Method for preparing inorganic fiber fused mass from blast furnace molten slag

A technology of inorganic fiber and blast furnace slag, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as unreasonable process, difficulty in melting and homogenizing flux, and achieve the effects of ensuring product quality, reducing carbon emissions, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

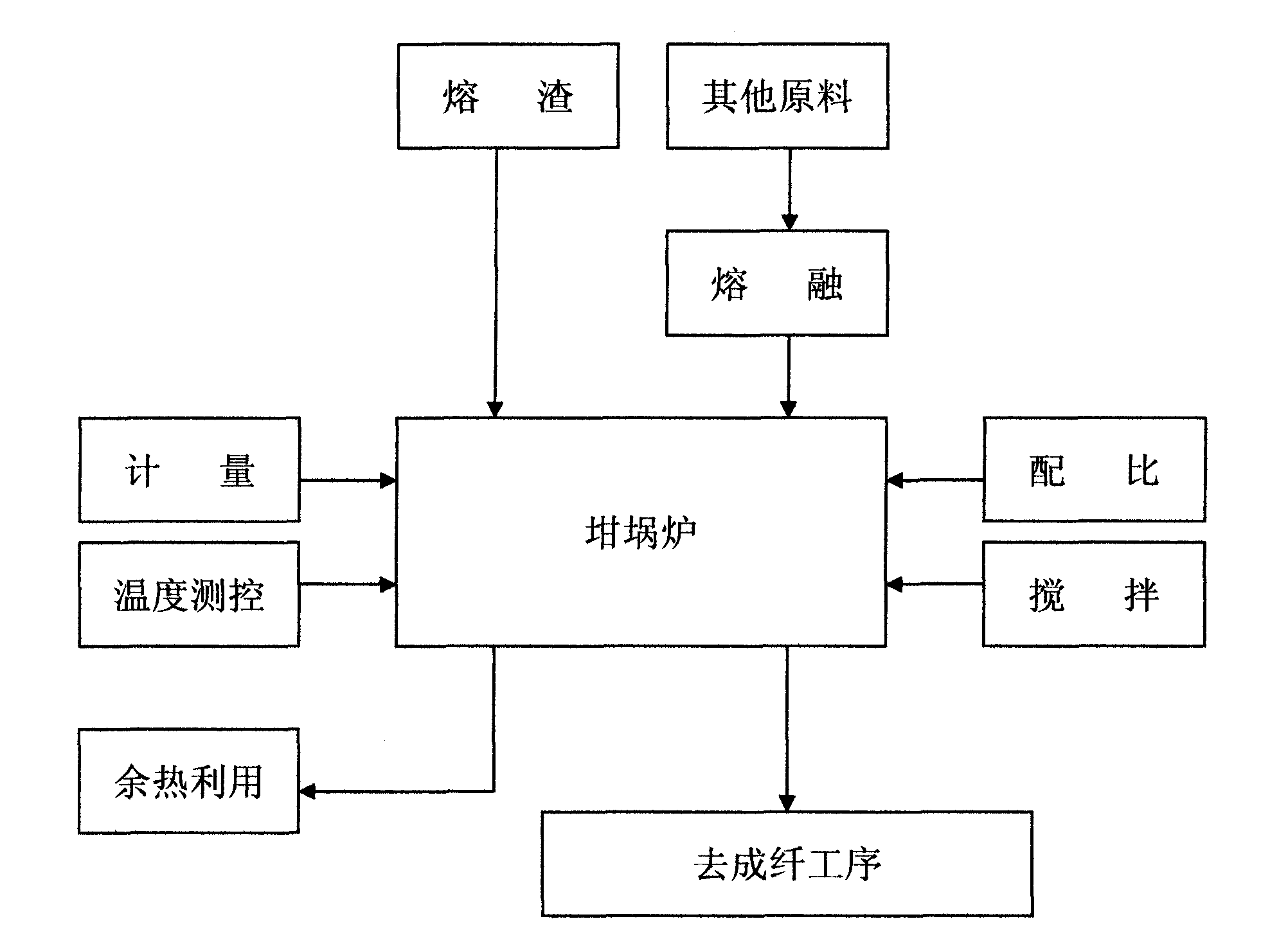

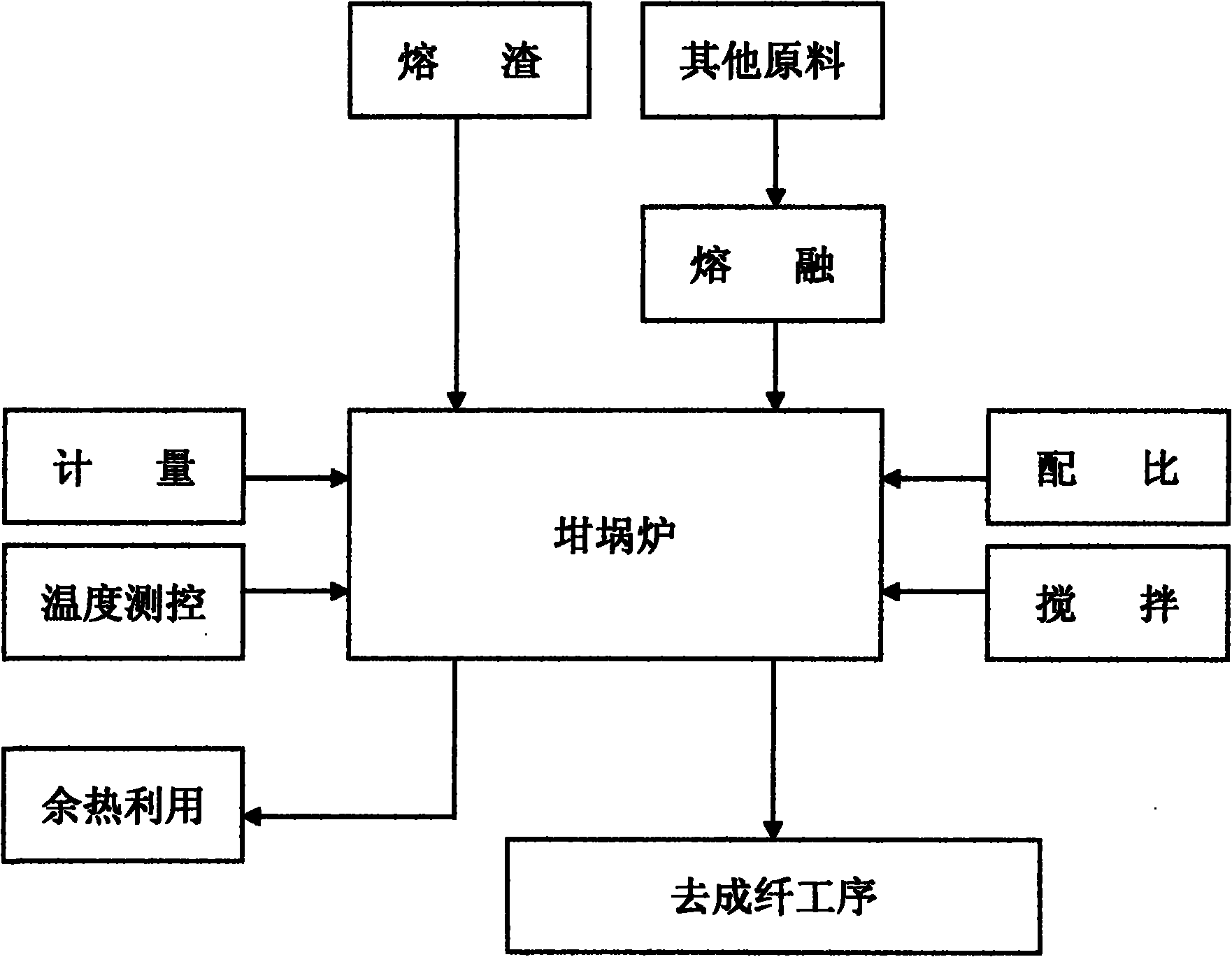

Image

Examples

Embodiment 1

[0016] Coal gangue and a small amount of flux are melted in a kiln, the blast furnace slag flows into the crucible furnace through the slag ditch, and the quality of the slag in the crucible furnace is measured. The molten coal gangue is added to the crucible furnace, and after stirring, temperature measurement and control to 1300 ° C, the melt is guided to the fiber forming process to form fibers. Compared with the traditional process, the range of energy saving and emission reduction is more than 35%.

Embodiment 2

[0018] Fly ash and a small amount of flux are melted in a kiln, and the blast furnace slag flows into the crucible furnace through the slag ditch. Add the molten fly ash to the crucible furnace, and after stirring, measuring and controlling the temperature to 1300°C, the melt is guided to the fiber forming process to form fibers. Compared with the traditional process, the range of energy saving and emission reduction is more than 40%.

[0019] According to the method of the present invention, the added molten other raw materials can be added after the slag is introduced into the crucible furnace; it can also be added during the introduction of the slag into the crucible furnace; it can also be added at the same time when the slag is introduced into the crucible furnace. Add; or add before the slag is introduced into the crucible furnace.

[0020] The added molten other raw materials may be in a fully molten state; or in a semi-molten state.

[0021] According to the method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com