Process for treating oily sludge

A sludge treatment and treatment process technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, biological water/sewage treatment, etc., can solve the waste of petroleum resources and insufficient treatment of oily sludge , complex equipment and other problems, to achieve the effect of recycling, realizing harmless treatment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

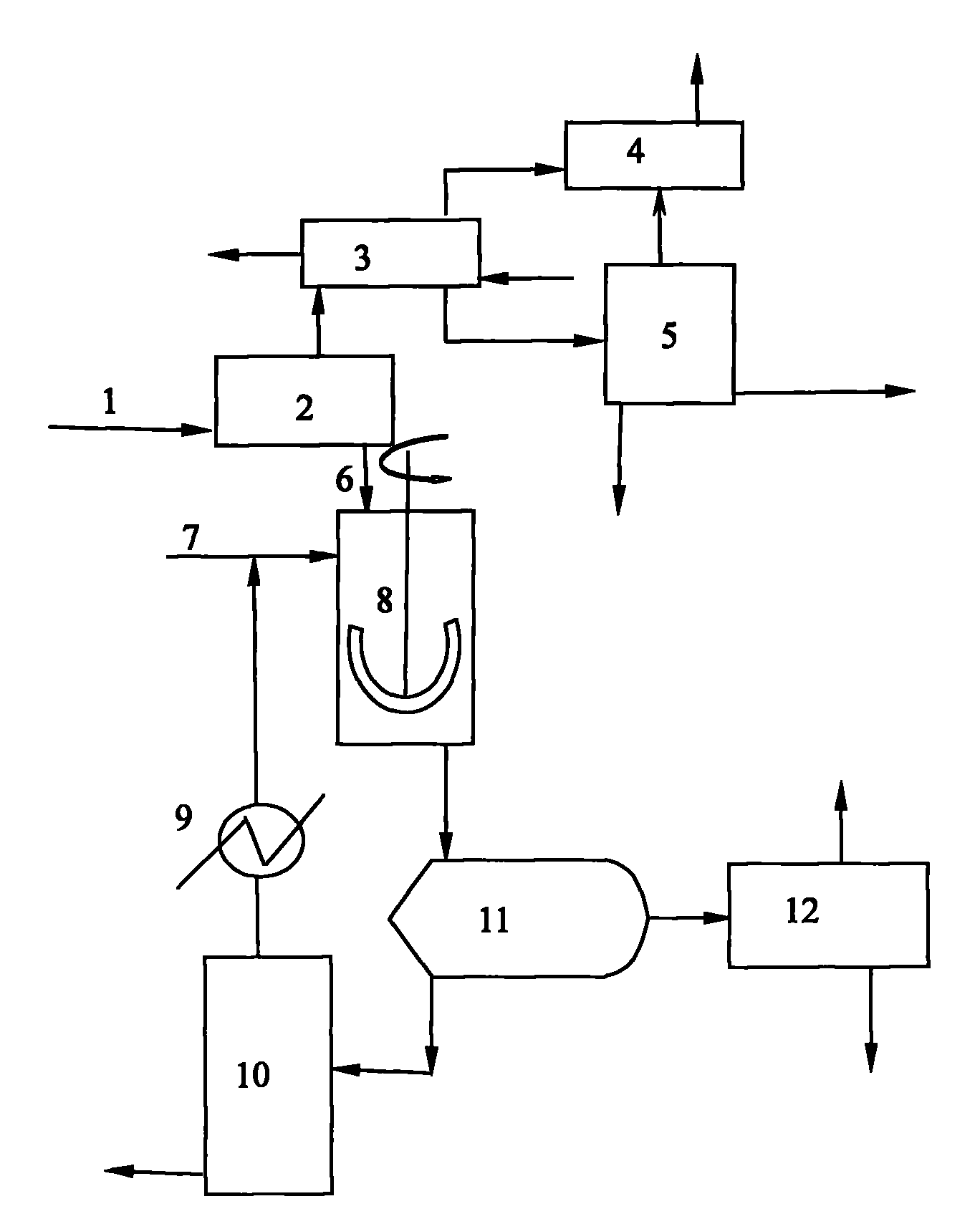

Method used

Image

Examples

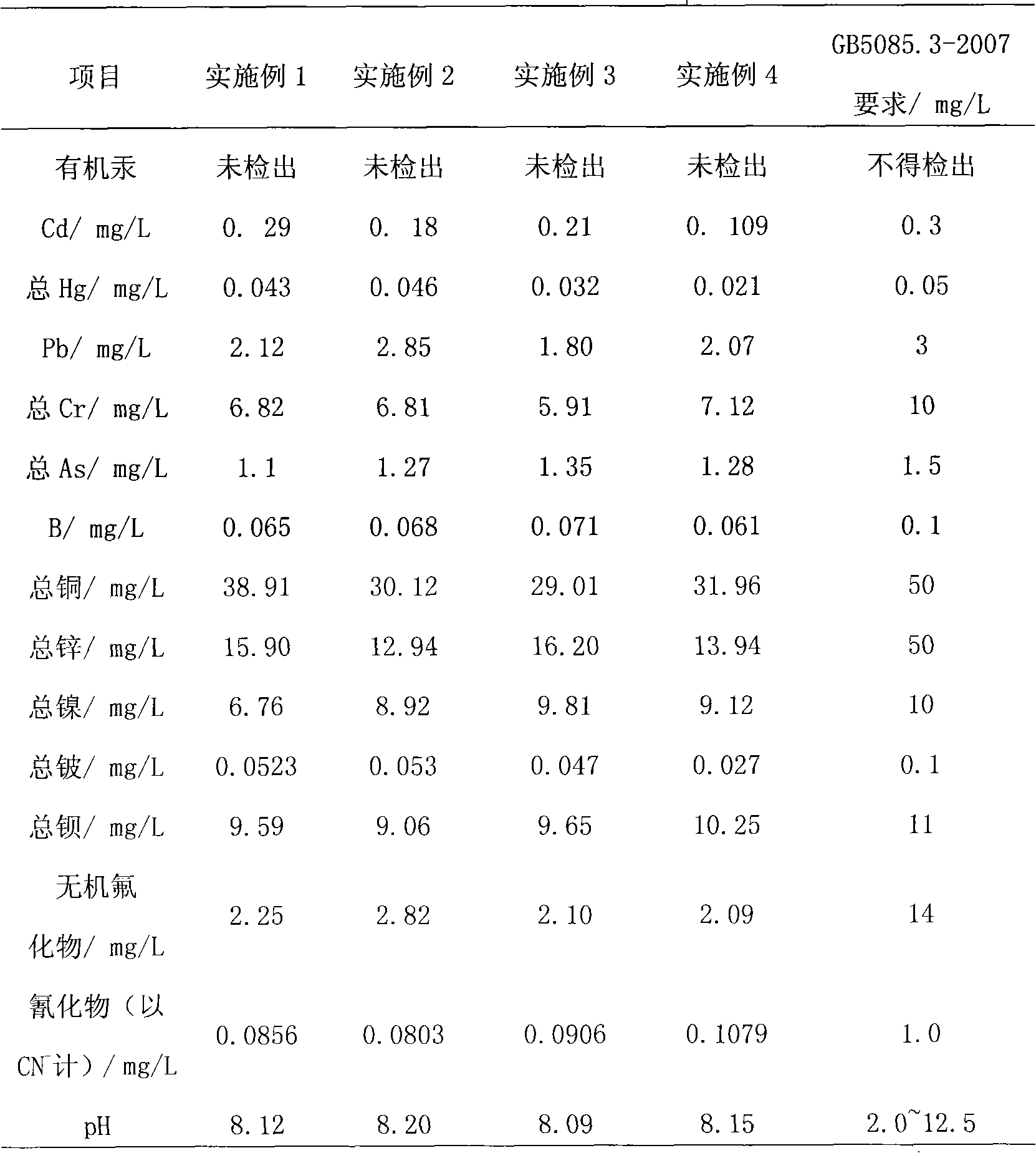

Embodiment 1

[0028]The oily sludge produced by a refinery sewage treatment plant has a water content of 75.5wt%, an oil content of 19.6wt%, and a solid content of 4.9wt% after mechanical dehydration. After the sludge was dried in the paddle-leaf sludge dryer (drying temperature 300°C, pressure 20kpa (absolute pressure)) for 85min, the water content of the coke produced was 1.2wt%, and its mass ratio to butane was 1 : 95 mixed for extraction for 30min (at a temperature of 0°C). After the extraction is completed, the solid-liquid mixture is sent to a centrifugal separator, and the separated liquid phase mixture is recycled after solvent regeneration in the rectifying tower, and the solid phase enters the rotary The evaporator, at a temperature of 180°C and a pressure of 100KPa (absolute pressure), evaporated for 65 minutes to obtain the final solid waste residue. The analysis results are shown in Table 1. The analysis results show that the final residue generated by this treatment method can...

Embodiment 2

