Panel drying device for wood industry

A drying device and plate technology, applied in drying, drying machine, veneer drying, etc., can solve the problems of serious heat loss, reduce the cost of plate drying, reduce the efficiency of plate drying, etc., and achieve good drying effect , High working efficiency and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is not limited by the following examples, and specific implementations can be determined according to the technical solution and actual conditions of the present invention.

[0016] The present invention will be further described below in conjunction with embodiments and drawings:

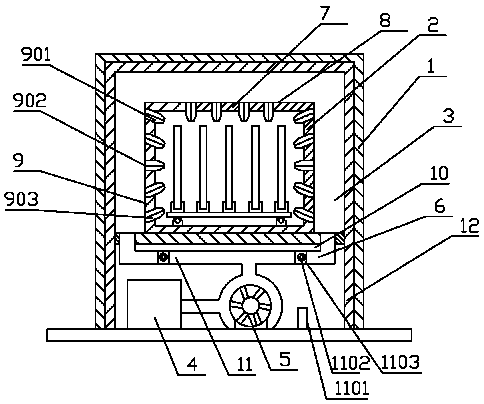

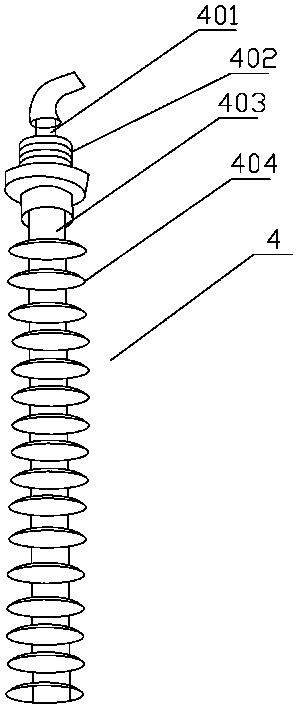

[0017] Such as figure 1 , 2 As shown, the wood board drying device includes an outer chamber body 1, an inner chamber body 2 and a hot air circulation system. A hot air flow space 3 is formed between the inner chamber body 2 and the outer chamber body 1. The hot air circulation system It includes a finned stainless steel heating tube 4, a fan 5, and an air duct 6 for introducing hot air into the hot air flow space 3. The stainless steel heating tube 4 is arranged inside the outer chamber 4, and the finned stainless steel heating tube 4 includes The high resistance electric heating alloy wire 401, the connecting screw 402, the electric heating tube 403, and the heat sink 404....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com