Combustor air distribution device and air distribution method

A technology of air distribution device and burner, which is applied in the combustion method, burner, controlled combustion, etc., can solve the problems of heat pollution, poor combustion efficiency and combustion stability, uneven mixing of air and fuel, etc., to achieve recirculation , to ensure the effect of sufficient and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

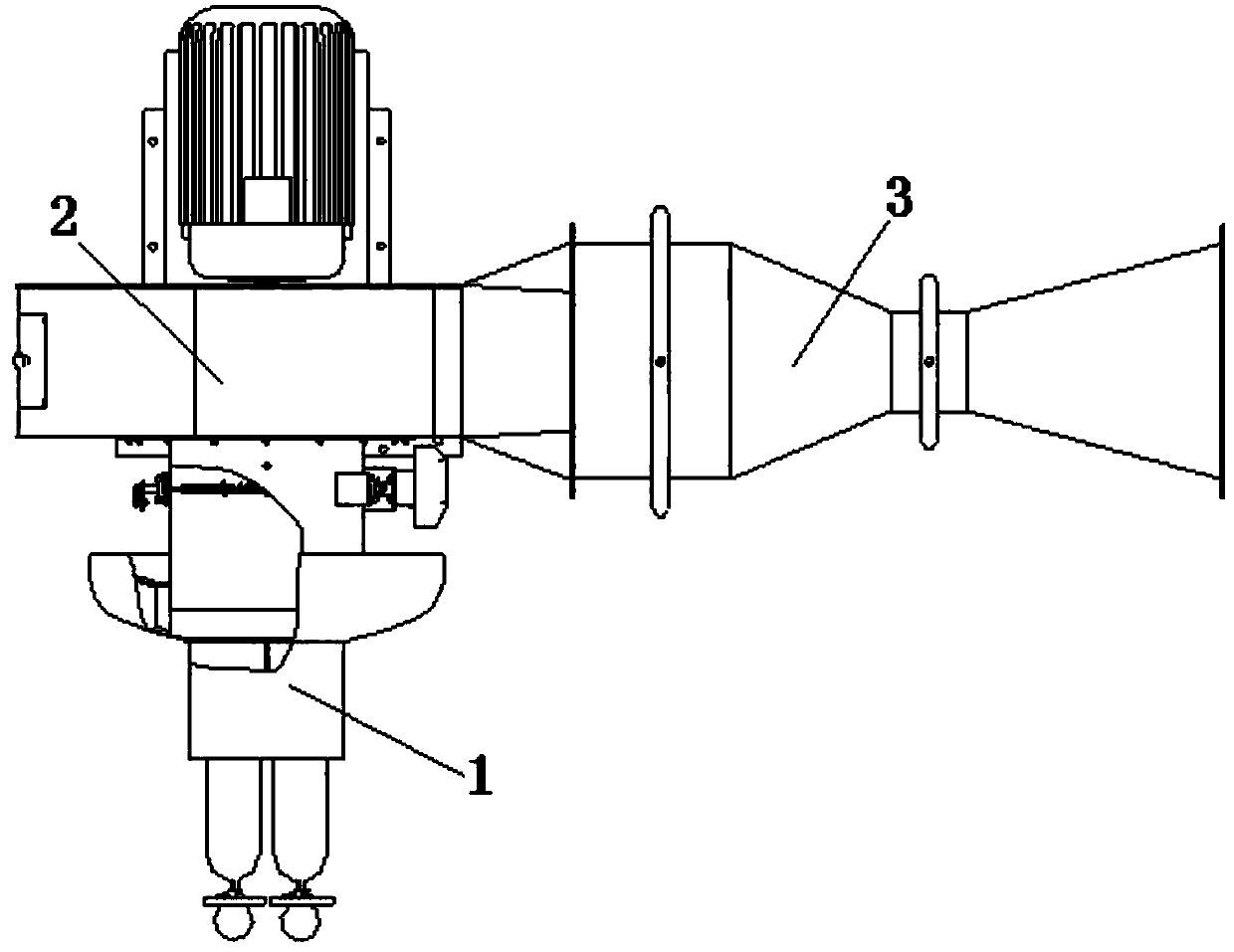

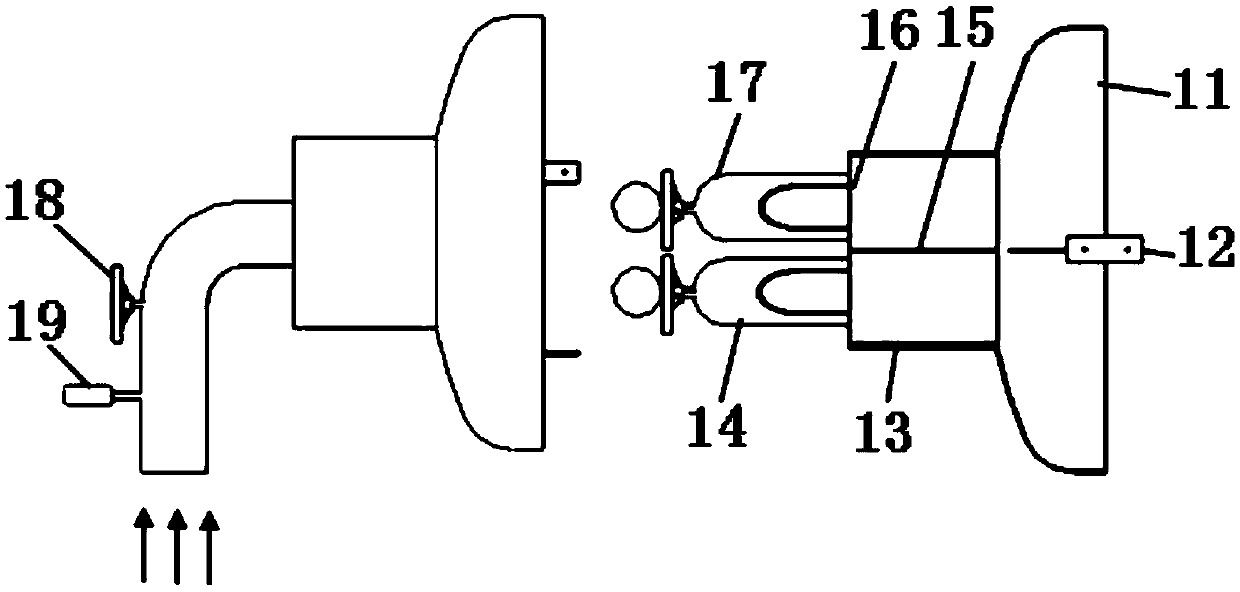

[0068] like figure 1 , figure 2 , image 3 As shown, it is a burner air distribution device, including an air intake device 1 , a blower 2 , and a blower output air volume detection device 3 .

[0069] The outlet of the air inlet device 1 is communicated with the blower 2, and the air outlet of the blower is delivered to the burner;

[0070] The air intake device 1 is provided with a flow detection sensor 19 for real-time detection of the gas flow entering the blower through the air intake device;

[0071] The blower 2 is provided with an air inlet for the intake of fresh air;

