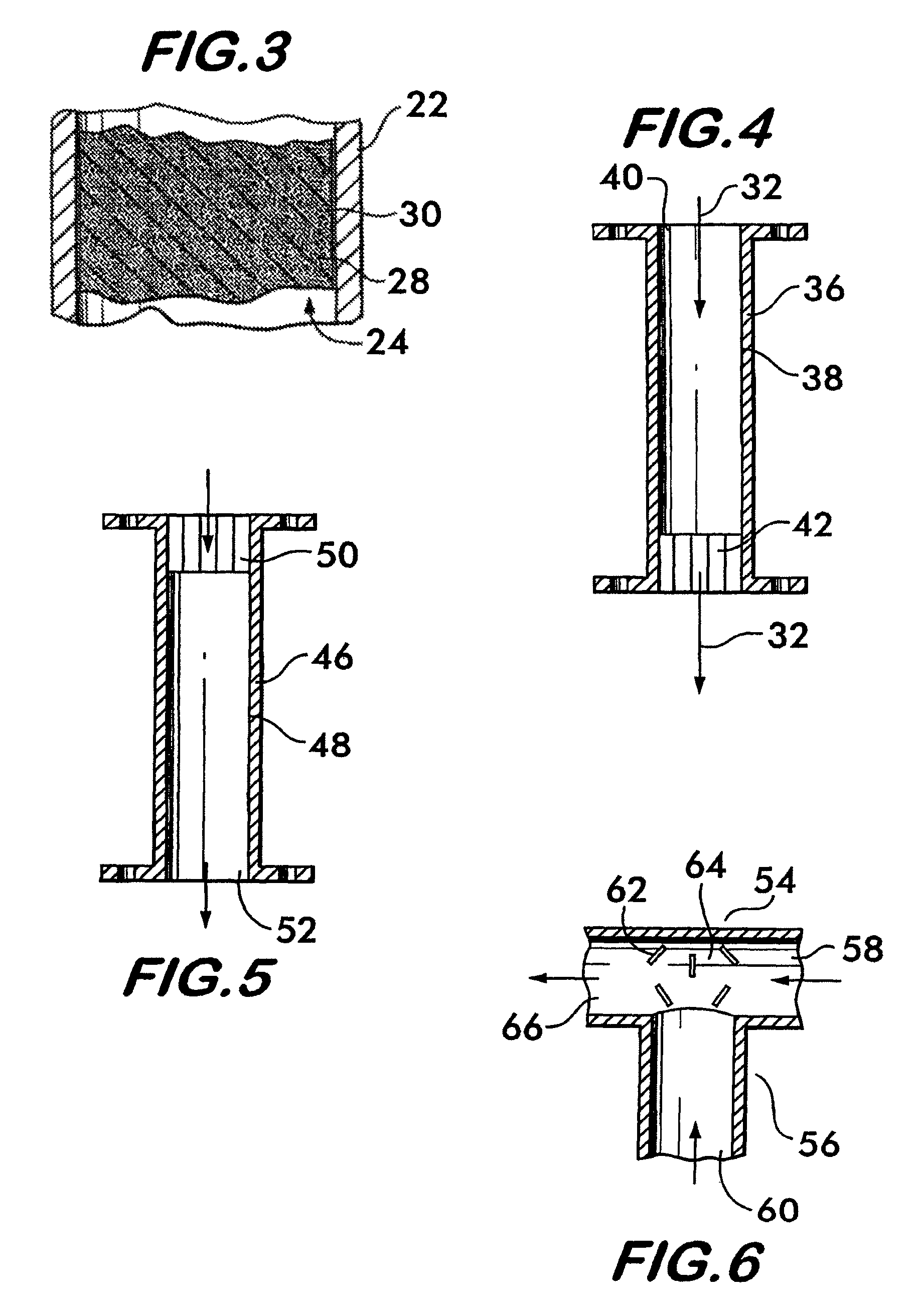

Staged Hydrocarbon/Steam Reformer Apparatus And Method

InactiveUS20090104110A1Increase the concentration of hydrogenLow overall and average steam-to-carbon ratioHydrogenHydrocarbon from carbon oxidesHydrogen concentrationSteam reforming

A staged steam hydrocarbon reformer is disclosed having a chamber within which convectively heated reformer stages are enclosed. The reformer stages are tubes containing steam reforming catalyst. The stages are in serial fluid communication with one another through mixing vessels positioned between each stage. The first reforming stage is fed a mixture of steam and a gaseous hydrocarbon. Partially reformed gases having increased hydrogen concentration are produced at each stage and are mixed with additional gaseous hydrocarbon and optionally steam in the mixing vessels. Collection and distribution manifolds provide fluid communication between the reformer stages and the mixing vessels. A method is also disclosed in which partially reformed gases from a preceding stage are mixed with gaseous hydrocarbon and steam having a lower steam to carbon ratio than the fresh feed to the previous stage.

Owner:AIR PROD & CHEM INC

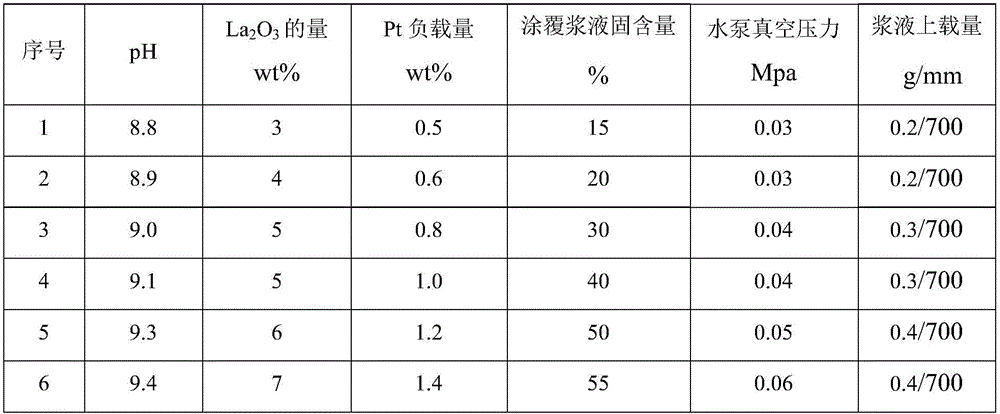

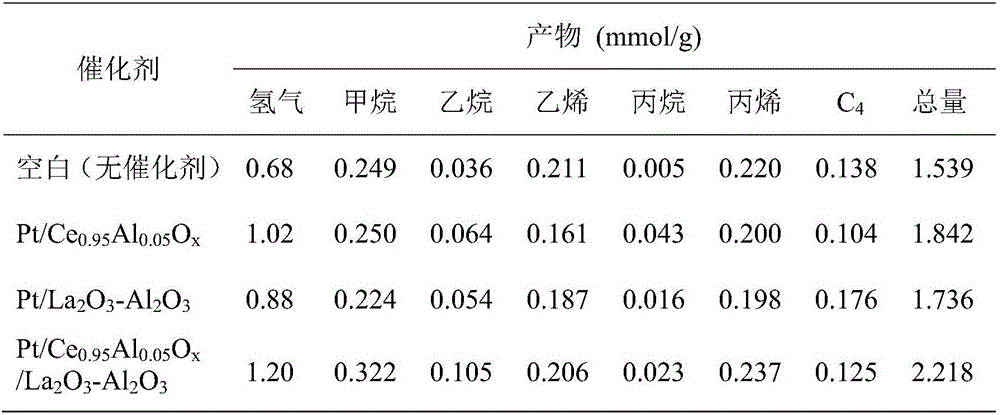

Preparation and application of dual-function catalyst Pt/Ce0.95Al0.05Ox/La2O3-Al2O3

InactiveCN105879870AHigh yieldStrong cracking activityCatalytic crackingHeterogenous catalyst chemical elementsCombustionAlkali metal oxide

The invention provides a Pt / Ce 0.95 Al 0.05 o x / La 2 o 3 ‑Al 2 o 3 The preparation method and application of the quasi-bifunctional catalyst are modified by adding additives, and the modified species include alkali metal oxides, alkaline earth metal oxides and rare earth metal oxides. The alkali metal oxides, alkaline earth metal oxides and rare earth metal oxide additives added in the catalyst of the present invention have the effect of inhibiting the formation of carbon deposits, which can effectively prevent the contact between the catalyst and the metal (stainless steel), reduce metal catalytic coking, It can also effectively reduce the impact of additives on oil, and can also change the path of cracking reaction through coking inhibitors, reduce the number of free radical coke, and make the cracking reaction proceed as far as possible to produce small molecule olefins with better combustion performance.

