Passivation process and passivation system of active coke

A coal char and active technology, applied in the field of passivation process and passivation system of active coal char, can solve the problems of huge process cost burden, high oxidant cost and high requirements, and achieve low production process cost, high practicability, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

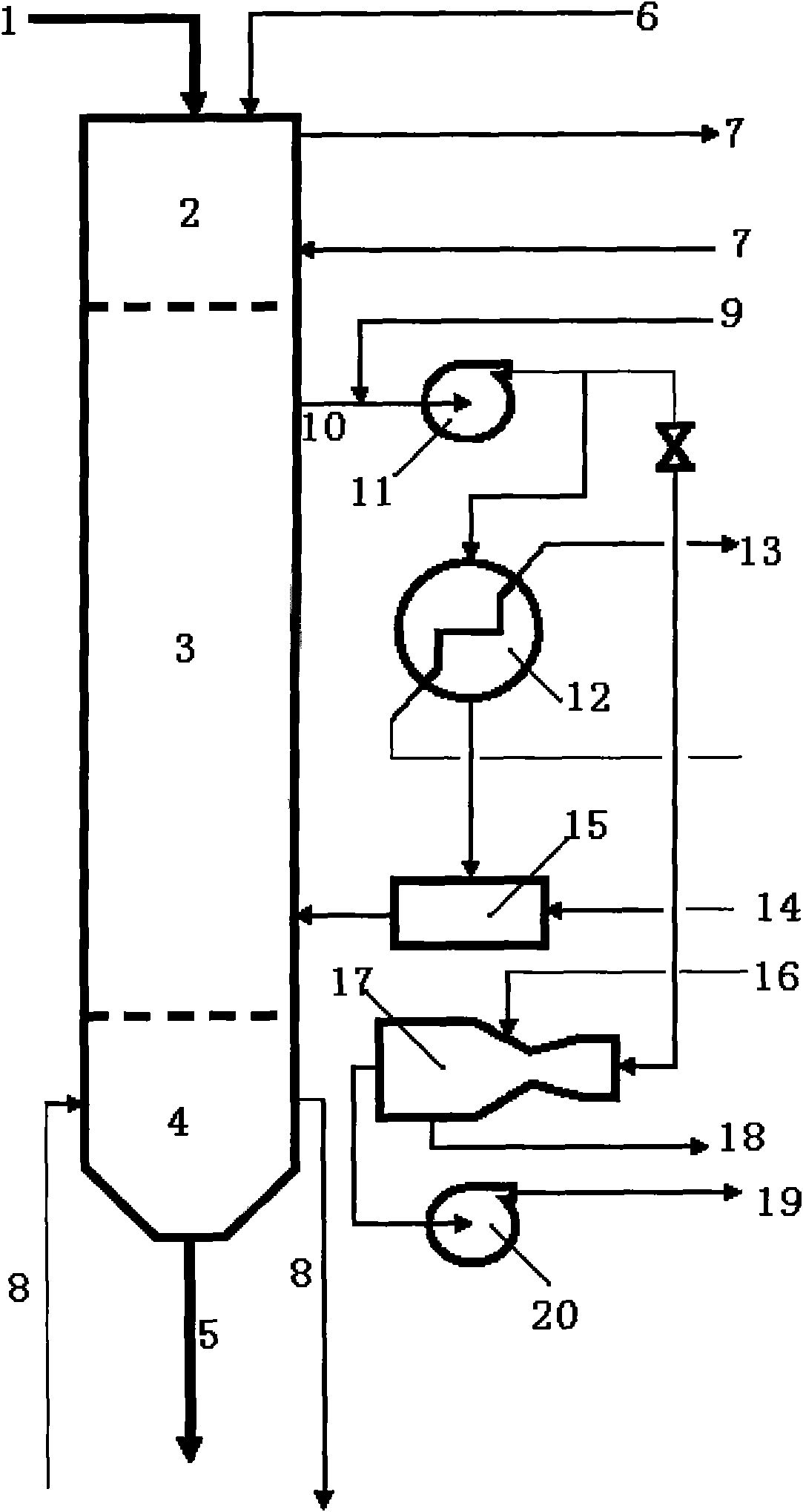

[0053] About 2 tons of high-activity coal char 1 with a water content of 5% and a temperature of 95°C that has undergone low-temperature dry distillation treatment (spontaneous combustion occurs within a short period of time when exposed to air), is added to the passivation refining reactor for continuous passivation treatment, First enter the rehydration reaction zone 2 for rehydration and cooling, after a period of reaction, the temperature of the coal char 1 entering the low temperature passivation reaction zone 3 is 50-55°C, and the water content is 9% (surrounding environment balance Humidity is 8%), the temperature is 50 ℃, the oxygen content is 16%, the relative humidity is 80% low-temperature passivation reaction gas for passivation treatment, the passivation gas flow rate is 5 to 10 cubic meters per kilogram of coal char , after 4 to 6 hours of passivation treatment, enter the cooling zone 4 and be cooled to the same temperature as the surrounding environment. The wat...

Embodiment 2

[0056] Continuous passivation treatment is carried out on about 19 tons of active coal char 1 with a water content of 1-3% and a temperature of 106°C that has undergone low-temperature carbonization treatment. The coal char is cooled and rehydrated in the reactor. The temperature after rehydration and cooling is 45-50°C, and the coal char with a water content of 9% is added to the passivation refining reactor. Inner 3 is passivated by low-temperature passivation reaction gas with a temperature of 55°C, an oxygen content of 18%, a relative humidity of 85%, and a flow rate of 12 to 15 cubic meters per kilogram of coal. After 16 to 19 hours of passivation treatment After entering into the cooling zone 4, it is cooled to normal temperature. Coal char with a water content of 8-9% is obtained after passivation treatment.

[0057] It has been verified that the coal coke after the above treatment is piled up in the environment and placed for a long time, and its properties are stable...

Embodiment 3

[0059] Continuous passivation treatment is carried out on about 10 tons of active coal char 1 with a water content of 4-5% and a temperature of 103°C that has undergone low-temperature carbonization treatment. The coal char is cooled and rehydrated in the reactor. The temperature after rehydration and cooling is 55-60°C, and the coal char with a water content of 8-9% is added to the passivation refining reactor. The reaction zone 3 is passivated by the low-temperature passivation reaction gas with a temperature of 58°C, an oxygen content of 19%, a relative humidity of 90%, and a flow rate of 8 to 13 cubic meters per kilogram of coal. After 7 to 11 hours of passivation After chemical treatment, enter the area of cooling zone 4 and cool to normal temperature. Coal char with a moisture content of 9% was obtained after passivation treatment.

[0060] It has been verified that the char after the above treatment has been placed in the environment for a long time, and its properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com