Free formaldehyde trapping agent and process for preparing same

A technology of free formaldehyde and production methods, applied in the direction of coating, etc., can solve the problems of increased production costs, deep color bending, and affecting the stability of urea glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

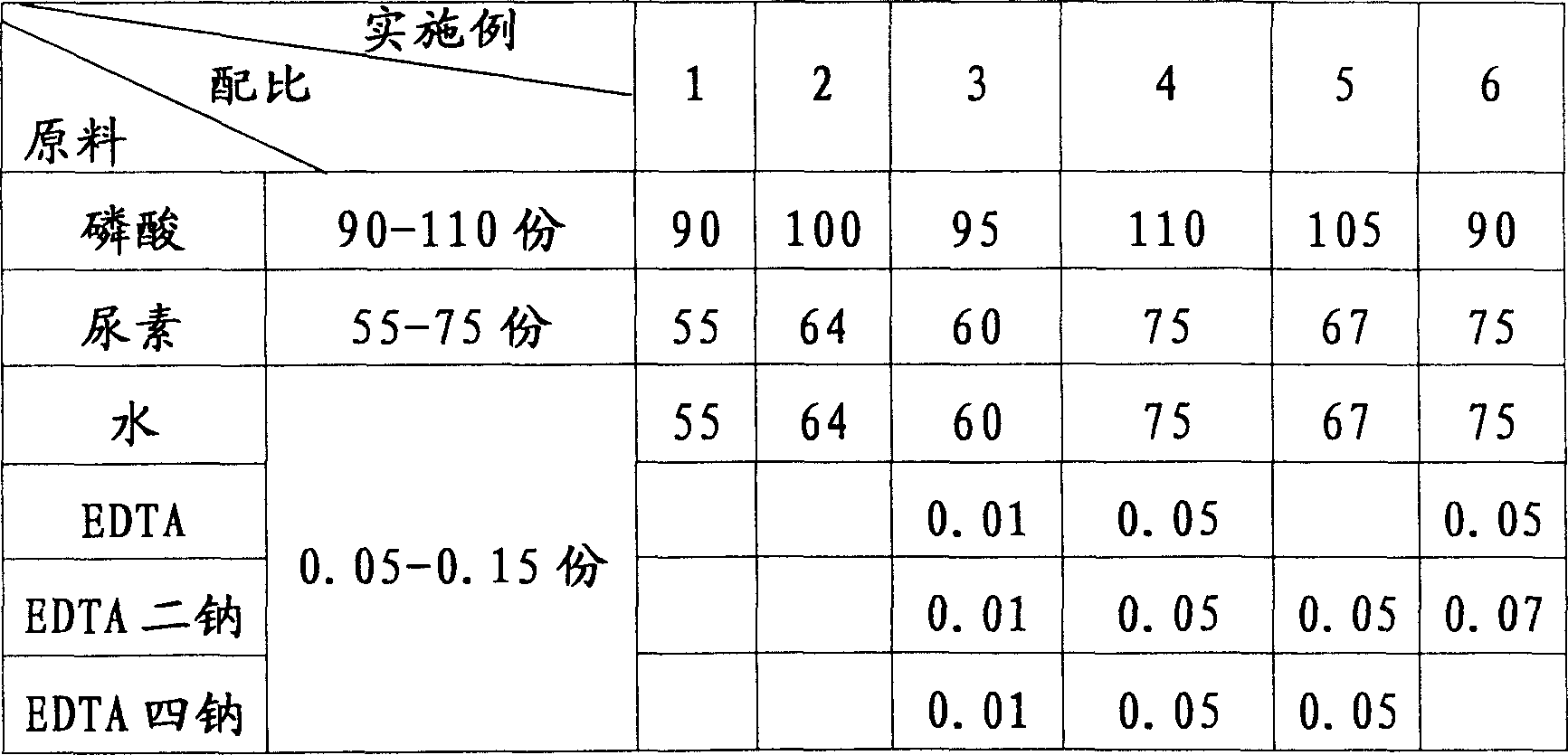

[0008] The present invention will be described in further detail below in conjunction with the examples: in the raw materials, phosphoric acid and urea are all used industrially pure, and their ideal mol ratio is 1: 1.05, and catalyst uses ethylenediaminetetraacetic acid, disodium edetate, At least one kind of tetrasodium edetate, the added amount is 0.05-0.15% of the sum of phosphoric acid and urea added. Raw materials and parts by weight thereof are listed six kinds of embodiments such as the following table 1 (wherein ethylenediaminetetraacetic acid is represented by EDTA) for ease of operation:

[0009]

[0010] Referring to the 6 kinds of embodiments listed in the table above, now illustrate with embodiment 1: earlier, 90 parts by weight (hereinafter referred to as parts) of phosphoric acid and 55 parts of urea are added to the reactor, stirred, and EDTA and 55 parts of water are added, heated to 120- Keep warm at 130°C. When the pH of the reaction solution is 6.0-6.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com