Owner:SICHUAN UNIV

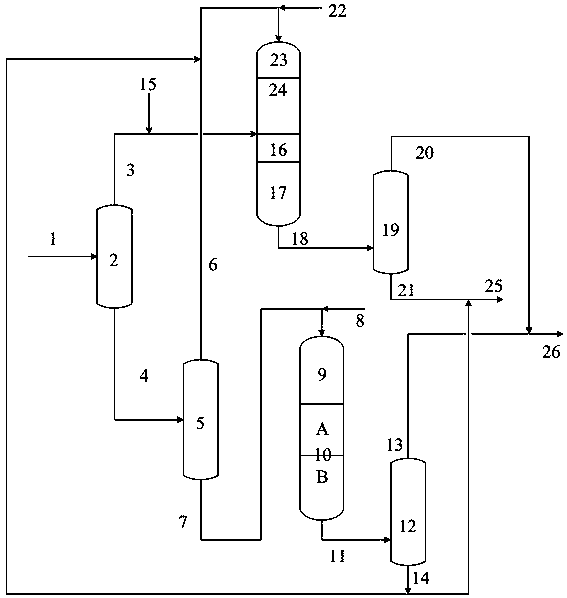

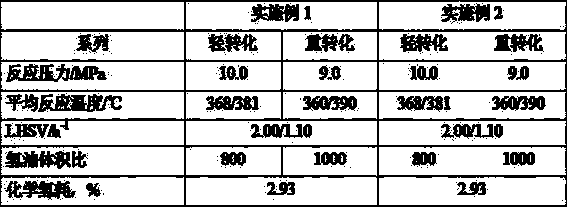

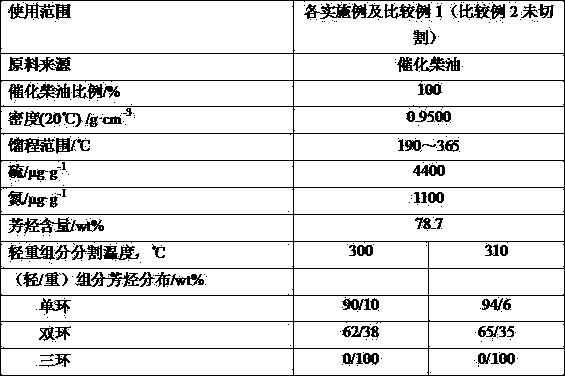

Processing treatment method of catalytic diesel

ActiveCN108102709AEasy to handleImprove targetingHydrocarbon oil crackingTreatment with hydrotreatment processesGasolineHydrocarbon

The invention discloses a processing treatment method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjectedto hydrofining and hydro-conversion reactions, and gasoline and diesel components are obtained; the heavy components are separated, and a triaromatic hydrocarbon component and a non-triaromatic hydrocarbon component are obtained; the non-triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, the triaromatic hydrocarbon component is subjected to hydrofining and hydro-conversion, and gasoline components and diesel components are obtained; a gasoline product is obtained after gasoline from all parts is mixed, and a diesel product is obtained after diesel components from all parts are mixed. Through the reasonable separation and processing process, different types of raw materials can be selectively and independently processed, so that qualified gasoline and dieselproducts can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

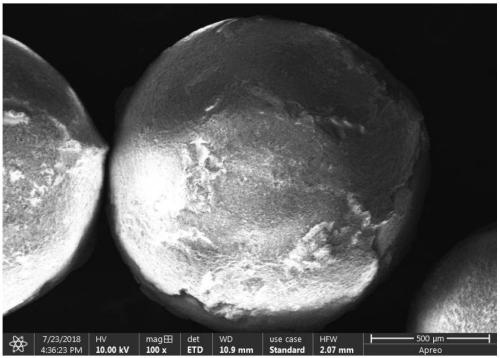

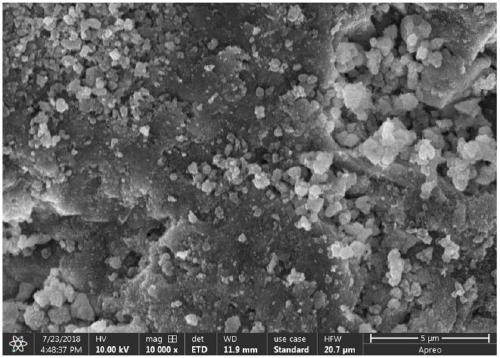

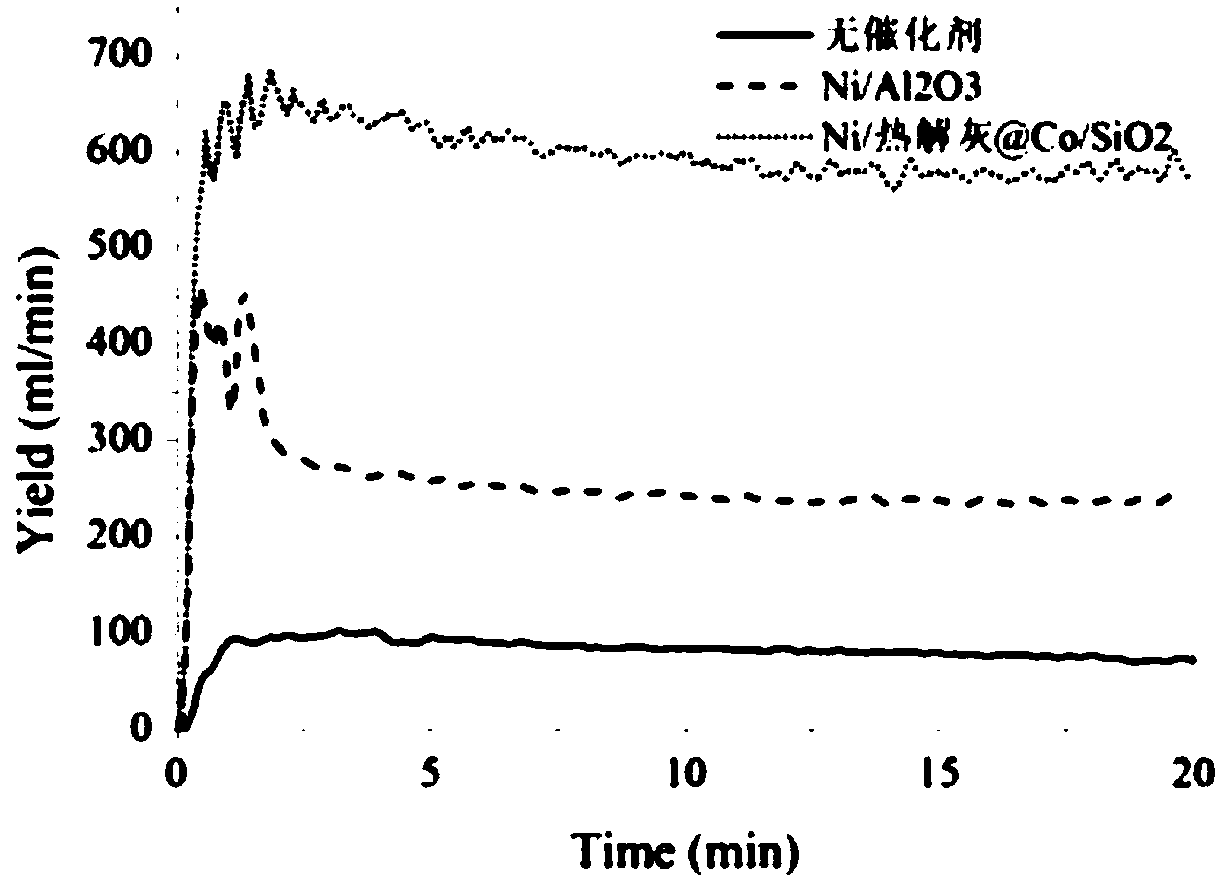

Core-shell catalyst, preparation method thereof and application of core-shell catalyst in hydrogen production by reforming

InactiveCN109603843AExtended service lifeEasy to prepareHydrogenHydrogen/synthetic gas productionCarbon depositCore shell

The invention provides a core-shell catalyst, a preparation method thereof and an application of the core-shell catalyst in hydrogen production by reforming, and belongs to the technical field of catalysts. The catalyst provided by the invention has a core-shell structure, catalytic activity of an active metal of an inner core can be protected, and carbon deposit coverage caused by a reforming reaction is avoided; biomass pyrolysis ash in the inner core of the catalyst has a porous structure, and the active metal of the inner core can be effectively supported, so that catalytic activity centers are uniformly distributed; and a catalyst outer shell supports a shell-layer active metal, and the shell-layer active metal can catalyze a carbon deposition reaction, inhibit generation of depositedcarbon, and promote consumption of the deposited carbon, so that the service life of the catalyst is prolonged. The invention provides the preparation method of the core-shell catalyst, and the method is simple and is easy to operate. The invention further provides the application of the core-shell catalyst in a reforming hydrogen production reaction.

