Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Solve slagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass solid formed fuel anti-slagging additive and preparation method thereof

The invention discloses a biomass solid formed fuel anti-slagging additive and a preparation method thereof, which belongs to the technical field of renewable energy sources and is used for solving the problems that straw biomass solid formed fuel has high alkali metal content, is slagged in the combustion process and the like. The anti-slagging additive mainly comprises 15% to 25% of magnesium carbonate, 20% to 30% of alumina and 45% to 65% of the calcium carbonate, different formula ratio is made according to different biomass raw materials; and the anti-slagging additive is added into different biomass raw materials according to the proportion of 1% to 5%. The preparation method comprises the following steps: the calcium carbonate is firstly put into a special container, the container keeps dry, then alumina is added, finally the magnesium carbonate is added, the mixture is ground and evenly mixed for 10 to 15 minutes with the grinding particle size less than 1 mm, and then a finished product is obtained. The additive can solve the problem of slagging in the combustion process of the formed fuel and increases the combustion efficiency of the formed fuel.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Method for preparing biomass lump coal

The invention discloses a method for preparing lump coal by adopting biomass as raw material and relates to the preparation method for the lump coal. The method comprises the following steps: (1) crushing straws into thick-filament straws, and crushing firewood and twigs into sawdust; (2) mixing the thick-filament straws and the sawdust, then, soaking the mixture with an aqueous alkaline solution, then, fermenting the mixture, and then, continuing to ferment under the condition of high-speed stirring; (3) crushing cattle manure and combustible refuse in municipal domestic waste, then, adding the crushed material into a fermentation softening solution, soaking the crushed material, and then, fermenting for 6 to 10 hours; (4) standing the fermented solution, and filtering out moisture, thereby obtaining viscous biomass slurry; (5) crushing barks, then, adding water to the crushed barks, heating, and then adding starch; and (6) uniformly mixing coal slurry, a binder and the biomass slurry which are in the mass ratio of 1 to (2 to 3) to (40 to 45), and then, carrying out compacting molding at molding pressure, thereby obtaining the finished product. The method disclosed by the invention has the advantages that the method is low in cost and easy to operate, and the product is easy to mold, high in mechanical strength, difficult in slag-bonding and little in smoke dust.

