Process and device for sludge pyrolysis

A sludge and pyrolysis technology, which can be used in combined devices, pyrolysis sludge treatment, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high water content, secondary pollution, secondary environmental pollution, etc. The effect of increasing furnace loading, high heating efficiency and increasing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

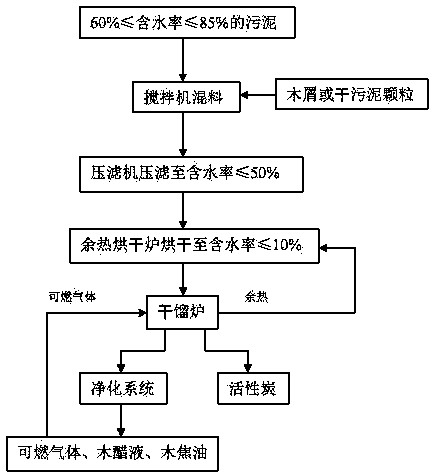

Method used

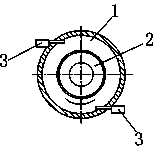

Image

Examples

Embodiment 1

[0028] The sludge with a moisture content of 85% is added to wood chips, and the weight percentages of the two are: sludge with a moisture content of 85% is 85%, and wood chips are 15%; mix evenly in a mixer, and press filter in a crawler filter press to The moisture content is ≤50%, and made into strip-shaped sludge briquettes; the sludge briquettes are put into the hanging basket and put into the waste heat drying furnace. The pre-drying temperature is about 200°C. Pre-dried in a waste heat drying furnace until the moisture content is ≤10%, and then put it into the inner kettle of the carbonization furnace for carbonization. The furnace heating temperature of the carbonization furnace is 550°C; the gas generated by the carbonization is separated and purified by the purification system to become a Gas, wood vinegar, wood tar, the calorific value of the combustible gas can reach 4500 kcal, the combustible gas is transported to the burner, and is directly used for heating the re...

Embodiment 2

[0030]The sludge with a water content of 70% is added to the dry sludge granules, and the weight percentage of the two is: 80% of the sludge with a water content of 70%, and 20% of the dry sludge granules. Press filter in the filter until the water content is ≤50%, and make strip-shaped sludge briquettes; put the sludge briquettes into hanging baskets and put them into the waste heat drying furnace, and the pre-drying temperature is about 200°C , pre-dried in the waste heat drying furnace using the waste heat of the retort furnace to a moisture content of ≤10%, and then put it into the inner kettle of the retort furnace for retort distillation. The furnace heating temperature of the retort furnace is 500°C; Combustible gas, wood vinegar, and wood tar can be made from the separation and purification of the combustible gas. The calorific value of the combustible gas can reach 4500 kcal. The combustible gas is transported to the burner and directly used for heating the retort furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com