Preparation method of lube base oil

A lubricating oil base oil and raw material oil technology, which is applied in chemical instruments and methods, petroleum industry, and hydrocarbon oil treatment, can solve the problems of different catalyst combinations and loading methods that are rarely reported, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

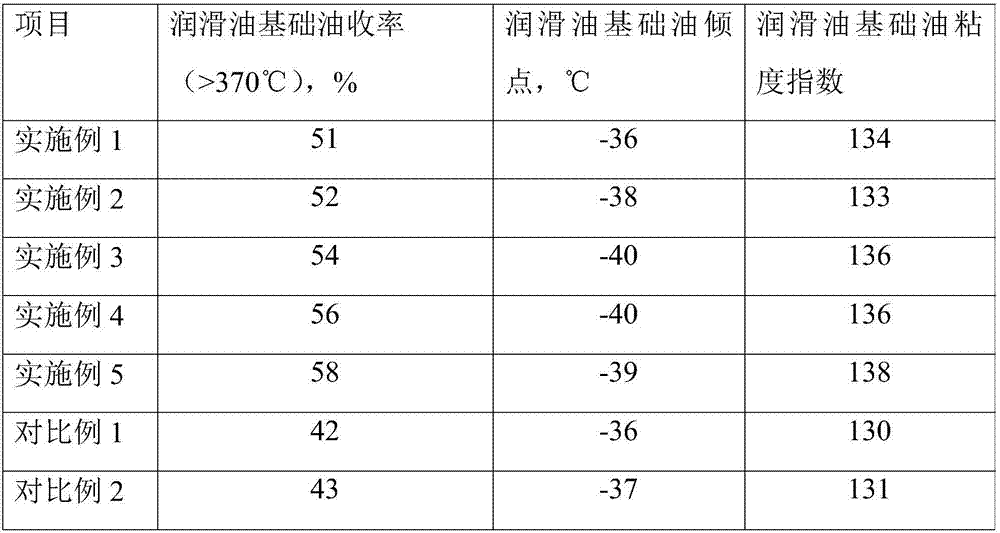

Examples

preparation example Construction

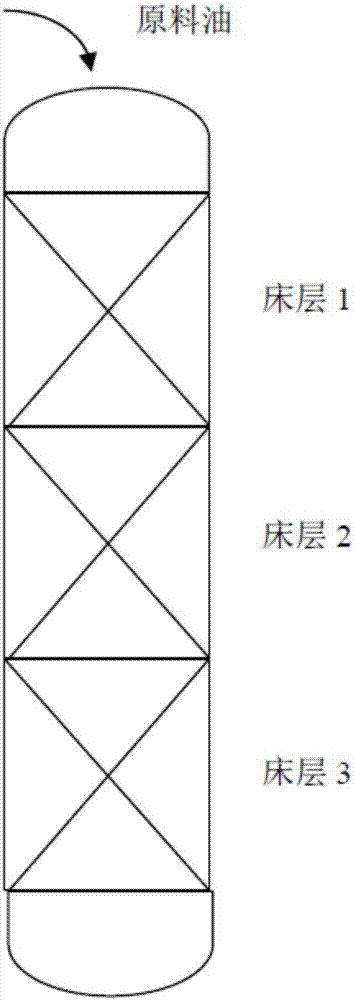

[0031] The invention provides a method for preparing lubricating oil base oil, the method comprising: contacting raw material oil with at least two isomerization catalysts including molecular sieves and Group VIII noble metals in a reactor and performing hydroisomerization reaction to obtain Lubricating oil base oil; wherein, according to the flow direction of the feedstock oil, at least two isomerization catalysts in the reactor are configured such that the diameter of the isomerization catalyst located downstream is larger than the strip diameter of the isomerization catalyst located upstream path.

[0032] According to the present invention, according to the flow direction of the raw material oil (the raw material oil can flow from top to bottom, from bottom to top or alternately from top to bottom), at least two isomerization catalysts can be filled in the reactor in a manner that only one reactor is filled , and multiple reactors can also be filled; if only one reactor is...

preparation Embodiment 1

[0073](1) Take 30g (by weight on a dry basis, the same below) ZSM-12 molecular sieve (12-membered ring molecular sieve, with a silicon-aluminum ratio of 80) and 70g (by weight on a dry basis, the same below) alumina (by weight on a dry basis, the same below). Provided in the form of boehmite, the same below) was prepared into cylindrical wet bars with a diameter of 1.4 mm by dry mixing and extrusion. The wet strip was dried at 120°C for 4h, and then calcined at 500°C for 6h to obtain the catalyst carrier. The water absorption of the catalyst carrier was measured to be 0.9. The method of measuring water absorption is: put 100g carrier into a beaker, add 2 times deionized water to soak for 2 hours, filter out excess water and weigh the wet bar, subtract 100g from the wet bar weight and divide it by 100 to get the water absorption rate .

[0074] (2) Dissolve 2.29g of zinc nitrate hexahydrate in water, then add water to make the volume to 100mL. 100 g of the catalyst carrier o...

preparation Embodiment 2

[0078] Preparation Example 2 is basically the same as the method of Preparation Example 1, except that the diameter of the cylindrical wet bar in step (1) is 1.6 millimeters, and the catalyst B-2 prepared in Preparation Example 2 has a composition as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com