Owner:SHANDONG UNIV OF TECH

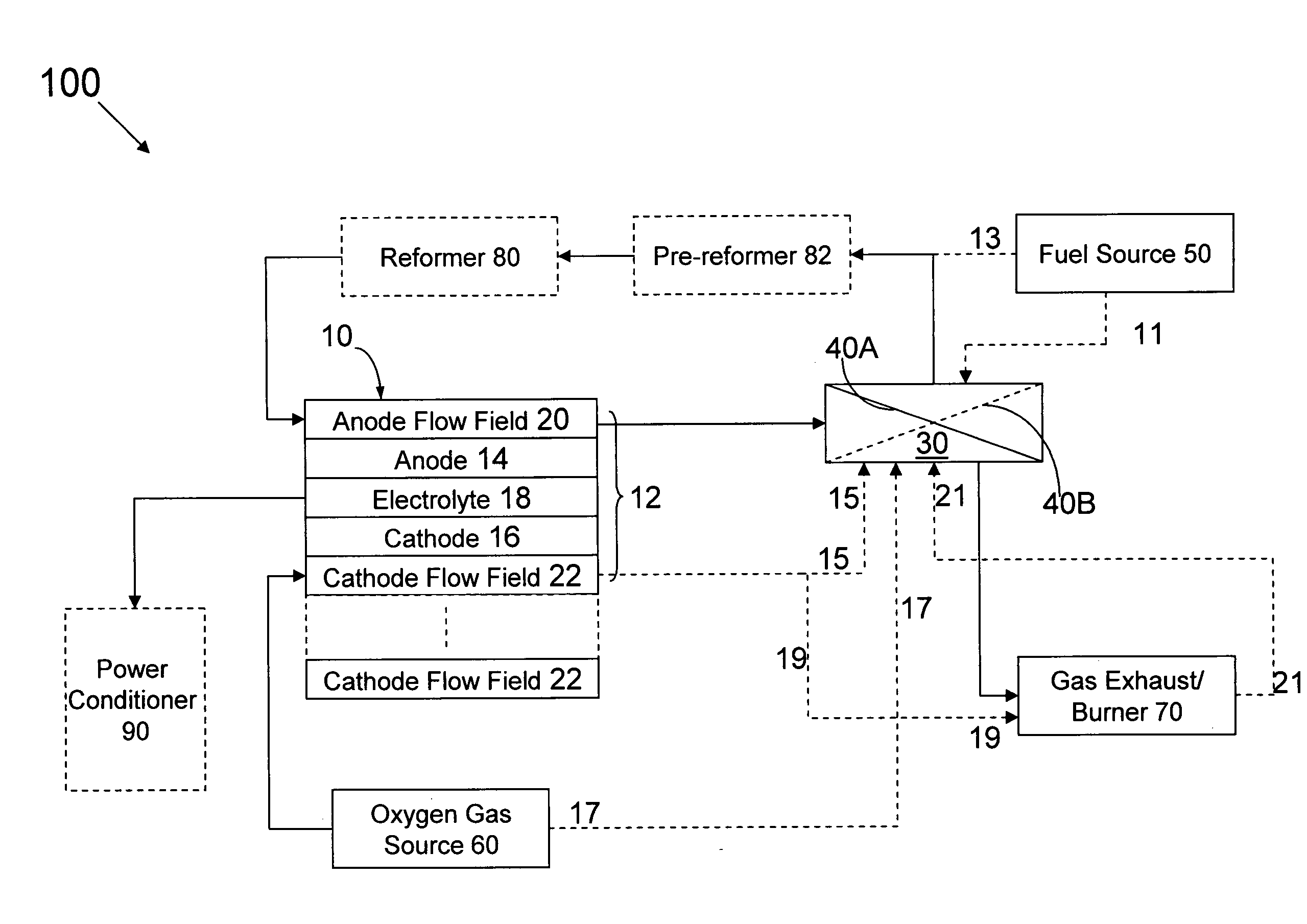

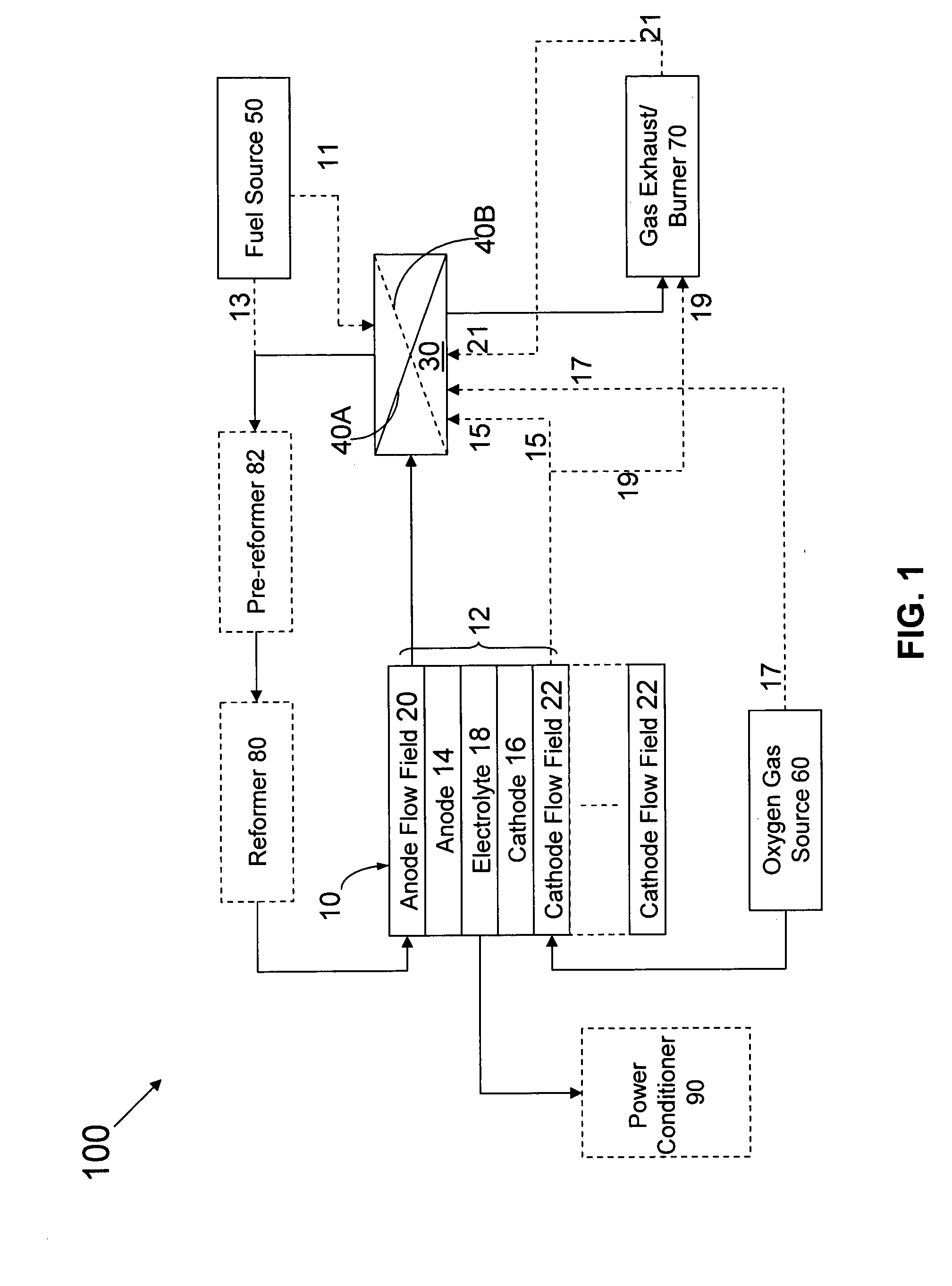

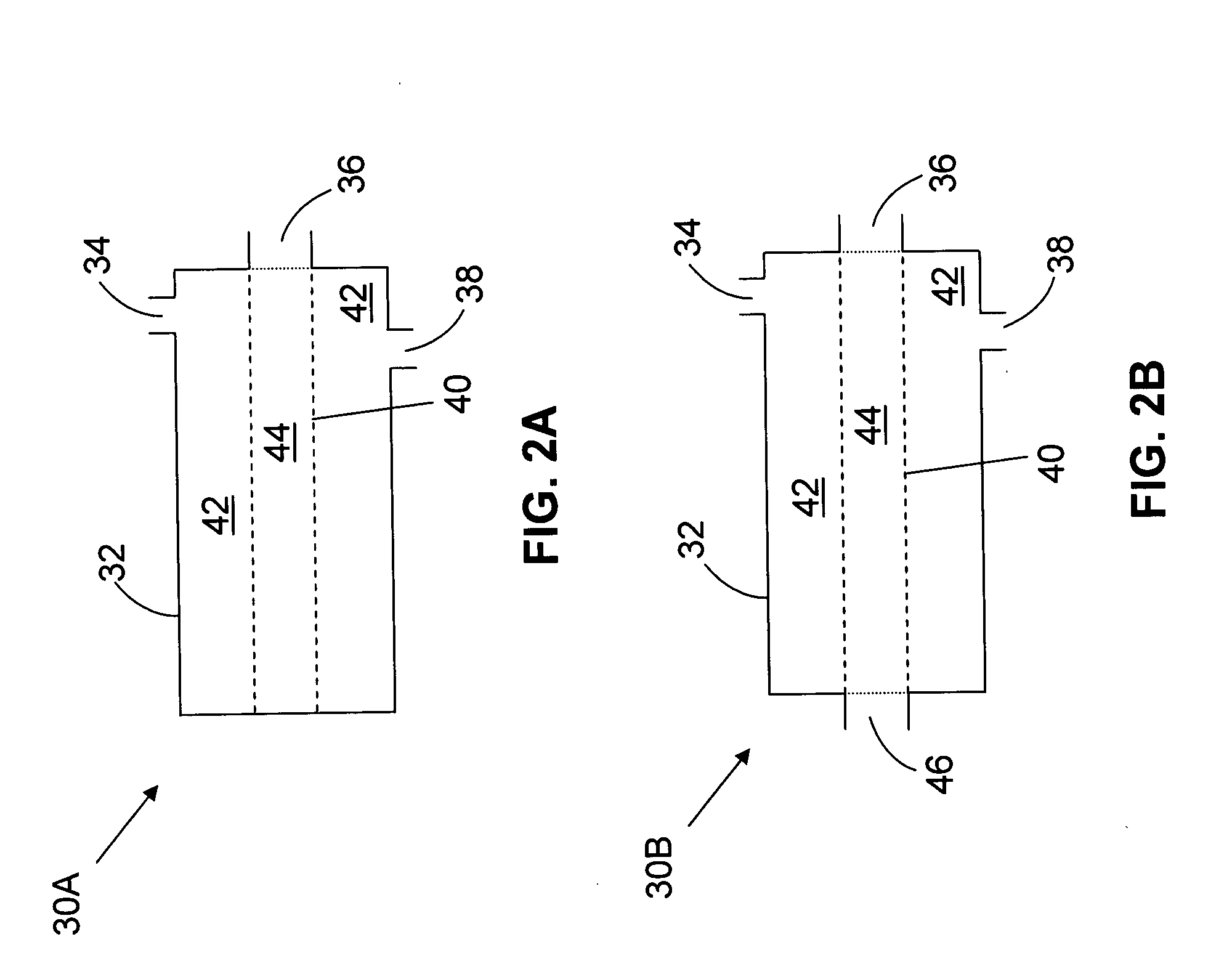

Anode exhaust recycle system

InactiveUS20090047557A1Improve efficiencyImprove fuel efficiencyPrimary cellsElectrode carriers/collectorsFuel cellsEngineering

