Method for processing waste water/gas from tungsten smelting and a device thereof

A technology for waste gas treatment and waste water, which is applied in the field of metallurgy, can solve problems such as heating, high energy consumption, and large water consumption, and achieve the effects of simple process steps, low processing costs, and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

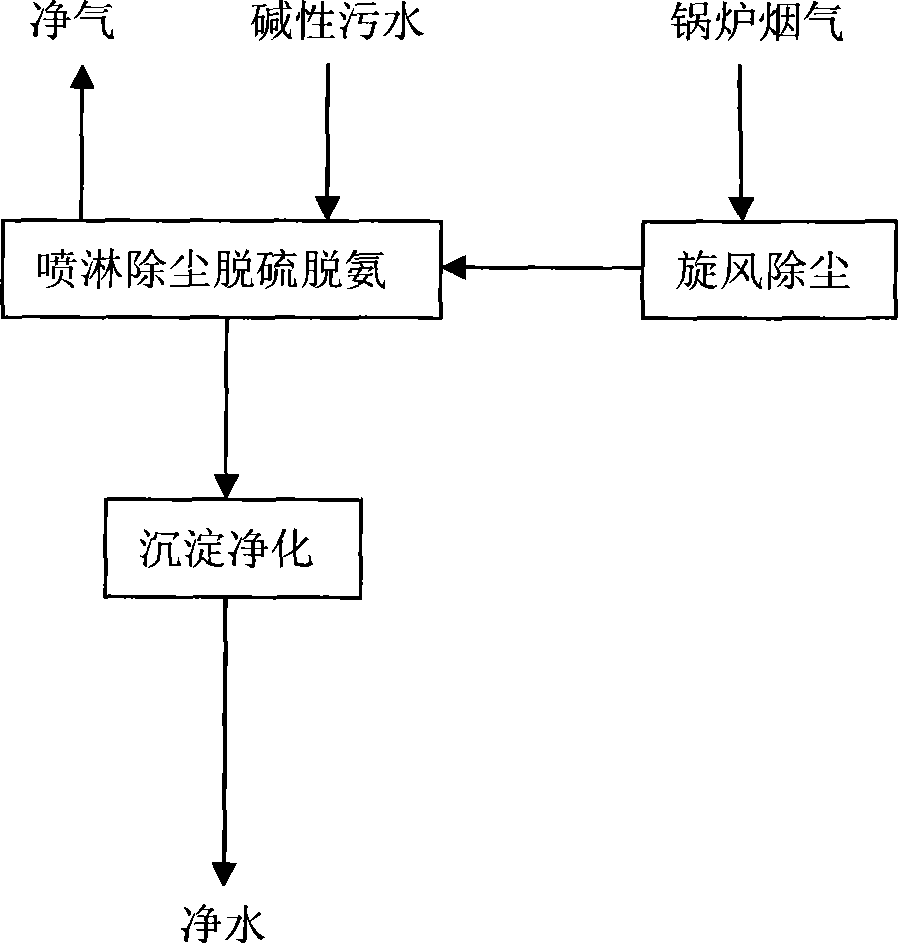

example 1

[0035] First discharge the alkaline wastewater with a PH value of 12-13 and an ammonia content of 385g / l into the alkaline wastewater pool of the APT production line of the ion exchange process, and then use a pump to add the wastewater from the upper part of the dedusting, desulfurization and deammonization tower, and control the flow of wastewater at 13-15m 3 / H. The boiler flue gas is extracted from the boiler through the induced draft fan. After the flue gas passes through the multi-tube cyclone dust collector to remove the coarse dust, it is sent from the lower part of the dust removal, desulfurization and deamination tower. The flue gas temperature is 160-200 ° C, and the air volume is controlled at 13000 -15000m 3 / H, in the dust removal, desulfurization and deamination tower, the flue gas diffuses from the bottom to the top, and the waste water is sprayed from the top to the bottom. The lower part of the desulfurization and deamination tower is discharged into the se...

Embodiment 2

[0037] The process steps and devices are the same as in Example 1, except that the four parameters of alkaline wastewater ammonia content and flow rate, flue gas temperature and air volume are different, that is, the pH value of alkaline wastewater is 12-13, the ammonia content is 395g / l, the flow rate of alkaline wastewater Controlled at 15-16m 3 / H; flue gas temperature is controlled at 140-160°C, air volume is controlled at 15000-18000m 3 / H. After testing: the discharged water ammonia content is 11mg / l, the discharged gas SO 2 Content 400mg / m 3 , smoke content: 90mg / m 3 , to meet the requirements of the national first-level emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com