Direct fired pulverizing system of smoke drying lignite coal fan mill

A technology of pulverizing system and fan mill, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of poor operation reliability, large investment, failure to effectively solve the safety problems of lignite pulverizing system, and avoid The effects of fire, safe and reliable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

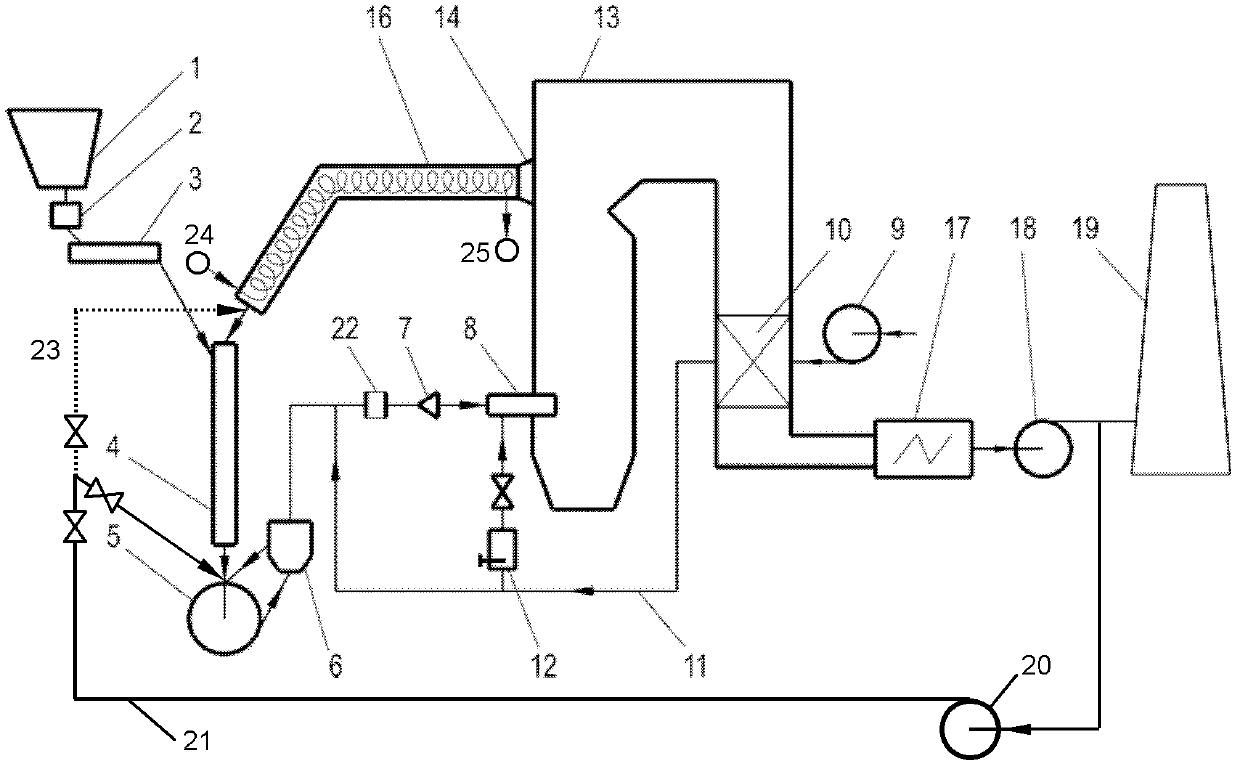

[0018] Such as figure 1 As shown, the flue gas drying lignite fan grinding pulverization system of the present invention includes a raw coal hopper 1, an automatic weighing scale 2, a coal feeder 3, a downward drying pipe 4, a fan coal mill 5, a coarse powder separator 6, and a pulverized coal Distributor 7, burner 8, blower 9, air preheater 10, secondary air wind box 12, high temperature furnace smoke pipe 16, flue gas dust collector 17, induced draft fan 18, cold smoke fan 20, cold smoke pipe 21, Hot air mixer 22, cold smoke branch pipe 23.

[0019] Among them, the raw coal scuttle 1 is connected to the coal feeder 3 through the automatic weighing scale 2, the coal feeder 3 is connected to the coal inlet of the down drying pipe 4, and the coal outlet of the down drying pipe 4 is connected to the inlet of the fan coal mill 5. coal mouth. The coal outlet of the fan coal mill 5 is connected to the coal inlet of the coarse powder separator 6, and the coarse powder outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com