Owner:SHANXI TIANRUNFENG AGRI TECH DEV CO LTD

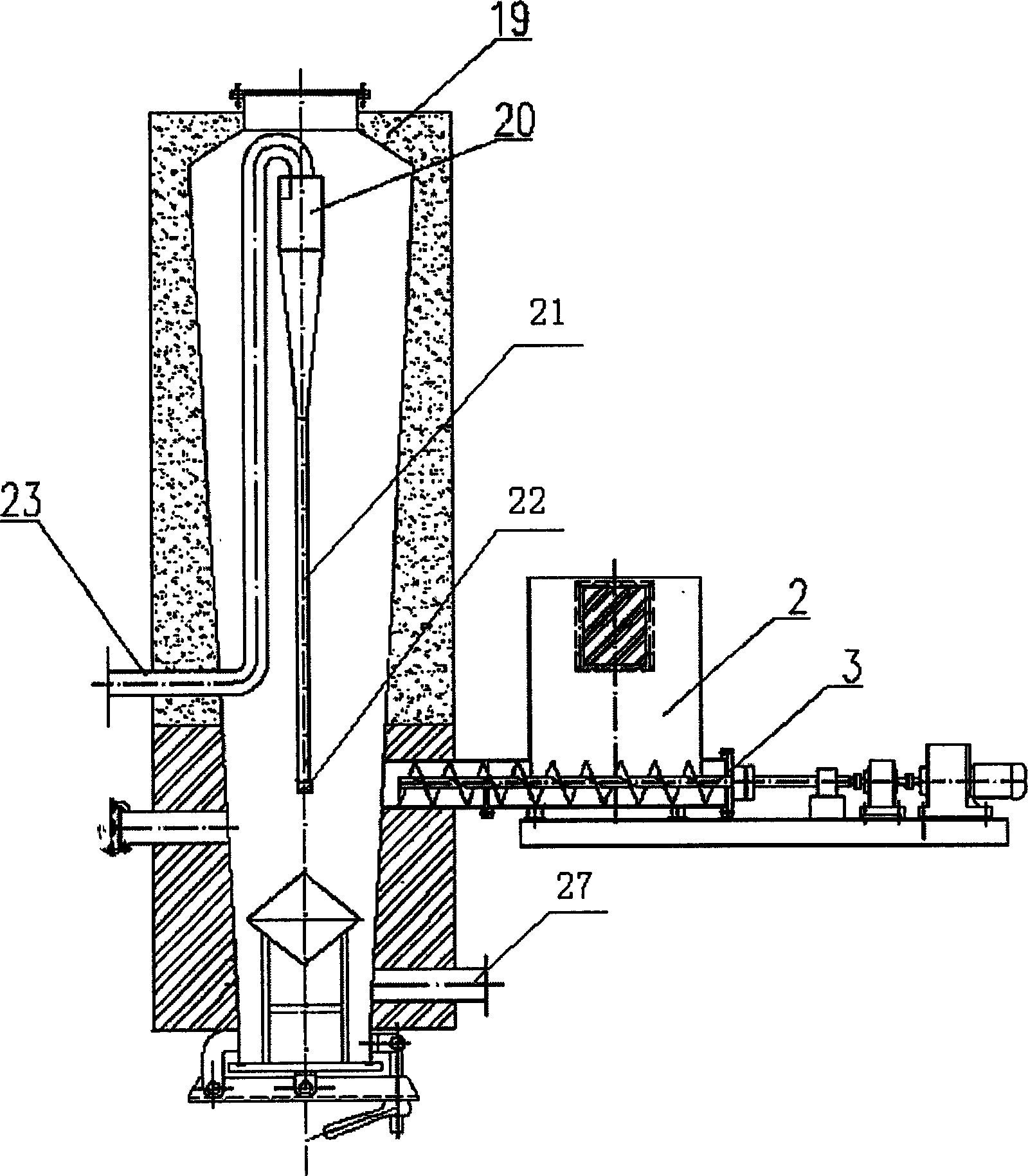

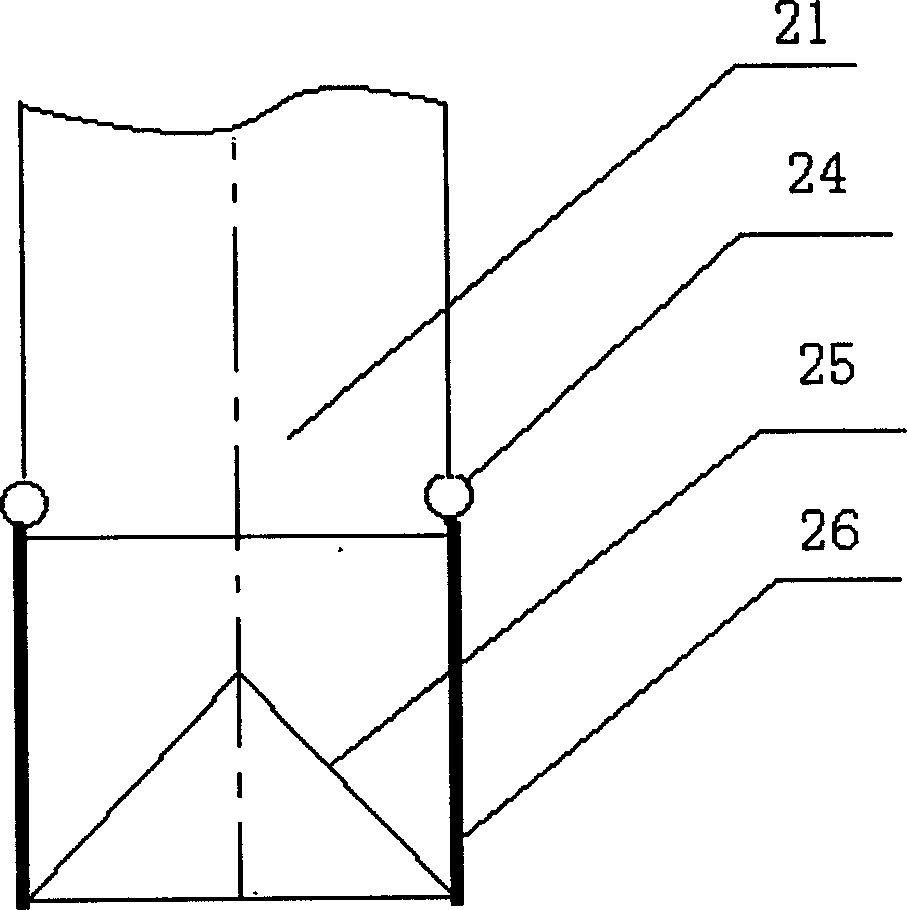

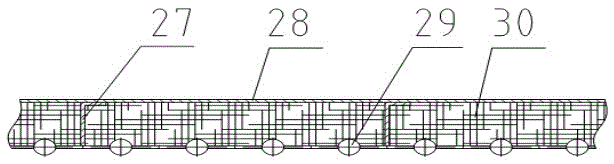

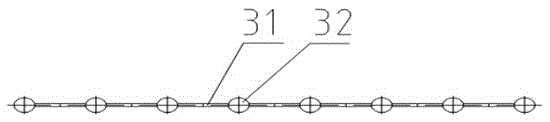

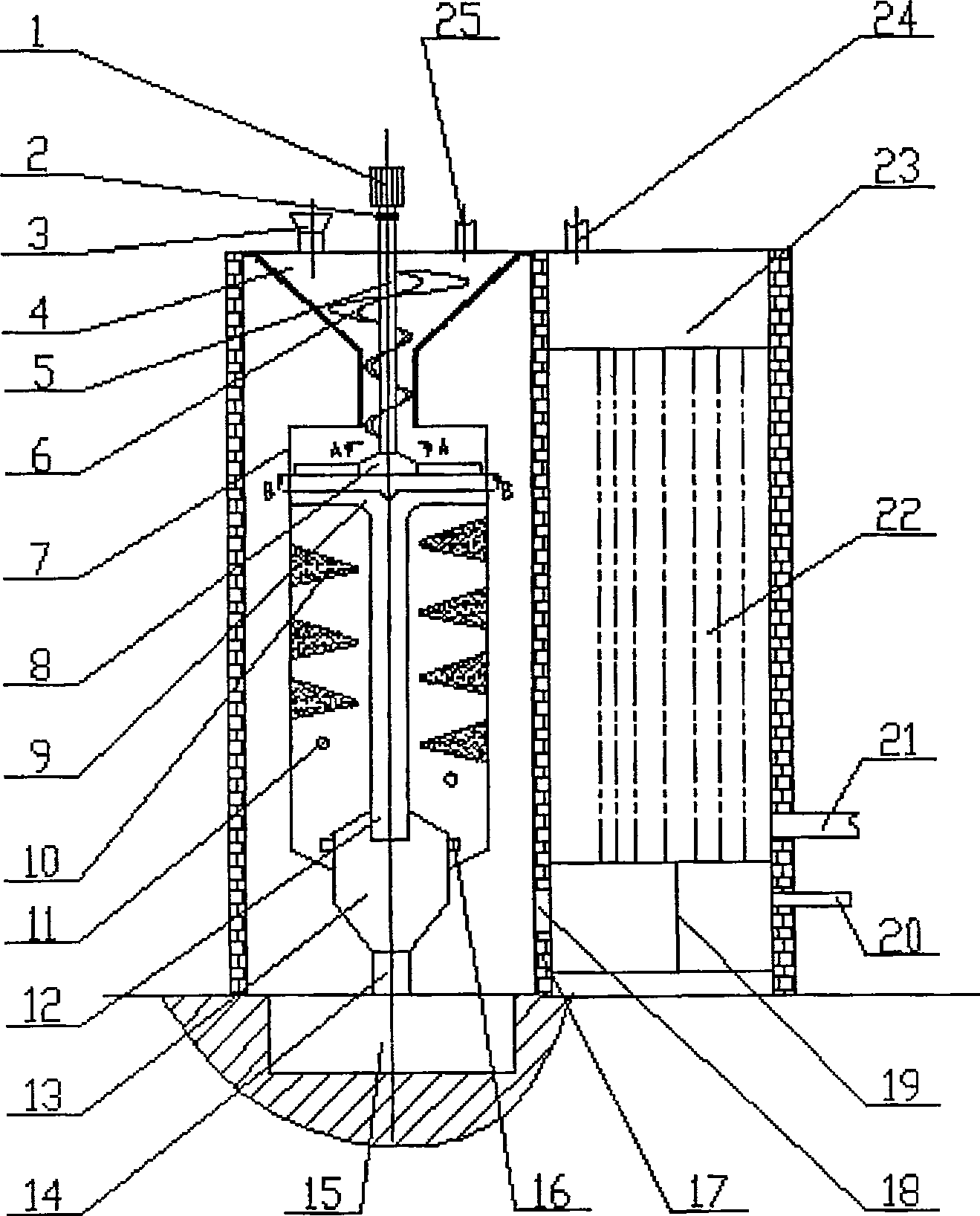

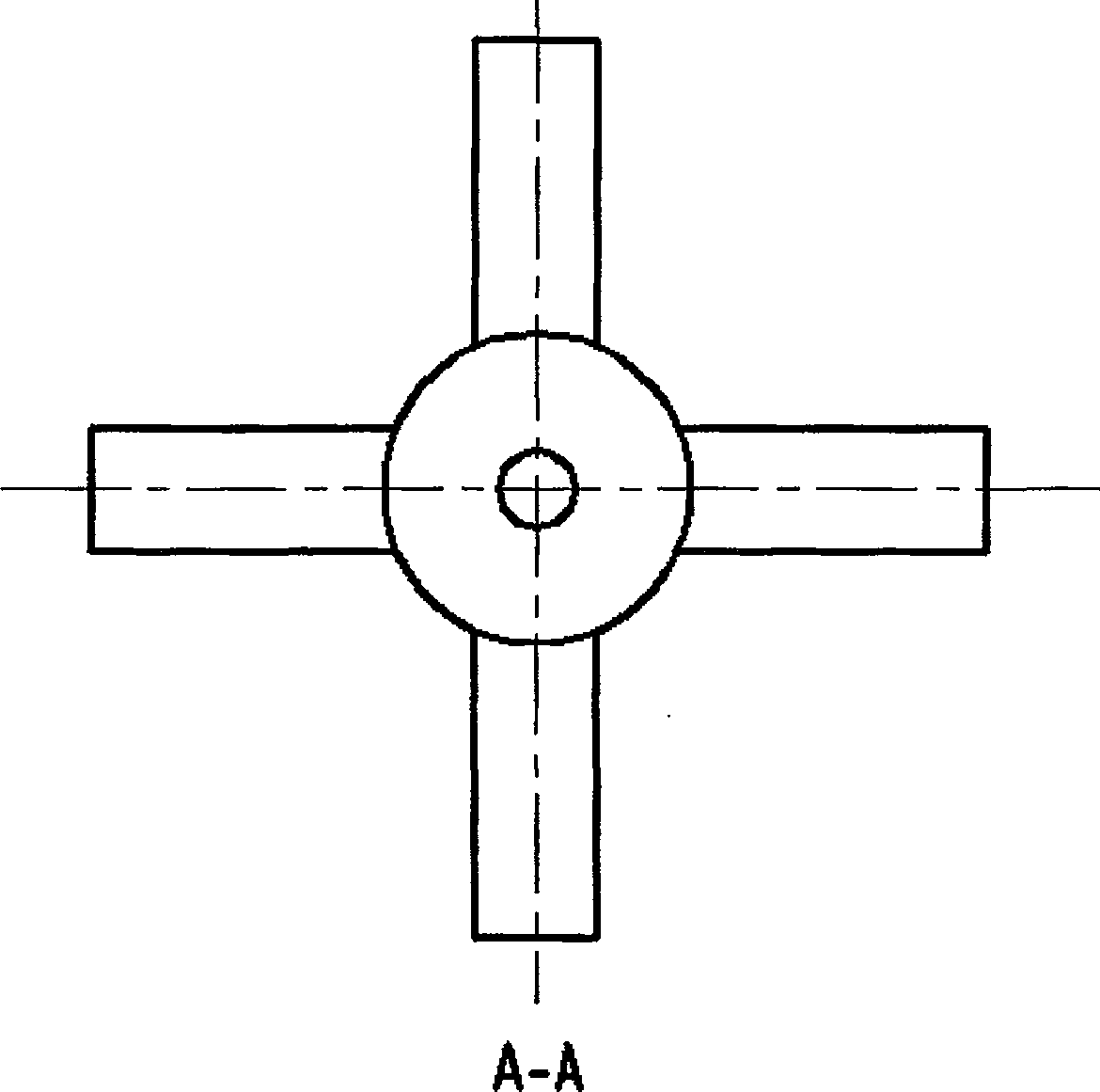

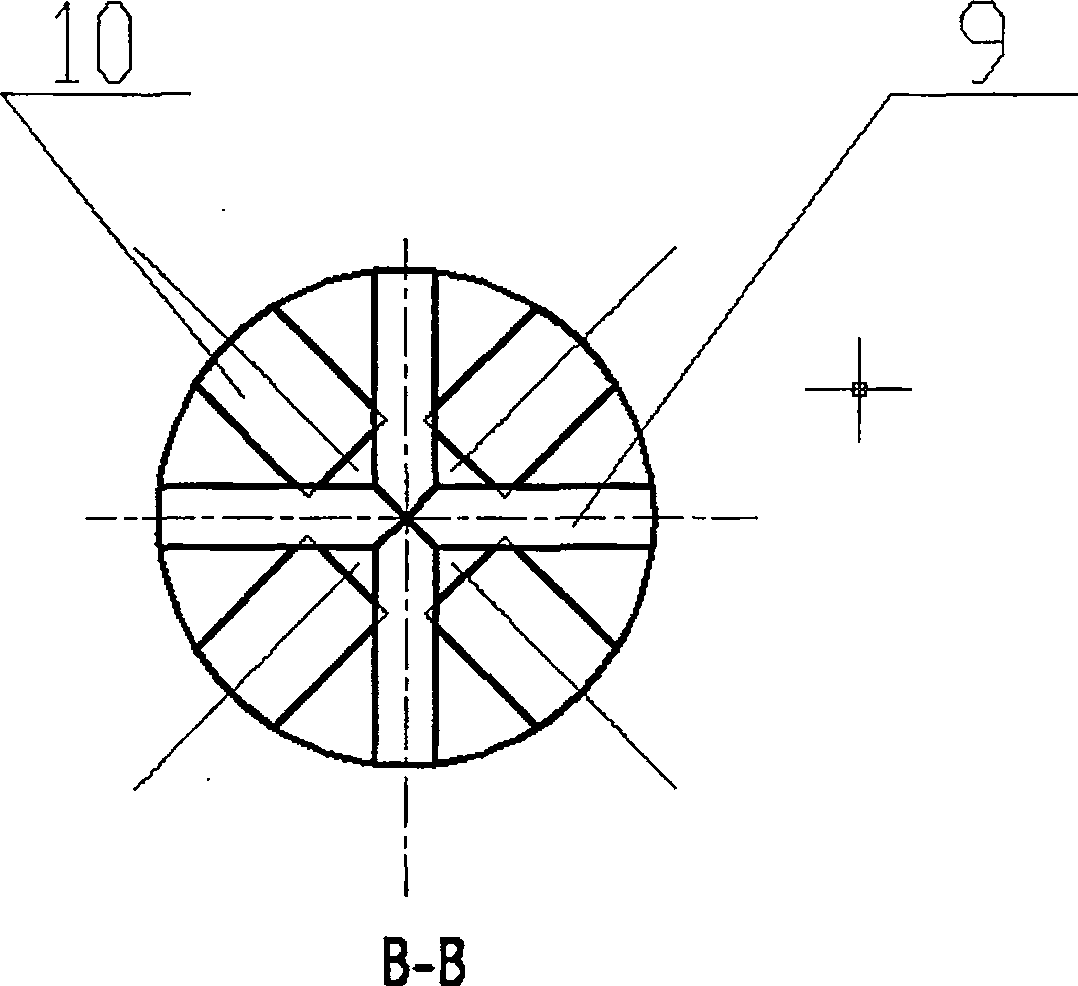

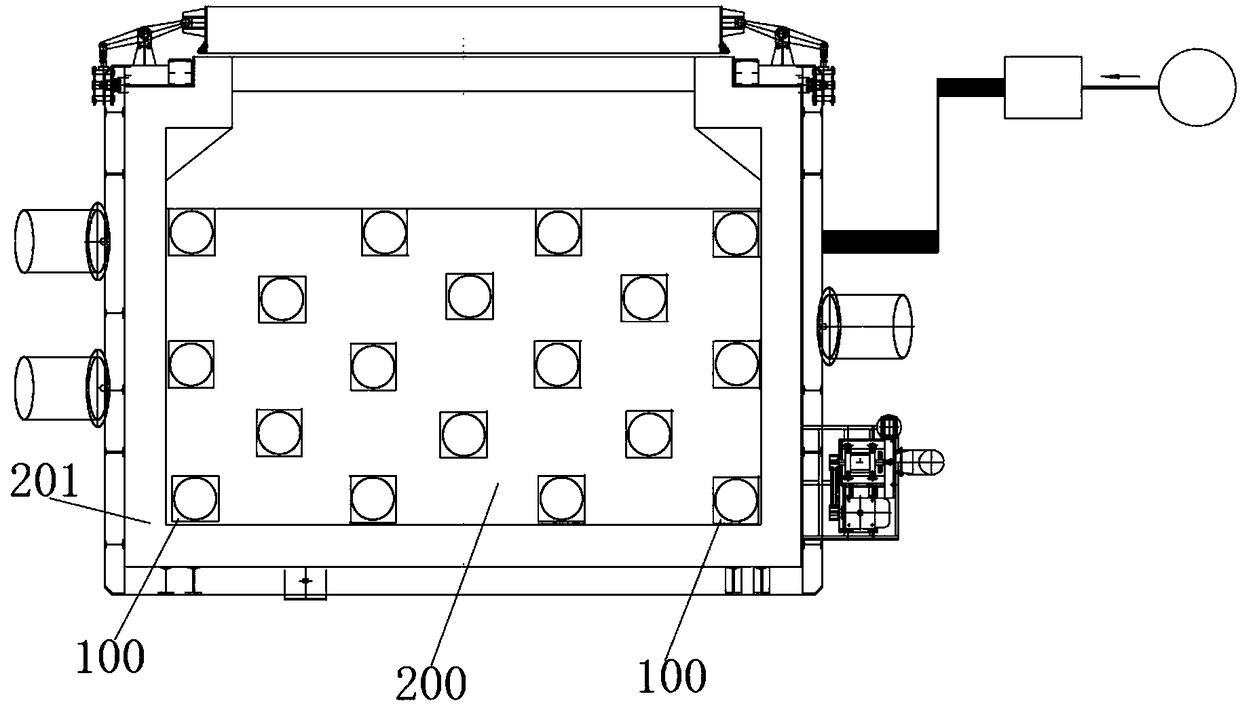

Biomass high temperature combustion boiler

InactiveCN101122384AEven distribution of feedExtended stayBoiler flue tubes/fire tubesSolid fuel combustionSolid phasesFlue gas

The invention is high-efficiency and low-pollution biomass high-temperature combustion boiler and belongs to the boiler technical field. The invention comprises a biomass granule feeding device, a fuel even distribution plate, a cross flue tube, a radiate diversion block, an air nozzle in sections, a cyclone dust collector, a liquid drainage pool, a furnace, and a heat convection chamber. The invention is characterized in that a hopper of the biomass granule feeding device is arranged above the boiler for pre-drying; radiate diversion blocks are arranged in good order in the boiler; the pre-heated high-temperature is injected upwards