Method for preparing butadiene by oxidization and dehydrogenation of butane using constant-temperature static bed

A technology of oxidative dehydrogenation and bed butene, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of long production process, large consumption of raw materials and energy, and has not been promoted, so as to prolong the service life , Reduction of energy consumption, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

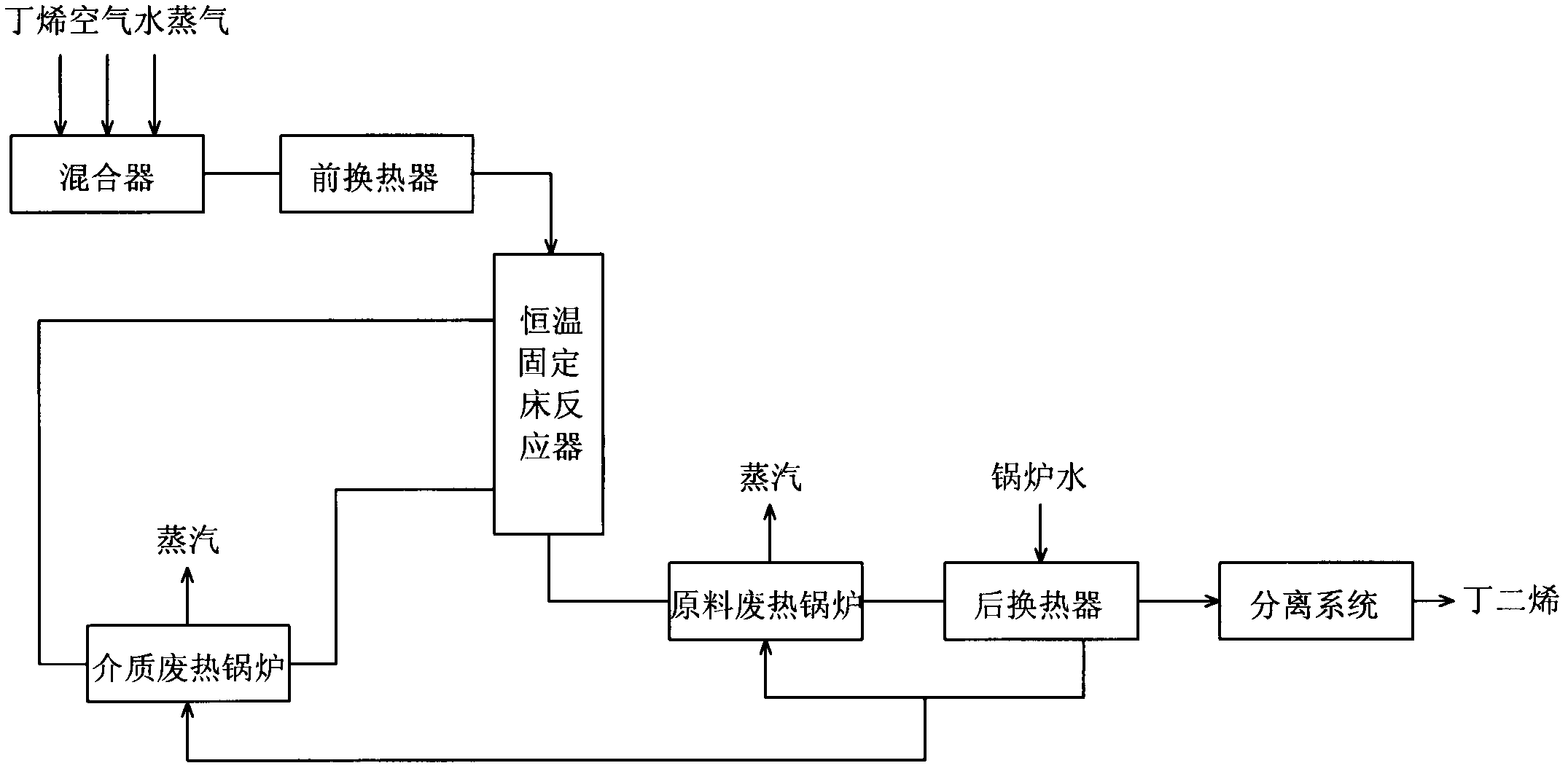

Method used

Image

Examples

Embodiment 1

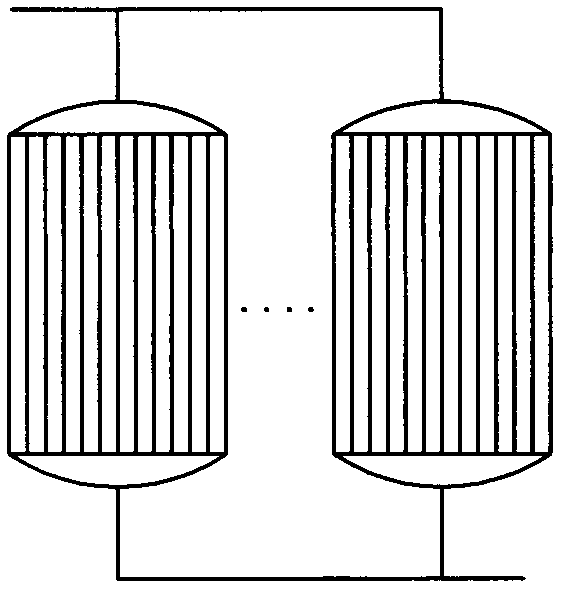

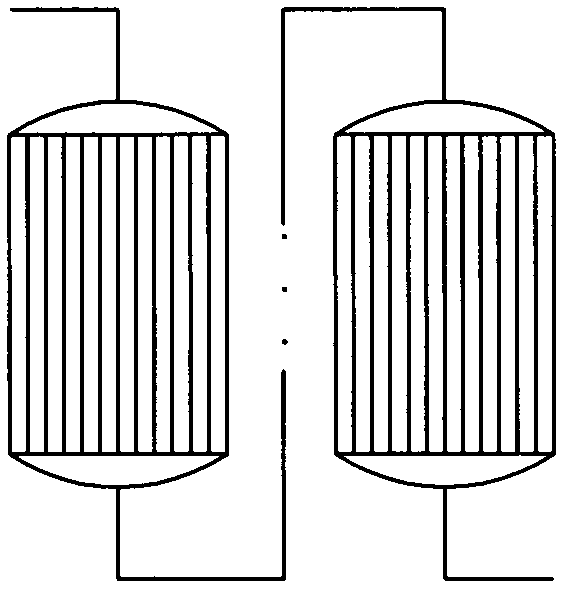

[0038] The size of the reactor is Φ2500×5000mm, the size of the tubes is Φ50.8×2.6×5000, and the number of tubes is 1211. Heat exchange area 966m 2 , The catalyst bed height is 5000mm. Airspeed 800h -1 , the oxidative dehydrogenation temperature is 370°C, and the molar ratio of alkene: oxygen: water is 1:0.6:0.5. The average data of the 200-hour test results are shown in Table 1.

[0039] Table 1 200-hour test result table

[0040] Reaction temperature °C

Embodiment 2

[0042] The size of the reactor is Φ2500×5000mm, the size of the tubes is Φ50.8×2.6×5000, and the number of tubes is 1211. Heat exchange area 966m 2 , The catalyst bed height is 5000mm. Airspeed 600h -1 , the oxidative dehydrogenation temperature is 360°C, and the molar ratio of alkene: oxygen: water is 1:0.6:1. The average data of the 200-hour test results are shown in Table 2.

[0043] Table 2 200-hour test result table

[0044] Reaction temperature °C

Embodiment 3

[0046] The size of the reactor is Φ2500×5000mm, the size of the tubes is Φ50.8×2.6×5000, and the number of tubes is 1211. Heat exchange area 966m 2 , The catalyst bed height is 5000mm. Airspeed 1000h -1 , the oxidative dehydrogenation temperature is 390°C, and the molar ratio of alkene: oxygen: water is 1:0.55:2. The average data of the 200-hour test results are shown in Table 3.

[0047] Table 3 200-hour test result table

[0048] Reaction temperature °C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com