Multilayer rotary kiln based small granular material destructive distillation method

A small particle, rotary kiln technology, applied in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve the problems of unutilized latent heat, low operation rate, huge equipment, etc., to reduce gas purification and storage and transportation links, Effects of reducing gas purification links and saving equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

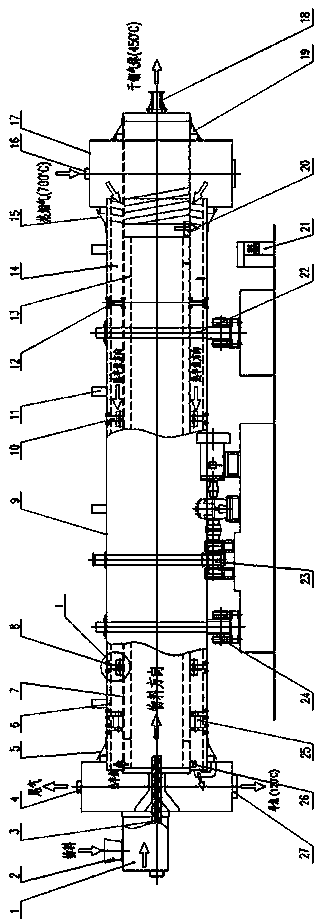

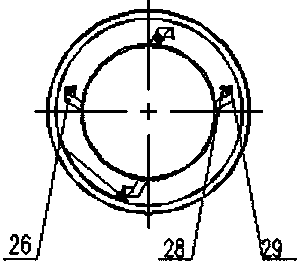

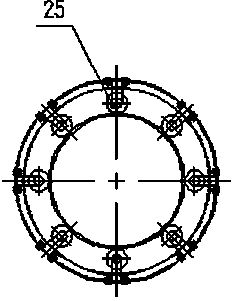

[0030] See Figure 1 to Figure 7 The specific structure of a multi-layer rotary kiln for dry distillation of small particles in the present invention is:

[0031] Including kiln head 1, kiln tail 17, kiln body 9, supporting devices 22, 24, transmission device 23, wireless temperature measuring device 11 and automatic control system 21; among them,

[0032] The front end of the kiln head 1 is provided with a feeding device 2 and a screw conveying device 3, the upper part of the kiln head 1 is provided with a hot flue gas exhaust pipe 4, the lower part of the kiln head 1 is provided with a discharge device 27, and the kiln head 1 and the kiln body 9 A feed seal 5 is provided in the room;

[0033] A dry distillation gas exhaust pipe 18 is provided at the end of the kiln tail 17, a hot flue gas inlet pipe 16 is provided on the kiln tail 17, and seals 15 and 19 are provided between the kiln tail 17 and the kiln body 9;

[0034] The kiln body 9 includes an outer cylinder body 6 and an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com