A fuel cell system includes a fuel cell stack including at least one fuel cell and a separator. Each fuel cell includes a cathode, an anode and an electrolyte between the cathode and the anode. The separator includes a membrane, and a housing defining an anode exhaust inlet, a recycled gas outlet and an exhaust gas outlet. The anode exhaust inlet and the recycled gas outlet are independently in fluid communication with the anode. The housing and the membrane defines at least in part a first chamber that is in fluid communication with the anode exhaust inlet, and a second chamber. In one embodiment, the membrane is an H2-gas permeable membrane, the recycled gas outlet is in fluid communication with the second chamber, and the exhaust gas outlet is in fluid communication with the first chamber. In another embodiment, the membrane is a CO2-gas permeable membrane, the recycled gas outlet is in fluid communication with the first chamber, and the exhaust gas outlet is in fluid communication with the second chamber.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Nickel-based composite catalyst for methane reforming with carbon dioxide to produce synthesis gas under pressurization

ActiveCN108620079ARemove surface carbonHigh catalytic activity and stabilityHydrogenHeterogenous catalyst chemical elementsComposite oxideCarbon dioxide

The invention discloses a nickel-based composite catalyst for methane reforming with carbon dioxide to produce a synthesis gas under pressurization. A carrier of the catalyst is at least one selectedfrom SiO2, Al2O3 and TiO2, an active component is Ni, Ni-Fe or Ni-Co, and an auxiliary agent is one selected from composite oxides such as CeO2-La2O3, CeO2-Sm2O3, CeO2-Pr6O11, CeO2-Nd2O3 and CeO2-Y2O3; based on a mass of the catalyst of 100%, the catalyst comprises 5%-15% of the active component, 3%-15% of the auxiliary agent, and the balance of the carrier; and the catalyst is prepared by adopting a coordination-decomposition method with glycine, alanine, threonine, citric acid and oxalic acid as a coordination-combustion improver. The catalyst disclosed by the invention has a simple preparation process and lower costs, and is economic and environmentally friendly; and the catalyst has a higher methane and carbon dioxide conversion rate for methane reforming with the carbon dioxide underthe pressurization, exhibits high activity, high stability and extremely high resistance to carbon deposition and sintering.

Owner:SHAANXI NORMAL UNIV

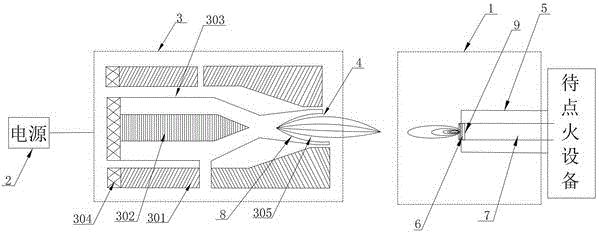

Non-impact self-adaptive trigger ignition device utilizing laminar flow plasma system

ActiveCN106304593AAchieve one ignitionAvoid arc breakingElectric spark ignitersPlasma techniquePlasma jetPlasma generator

The invention discloses a non-impact self-adaptive trigger ignition device utilizing a laminar flow plasma system, and belongs to the technical field of ignition equipment. The non-impact self-adaptive trigger ignition device comprises the laminar flow plasma system and an ignition nozzle. The laminar flow plasma system comprises a power supply, a laminar flow plasma generator and a jet nozzle, wherein the power supply is connected with the laminar flow plasma generator, and the jet nozzle and the laminar flow plasma generator are connected detachably. The ignition nozzle is arranged on equipment to be ignited, and comprises a shell, an ignition electrode and a guide tube, wherein the ignition electrode is arranged at the front end of the guide tube, the guide tube extends into the equipment to be ignited, and the shell is arranged outside the ignition electrode and the guide tube. The central axis of the jet nozzle coincides with the central axis of the ignition nozzle. The central axes of an electric arc channel, the jet nozzle and the ignition nozzle coincide, plasma is emitted along the central axis, an electric arc guidance effect is achieved through the design, the ignition steps are simplified, the ignition difficulty is reduced, ignition is achieved at a time with working gas, and meanwhile stability of laminar flow electric arc hot plasma jet is ensured.

