Low-NOx combustor with internal reflux of flue gas and homogeneous combustion and gas configuration method thereof

A burner, internal recirculation technology, applied in gas fuel burners, combustion methods, burners, etc., can solve the problems of large excess air coefficient, flame stabilization to reduce NOx emissions, low root temperature, etc., to achieve stable combustion, reduce NOx Generate volume, enhance the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

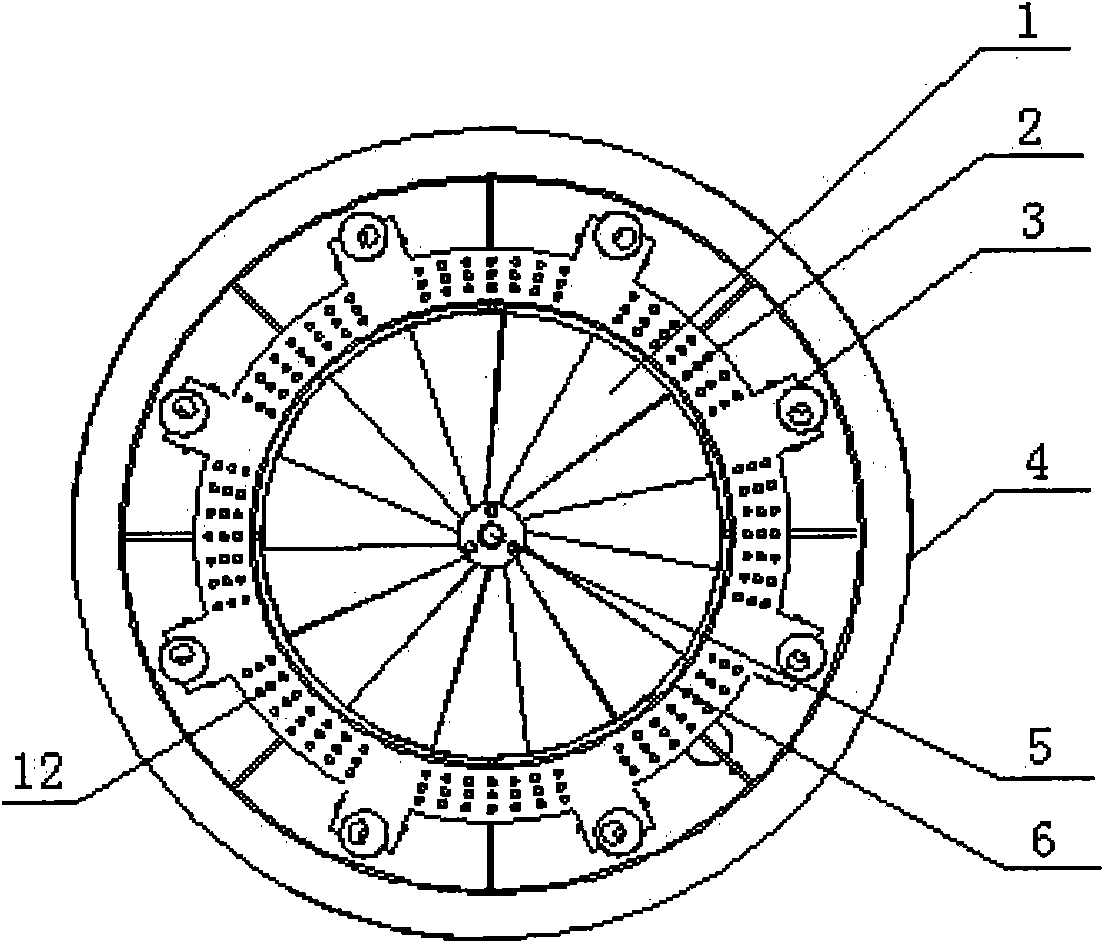

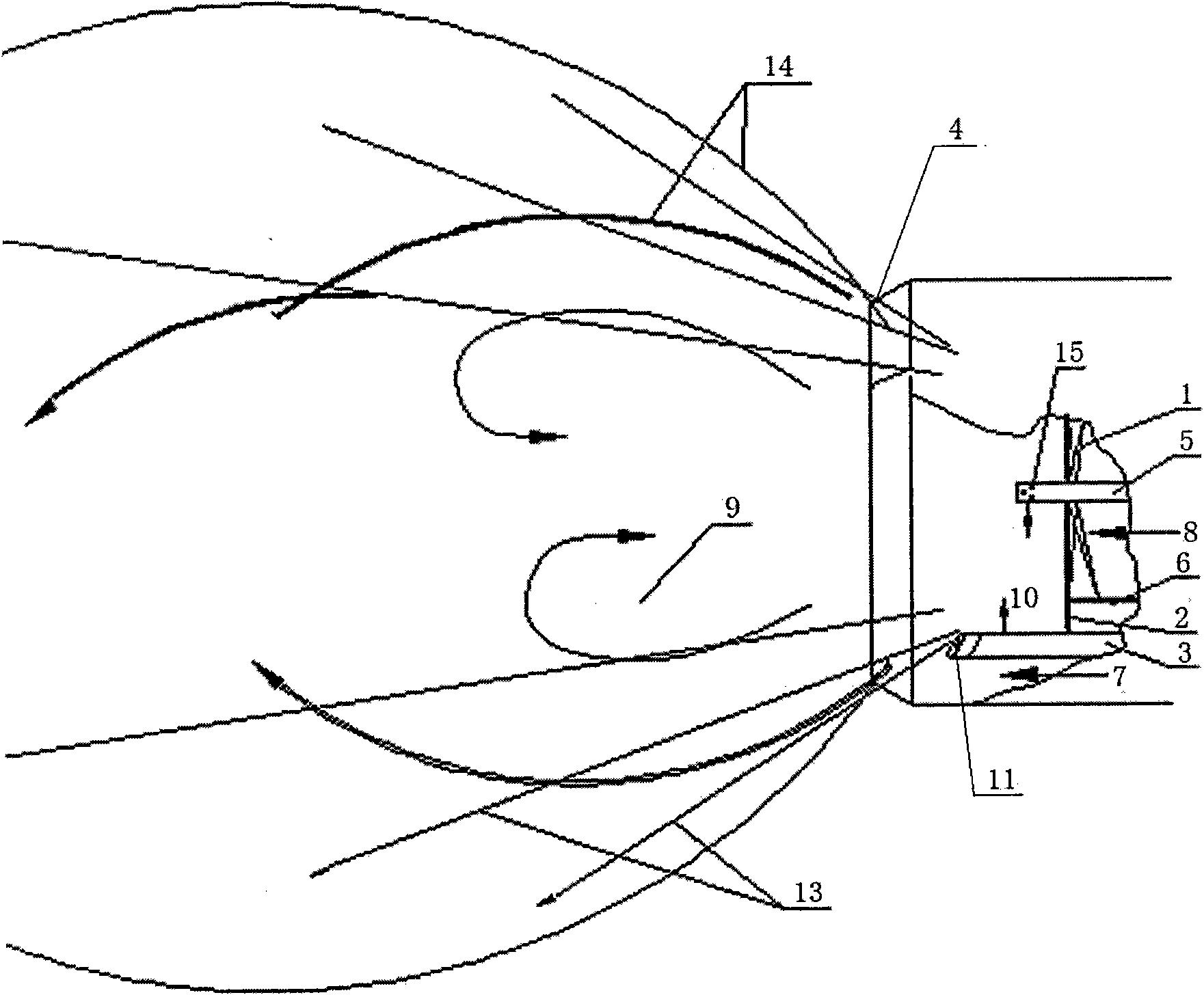

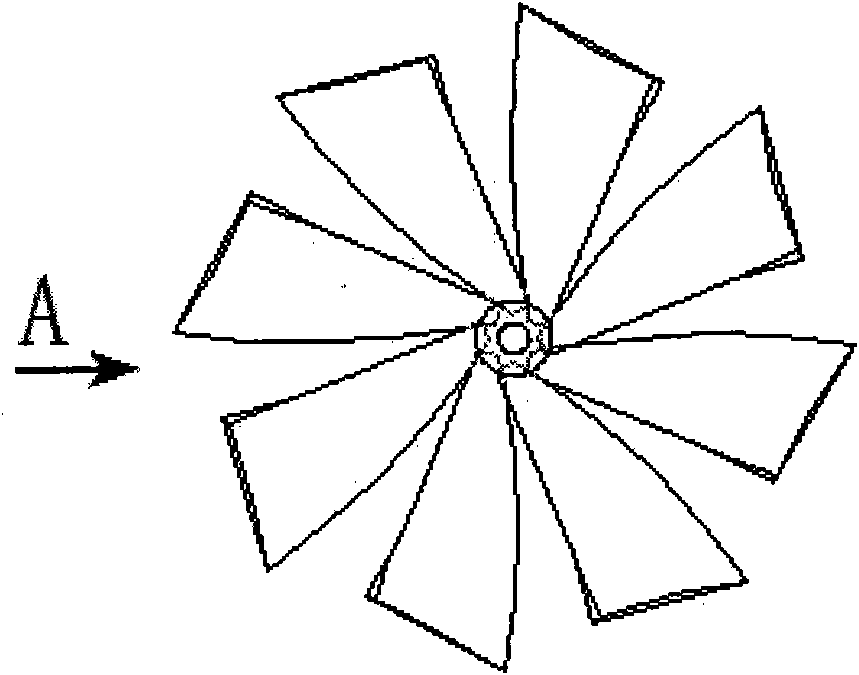

[0020] by figure 1 with 2 As shown in the structural schematic diagram of the present invention, a low-NOx combustor for homogeneous combustion in flue gas with internal reflux includes a flame stabilizing plate 2 and an intermediate tube arranged coaxially from outside to inside in the throat 4 of the burner body 6. The swirler 1 and the intermediate gas gun 5 are characterized in that: the upper end of the intermediate gas gun 5 is provided with a plurality of radial small holes 15, and the outer periphery of the flame stabilizing disk 2 in the throat 4 is axially The gas gun head 3 is uniformly distributed. The gas gun head 3 is provided with a gas small hole 10 on the side, the height of which is different from the radial small hole 15 of the middle gas gun 5, and the end of the gas gun head is a wedge-shaped inclined surface ( Figure 5 ), the angle between the wedge-shaped inclined surface and the burner axial direction is β angle, and the angle between the direction and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com