Recycling system for waste cathode block from electrolytic aluminum and recycling method

A waste cathode carbon block and treatment system technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of inability to achieve strict temperature control, difficult to use heat effectively, and inability to remove cyanide, etc. recycling, reducing the cost of solid waste treatment, and achieving the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

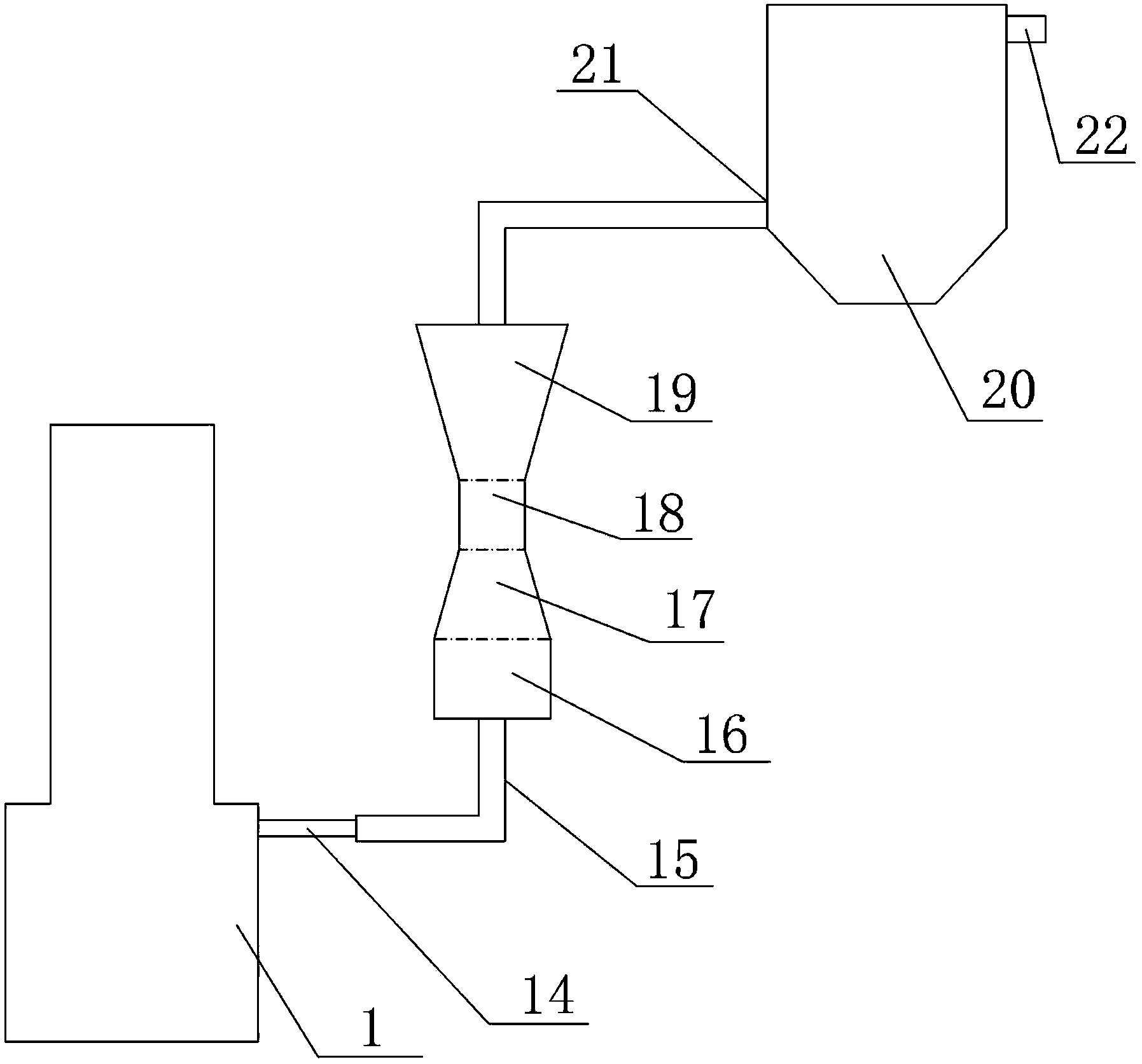

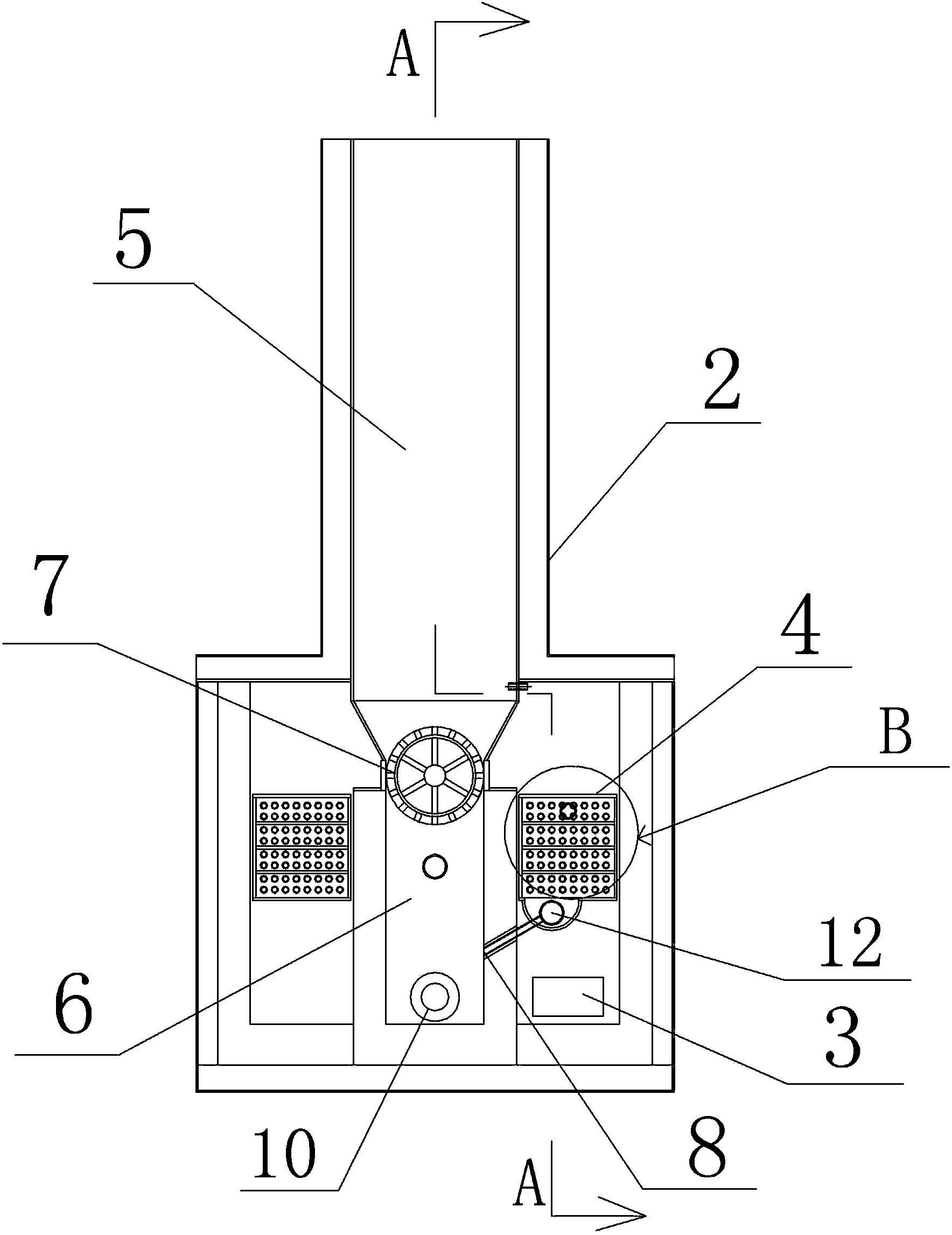

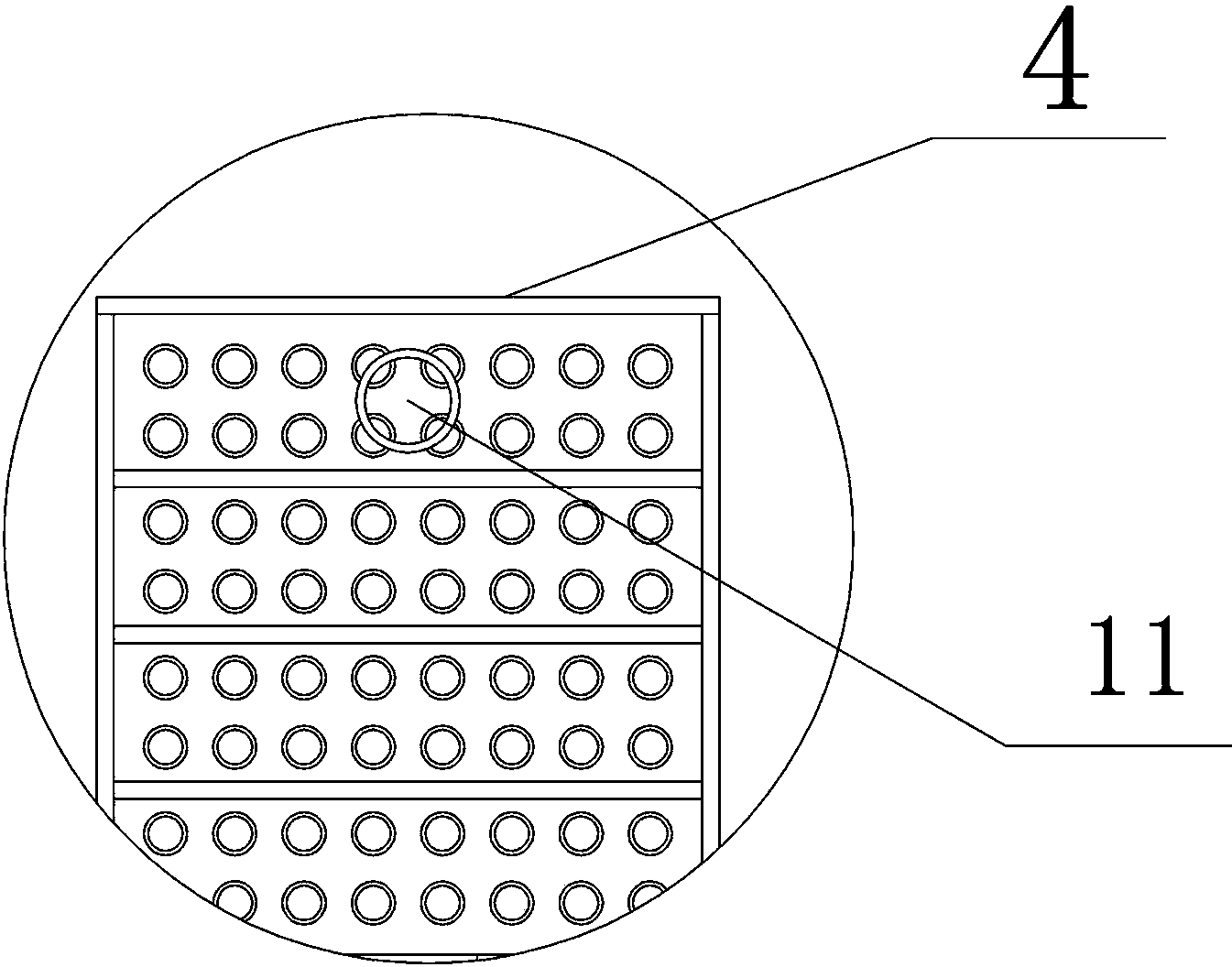

[0034] Embodiment 1: A kind of electrolytic aluminum waste cathode carbon block processing system, such as Figure 1~Figure 4As shown, it includes a high-temperature cyclone furnace 1 and a dry purification device. The high-temperature cyclone furnace 1 includes a furnace body 2, a burner 3 and a heat exchanger 4; the upper part of the furnace body 2 is provided with a raw material box 5, and the lower part