Owner:四川金虹等离子技术有限公司

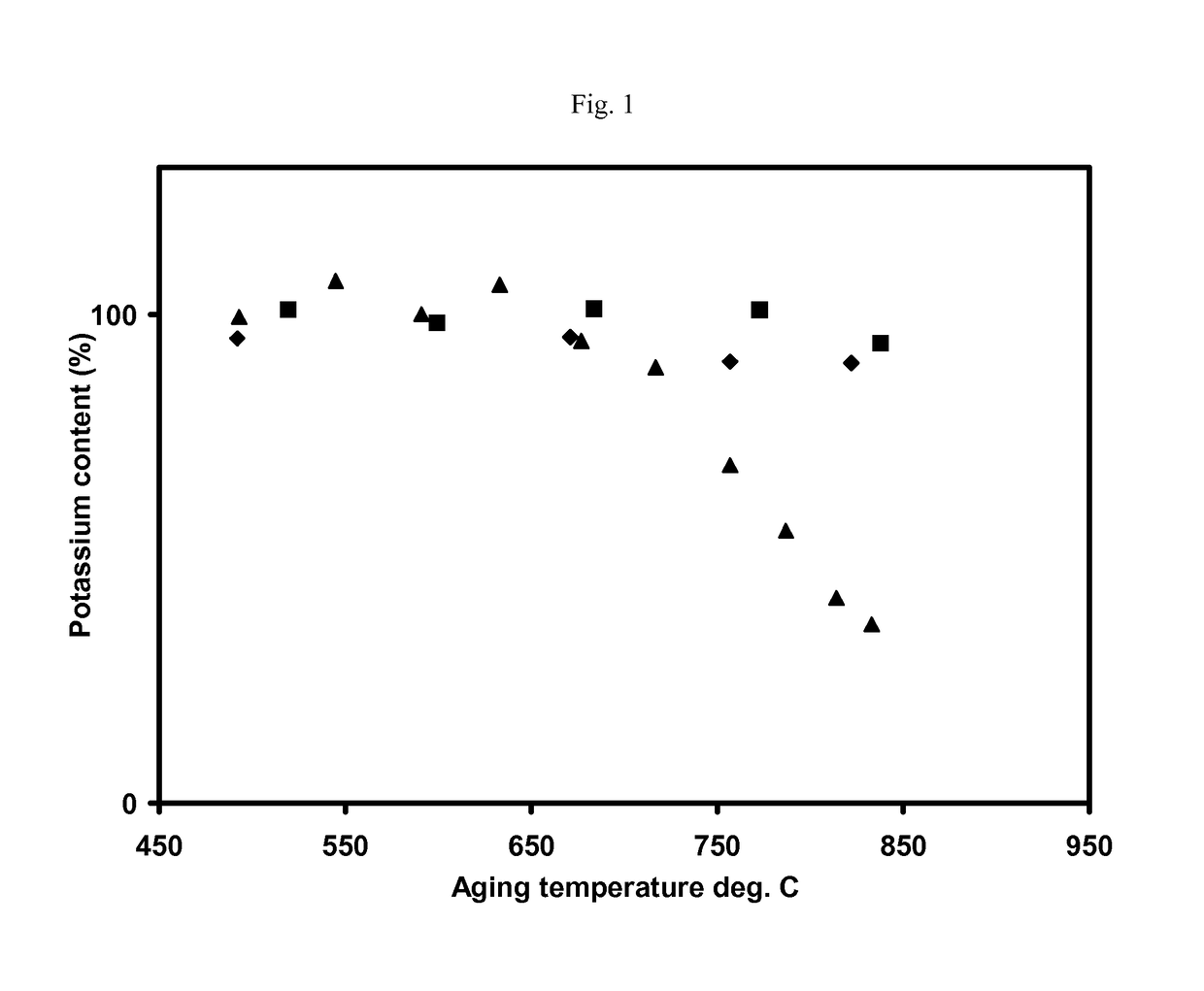

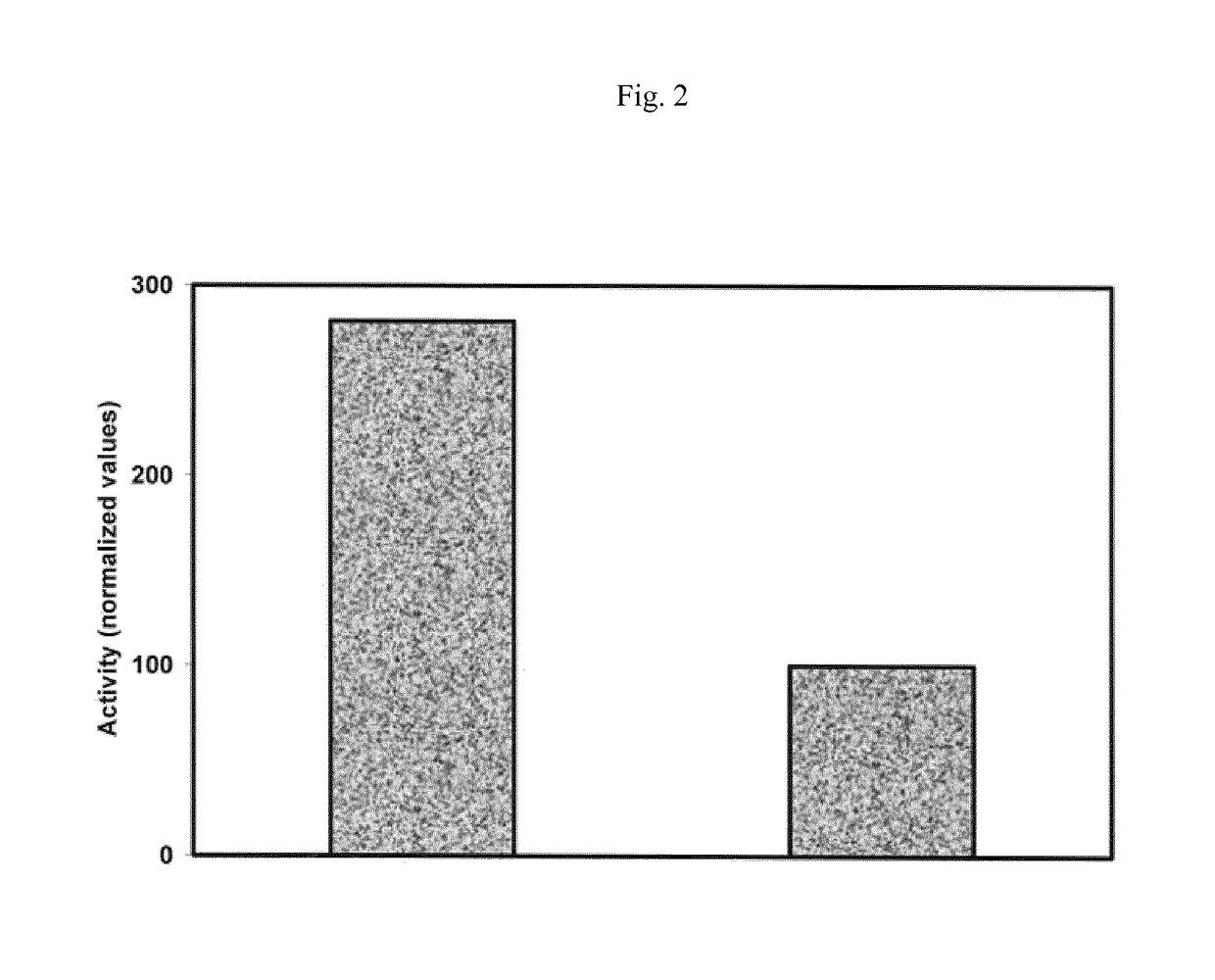

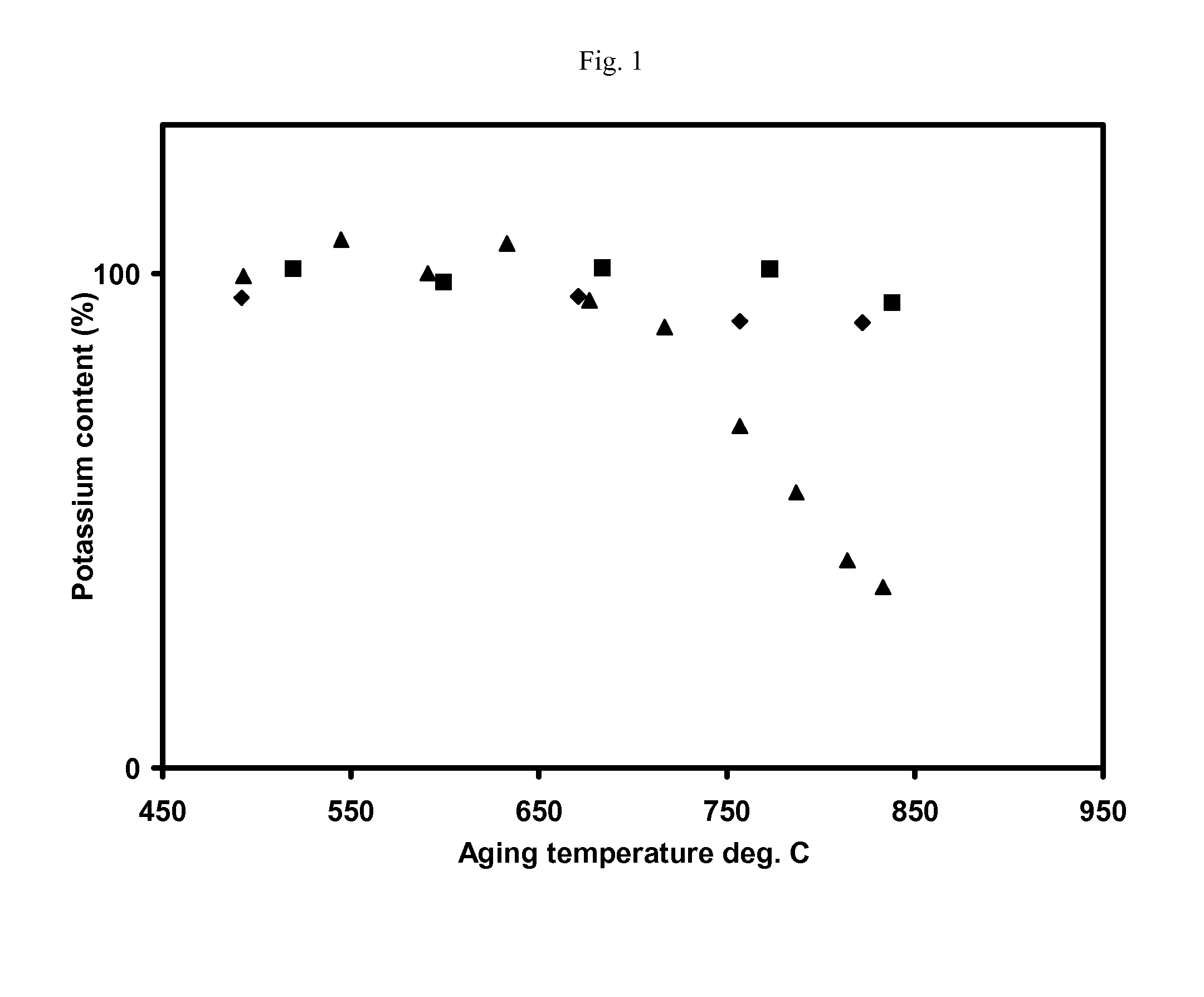

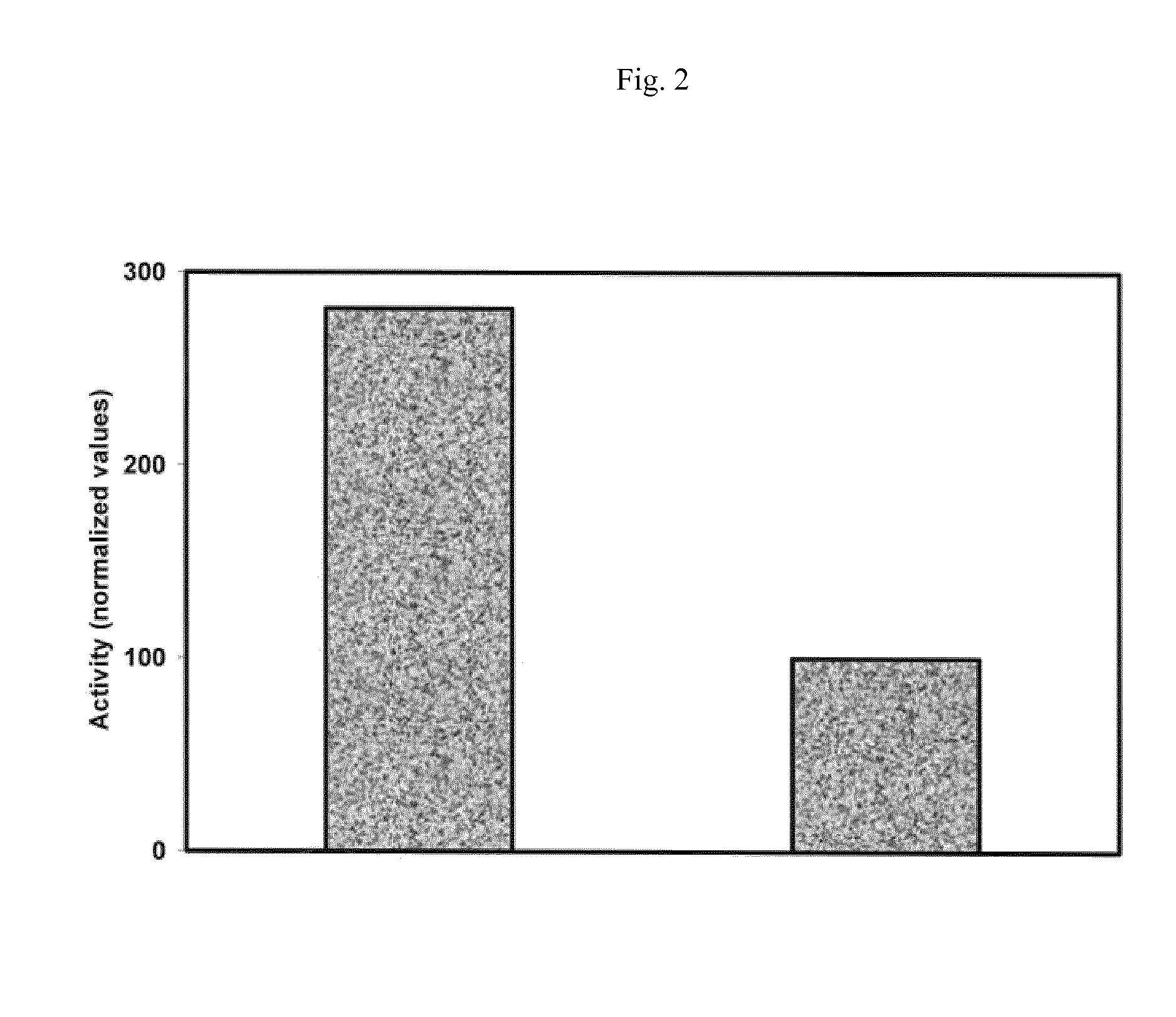

Preparation method and application of light alkane dehydrogenation catalyst with high thermal stability

