Method for preparing semicoke, empyreumatic oil and coal gas by pyrolyzing coal

A technology of coal pyrolysis and semi-coke, which is applied in coke cooling, coke oven, petroleum industry, etc., can solve the problems of difficulty in meeting industrial and civil requirements, unstable product quality, high price, etc., to ensure maximum utilization rate and guarantee Extensive adaptability and strong adaptability to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

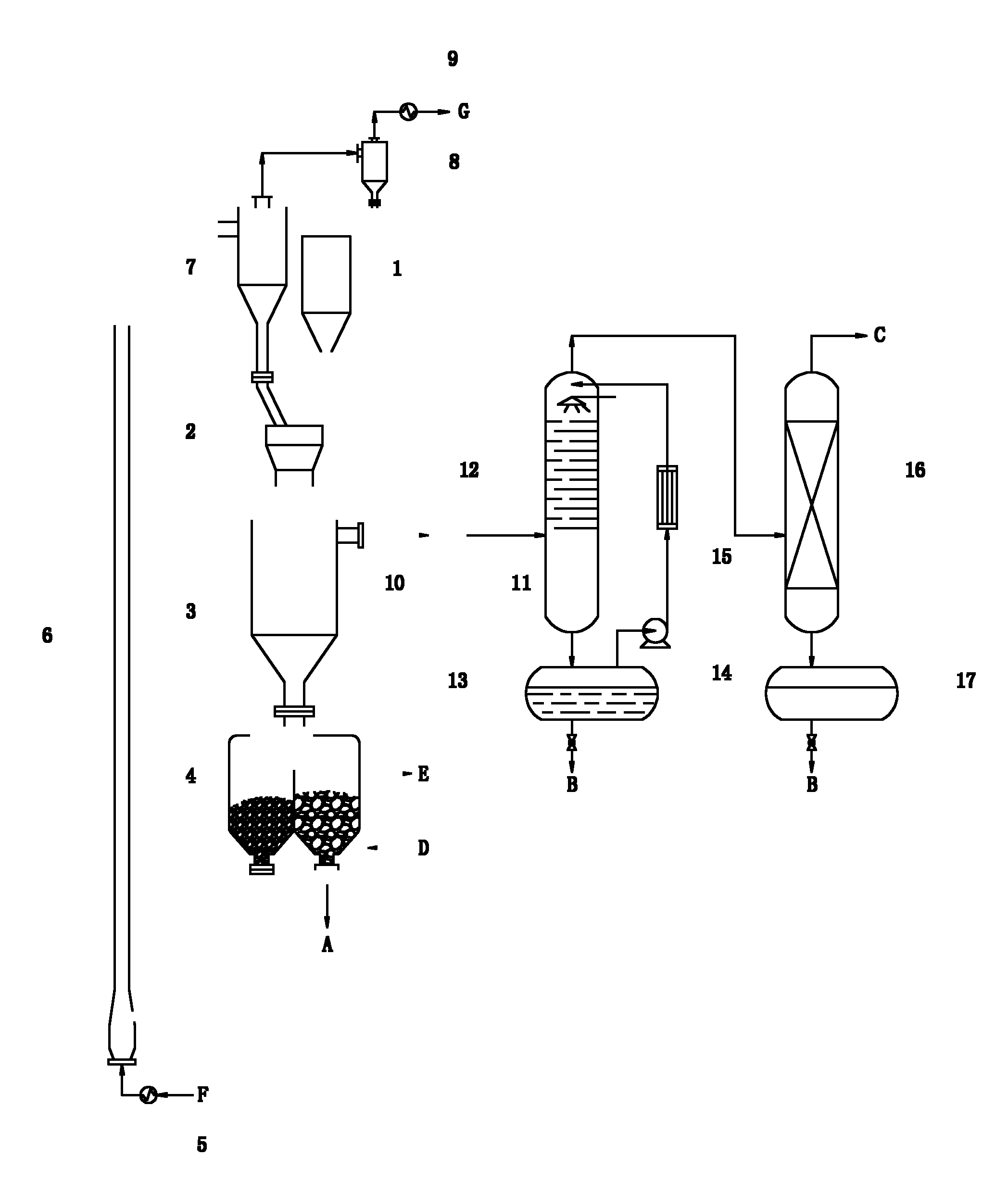

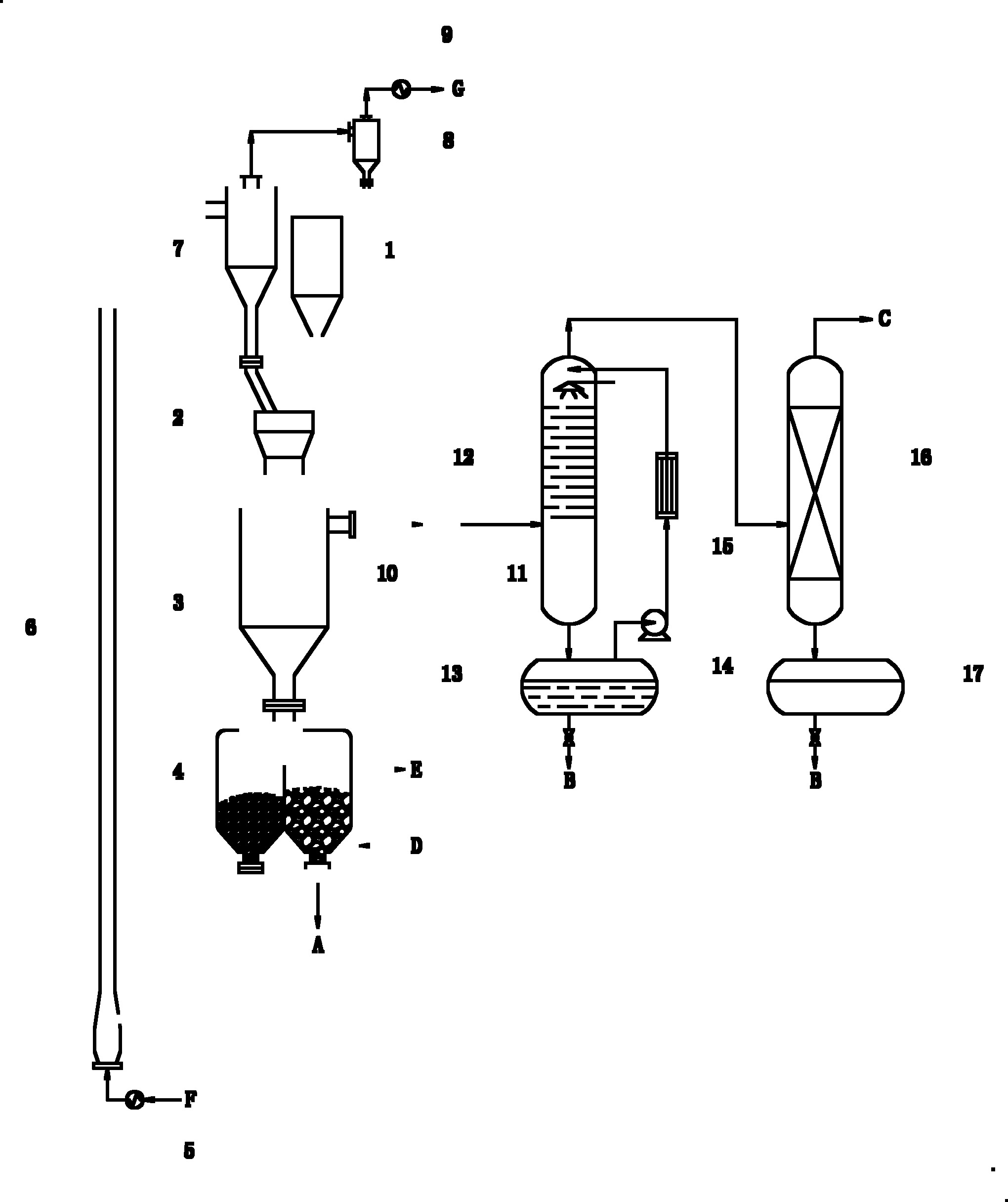

[0026] As shown in the figure, the raw coal is fed into the mixer 2 from the raw material storage tank 1 through the feeder, mixed with the high-temperature solid heat carrier circulated from the heat carrier warehouse 7, and the temperature rises rapidly, and then the heat carrier and the coal enter the lower heat sink together. Solution Reactor 3.

[0027] The heat carrier and coal move slowly downwards in the pyrolysis reactor 3 under the control of the material level control system. At the same time, the coal undergoes pyrolysis reaction here to generate solid semi-coke and volatile pyrolysis gas products (the main component of the gas is H 2 , CO, CO 2 、CH 4 , water vapor and tar vapor, etc.). The gaseous products are drawn off via the pyrolysis gas channel 10 on the pyrolysis reactor. The heat carrier and semi-coke enter the solid classification separator 4 from the bottom of the reactor.

[0028] The solid fractionation separator 4 separates materials of different s...