[0032] The oily sludge produced by a refinery sewage treatment plant has a water content of 79.5wt%, an oil content of 15.7wt%, and a solid content of 4.8wt% after mechanical dehydration. The sludge is dried in the rotary kiln evaporator at a temperature of 300°C and a pressure of 100KPa (absolute pressure). After drying for 75 minutes, the water content of the coke produced is 58.5wt%, and its mass ratio to octane is 1 : 8 mixed for extraction, the extraction temperature is 45°C, and the extraction time is 15min. After the extraction is completed, the solid-liquid mixture is sent to a centrifugal separator, and the separated liquid phase mixture is recycled after realizing solvent regeneration in the rectifying tower. The solid phase enters the rotary kiln evaporator and evaporates for 72 minutes at a temperature of 150°C and a pressure of 60kpa (absolute pressure) to obtain the final solid waste residue. The analysis results show that the residue generated by this treatment m...

Embodiment 3

[0036] The oily sludge produced by a refinery sewage treatment plant has a water content of 82.5wt%, an oil content of 15.7wt%, and a solid content of 4.8wt% after mechanical dehydration. This sludge is 160 ℃ in the rotary evaporation heater, under the condition of 40kpa (absolute pressure) at the temperature, after drying for 60min, the water content of the coke produced is 40.5wt%, and its mass ratio with diesel oil is 1: 20 mixed for extraction, the extraction temperature is 20°C, and the extraction time is 10 minutes. After the extraction is completed, the solid-liquid mixture is sent to a centrifugal separator, and the separated liquid-phase mixture is regenerated in the rectification tower and then recycled. The phase enters the rotary steam evaporator and evaporates at a temperature of 135°C and a pressure of 60KPa (absolute pressure) for 80 minutes to obtain the final solid waste residue. The analysis results show that the residue generated by this treatment method can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com