into a hearth from the nozzle sections in a tangential direction to realize the staged and swirl combustion; the bottom is equipped with a gas, liquid and solid phase high-temperature cyclone segregator; the central high-temperature flue gas flows through a central flue tube to the upper cross flue tube and then enters the annular clearance between the furnace and the boiler wall and the hot convection chamber from below the boiler wall. The invention combines characteristics of biomass fuel and comprehensively absorbs the advantages of high-temperature air combustion, staged combustion, cyclone combustion, cyclone dust collection, liquid drainage, flue gas recirculation and other technologies, so the invention can realize the clean and high-efficiency use of the renewable energy of biomass.

Owner:UNIV OF SCI & TECH OF CHINA

Ash agglomeration gasification reaction device

ActiveCN104449870ASolve slaggingBig spaceGasification processes detailsGasification apparatus detailsSlagProcess engineering

Owner:SHANGHAI BOILER WORKS

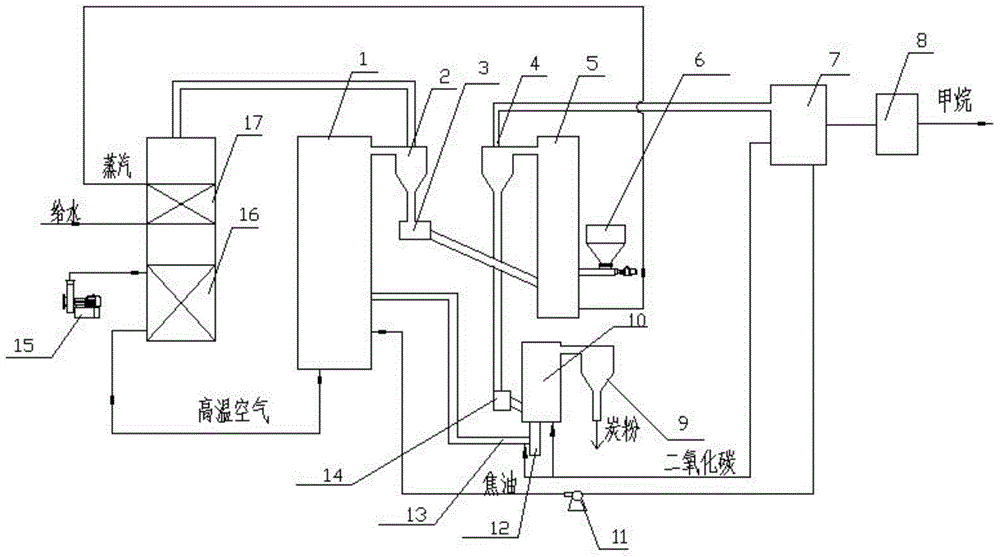

Device and process for preparing natural gas by virtue of double-fluidization bed gasification of biomass

