Efficient segmentation control combustion method and system for biomass boiler with charcoal combustion cell

A biomass boiler, segmented control technology, applied in combustion equipment, solid fuel combustion, lighting and heating equipment, etc. The effect of compact, high combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

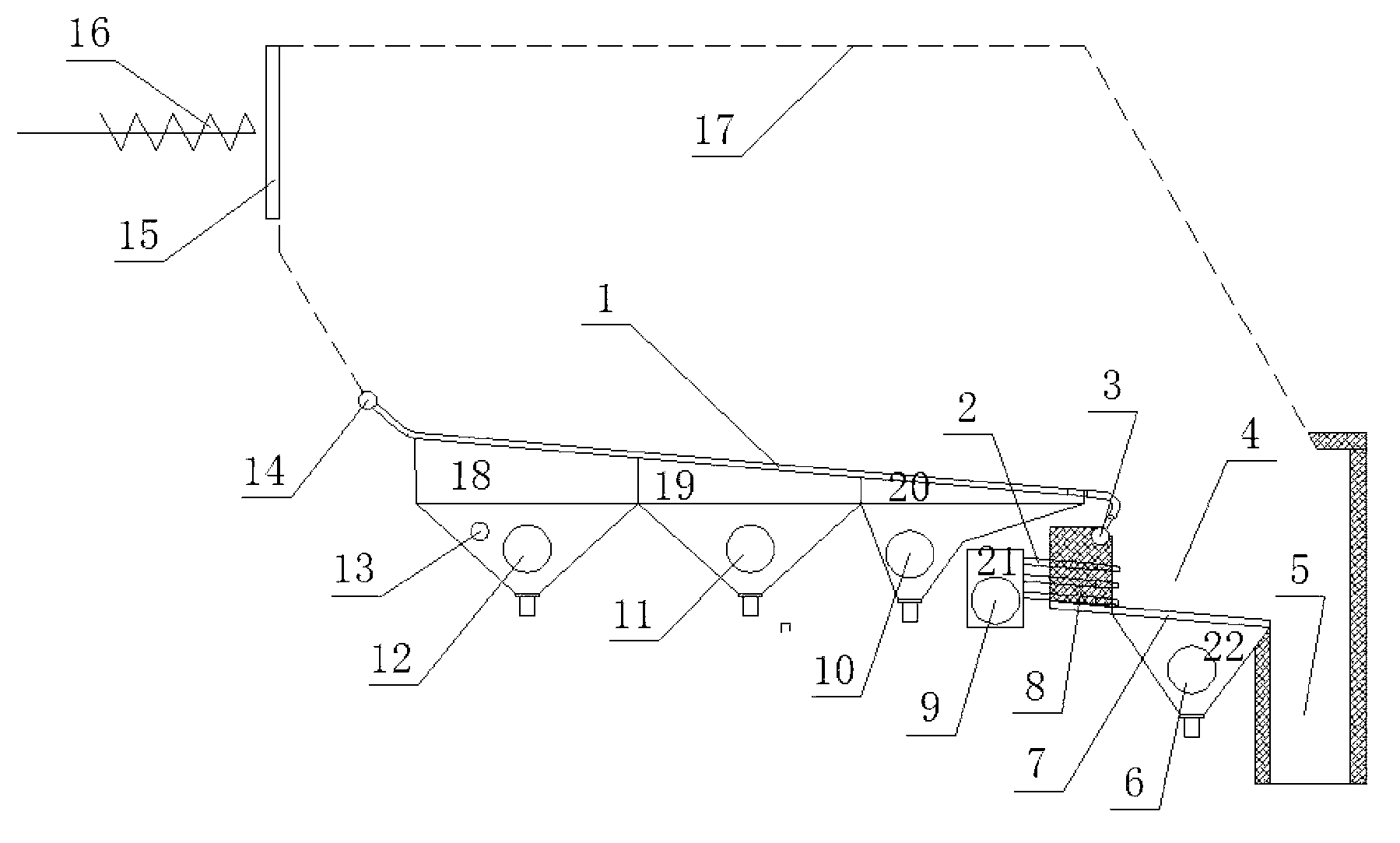

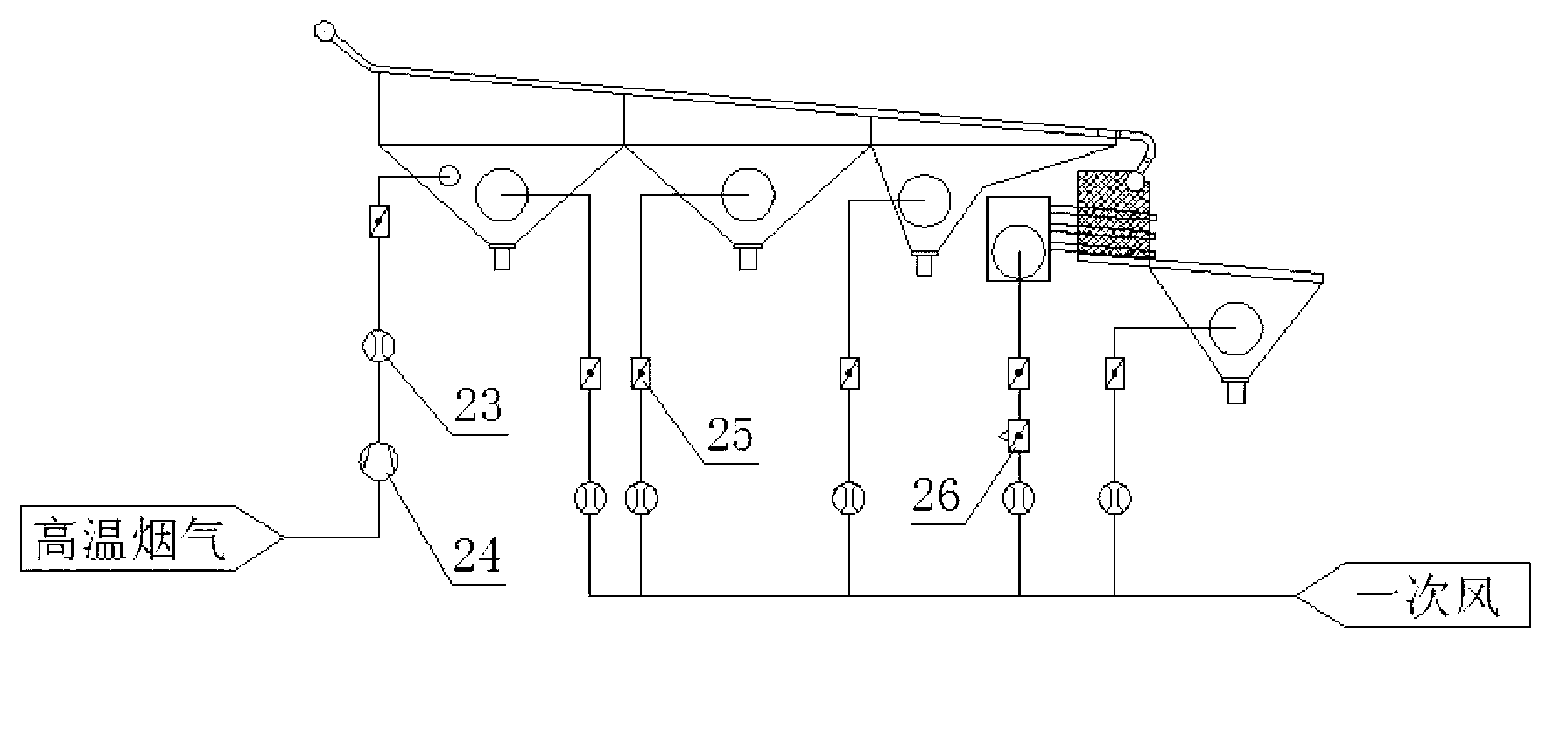

[0028] The present invention provides a high-efficiency segmental control combustion method and system for a biomass boiler with a charcoal combustion pool. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0029] The theoretical basis of the present invention to realize the high-efficiency segmental control combustion of biomass fuels is that the combustion of different biomass fuels can be roughly divided into three stages, and each stage has distinct characteristics.

[0030] The first stage is the preheating drying section (the temperature is less than 150°C). When the temperature of biomass fuel rises to about 100°C, the external moisture contained in it is first evaporated, and the wet fuel becomes dry fuel. When the water evaporates, it needs to absorb the heat released during the combustion process, which will reduce the temperature of the combustion chamber and slow down the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com