Cyclone furnace and method for improving slag captured rate of cyclone furnace

The technology of a vortex furnace and a cyclone can be applied to the combustion method, the combustion of various fuels, the combustion of lump fuel and liquid fuel, etc., to achieve the effect of improving the slag capture rate and the slag capture rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

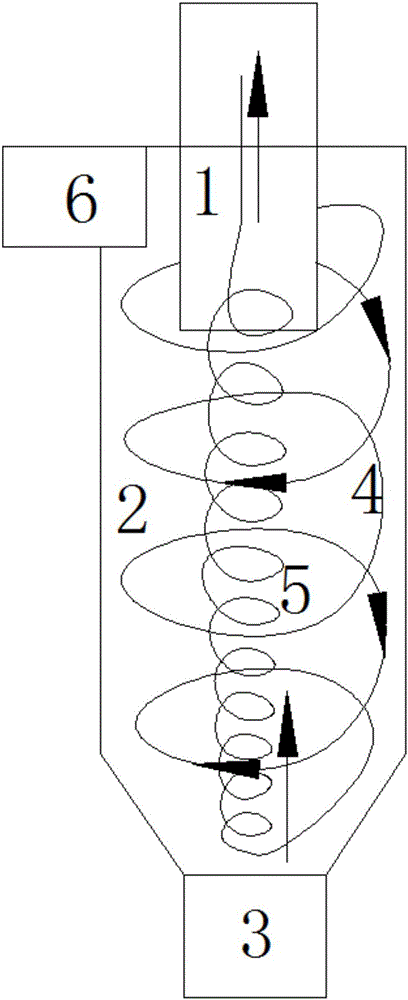

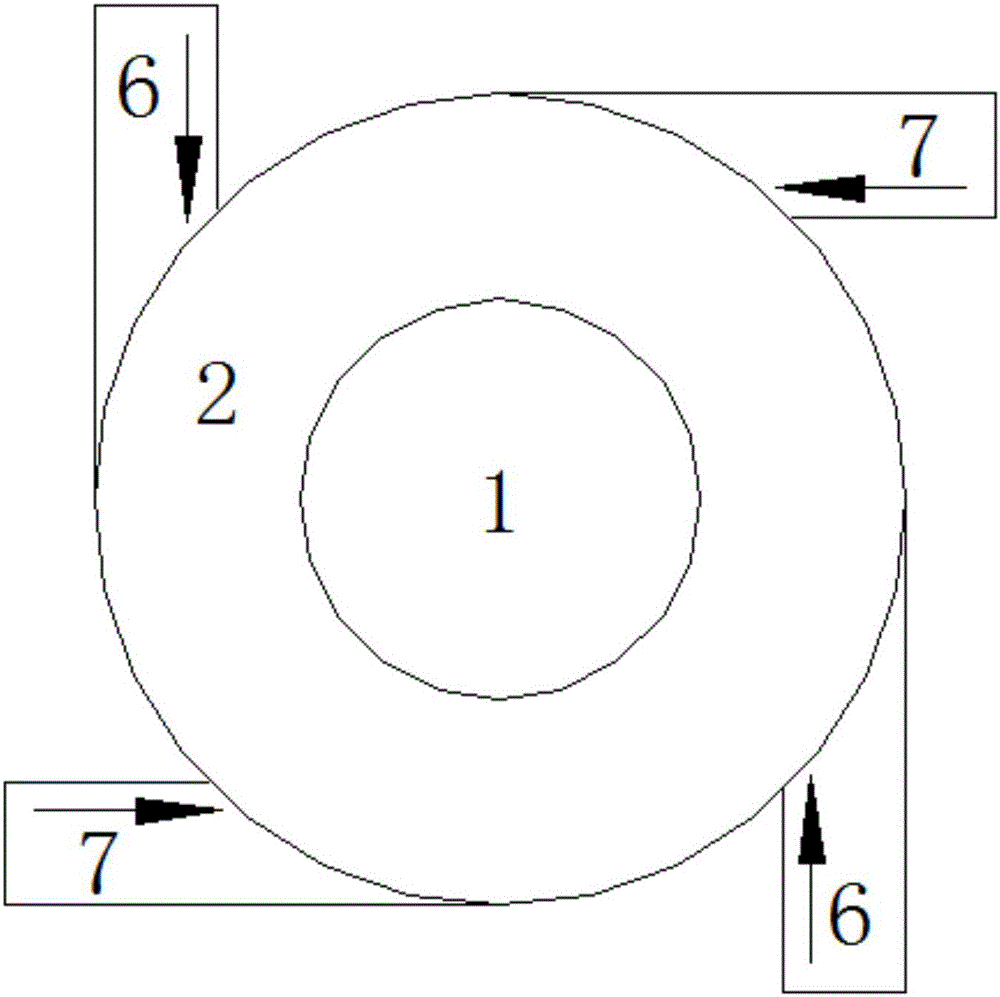

[0031] like figure 1 and 2 As shown, the vortex furnace includes: the vortex furnace cyclone tube 2 and the central tube 1 added inside the vortex furnace cyclone tube, and the slag pool 3 is arranged at the lower part of the vortex furnace cyclone tube.

[0032] The upper part of the vortex furnace cyclone 2 is provided with a tangential first air inlet and a second air inlet, and the first air inlet and the second air inlet are arranged on both sides of the vortex furnace cyclone and arranged at intervals.

[0033] Wherein, the first air inlet is used for feeding primary air carrying fuel, and the second air inlet is used for feeding combustion-supporting secondary air.

Embodiment 2

[0035] The method for improving the slag collection rate of the vortex furnace by adopting the vortex furnace of embodiment 1 specifically comprises the following steps:

[0036] The primary air 6 carrying fuel is arranged tangentially on both sides of the vortex furnace cyclone 2, and the combustion-supporting secondary air 7 is also tangentially arranged on both sides of the vortex furnace cyclone 2, the primary air 6 carrying fuel and the combustion-supporting secondary air 7 Arranged at intervals, the fuel-carrying primary air 6 and the combustion-supporting secondary air 7 burn in the vortex furnace cyclone 2 to produce high-temperature flue gas 4 carrying liquid slag, and the high-temperature flue gas 4 carrying liquid slag runs along the direction of the vortex furnace cyclone 2. The inner wall rotates and flows from top to bottom to the bottom of the cyclone tube 2 of the vortex furnace. At the bottom of the cyclone tube 2 of the vortex furnace, the liquid slag is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com