ActiveCN104910986AFlexible temperature controlRelieve pressureGaseous fuelsEnergy inputMethane gasHydrolysis

The invention provides a device and a process for preparing natural gas by virtue of double-fluidization bed gasification of a biomass. The device comprises a burning carrier heating unit, a pyrolysis gasification unit, a biological carbon / carrier separation and conveying unit and a methane synthesis and tar returning unit, wherein the pyrolysis gasification unit is connected with the burning carrier heating unit, the biological carbon / carrier separation and conveying unit and the methane synthesis and tar returning unit. The other components are converted into methane gas as much as possible while the biological carbon is obtained, the content of methane in a pyrolysis product is about 10%, the pressure for subsequent synthesis is reduced, the tar in hydrolysis gas is used as a fuel for a double-fluidization bed, and the problems that combustion cannot be stabilized at a low temperature and alkali metals causes scorification in a high-temperature state when other double-fluidization beds adopt biological carbon combustion can be avoided to ensure that the temperature of a combustion furnace can be controlled very flexibly. The device and the process provided by the invention fully use different pyrolysis products of the biomass, can realize treatment of various biomasses, and are wide in raw material application range.

Owner:合肥德博电力有限公司

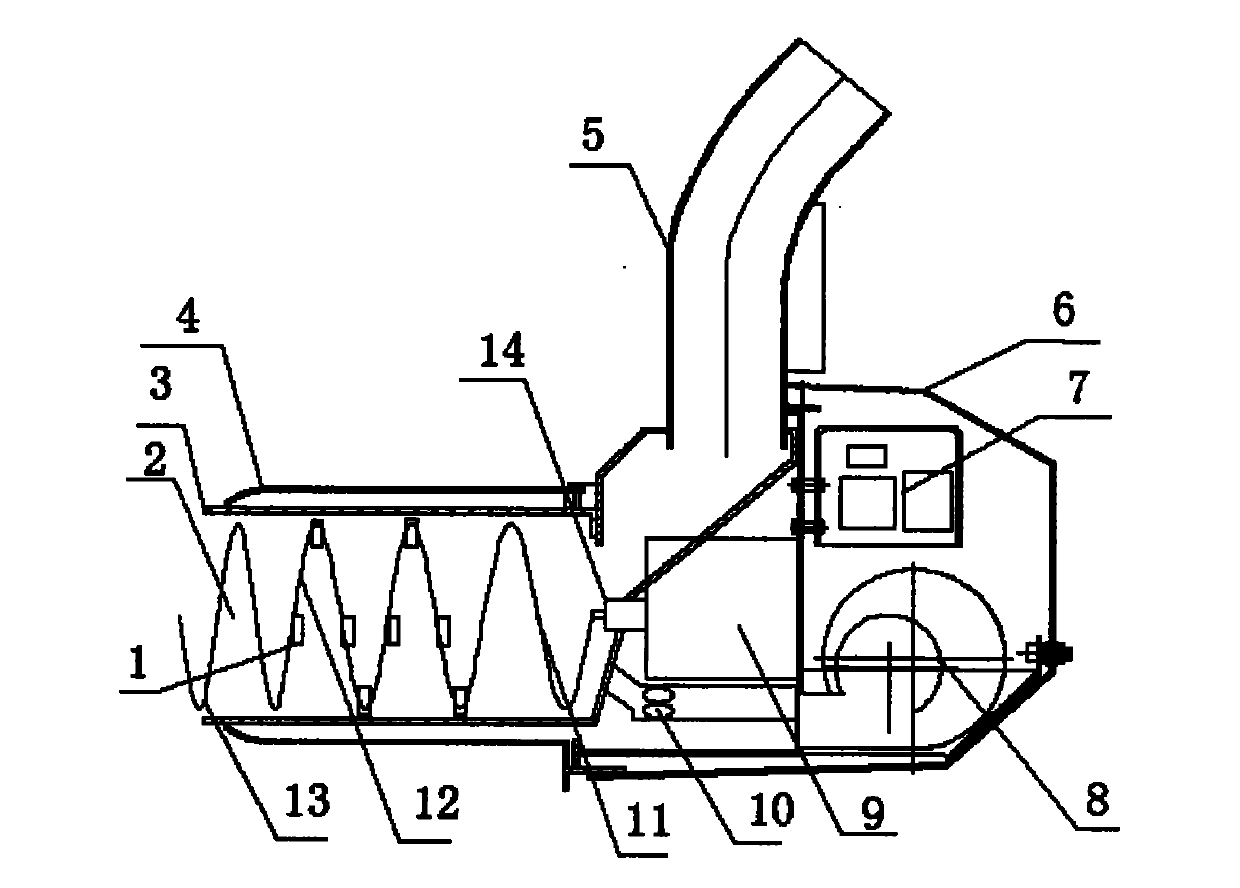

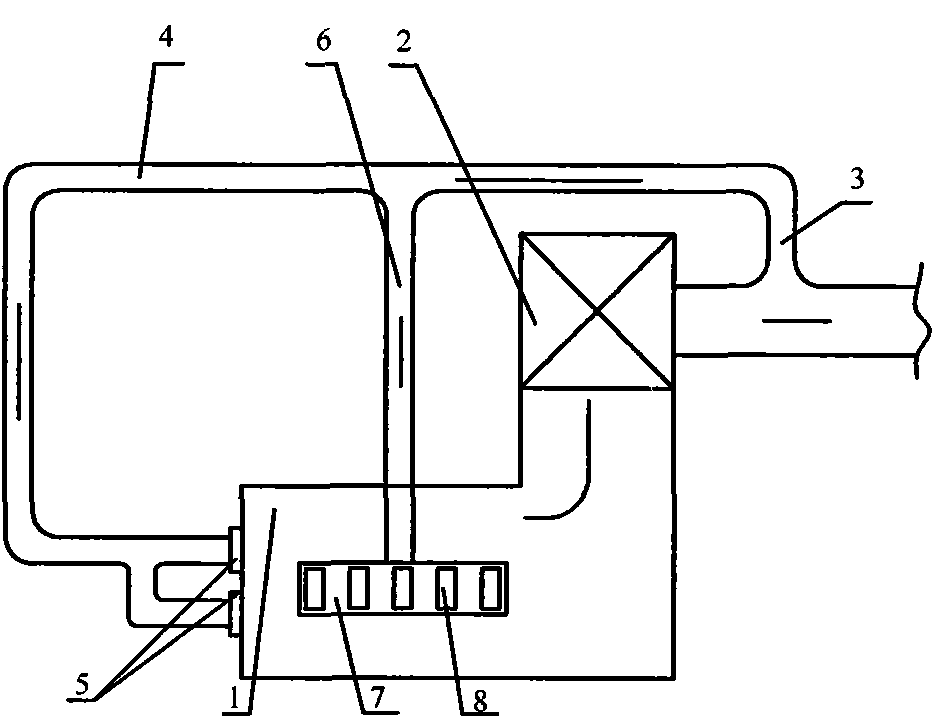

Automatic high-efficient biomass granular fuel combustor

InactiveCN101793391ASolve slaggingReasonable structureSolid fuel combustionCombustion apparatusForest industrySlag

The invention discloses an automatic high-efficient biomass granular fuel combustor, which belongs to the technical field of renewable energy sources. The technical scheme comprises a slag-breaking and ash-removing mechanism (2) and a combustion liner (3), the slag-breaking and ash-removing mechanism (2) which is connected with a motor (9) via a movable port (14) is mounted in the combustion liner (3), and consists of a fuel-pushing screw (11), a combustion stirring screw (12) and an ash-slag discharge screw (13), and different air inlets are arranged at three positions on the cylinder of the combustion liner (3), which correspond to the slag-breaking and ash-removing mechanism (2). The combustor effectively avoids the slagging phenomenon in the process of granular fuel combustion, realizes the granule conveying, stirring, slag breaking, ash removing and the like, increases the combustion efficiency, and is applicable to different types of granular fuels such as crop straws and forestry residues, and the invention provides a guarantee for the promotion of the development of the biomass pellet fuel industry in China.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