Embodiment 2

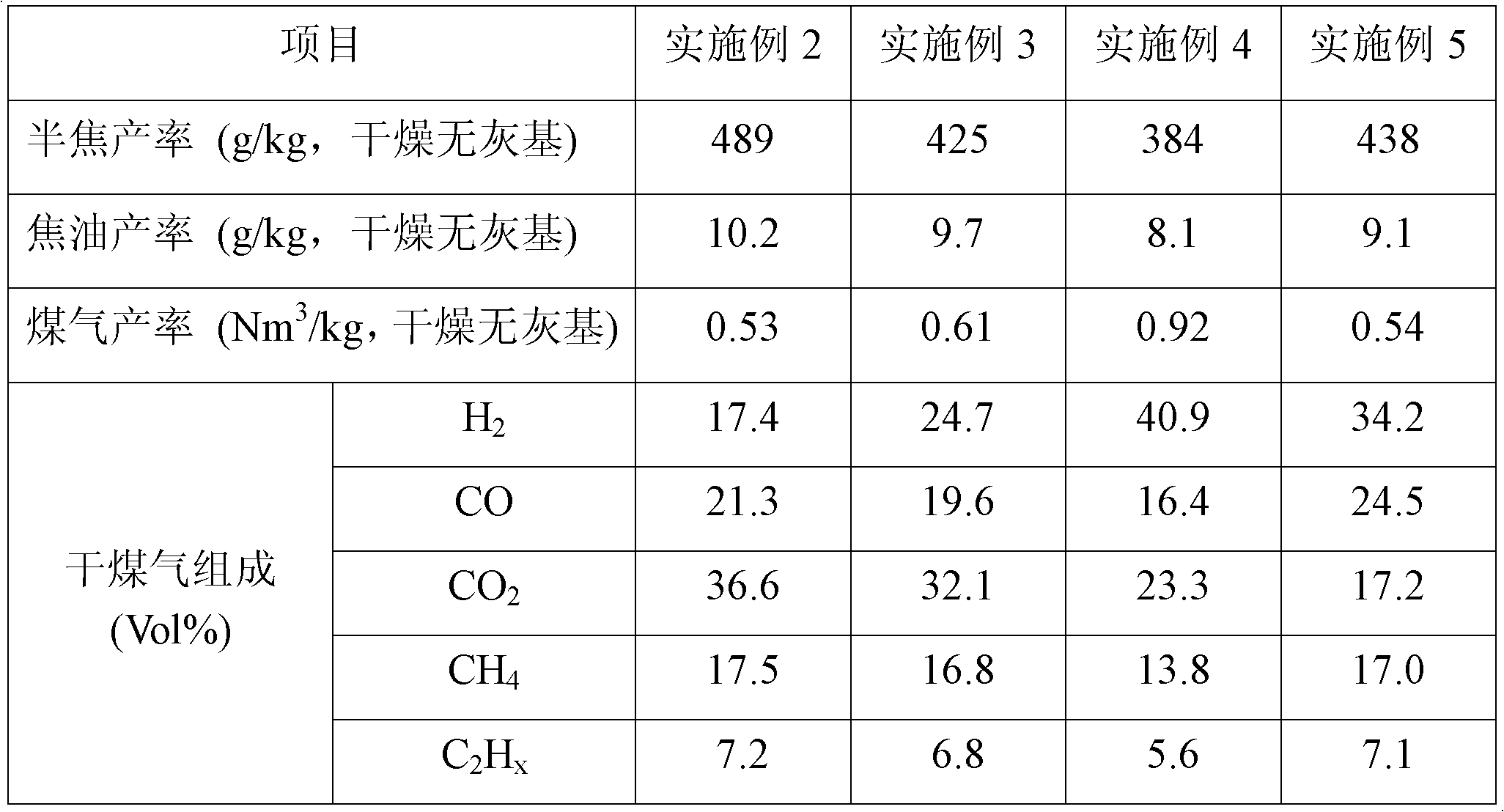

[0032]As shown in the attached figure, in the atmospheric pressure experimental device, the raw material is lignite, the particle size is less than 10mm, and its dry ash-free element mass composition is: C 72.2%, H 5.6%, O 21.1%, N 1.0%, S 0.1% . The solid heat carrier used is natural olivine with a particle size of 0.4-1.5mm. The temperature of the pyrolysis reactor was controlled at 550°C, the temperature of the riser combustion reactor was 800°C, and the mass ratio of solid heat carrier to coal was 1:1. The data of product composition and yield are shown in Table 1.

Embodiment 3

[0034] As shown in the attached figure, in the atmospheric pressure experimental device, the raw material is lignite, the particle size is less than 50mm, and its dry ash-free element mass composition is: C 72.2%, H 5.6%, O 21.1%, N 1.0%, S 0.1% . The solid heat carrier used is natural olivine with a particle size of 1.5-3.0mm. The temperature of the pyrolysis reactor was controlled at 700°C, the temperature of the riser combustion reactor at 900°C, and the mass ratio of solid heat carrier to coal was 4:1. The data of product composition and yield are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com