InactiveCN104289220AImprove thermal stabilityHigh dehydrogenation activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlkaline earth metal

The invention discloses a preparation method and application of a light alkane dehydrogenation catalyst with high thermal stability. The light alkane dehydrogenation catalyst with high thermal stability is a PtSn load-type catalyst which uses Si-containing gamma-Al2O3 pellets as a carrier, and the catalyst also contains rare-earth metal elements, alkali metal elements and / or alkaline earth metal elements as auxiliaries; an element Si in the Si-containing gamma-Al2O3 pellet carrier accounts for 0.1-30 percent by weight; based on the weight of the Si-containing gamma-Al2O3 pellet carrier, the content of an element Pt loaded on the carrier is 0.3-0.5 percent by weight, the content of an element Sn is 0.6-1.0 percent by weight, the content of the rare-earth metal elements is 0.8-1.0 percent by weight, and the content of the alkali metal elements or the alkaline earth metal elements is 0.2-1.0 percent by weight. The catalyst is suitable for being used under light alkane dehydrogenation process conditions such as high temperature, long time and multiple regeneration, and is high in light alkane conversion rate and stability.

Owner:南京沃来德能源科技有限公司

Method for preparing acetylene by hot plasma cracking methane containing gas

InactiveCN1235846CImprove conversion rateHigh yieldHydrocarbon by hydrocarbon condensationHydrocarbon by hydrocarbon crackingPlasma jetPlasma generator

A process for preparing acetylene by using hot plasma to crack the gas containing methane includes such steps as using plasma generator to ionize the argon or N2 or H2 to form a plasma jet, spraying raw gas via a gas inlet ring in reactor, mixing the plasma jet with the raw gas in the reactor, cracking reacting, and quickly cooling the cracked gas in an expansion cavity of cooler to obtain acetylene, carbon black and H2.

Owner:德阳市旌能天然气有限公司 +1

Oxidation inhibitors for alcohol fuel engine lubricating oil and preparation method thereof

The invention discloses oxidation inhibitors of different proportions for alcohol fuel engine lubricating oil and a preparation method thereof. The oxidation inhibitors are a group of composite additives composed of 5 to 45% of N-phenyl-alpha-naphthylamine, 3 to 35% of 2,5-mercaptothiadiazole, 10 to 60% of aminoborate, 15 to 40% of modified low-base number petroleum calcium sulfonate and 5 to 10% of dilution oil. The preparation method comprises the following steps: heating dilution oil to 55 to 65 DEG C; then successively adding N-phenyl-alpha-naphthylamine, 2,5-mercaptothiadiazole, aminoborate and modified low-base number petroleum calcium sulfonate; and carrying out stirring at a constant temperature of 45 to 50 DEG C for no less than 45 min so as to obtain the oxidation inhibitors. 3.5 to 5% of the oxidation inhibitors are added into in-use internal combustion engine oil, so oxidation and decay of alcohol fuel engine lubricating oil can be effectively inhibited, the service life of engine lubricating oil is prolonged, and carbon formation in an engine is reduced. The oxidation inhibitors are convenient to use.

Owner:HARBIN UNIV OF COMMERCE

Processing method of catalytic diesel

ActiveCN108102702AHigh Yield High OctaneReduced activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsContact reactionGasoline

The invention discloses a processing method of catalytic diesel. Raw materials of the catalytic diesel are cut into light components and heavy components; the light components are subjected to a conversion reaction in a bed layer containing a light aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and converted diesel are obtained; the heavy components are subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, and converted gasoline and diesel fractions are obtained; the diesel fractions obtained through conversion of heavy componentsare subjected to a contact reaction with a heavy aromatic hydrocarbon hydro-conversion catalyst, a reaction effluent is then subjected to a contact reaction with a light component hydro-conversion catalyst; the converted gasoline obtained from each part is mixed, and high-quality gasoline is obtained. Through the reasonable separation and processing process, different types of raw materials can beselectively and independently processed, so that the qualified gasoline product with high octane value can be produced through reasonable utilization of inferior catalytically cracked diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of catalytic diesel oil

ActiveCN108102713AGreat suitability and pertinenceImprove product qualityTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryGasoline

The invention discloses a processing method of catalytic diesel oil. A catalytic diesel oil material is cut into a light component and a heavy component; the light component is subjected to hydrofining and hydroupgrading reactions and gasoline and diesel oil components are obtained; the obtained heavy component is subjected to hydrofining and hydroconversion, and a gasoline component and a dieseloil component are obtained; a gasoline product is obtained after the two parts of gasoline are mixed, and a diesel oil product is obtained after the two parts of diesel oil components are mixed. Through reasonable separation and processing processes, different types of raw materials can be selectively and independently processed, so that qualified gasoline and diesel oil products can be produced by reasonably utilizing inferior catalytic cracking diesel oil .

Owner:CHINA PETROLEUM & CHEM CORP +1

Staged hydrocarbon/steam reformer apparatus and method

InactiveUS7790059B2Low overall and average steam-to-carbon ratioImprove thermal efficiencyHydrogenHydrocarbon from carbon oxidesHydrogen concentrationSteam reforming

A staged steam hydrocarbon reformer is disclosed having a chamber within which convectively heated reformer stages are enclosed. The reformer stages are tubes containing steam reforming catalyst. The stages are in serial fluid communication with one another through mixing vessels positioned between each stage. The first reforming stage is fed a mixture of steam and a gaseous hydrocarbon. Partially reformed gases having increased hydrogen concentration are produced at each stage and are mixed with additional gaseous hydrocarbon and optionally steam in the mixing vessels. Collection and distribution manifolds provide fluid communication between the reformer stages and the mixing vessels. A method is also disclosed in which partially reformed gases from a preceding stage are mixed with gaseous hydrocarbon and steam having a lower steam to carbon ratio than the fresh feed to the previous stage.

