Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

A low-nitrogen oxide, pulverized coal combustion technology, which is applied in the combustion of various fuels, the combustion of lump fuel and liquid fuel, the combustion of lump fuel and gaseous fuel, etc., can solve the problem of low load and stable combustion of boilers. It can improve the combustion intensity and stability of combustion, reduce the deviation of steam temperature, and reduce the carbon content of fly ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The #3 boiler in a power plant of Huadian Group is a subcritical boiler with an evaporation capacity of 1025t / h, a reheating in the middle, and a controlled circulation drum boiler. The combustion method is a four-corner tangential combustion method. The air nozzles are arranged at intervals, the pulverizing system is a direct blowing type of double-inlet and double-outlet steel ball coal mill, and the coal type is lean coal. The boiler burner adopts the early American CE technology, and the NOx emission concentration is relatively high, and the emission concentration is 750-900mg / Nm 3 , the carbon content of fly ash is 5-6%. In order to meet the latest national pollutant emission standards for thermal power plants, the #3 boiler has undergone low-nitrogen combustion transformation, and adopted this low-NOx direct-flow pulverized coal combustion device suitable for lean coal.

[0064] figure 1 The present invention is applied to the structure schematic diagram in embo...

Embodiment 2

[0069] Boiler #3 of a power plant of Huaneng Group is a subcritical boiler with an evaporation capacity of 1025t / h, a reheating in the middle, and a controlled circulation drum boiler. The nozzles are arranged at intervals, and the pulverizing system is DTM350 / 600 steel ball mill medium-storage pulverizing system. The powder is fed by hot air, and the exhaust gas is sent into the furnace as the tertiary air. The coal type is Jinzhong lean coal. The NOx emission concentration of the boiler is relatively high, and the emission concentration is 800-950mg / m 3 , the carbon content of fly ash is 3-6%. In order to meet the latest national pollutant emission standards for thermal power plants, the #3 boiler has undergone low-nitrogen combustion transformation, and this low-NOx direct-flow pulverized coal combustion device suitable for lean coal has also been adopted.

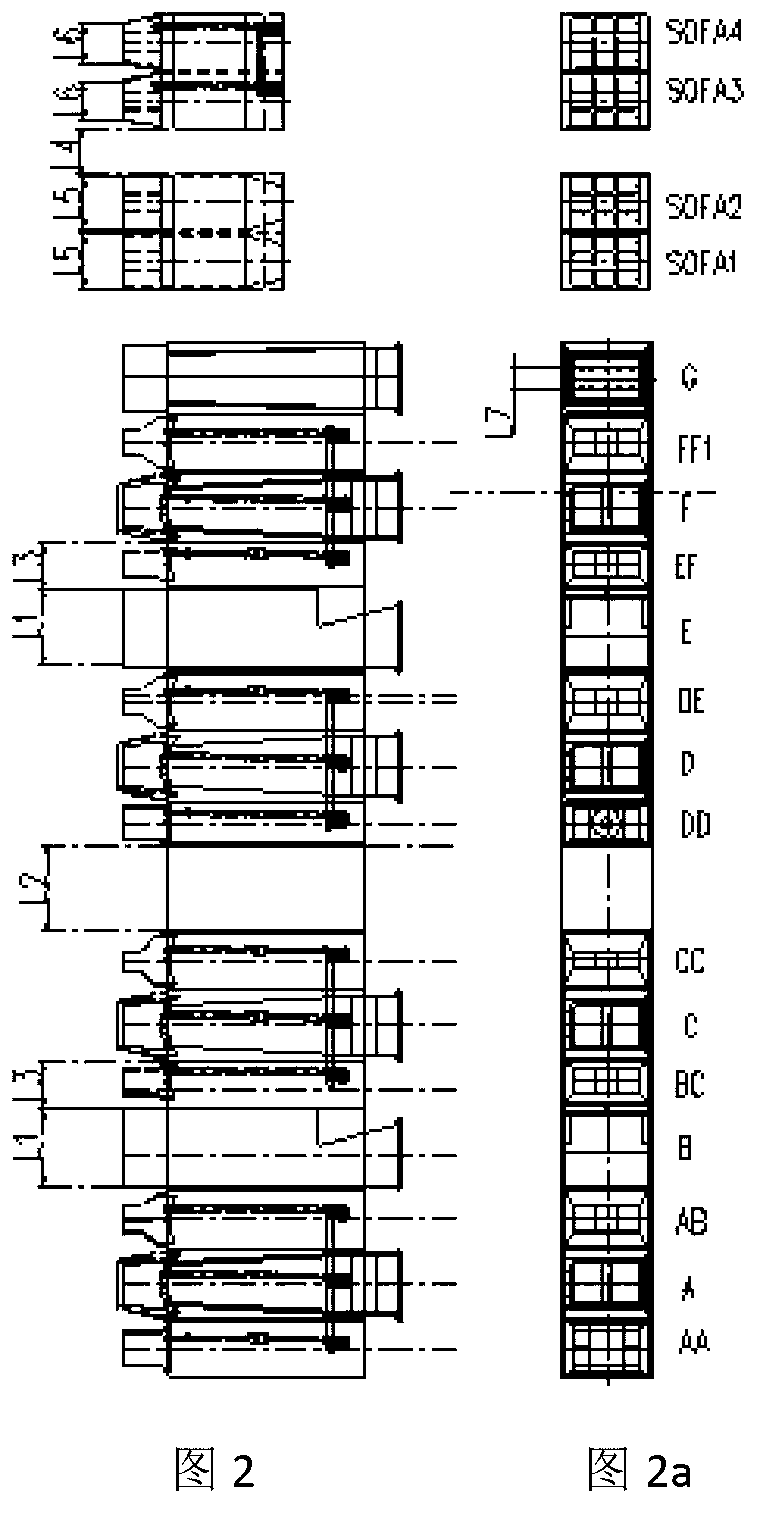

[0070] figure 2 It is a structural schematic diagram of the present invention applied in Embodiment 2, and there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com