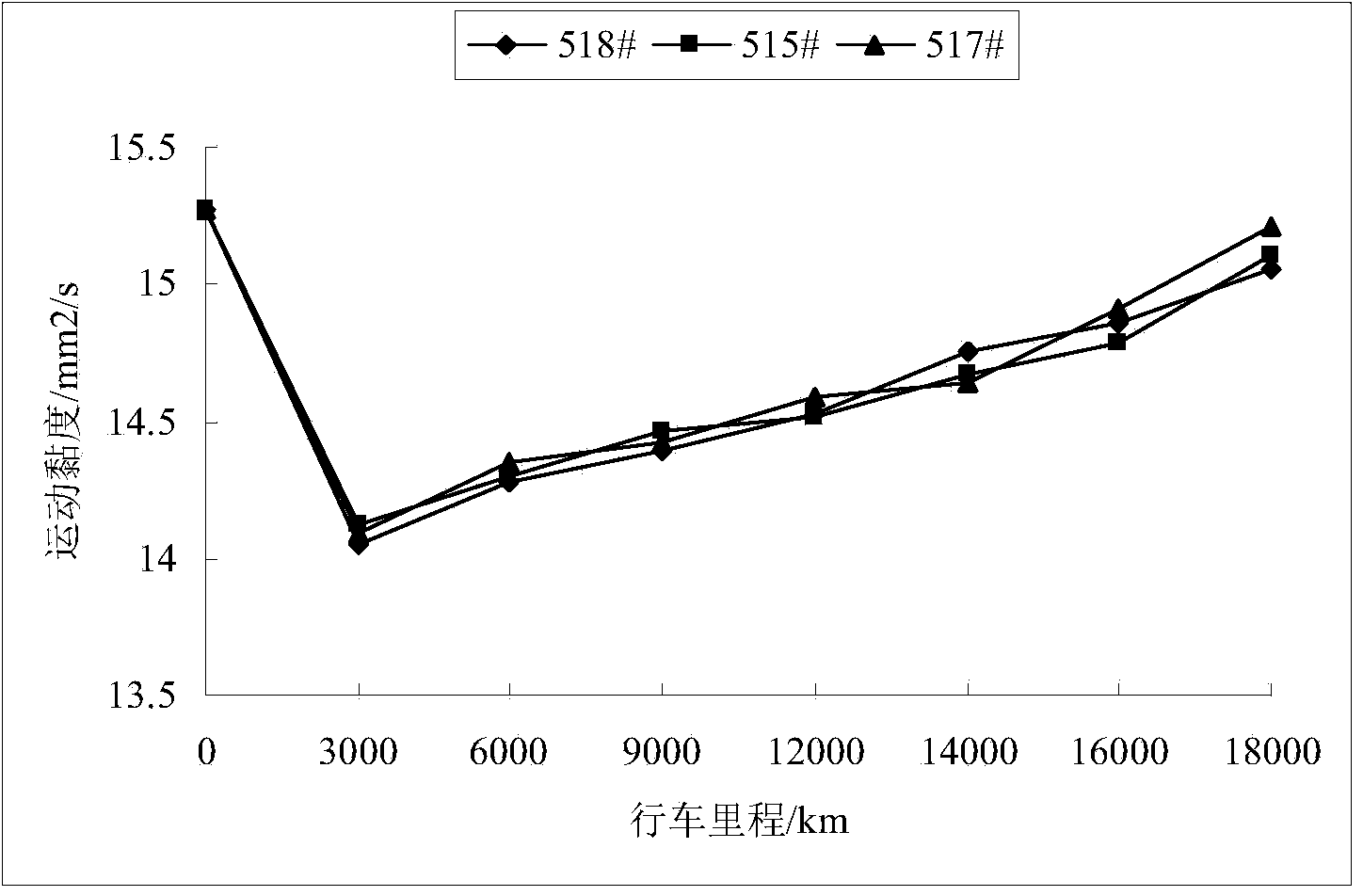

Special lubricating oil for fuel gas engine of public transport automobile

A gas engine and lubricating oil technology, applied in the field of lubricating oil, can solve problems that restrict the promotion, development and use of public natural gas vehicles, affect the operating efficiency of enterprises, and increase the production costs of enterprises, so as to prolong the anti-oxidation time and improve wear resistance And surface repair effect, the effect of extending the oil change interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking 1000g of blended base oil used in the preparation of special lubricating oil for bus gas engines as an example, its raw material composition and preparation method are as follows:

[0033]

[0034] The blended base oil mentioned above is formed by mixing 200g of base oil 250N, 600g of base oil 600N, and 200g of base oil 150BS.

[0035] The preparation method of the above-mentioned special lubricating oil for bus gas engines is as follows: stir sulfurized alkyl phenate calcium T115B and high alkali value synthetic calcium sulfonate T106D at 50°C for 20 minutes to obtain mixture A; Diimide T154B and borated polyisobutylene succinimide T154C with a number average molecular weight of 1000 were stirred at 50°C for 20 minutes to obtain mixture B; alkylated phenyl-α-naphthylamine T531, p, p' Octyldiphenylamine L101 and hindered phenolic antioxidant T501 were stirred at 50°C for 20 minutes to obtain mixture C; molybdenum dialkyldithiocarbamate and nano-copper particle...

Embodiment 2

[0037] Taking 1000g of blended base oil used in the preparation of special lubricating oil for bus gas engines as an example, its raw material composition and preparation method are as follows:

[0038]

[0039] The above blended base oil is prepared by mixing 170g of base oil 250N, 700g of base oil 600N, and 130g of base oil 150BS.

[0040] The preparation method of the special lubricating oil for bus gas engines is the same as in Example 1.

Embodiment 3

[0042] Taking 1000g of blended base oil used in the preparation of special lubricating oil for bus gas engines as an example, its raw material composition and preparation method are as follows:

[0043]

[0044]

[0045] The above blended base oil is prepared by mixing 100g of base oil 250N, 800g of base oil 600N, and 100g of base oil 150BS.

[0046] The preparation method of the special lubricating oil for bus gas engines is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com