A method for preparing biomass fuel from kitchen waste

A technology of biomass fuel and kitchen waste, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problem of incomplete treatment of solid residues, and achieve the effect of comprehensive treatment, no secondary pollution, and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

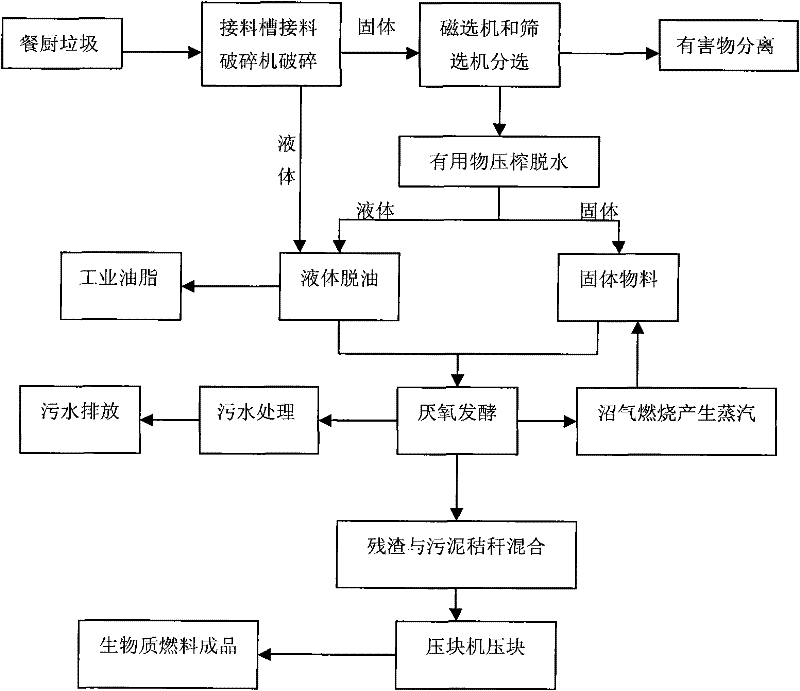

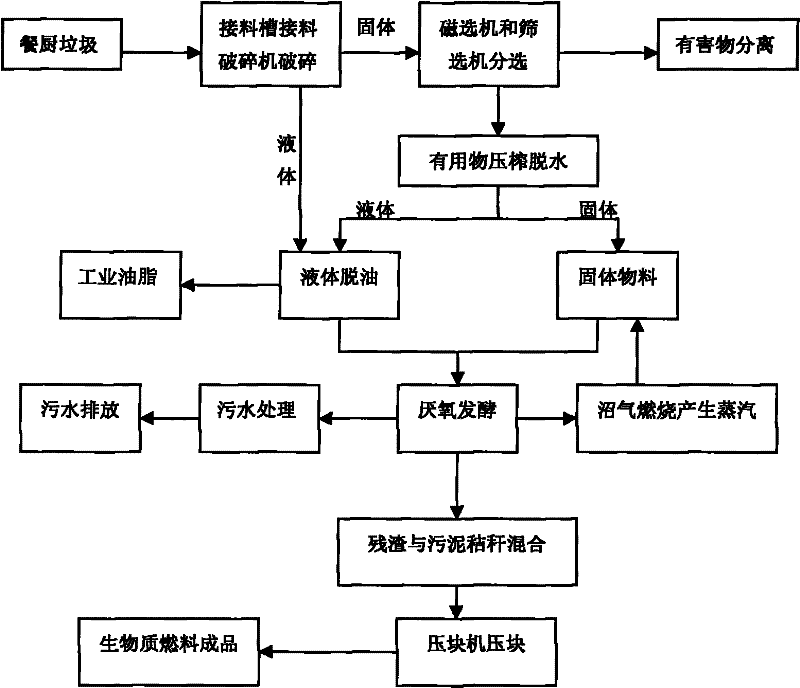

Image

Examples

Embodiment Construction

[0017] The detailed technological process of the method for preparing biomass fuel by using kitchen waste according to the present invention is:

[0018] 1. Unload the food waste collected by the food waste transport vehicle into the self-conveyor unloading hopper, where the oil and water mixture mixed in the food waste flows into the inlet of the mixed liquid pump, and the wet material is sent into the feeder through the conveyor Crusher, after the crusher crushes the material, the chain plate conveyor sends the material to the magnetic separator to remove iron and other objects, and then the chain plate conveyor transports it to the screen surface of the vibrating separator. The screen aperture is 15 mesh. At this time, more than 95% of the useful materials fall into the feed port of the dehydrator through the screen under the vibration force of the vibrating separator, and the harmful materials that do not pass the screening are sent to the waste collection barrel. The disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com