Owner:AIR PROD & CHEM INC

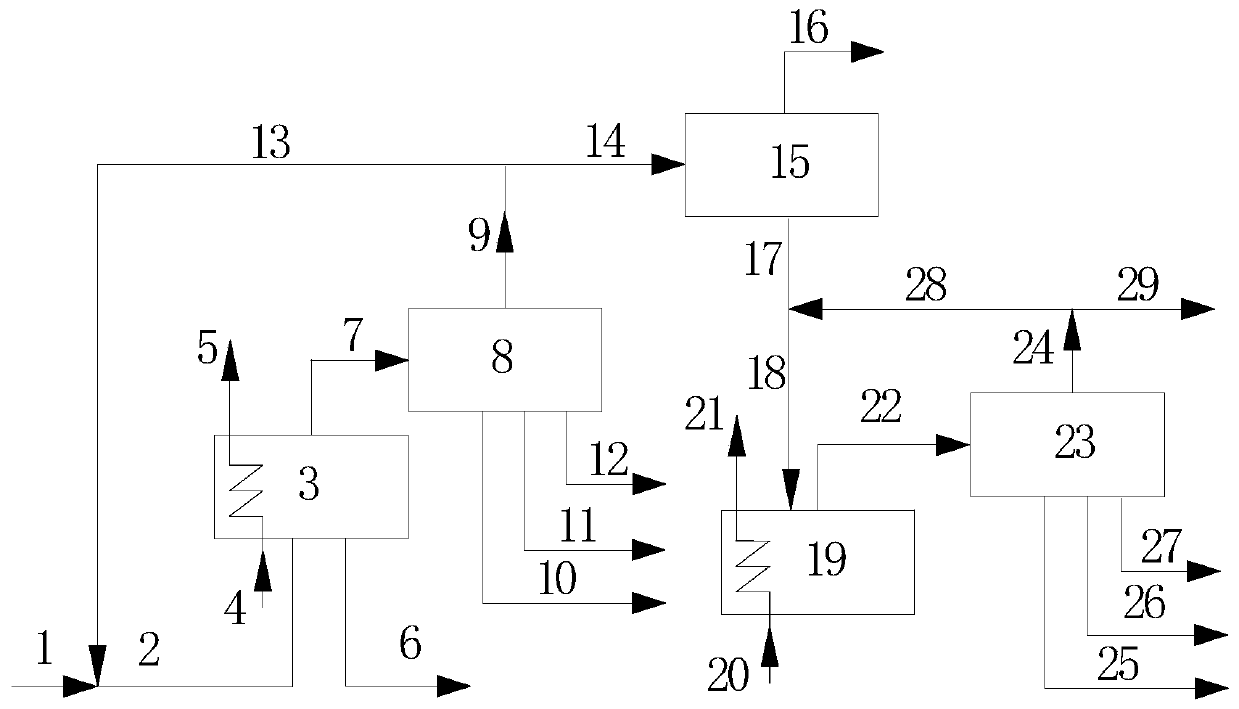

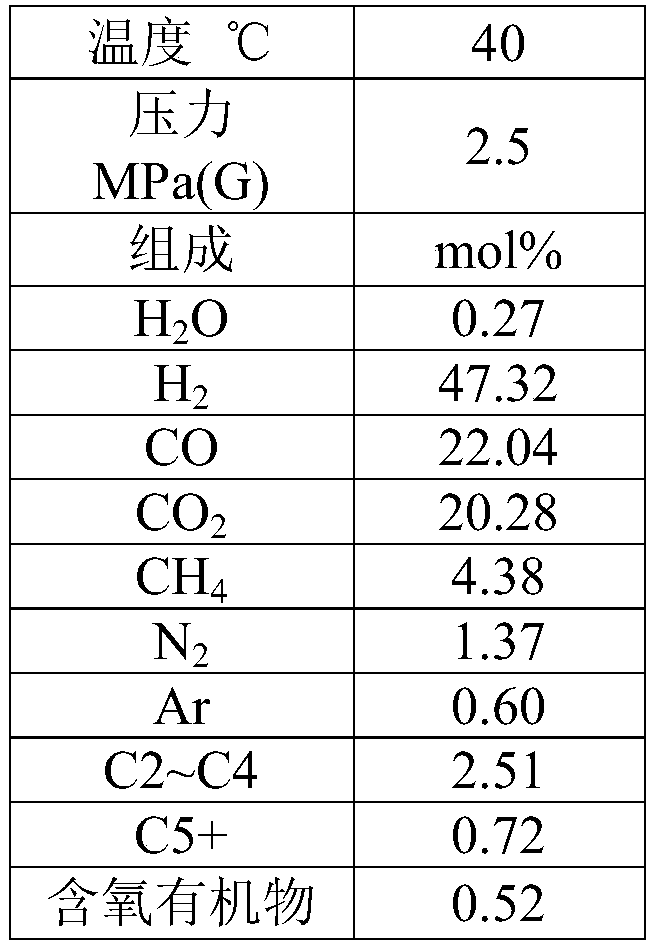

Method and device for producing hydrocarbons by connecting low-temperature Fischer-Tropsch section and high-temperature Fischer-Tropsch section in series

InactiveCN111286354ALow phase yieldHigh phase yieldLiquid hydrocarbon mixture productionPhysical chemistryLiquid hydrocarbons

The invention relates to a method for producing hydrocarbons by connecting a low-temperature Fischer-Tropsch section and a high-temperature Fischer-Tropsch section in series, wherein the method comprises the following steps: (1) introducing synthesis gas into a low-temperature Fischer-Tropsch synthesis reactor, carrying out a reaction, and separating reaction products to obtain high-carbon-numberhard paraffin, a low-temperature liquid hydrocarbon product, low-temperature reaction water and low-temperature Fischer-Tropsch tail gas; (2) feeding the low-temperature Fischer-Tropsch tail gas intoa decarburization device to completely or partially remove CO2, feeding the CO2-removed gas as a high-temperature Fischer-Tropsch raw material gas into a high-temperature Fischer-Tropsch synthesis reaction for reaction, and separating reaction products to obtain a high-temperature liquid hydrocarbon product, high-temperature reaction water and high-temperature Fischer-Tropsch tail gas; and (3) carrying out separation treatment on the low-temperature liquid hydrocarbon product and the high-temperature liquid hydrocarbon product to obtain the product. Compared with the prior art, efficient conversion of raw material gas and gradient utilization of energy are realized, the utilization efficiency of carbon is improved, the diversity of coal chemical products is realized, and the risk resistance of the Fischer-Tropsch synthesis device is improved.

Owner:YANKUANG ENERGY R&D CO LTD

Steam reforming catalyst and method of making thereof

ActiveUS9789470B2Improve catalytic stabilityExtended service lifeHydrogenCatalyst activation/preparationNickel catalystSteam reforming

Owner:TOPSOE AS

Steam reforming catalyst and method of making thereof

ActiveUS20150231608A1Extended service lifePreventing undesired carbon formationHydrogenHydrocarbon from carbon oxidesSteam reformingNickel catalyst