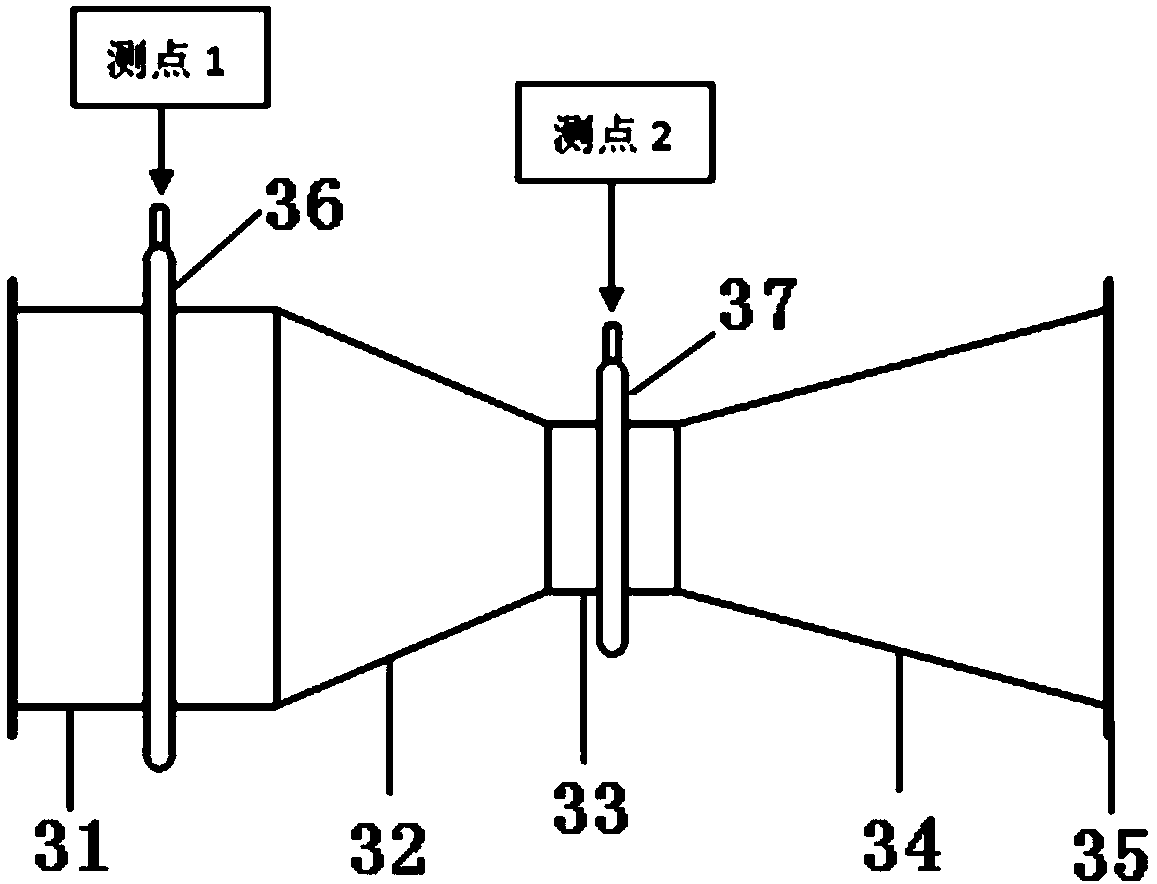

[0072] The blower output air volume detection device 3 is used for real-time detection of the output air volume of the blower, that is, the total air supply volume of the air distribution device;

[0073] The blower 2 is provided with a blower output air volume adjusting device for adjusting the output air volume of the blower.

[0074] The air intake device of the air distribution device can hav...

Embodiment 2

[0094] like Figure 4 As shown, a burner air distribution control device includes:

[0095] The acquisition unit is used to acquire information on the rotational speed of the blower, the flow rate of combustible waste gas, the flow rate of the recirculated flue gas, and the total air supply volume of the blower;

[0096] The calculation / comparison unit is used to calculate and obtain the preset value of the total air supply volume, calculate whether the difference between the measured value of the total air supply volume of the blower and the set value of the total air supply volume exceeds the set error value; calculate the measured value of the combustible waste gas flow and Whether the difference between the preset values of the combustible waste gas flow exceeds the set error value; calculate whether the difference between the measured value of the recirculation flue gas flow and the preset value of the recirculation flue gas flow exceeds the set error value; get the cal...

Embodiment 3

[0101] like figure 1 , figure 2 , image 3 , Figure 4 As shown, it is a burner air distribution system, including the above-mentioned burner air distribution device and the above-mentioned burner air distribution control device.

[0102] Further, the detection unit on the air distribution device includes a blower rotation speed detection unit to detect the blower rotation speed information; a combustible waste gas flow detection sensor to detect the combustible waste gas flow information; a recirculation flue gas detection unit to detect Recirculated flue gas volume and flue gas oxygen content information; used to detect and collect information such as blower speed, combustible waste gas flow, recirculated flue gas flow, flue gas oxygen content, and total air supply volume of the blower; and send the information to The control device, the control device receives the blower speed, the combustible waste gas flow rate, the recirculating flue gas flow rate, the oxygen content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com