Aviation lubricating oil composition

A technology of aviation lubricating oil and composition, which is applied in the field of lubricating oil and can solve problems such as easy coking and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

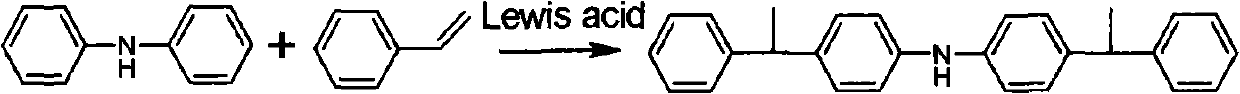

Method used

Image

Examples

Embodiment 1~6

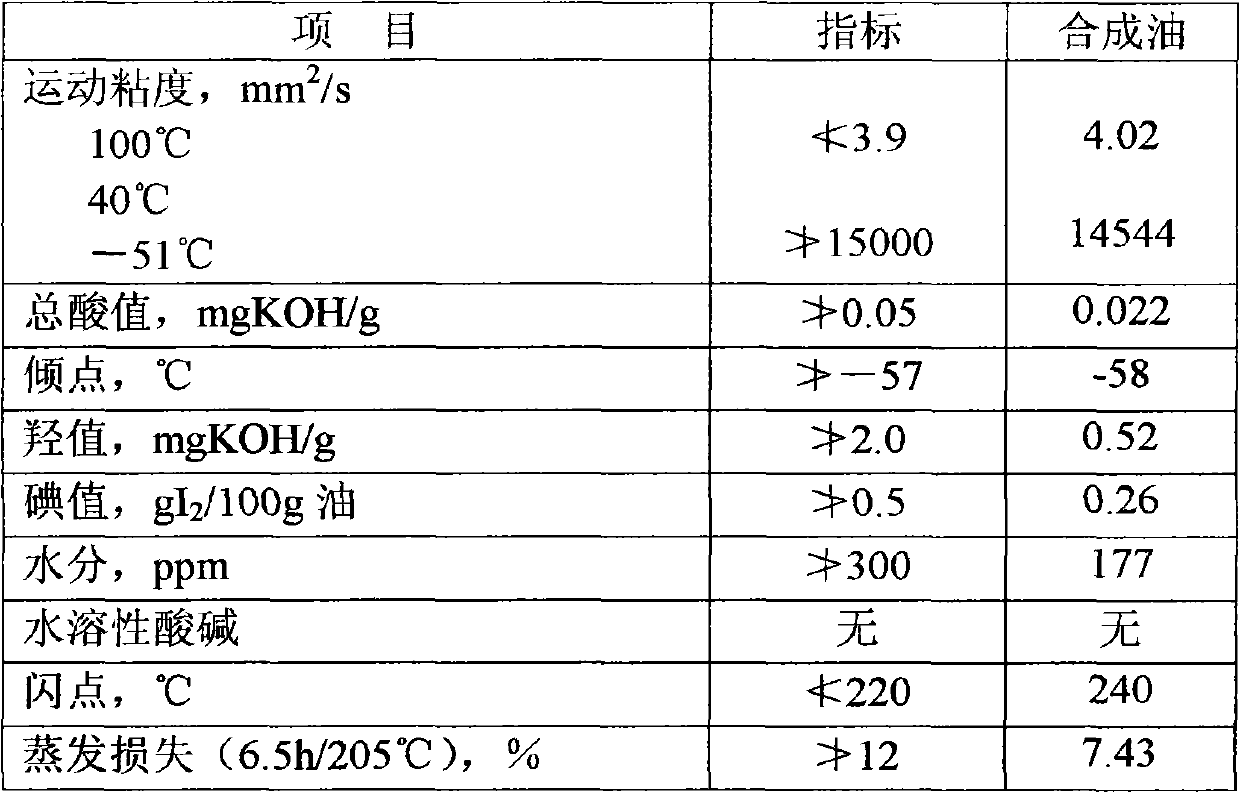

[0037] According to the ratio shown in Table 3, the synthetic aviation lubricating oil composition of 4 centistokes was prepared; the preparation method was the conventional preparation method in the prior art.

[0038] Table 3: Based on the total weight of the lubricating oil composition (%)

[0039] Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Synthetic base oil

margin

margin

margin

margin

margin

margin

NHA11

0.5

0.8

0.3

0.2

0.5

0.7

p,p-Diisooctyldiphenylamine

0.5

0.8

1.0

1.0

0.8

0.5

N-Phenyl-α-naphthylamine

0.2

0.5

0.3

0.2

0.5

0.4

Additin RC7115

0.6

0.5

0.8

1.0

0.6

0.8

2.5

2.5

2.0

2.2

2.4

2.0

0.06

0.1

0.08

0.1

0.1

0.05

Non-silicon type antifo...

Embodiment 7~12

[0058] According to the ratio shown in Table 6, the synthetic aviation lubricating oil composition of 4 centistokes was prepared; its preparation method was a conventional preparation method in the prior art.

[0059] Table 6: Based on the total weight of the lubricating oil composition (%)

[0060] Example 7

[0061] Tricresyl Phosphate

[0062] Among them, the preparation method of synthetic base oil and NHA11 refers to Example 1.

experiment example 1

[0064] Using the oxidation test method "ASTM D4636-Standard Test Method for Corrosion and Oxidation Stability of Hydraulic Oils, Aviation Turbine Engine Lubricants, and Other Deeply Refined Oils" required by 4 centistokes, by adding NHA11 to the developed base oil and mixing it with aviation Antioxidants in the traditional formulation of lubricating oil were used in combination, and the oxidation corrosion tests were carried out at 200 °C for 96 hours and 220 °C for 40 hours respectively. The results are shown in Table 8 and Table 9.

[0065] Table 7: Comparative Example Preparation:

[0066]

[0067] Based on the total weight of the lubricating oil composition (%), other components are the same as in Example 1.

[0068] Table 8: Oxidation test results at 200℃, 96h

[0069]

[0070] Table 9: Oxidation test results at 220°C, 40h

[0071]

[0072] As can be seen from Table 8 and Table 9, by using the styrenated amine antioxidant NHA11 in combination with p, p-diisooct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com