is provided with a combustion chamber 6, the raw material box 5 and the combustion chamber 6 are connected through a feed passage, and a feed valve 7 is provided on the feed passage, and the combustion chamber 6 is provided with an air inlet 8, a flue gas The pipeline 9 and the discharge port 10 are provided with an air volume regulating valve on the air inlet 8; the burner 3 is arranged below the combustion chamber 6; the heat exchanger 4 is arranged at the bottom of the combustion chamber 6 The outside includes a cold air inlet 11, a hot air outlet 12, a high temperature ...

Embodiment 2

[0041] Embodiment 2: A method for recycling electrolytic aluminum waste cathode carbon blocks, comprising the following steps:

[0042] (1) Jaw breaking and ball milling the electrolytic aluminum waste cathode carbon block to obtain powder with a particle size of 50 mesh to 200 mesh;

[0043] (2) Add the powder obtained in step (1) into the high-temperature cyclone furnace in the waste electrolytic aluminum cathode carbon block recycling system, add a combustion enhancer to fully burn the carbon powder in the powder, and the combustion The additive amount of the agent is 3‰ of the mass of the powder. The combustion enhancer is composed of nitrate, potassium permanganate, calcium oxide, iron oxide and starch, wherein the mass percentage of each component is: 3% of nitrate, 40% of potassium permanganate, 6% of calcium oxide, oxidized Iron 8%, the balance is starch;

[0044] (3) The high-temperature flue gas obtained from powder combustion in step (2) passes through the heat ex...

Embodiment 3

[0048] Example 3: The difference from Example 2 is that the addition amount of the combustion aid in step (2) is 5‰ of the mass of the powder, and the mass percentage of each component of the combustion aid is: nitric acid Salt 1%, potassium permanganate 20%, calcium oxide 4%, iron oxide 5%, and the balance is starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com