Manufacturing method of simulation tree mould

A manufacturing method and simulation tree technology, applied in special decorative structures, decorative arts, etc., can solve problems such as high mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] A method for manufacturing a simulation tree mold, characterized in that: comprising the following steps:

[0026] (1) The production of molded tires, making a simulation tree 1 with mixed resin;

[0027] (2) The production of the upper mold,

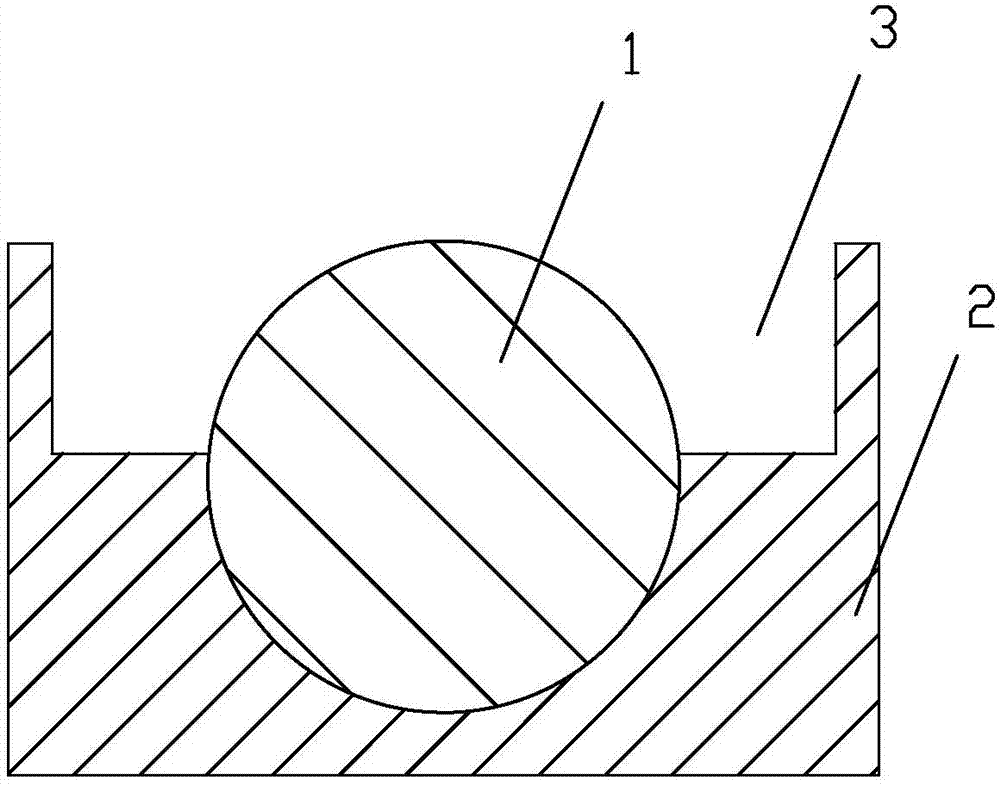

[0028] A. Lay oil sludge 2 on the ground and make it flat, half of the simulation tree 1 is embedded in the oil sludge 2, and use the oil sludge 2 to form a frame around the simulation tree 1 to form a perfusion groove 3;