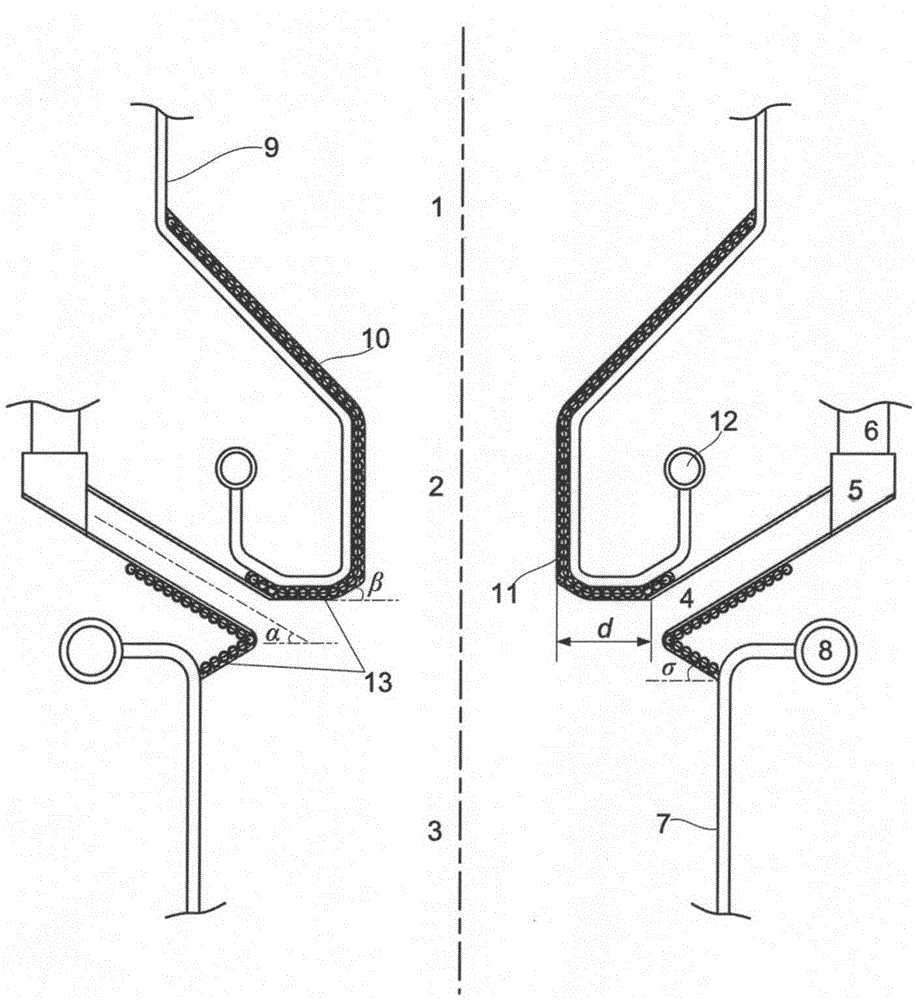

Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

ActiveCN106918039ASolve cokingSolve slaggingSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

The invention provides a biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device and belongs to the technical field of biomass combustion. The biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device is characterized in that a feeding opening of a smoldering region (3) communicates with a discharging opening of a hearth (1), a discharging opening of the smoldering region (3) communicates with a cooling region (4), a furnace grate (13) is arranged on the lower portion of the hearth (1), a crushing mechanism (2) for crushing materials is arranged on the furnace grate (13), the furnace grate (13) is connected with a rotating mechanism for disturbing biomass fuel so that carbon powder can fall into the smoldering region (3) to be smoldered, meanwhile the block-shaped biomass fuel is made to move to the middle of the furnace grate (13), and the crushing mechanism (2) is used for crushing the block-shaped biomass fuel into the carbon powder and then enabling the carbon powder to fall into the smoldering region (3) to be smoldered. By the adoption of the biomass forming fuel solid-phase low-temperature gas-phase high-temperature combustion device, the problems of coking, slag bonding, the high gas-solid pollutant emission and invalid ash fertilizer existing in combustion equipment for agricultural waste such as straw are solved fundamentally.

