Core-shell catalyst, preparation method thereof and application of core-shell catalyst in hydrogen production by reforming

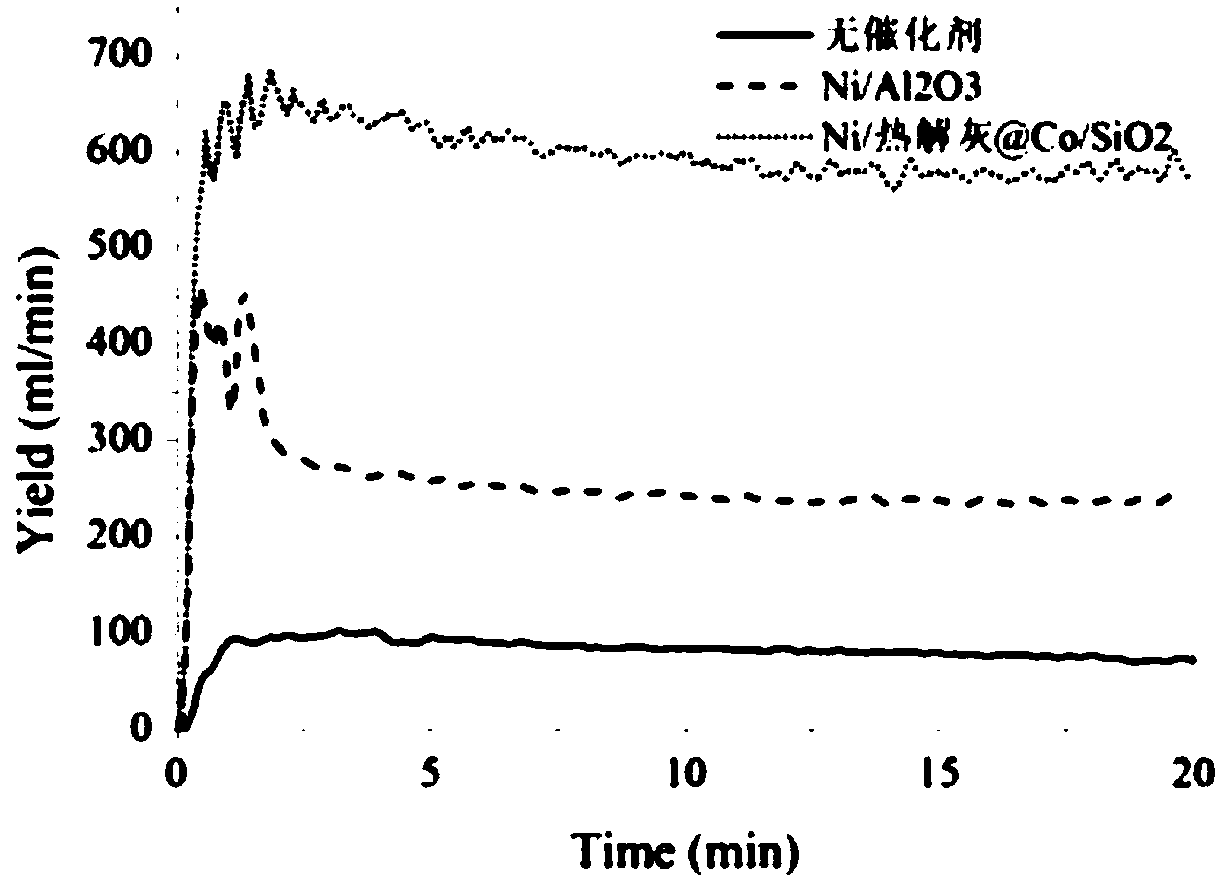

A catalyst and core-shell technology, which is applied in the field of core-shell catalysts and their preparation, can solve problems such as deactivation, limited catalyst reactivity, and difficulty in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a core-shell catalyst, comprising the following steps:

[0032] (1) immersing the biomass pyrolysis ash in the inner core active metal salt solution, followed by drying and calcination treatment to obtain the catalyst inner core;