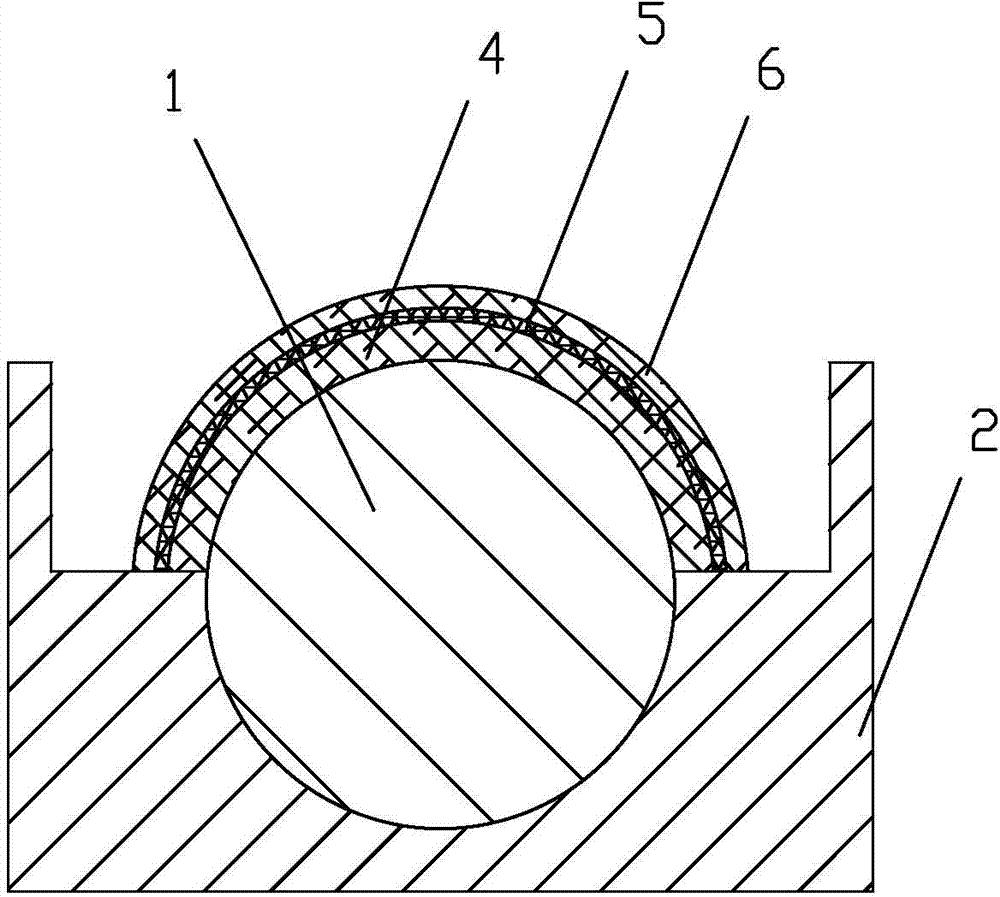

[0029] B. Apply a layer of vaseline on the simulation tree 1;

[0030] C, coating silica gel layer 4 on the vaseline layer;

[0031] D. Cover the abrasive cloth layer 5 on the silica gel layer 1;

[0032] E, tank silica gel in the perfusion tank 3 to form the second silica gel layer 6;

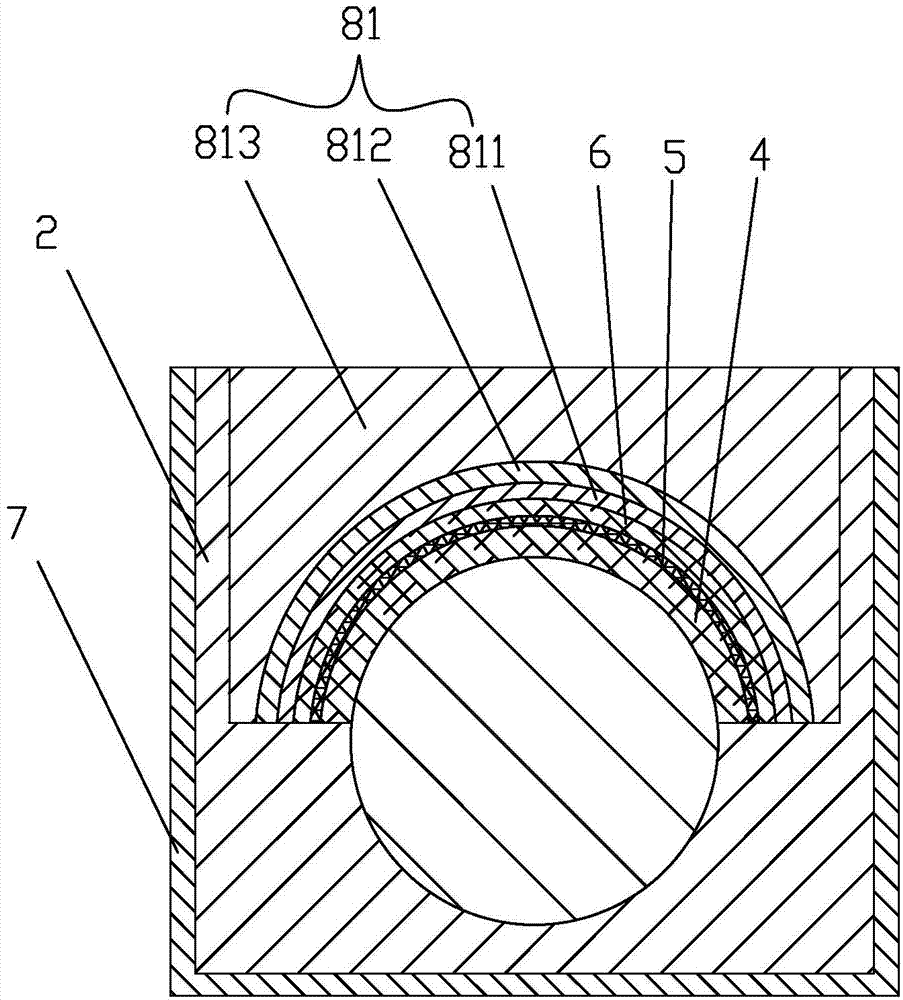

[0033] F, make the box body 7, remove the oil sludge 2 around the simulation tree 1, and frame the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com