Owner:SHANDONG UNIV OF TECH

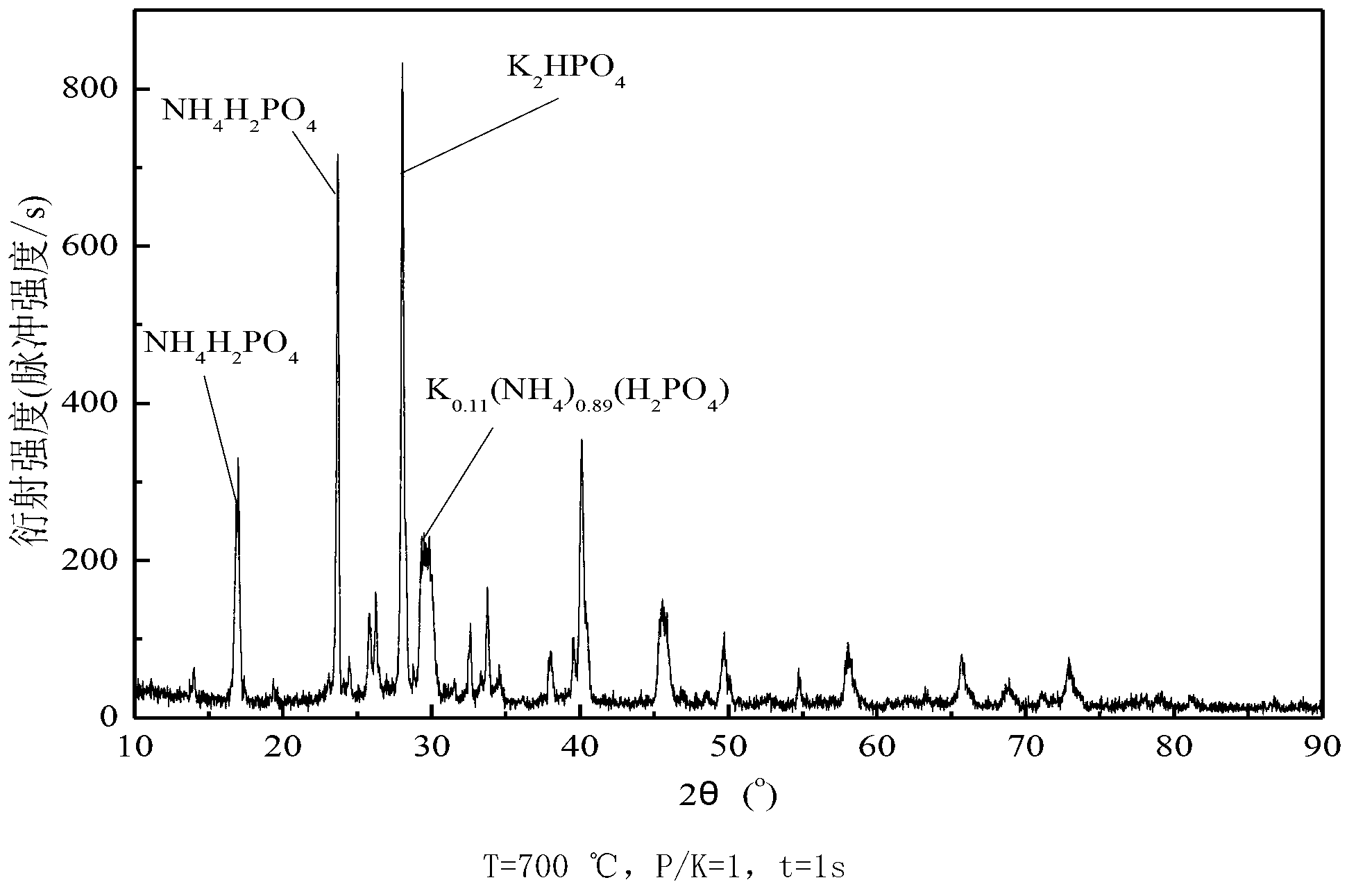

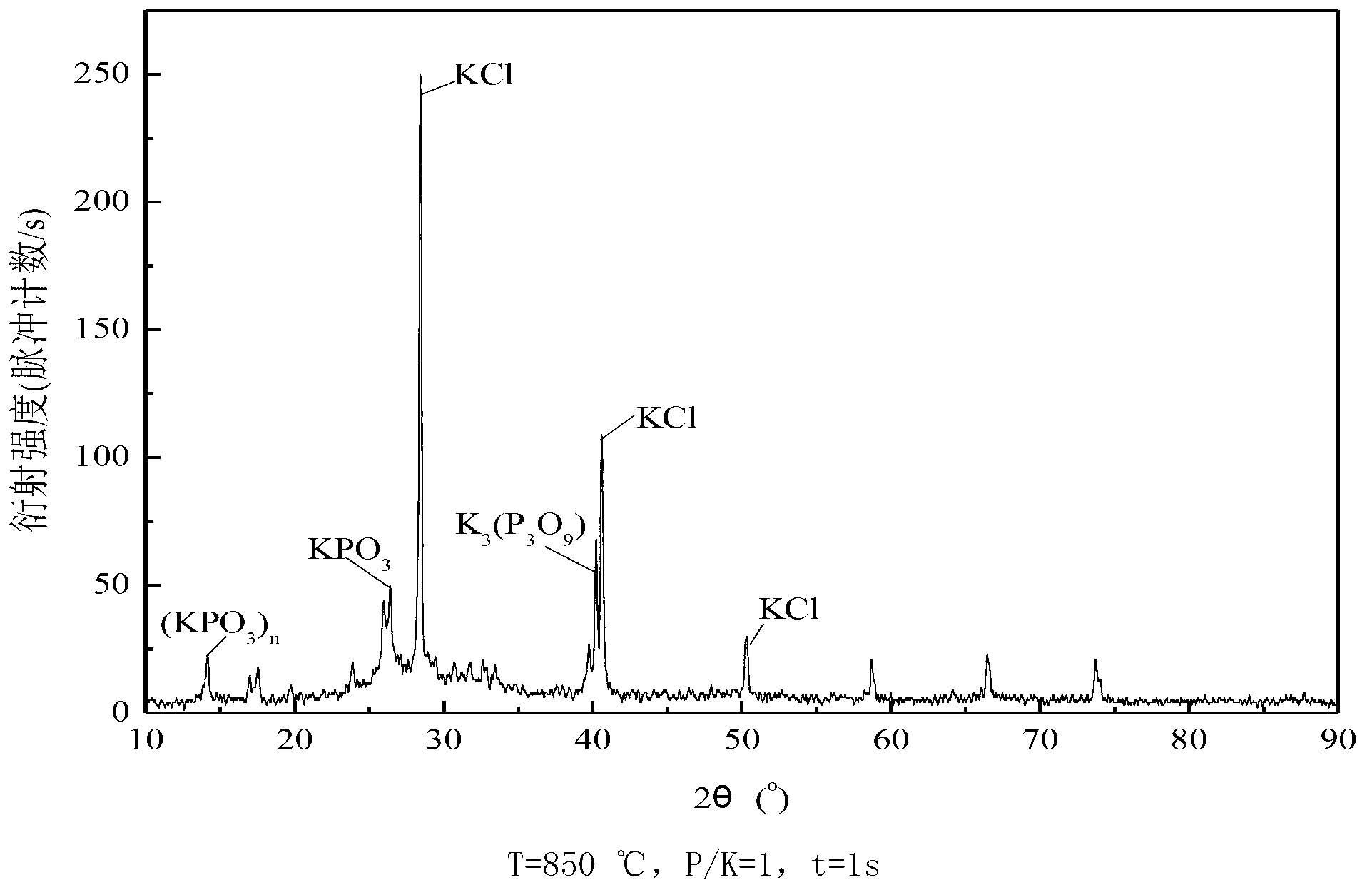

Method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate

ActiveCN103252162ASolve dust accumulationAvoid dust and corrosionDispersed particle separationFuel additivesChemistryPotassium ions

The invention discloses a method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate. The method comprises the following steps of: adding quantitative ammonium phosphate additive onto a material layer of a fire grate of a boiler or into the hearth of the boiler by virtue of a spraying device in a biomass combustion device, and carrying out a reaction on the ammonium phosphate additive as well as gas-phase potassium chloride and potassium carbonate in the flue gas at a set temperature to generate potassium phosphate, so as to remove the gas-phase potassium ions in the biomass combustion flue gas. By adopting the method for removing gas-phase potassium ions in biomass flue gas by utilizing ammonium phosphate, potassium ions in the flue gas when biomass fuel combusts can be effectively removed, the problems that ash is deposited on a biomass boiler heating surface and the biomass boiler heating surface is slagged and corroded can be avoided, and removal of NOx can be promoted by amino groups produced when ammonium phosphate is heated and decomposed.

Owner:SHANDONG UNIV

Process and apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1603388ASimple structureLow costSpecial form destructive distillationPhysical strengthCoal gasification

The invention discloses a kind of use fluffy biology raw material preparation coal gas craft and the equipment. The craft including the raw material pretreatment, the raw material gasification, is divided the principle to leave the dregs, the coal gas purifies, the coal gas transportation step; The equipment including the raw material pretreatment system, the coal gas has the system, the coal gas purification system, the coal gas transportation storing system. In this invention uses sets at the type fast fluidized gasification furnace and furnace accessories to have the production intensity in a big way, the gasified efficiency high, the gas tar content low, the operation stability is good and so on the characteristic. The gasification responded completes under the physical strength transfer rate, in sets at in the type separator realization gasification stove fresh material raw material fast circulation, the coal gas purification uses the method which the laundering and the organic solvent washes unifies, has tar removing rate to be high, in the coal gas the tar content change undulates slightly and so on the characteristic. The invention craft and the equipment may continuously gasify the fluffy fresh material raw material, gasifies the coal gas which produces to be possible to serve as the fuel gas generator the gas source, also may pass the pipe network to all around the side inhabitant user air feed.

Owner:NANJING TECH UNIV

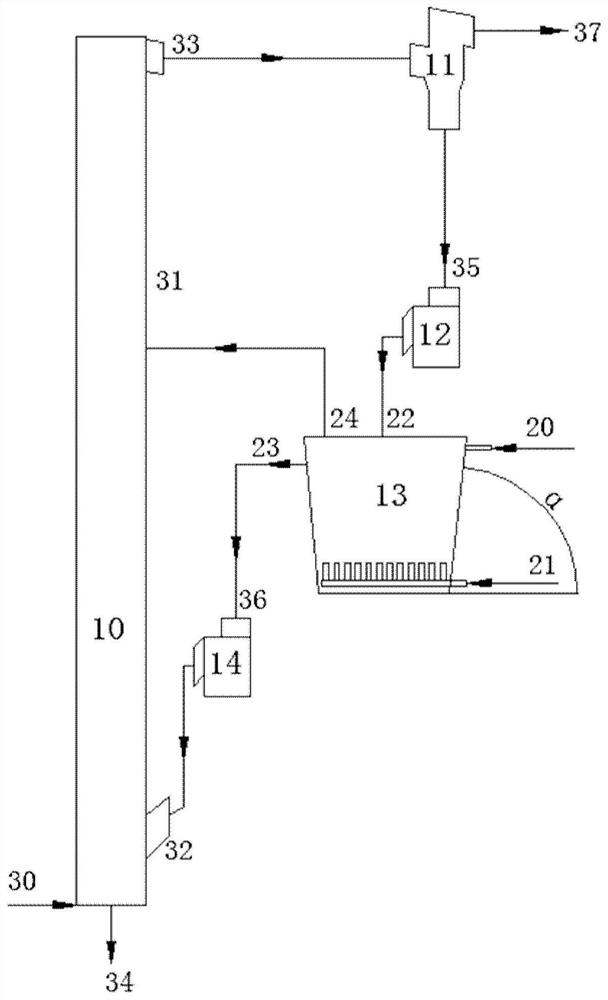

High-temperature high-dust content high-corrosion waste heat boiler of metallurgical industry

ActiveCN105605543AReduce energy costsReduce manufacturing costChemical industryEnergy industryChemical industrySlag

The invention discloses a high-temperature high-dust content high-corrosion waste heat boiler of metallurgical industry. A high-temperature platen superheater and a low-temperature platen superheater are arranged in a cooling room I and a cooling room II respectively; a convection evaporation tube platen I, a convection evaporation tube platen II and a convection evaporation tube platen III are arranged in a cooling room III, a cooling room IV and a cooling room V respectively; platen heating surfaces are longitudinally arranged in the cooling rooms; a high-temperature radiation settling room and each cooling room are formed by membrane walls and communicated in a staggered manner; an ash bucket is arranged at the lower part of each heating surface; the collected dust is conveyed out of the boiler by a slag extractor. The high-dust content high-temperature flue gas generated in a metallurgical production process sequentially enters the high-temperature radiation settling room, multi-level cooling rooms and an economizer to realize heat energy recovery of a convection bank; the superheated steam generated by the waste heat boiler is applied to enterprise production. The waste heat boiler disclosed by the invention has the advantages of simple production technology, convenience in maintenance and safe and stable operation and is suitable for popularization and application in the waste heat recovery of high-dust content high-temperature flue gas in the metallurgical and chemical industries.

