Coke inhibitor of high-temperature refining equipment

A high-temperature equipment, petroleum refining technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking and other directions, can solve problems such as decomposition and corrosion of phosphate esters, and achieve the effects of improved coke inhibition effect, easy production and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0041] Phosphorothioate Alkylbenzene Sulfonate Diamine Salt 89g

[0042] N,N'-di-sec-butyl-p-phenylenediamine 6g

[0043] 4-tert-butylcatechol 5g

[0044] Solvent oil 20g

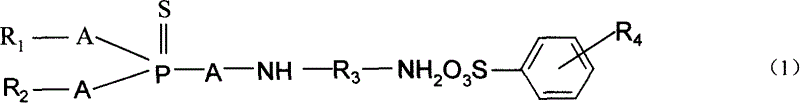

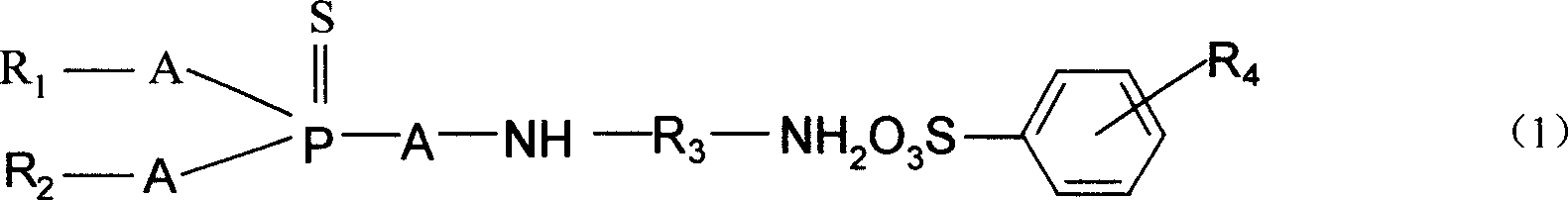

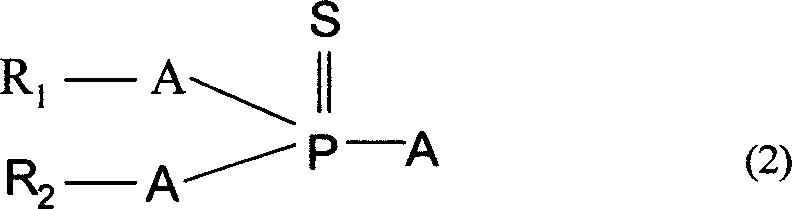

[0045] A in structural formula (1) is O atom, R 1 for H, R 2 for C 8 Hydrocarbyl, R 3 for C 6 Hydrocarbyl, R 4 for C 12 of hydrocarbon groups.

[0046] Its preparation method is as follows:

[0047] Mix phosphorothioate alkylbenzenesulfonic acid diamine salt, N,N'-di-sec-butyl-p-phenylenediamine, p-tert-butylcatechol and solvent oil in a beaker according to the weight ratio, and heat to 60~ Stir at 70°C for 30-60 minutes to obtain a coking retarder for high-temperature equipment in petroleum refining.

Embodiment 2

[0049] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0050] Phosphorothioate Alkylbenzene Sulfonate Diamine Salt 75g

[0051] N,N'-di-sec-butyl-p-phenylenediamine 15g

[0052] 4-tert-butylcatechol 10g

[0053] Solvent oil 20g

[0054] A in structural formula (1) is O atom, R 1 for C 1 Hydrocarbyl, R 2 for C 1 Hydrocarbyl, R 3 for C 2 Hydrocarbyl, R 4 for C 12 of hydrocarbon groups.

[0055] Its preparation method is identical with embodiment 1.

Embodiment 3

[0057] Take preparation 120g product of the present invention as example, used raw material and proportioning thereof are as follows:

[0058] Phosphorothioate Alkylbenzene Sulfonate Diamine Salt 98g

[0059] N,N'-di-sec-butyl-p-phenylenediamine 1g

[0060] p-tert-butylcatechol 1g

[0061] Solvent oil 20g

[0062] A in structural formula (1) is O atom, R 1 for C 12 Hydrocarbyl, R 2 for C 12 Hydrocarbyl, R 3 is a C10 hydrocarbon group, R 4 It is a C12 hydrocarbon group.

[0063] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com