Wood industry plate drying device

A drying device and drying device technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of low energy saving, unsatisfactory drying effect, small lifting work, etc., and achieve the effect of strong energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

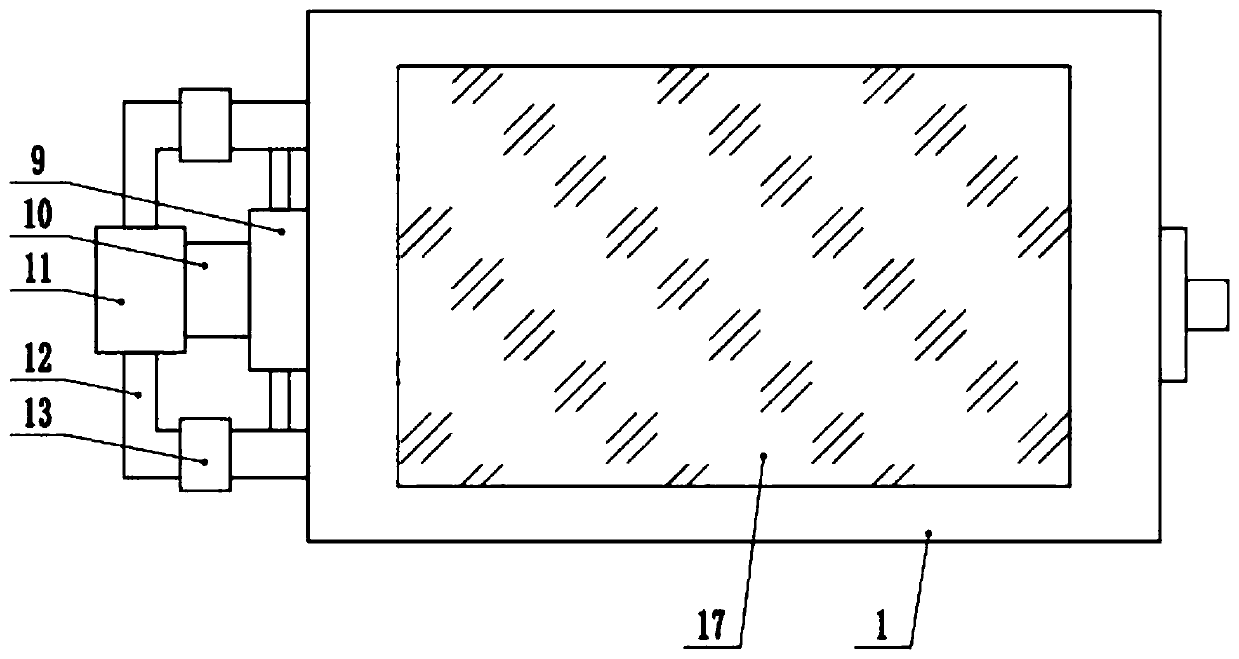

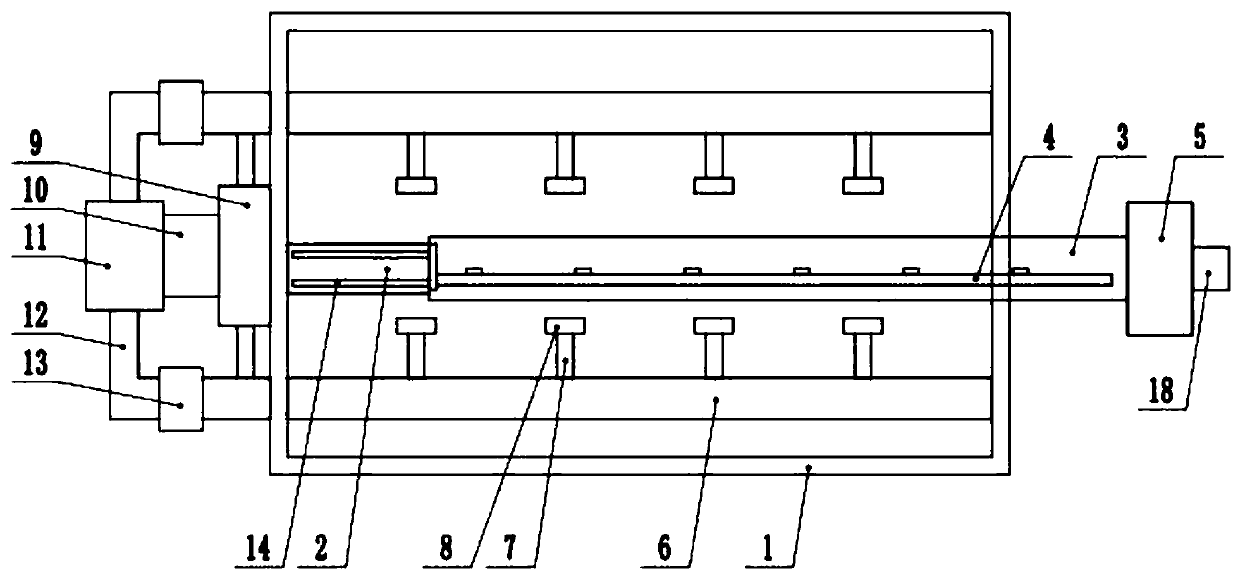

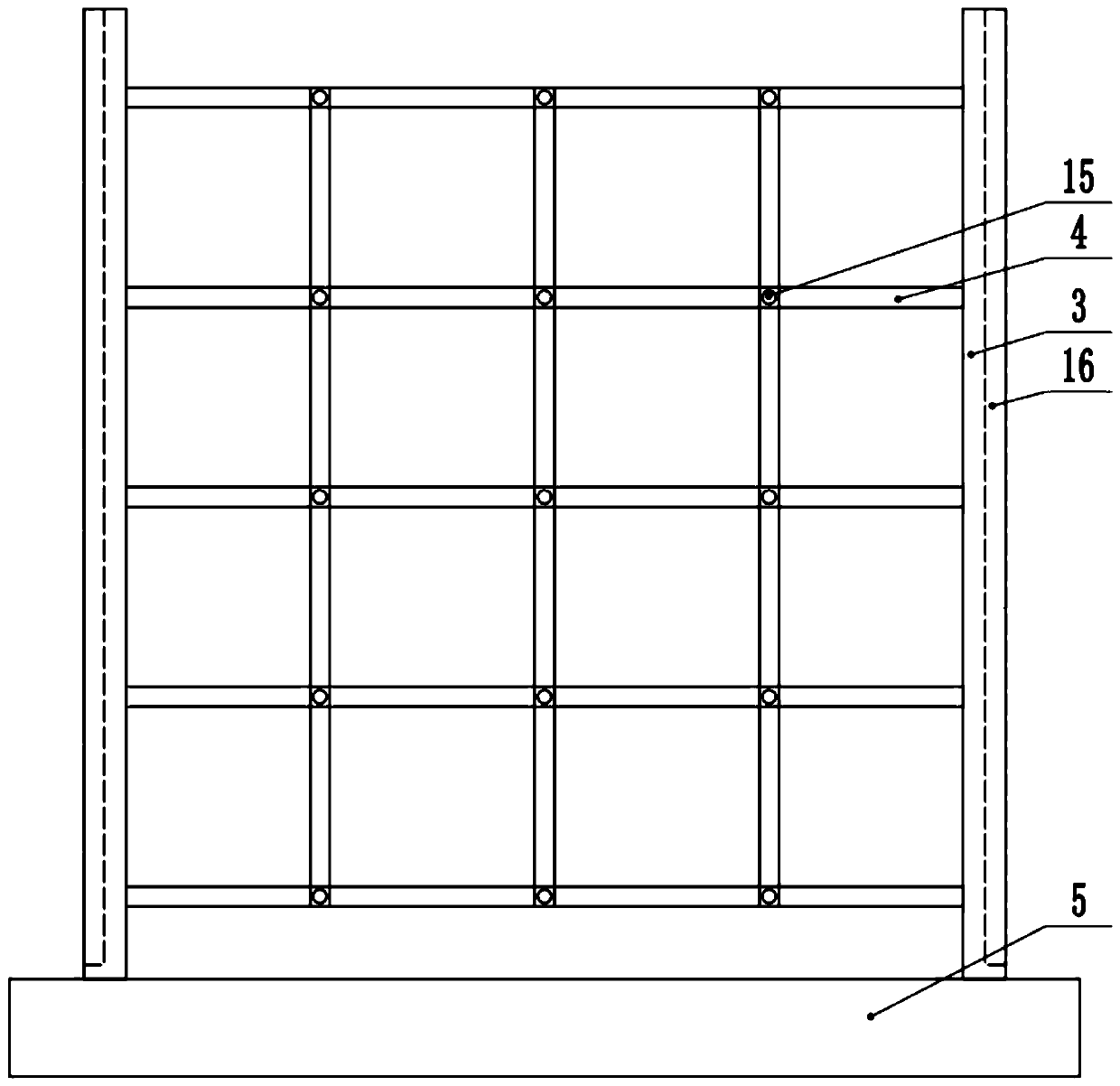

[0024] see Figure 1-3 , a wood panel drying device, comprising a drying box 1, the interior of the drying box 1 is provided with a drying mechanism and a plate placement mechanism, the outside of the drying box 1 is provided with a circulation drying mechanism, and the panel The placement mechanism includes fixed side plates 2 fixedly arranged on both sides of the inside of the drying box 1, a placement frame 4 is arranged between the two fixed side plates 2, and both sides of the placement frame 4 are fixedly connected to the sliding side plates 3. The ends of the side plates 3 are fixedly connected to the end plates 5, and the drying mechanism includes a return air pipe 6 and a hot air pipe arranged in the drying box 1. The end of the hot air pipe is fixedly provided with an exhaust head 8, and the return air There is a return air hole on the pipe 6, and the circulation drying mechanism includes a shunt cover 9 arranged at one end of the drying box 1, the shunt cover 9 is f...

Embodiment 2

[0027] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that a plurality of support blocks 15 are fixedly arranged on the placement frame 4, and one end of the end plate 5 away from the sliding side plate 3 is fixedly connected to a handle 18, The front side of the drying box 1 is provided with a viewing window 17 .

[0028] The present invention can conveniently move the wooden boards into the drying box 1 by setting the board placement mechanism, can dry the boards by setting the drying mechanism, and can dry the hot and humid air in the drying box 1 by setting the drying device 11 Drying can realize the recycling of hot air, which is highly energy-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com