Owner:大连科林能源工程技术开发有限公司

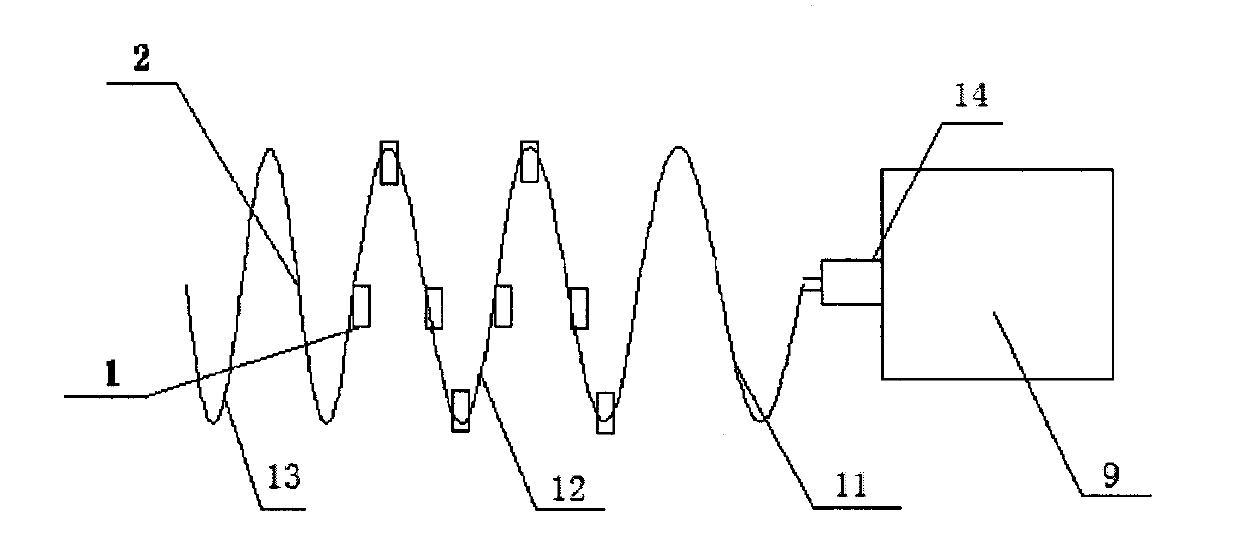

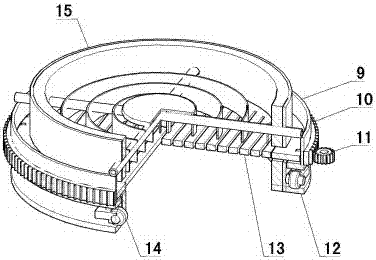

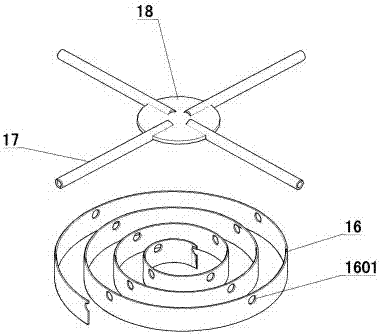

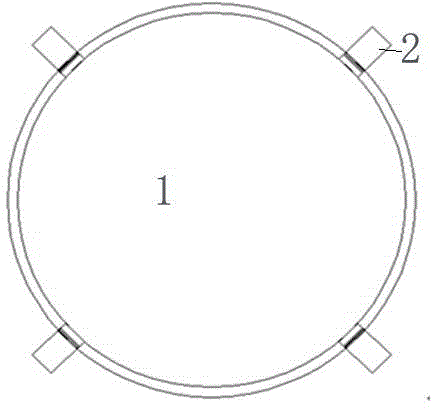

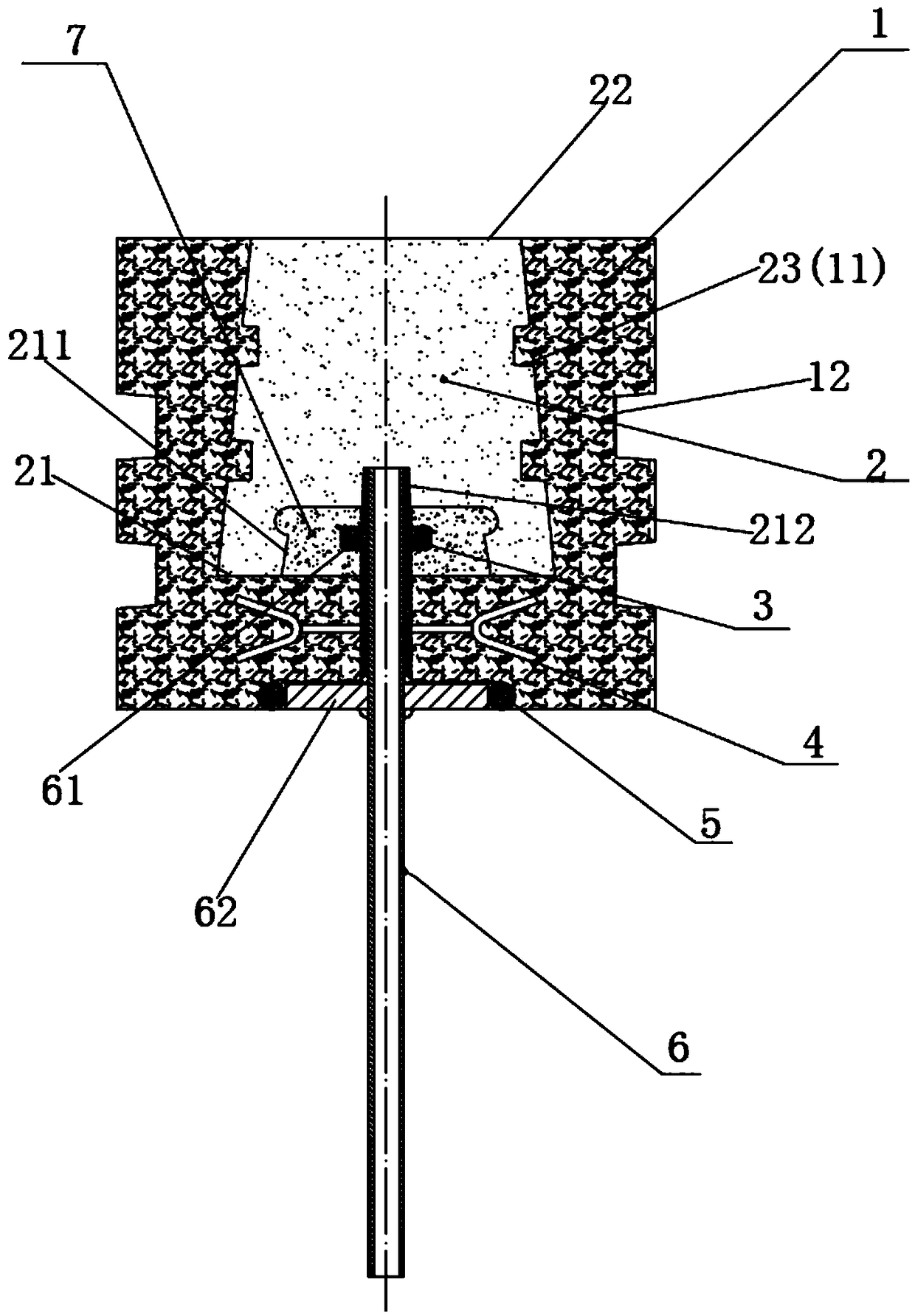

Spiral fire grate self-deslagging burner

InactiveCN104132328AExtended service lifeImprove combustion efficiencySolid fuel combustionAir/fuel supply for combustionCombustorSlag

The invention relates to a biomass particle burning device, namely a spiral fire grate self-deslagging burner. The spiral fire grate self-deslagging burner comprises a furnace body, wherein the furnace body is provided with a feed port and a flame and smoke outlet (secondary air port). The spiral fire grate self-deslagging burner is characterized in that a packing auger shaft penetrates through the lower portion in the furnace body, the packing auger shaft is a hollow shaft, the hollow shaft is provided with multiple air outlet holes, one end of the packing auger shaft is connected with a draught fan, and the other end of the packing auger shaft is connected with a furnace body ash outlet. A packing auger integrates the slag breaking function, the ash discharge function, the air supply function and the function of a fire grate. The spiral fire grate self-deslagging burner is compact in structure, and the overall size of the furnace body is reduced; the packing auger discharges slag, the deslagging mechanization and automation degree is high, and the deslagging effect is good; combustion is sufficient, and the thermal efficiency is high.

Owner:大连旺佳新能源科技开发股份有限公司

Biomass high temperature combustion boiler

InactiveCN100513869CImprove combustion efficiencyEfficient and stable combustion and clean emissionBoiler flue tubes/fire tubesSolid fuel combustionCycloneClean energy

The invention relates to a high-efficiency and low-pollution biomass high-temperature combustion boiler, which belongs to the technical field of boilers. The invention includes a biomass particle feeder, a fuel uniform distribution plate, a cross smoke pipe, a radiation guide block, a sectional air nozzle, a cyclone dust collector, a liquid slag discharge pool, a furnace, and a steam generating chamber. The feature is that the hopper of the biomass particle feeder is set above the boiler, which can realize pre-drying; the furnace is built with well-arranged radiation guide blocks; the preheated high-temperature air enters the furnace chamber tangentially and vertically from the nozzle to realize grading , swirling combustion; the bottom is equipped with a gas-liquid-solid three-phase high-temperature cyclone separator, and the high-temperature flue gas in the center flows through the central flue pipe to the upper cross flue pipe and enters the annular gap between the furnace and the furnace wall, and enters the steam generation chamber from the bottom of the furnace wall . The invention combines the characteristics of biomass fuel and comprehensively absorbs the advantages of high-temperature air combustion, graded combustion, cyclone combustion, cyclone dust removal, liquid slag removal and flue gas recirculation, and can realize clean and efficient utilization of renewable energy biomass.

