Method for preparing acetylene by hot plasma cracking methane containing gas

A thermal plasma and plasma technology, which is applied in hydrocarbon cracking to hydrocarbon, condensation hydrocarbon with dehydrogenated hydrocarbon, organic chemistry, etc., can solve the problem that the yield of acetylene and by-product carbon black cannot be controlled according to needs, and cracking gas does not have Economical rapid cooling measures, poor control of feed gas residence time, etc., to achieve complete control of cracking reactions, avoid cracking into carbon black, and avoid adverse consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below.

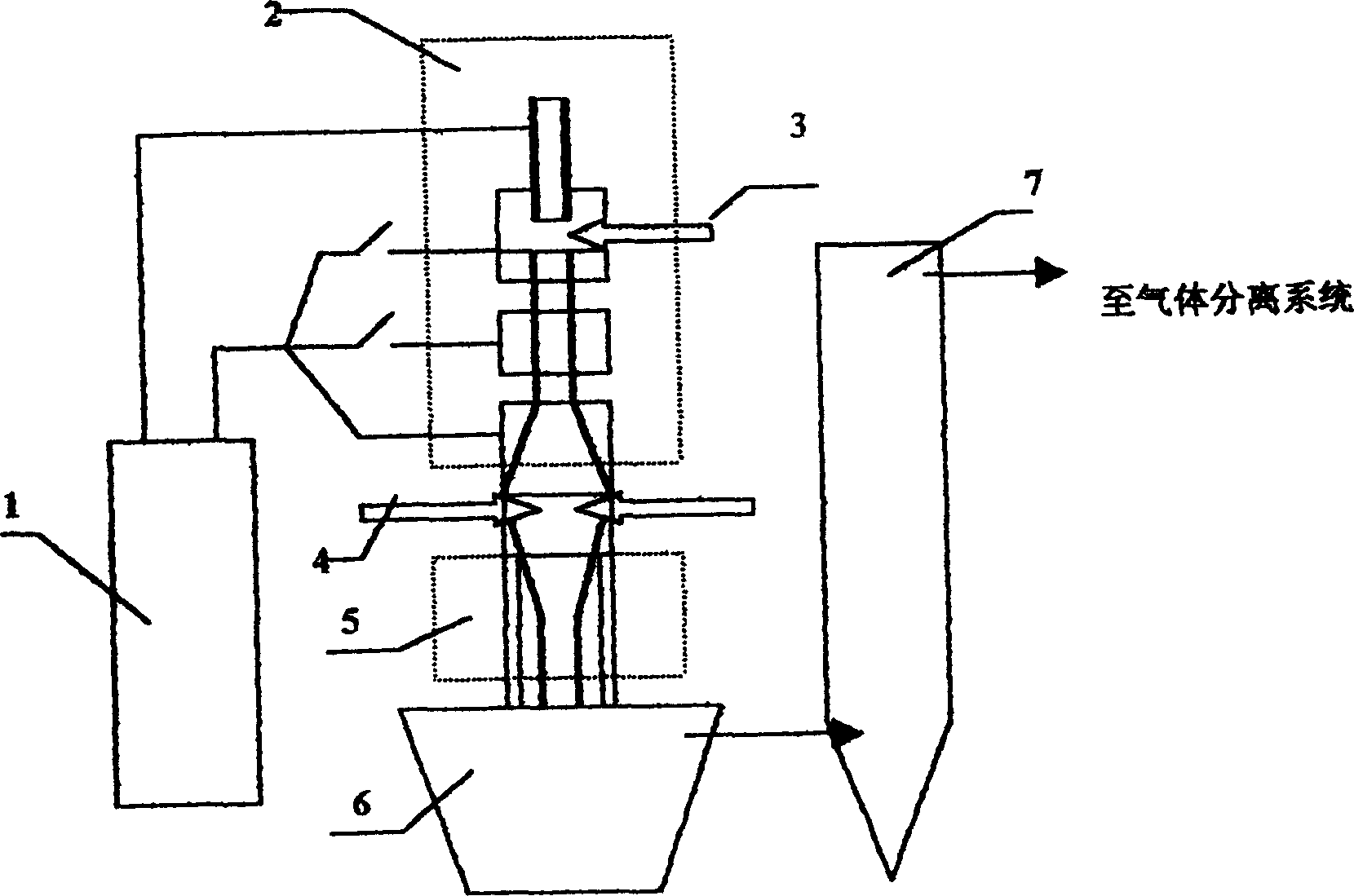

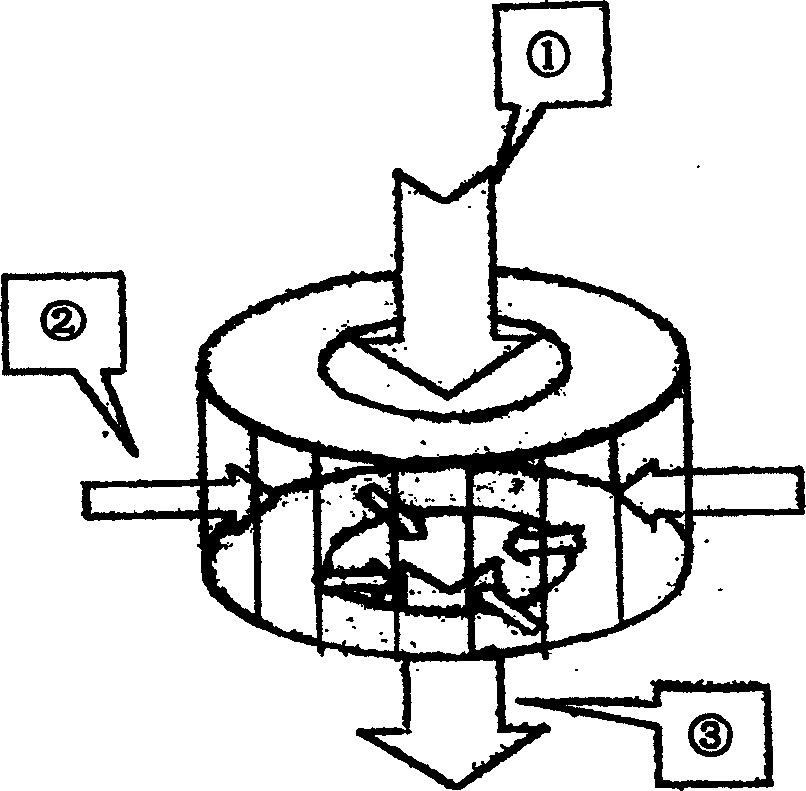

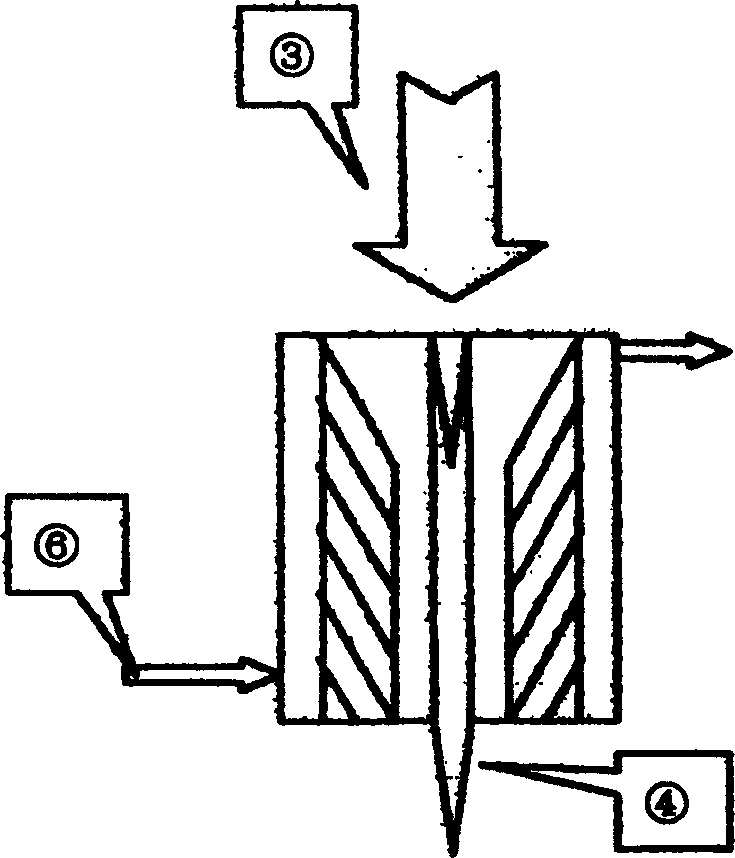

[0031] see figure 1 : implement this plasma cracking method that contains methane gas to make acetylene, at first be to arrange a device that implements this method, this device comprises high-power DC power supply 1, plasma generator 2, raw material gas inlet device 4, reactor 5, The cooling device 6, the gas-solid separator 7, and the plasma generator 2 are provided with a working gas inlet 3.

[0032] The method includes the following steps: the direct current power supply 1 supplies energy to the plasma generator 2, and the flow gas of the working gas is sent into the plasma generator 2 through the inlet 3, and the flow gas of the working gas is discharged and ionized under the action of a strong electric field A high-temperature plasma jet is formed, and the high-temperature jet forms a high-temperature environment above 5000K in the reactor 5. The raw material gas containing methane enters the reactor 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com