Owner:HALDOR TOPSOE AS

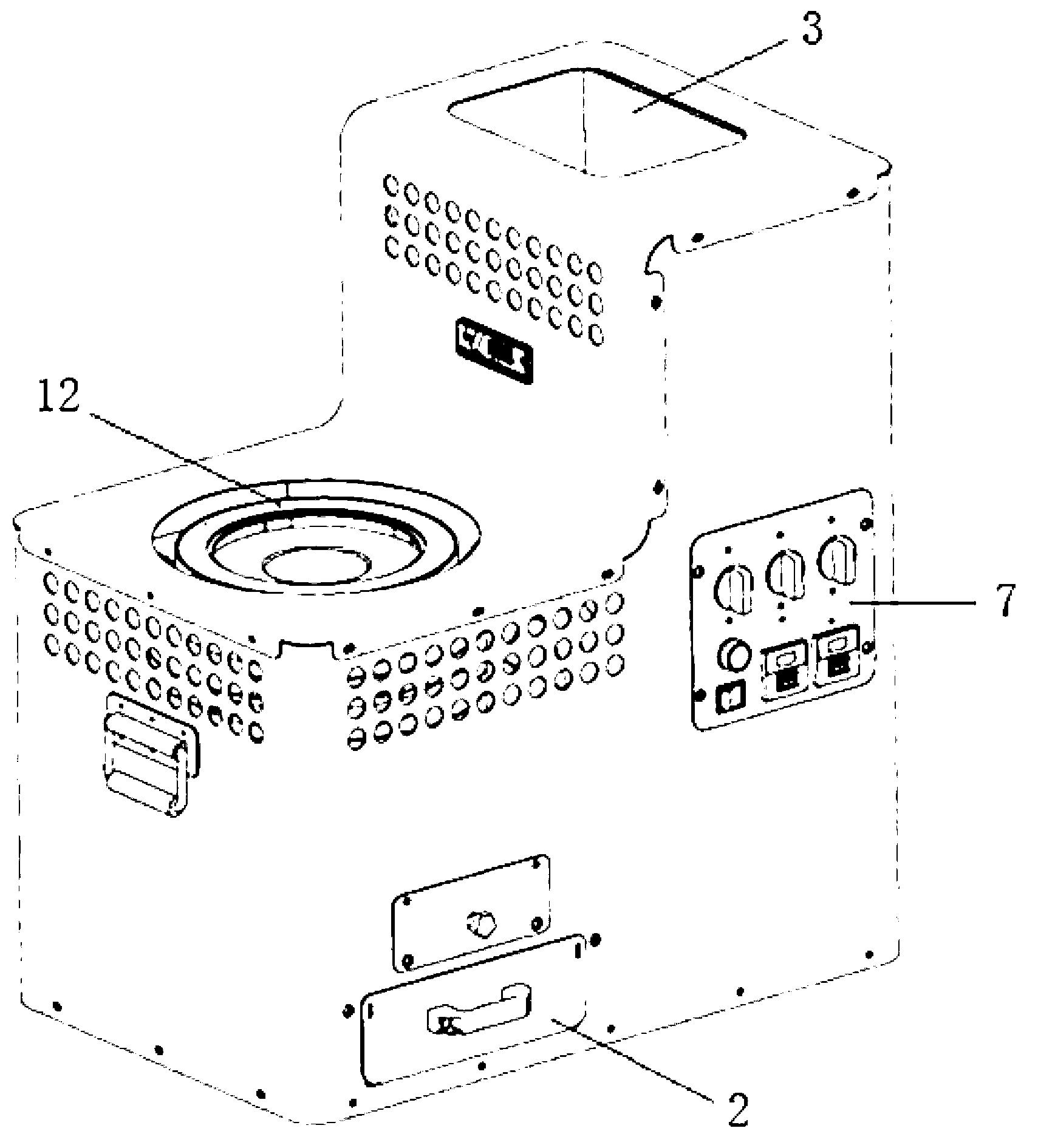

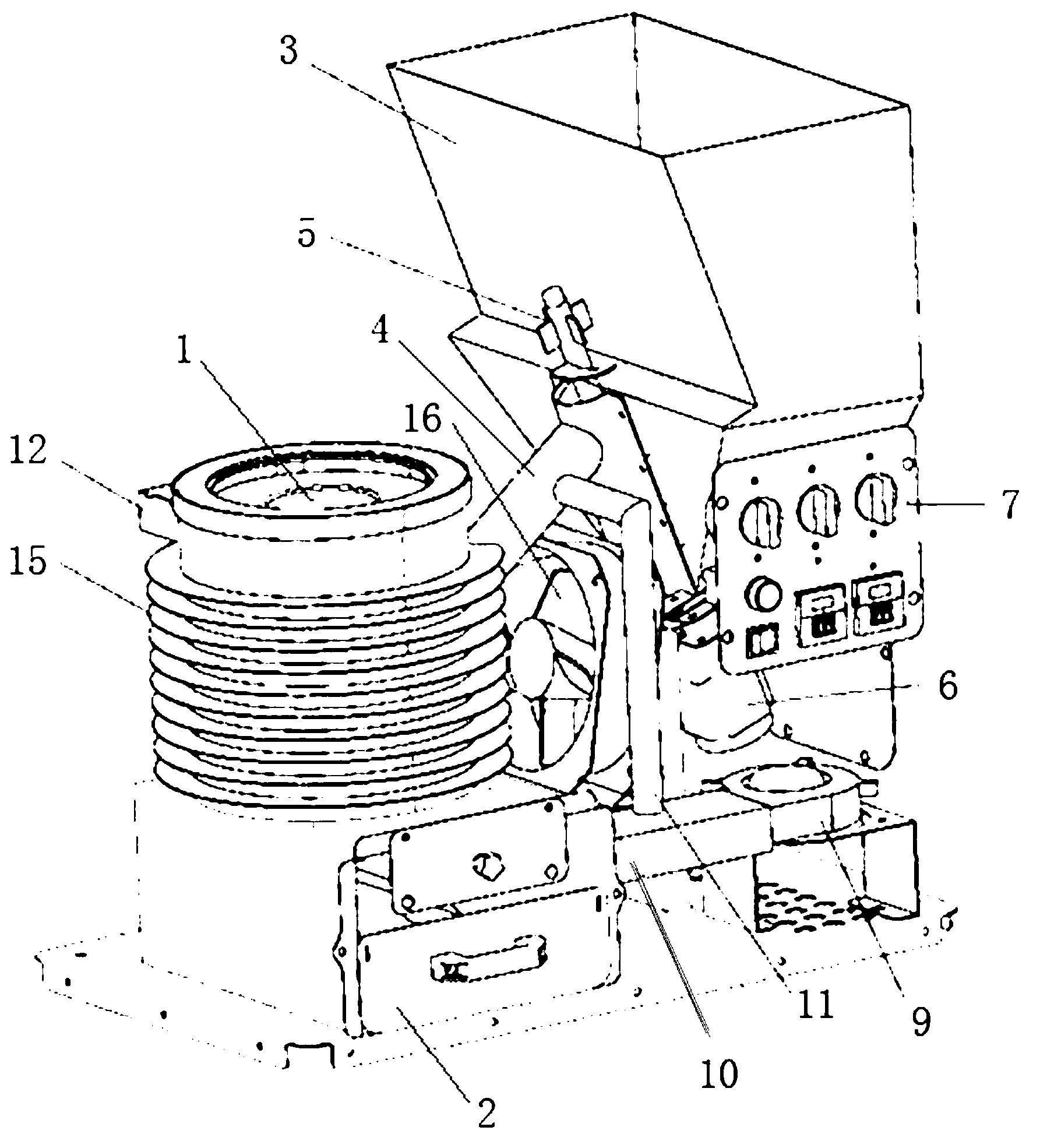

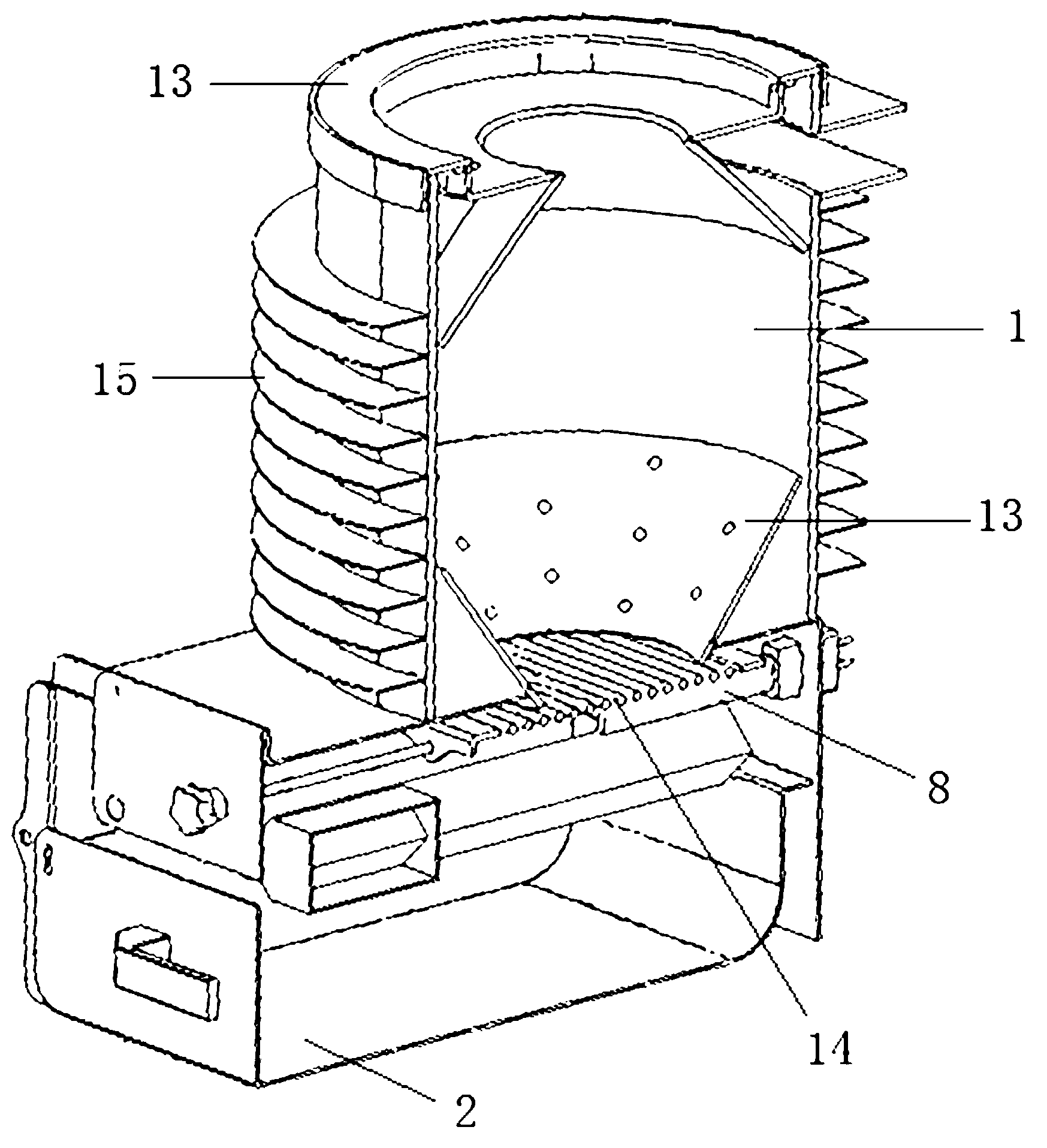

Automatic-feeding biomass combustion furnace

InactiveCN103216856ABurn fullyHas a cooling effectDomestic stoves or rangesLighting and heating apparatusMotor driveCarbonization

The invention discloses an automatic-feeding biomass combustion furnace comprising a hearth, a dust box and an automatic feeding device. The automatic feeding device comprises a hopper, a feeding barrel communicating the hopper with the hearth, a feeding conveying auger arranged on a feed inlet of the feeding barrel, a motor driving the feeding conveying auger to rotate, and a circuit controller controlling the motor to work. The bottom of the hearth is provided with a horn-shaped oxygen feeding shell, a sliding dust leaking grid is arranged under the hearth, and heat dissipating pieces are arranged on the outer wall of the hearth. The automatic-feeding biomass combustion furnace has the advantages that the circuit controller controls the rotating speed of the feeding conveying auger, automatic feeding is achieved, and uniformity of feeding is guaranteed. The oxygen feeding shell enables fuel to be burnt thoroughly and residues are not left. The movable dust leaking grid can effectively prevent carbonization and tar phenomena from occurring. A fire collecting shell can be used for cooking, and can achieve heating effects through connecting with other devices through a smoke outlet in the upper portion of the hearth. The heat dissipating pieces reduce safety hidden risks during use.

Owner:烟台市宜和环保设备有限公司

Hexafluoropropylene production method

InactiveCN1273427CPrevent self-aggregationAvoid carbon formationHalogenated hydrocarbon preparationHexafluoropropyleneOctafluorocyclobutane

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation method of 2, 3, 3, 3-tetrafloropropylene

ActiveCN103833511AReduce the probability of side effectsAvoid the production of highly toxic substance perfluoroisobutyleneHalogenated hydrocarbon preparationChemistryPyrolysis

The invention provides a preparation method of 2, 3, 3, 3-tetrafloropropylene. The method comprises the following steps: with monochlorodifluoromethane and monochloro methane which are in a molar ratio of (0.5-4):1 as reaction raw materials, preheating the reaction raw materials, then mixing with superheated steam, wherein the volume ratio of the superheated steam to the reaction raw materials is (1-20):1, the temperature of the superheated steam is 900-1100 DEG C, the temperature in the reaction section is 600-1100 DEG C, and the stay time of reactants in the reaction section is 0.01-1s; and quenching, deacidifying, drying and rectifying and separating the product mixed flow to obtain 2, 3, 3, 3-tetrafloropropylene. The method provided by the invention overcomes the deficiency that a hollow tube is prone to carbonization in pyrolysis and side reactions are complex, the equipment maintenance rate is reduced, and meanwhile, the reaction period is prolonged, and the utilization ratio of the device is improved. The method provided by the invention has the characteristics of use of easily available raw materials, simple reaction process and the like. The obtained 2, 3, 3, 3-tetrafloropropylene has the advantages of zero ODP (Ozone Depletion Potential) and low GWP (Global Warming Potential), and is used as a substituent of automotive air conditionor refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

A kind of foamed silicon carbide-based structured catalyst and its application in the preparation of butadiene

ActiveCN104001533BHigh yieldExtend your lifeCatalyst carriersHydrocarbonsCarbide siliconPtru catalyst

The invention relates to the catalyst field, particularly to a foam silicon carbide based structured catalyst and its application in preparation of butadiene by oxidative dehydrogenation of butylene. The foam silicon carbide based structured catalyst is the catalyst for preparation of butadiene by oxidative dehydrogenation of butylenes, and takes foam silicon carbide with a three-dimensional interconnected pore structure as the carrier. A ferrite catalyst with a spinel structure is loaded on the carrier surface as the main active component, and one or over two of alpha-Fe2O3, gamma-Fe2O3 and Fe3O4 are loaded on the carrier surface as the secondary active components, thus forming the structured catalyst. The structured catalyst can be processed into a plurality of complex configurations like wall flow type, parallel channel type, static hybrid type, granules and the like. The foam silicon carbide based structured catalyst provided by the invention can convert butylene into butadiene through oxidative dehydrogenation, thus reinforcing heat transfer and mass transfer, improving butadiene yield, prolonging the catalyst life, and reducing the energy consumption and material consumption of the reaction process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com