[0033] (2) mixing cetyltrimethylammonium bromide, ammoniacal liquor, ethanol, deionized water and catalyst core to obtain catalyst core dispersion;

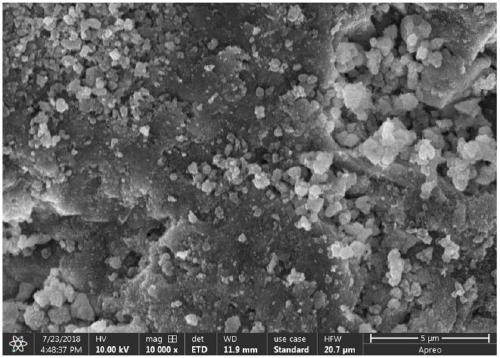

[0034] (3) Ethyl tetrasilicate is slowly dropped into the catalyst core dispersion liquid for mixing, and then the mixed liquid is transferred to a polytetrafluoroethylene-lined stainless steel reactor for crystallization, and the crystallized products are sequentially dried and calcination treatment to obtain a core-shell catalyst precursor;

[0035] (4) impregnating the core-shell catalyst precursor in the shell active metal salt solution, followed by drying, calcining and hydrogen reduction treatment in sequence to obtain the core-shell catalyst....

Embodiment 1

[0052] (1) 30.00 g of pyrolytic carbon from corn stalks was placed in a muffle furnace, and ashed at 500° C. for 1 hour to obtain 10.23 g of biomass pyrolytic ash;

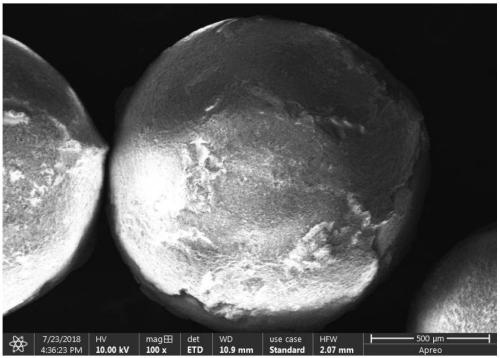

[0053] (2) Prepare a 0.2mol / L nickel nitrate solution, then put 10.00g of biomass pyrolysis ash into the nickel nitrate solution, stir and impregnate at a constant temperature of 60°C for 2h, then dry at 105°C for 24h, and calcined at 800°C 2h, 10.18g of the catalyst inner core was obtained;

[0054] (3) Ultrasonic dispersion and dissolution of CTAB, deionized water, ethanol, and ammonia water was mixed to form a transparent solution. During the process, the molar ratio of CTAB:ammonia water:ethanol:water was 1:10:150:275. Then get 3.00 g of the catalyst inner core prepared in step 1 and disperse it in the solution, stir evenly to obtain the catalyst inner core dispersion, wherein the quality of CTAB is 3.64 g;

[0055] (4) Add 3.12 g of tetraethyl orthosilicate dropwise to the catalyst core dispersion in step (3...

Embodiment 2

[0065] (1) Pyrolytic carbon from rice husks was placed in a muffle furnace, and ashed at 450°C for 1.5 hours to obtain biomass pyrolysis ash;

[0066] (2) Immerse the obtained biomass pyrolysis ash in 0.5mol / L nickel acetate solution for 0.5h, control the mass ratio of nickel acetate to biomass pyrolysis ash to be 1:10, then dry at 80°C for 12h, 650 Calcined at ℃ for 4h to obtain the catalyst core;

[0067](3) Ultrasonic dispersion and dissolution of CTAB, deionized water, ethanol, and ammonia water was used to form a transparent solution. During the process, the molar ratio of CTAB:ammonia water:ethanol:water was 1:15:100:300. Then take the catalyst core prepared in step 1 and disperse it in the solution, wherein the mass ratio of CTAB to the catalyst core is 1:5, stir evenly to obtain the catalyst core dispersion;

[0068] (4) Add orthosilicate ethyl ester dropwise to the catalyst core dispersion liquid described in step (3), wherein the mass ratio of orthosilicate to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com