Preparation and application of dual-function catalyst Pt/Ce0.95Al0.05Ox/La2O3-Al2O3

A dual-function catalyst, catalyst technology, applied in catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of metal carbonization, reducing heat exchange efficiency, and hindering the normal flow of fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides bifunctional catalyst Pt / Ce 0.95 Al 0.05 o x / La 2 o 3 -Al 2 o 3 The preparation method, its preparation steps are as follows:

[0043] (1) Ce 0.95 Al 0.05 o x Preparation of composite oxides

[0044] The precursors of cerium and aluminum respectively weighed Ce(NO 3 ) 3 ·6H 2 O and Al(NO 3 ) 3 9H 2 O, and dissolved in deionized water to prepare a certain proportion of mixed salt solution;

[0045] Stir quickly with a stirrer for 30 minutes to make it evenly mixed;

[0046] Precipitate under stirring conditions and control the pH;

[0047] After the precipitate is formed, continue to stir for 30 minutes and then stand and age for 2 days, then filter and wash the precipitate with deionized water until the filtrate is neutral;

[0048] The precipitate was dried at 120°C for 1 day, and then calcined with oxygen at 600°C for 3 hours in a muffle furnace to obtain the desired Ce 0.95 Al 0.05 o x composite oxides;

[0049] (3)La 2 ...

Embodiment 1

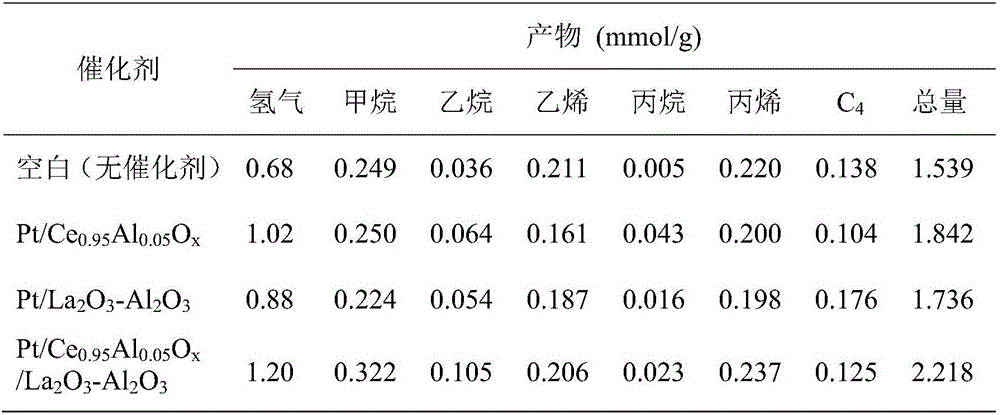

[0069] According to two kinds of catalyst powder Pt / Ce 0.95 Al 0.05 o x with Pt / La 2 o 3 -Al 2 o 3 , and mechanically mixed at a mass ratio of 1:1 to obtain Pt / Ce 0.95 Al 0.05 o x / La 2 o 3 -Al 2 o 3 catalyst. According to the method, the loading amount of the fixed catalyst is 0.2g±0.02 / 800mm, and the three catalysts are coated on the inner wall of the stainless steel tube to make a corresponding tubular coating catalyst.

[0070] In order to compare the cracking effect of the catalyst of the present invention, the cracking of RP-3 under supercritical conditions was used as a probe reaction, and its cracking activity was evaluated and compared on a kerosene cracking device built by the laboratory itself. The activity test conditions of this embodiment are as follows: two-stage heating is adopted, the preheating section of the reaction tube is 250 mm long, controlled at 250° C., the reaction section is 300 mm long, and the temperature is set at 650° C.

[0071] T...

Embodiment 2

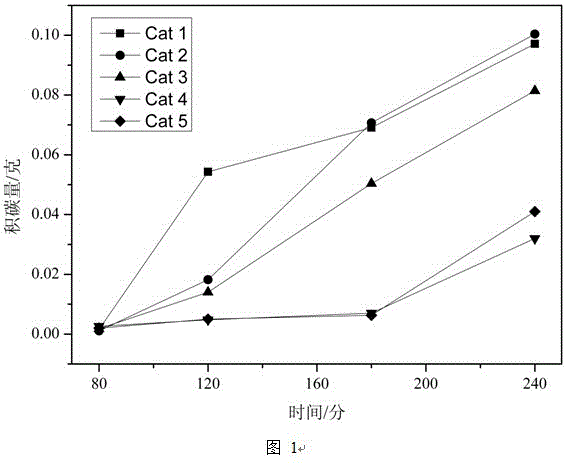

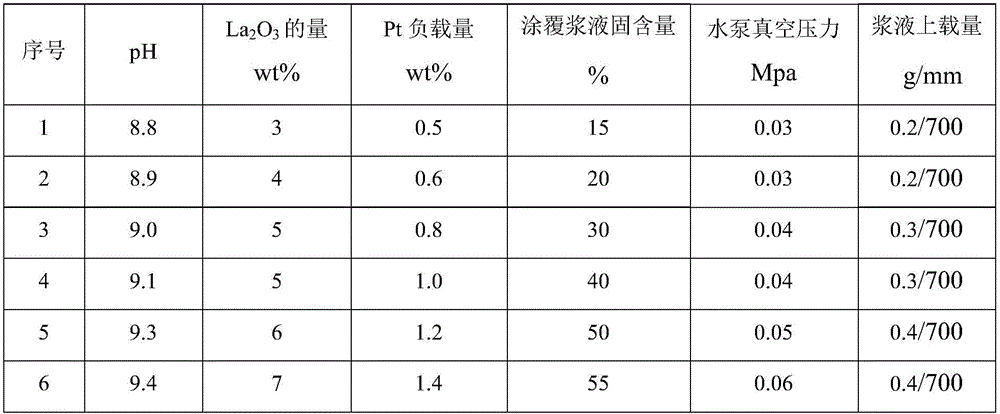

[0075] According to two kinds of catalyst powder Pt / Ce 0.95 Al 0.05 o x with Pt / La 2 o 3 -Al 2 o 3 , and then mechanically mix the two catalyst powders according to the mass ratio of 1:1 to obtain the Pt / Ce 0.95 Al 0.05 o x / La 2 o 3 -Al 2 o 3 Catalyst, which is divided into 5 parts, and different additives are added as shown in the table below to obtain five groups of Pt / Ce modified with different additives 0.95 Al 0.05 o x / La 2 o 3 -Al 2 o 3 Catalyst powder. These five groups of catalyzers are coated on the stainless steel pipe by the method described (the control catalyst slurry solid content is 30%, and the load is 0.2 ± 0.02g / 800mm), and this 1#-5# catalyzer is recorded as Cat1-Cat5.

[0076] Table 3 Additives and their addition amount

[0077]

[0078] The method described in Example 1 was used to evaluate the influence of additives on the cracking activity of the catalyst. The test results are shown in Table 4: the addition of the catalyst sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com