Special visco-elasticity adhesive for damping and construction method thereof

A technology of adhesives and viscoelasticity, applied in the direction of adhesives, adhesive types, chloroprene adhesives, etc., can solve the problem of low bonding and peeling strength of damping rubber sheets, which cannot guarantee the bonding strength of adhesives, and viscoelastic damping adhesives Poor performance and other problems, to achieve the effect of good initial tack and construction performance, good initial tack performance, flame resistance and mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A special adhesive for viscoelastic damping, its formula consists of:

[0026] Neoprene - 240:20 parts

[0027] Neoprene B-30: 80 parts

[0028] Magnesium oxide: 4 parts

[0030] Resin: 20 parts

[0031] Carbon black: 15 parts

[0032] N-phenyl-α-naphthylamine (antiaging agent A): 1 part

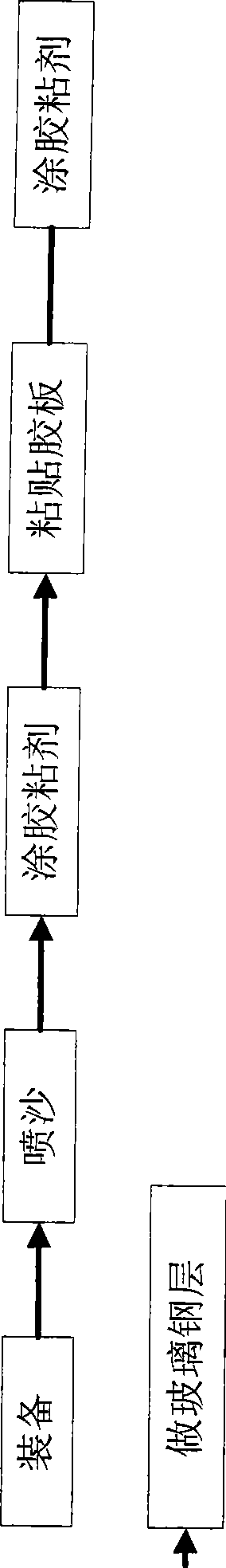

[0033] like figure 1 The special adhesive for viscoelastic damping shown, its manufacturing method:

[0034] Equipment used: open mill, turn on the cooling water of the open mill, adjust the roller distance to the minimum, put in raw rubber, thin pass plasticizing more than 10 times, widen the roller distance to 2-4mm, add various compounding agents, Reverse refining 3 times, adjust the roller distance to about 1mm, make 3-6 triangle bags, and lay down 1-2mm thick film for backup; to prevent the film from sticking.

[0035] Dissolution: Cut the film into strips, soak in solvent for more than 24 hours, stir until fully dissolved, the solution concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com