Owner:UNIV OF SCI & TECH OF CHINA

Anti-clogging coal-fired industrial furnace

InactiveCN101858692AReduce the temperatureSolve slaggingFurnace typesWaste heat treatmentSlagProcess engineering

The invention relates to an anti-clogging coal-fired industrial furnace which relates to an industrial furnace. The invention aims to solve the problems of low efficiency, serious slag bonding and high NOx discharge amount of the coal-fired industrial furnace adopting a heat-insulating hearth at present. The invention adopts twp schemes that: scheme 1: the heat-insulating hearth is connected with smoke gas utilization equipment, the smoke gas utilization equipment is communicated with a smoke gas recirculation main pipeline, the smoke gas recirculation main pipeline is respectively communicated with a first smoke gas recirculation branch pipeline and a second smoke gas recirculation branch pipeline, the first smoke gas recirculation branch pipeline is communicated with a corresponding swirl pulverized coal burner with smoke gas recirculation, a group of swirl pulverized coal burners with smoke gas recirculation are arranged on the front wall of the heat-insulating hearth, and an a group of smoke gas recirculation spouts are communicated with the second smoke gas recirculation branch pipeline; and the different point of the scheme 2 is as follows: the outlet of the smoke gas utilization equipment is communicated with the inlets of the first smoke gas recirculation branch pipeline and the second smoke gas recirculation branch pipeline. The invention is applied to the industrial field of material drying by utilizing hot smoke gas.

Owner:HARBIN INST OF TECH

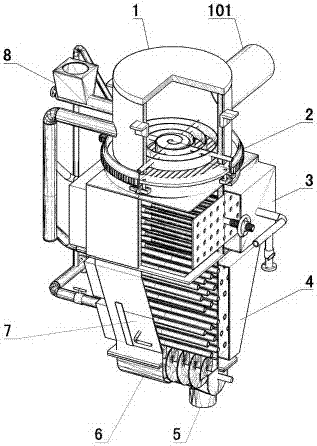

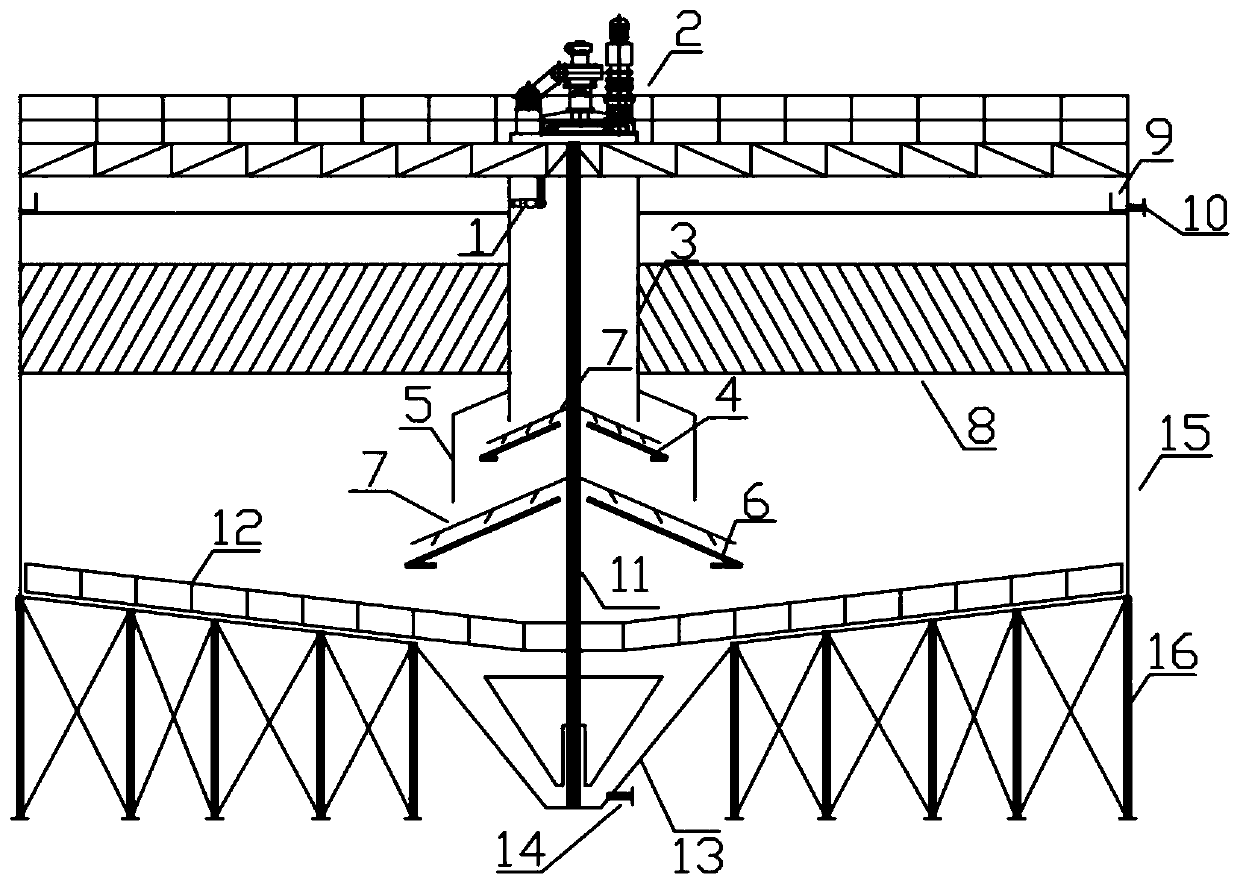

High-efficiency solid-liquid clarification and separation device

PendingCN111450581AReduce processing sizeReduce effluxSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeEngineering

The invention discloses a high-efficiency solid-liquid clarification and separation device. The device comprises a bottom bracket, a cylinder body, a flow guide device, an inclined plate, a mud scraping mechanism and a speed reducer, wherein the cylinder body is mounted on the bottom bracket, the speed reducer is arranged on the cylinder body, the flow guide device comprises a flow guide barrel and a reflecting plate, the reflecting plate is arranged below the flow guide barrel, the top of a first-stage flow guide barrel is communicated with a sewage / grey water inlet, the top of a second-stageflow guide barrel is connected to the outer side of a lower end opening of a first-stage flow guide barrel, and auxiliary scraping arms are arranged on the upper surface of a first-stage reflecting plate and the upper surface of a second-stage reflecting plate respectively, a slag / sludge concentration hopper is arranged at the bottom of the cylinder body, a scraping arm is arranged on a bottom plate of the cylinder body, and the scraping arm and auxiliary scraping arms jointly form the sludge scraping mechanism. According to the invention, the specific surface area is increased, the treatmentload is increased, the diffusion flow is enhanced by the flow guide reflection device, the water distribution is more uniform, the flow velocity is more stable, the liquid medicine is more fully mixed, and the clarification and separation efficiency is greatly improved.

Owner:宜兴市荣盛达环保有限公司

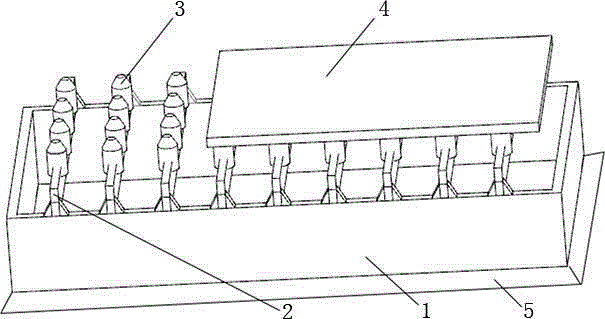

Replacement-free plate rib type steel plate flame cutting platform

InactiveCN105643047AEasy to pile upImprove cleanlinessWelding/soldering/cutting articlesMetal working apparatusEngineeringFlame cutting

The invention provides a replacement-free plate rib type steel plate flame cutting platform. The platform comprises a ground platform support frame; transverse steel plates and vertical steel plates are mounted on the ground platform support frame; multiple first clamping grooves are arranged on the vertical steel plates at equal intervals; transverse steel plates are arranged in the first clamping grooves, so that the transverse steel plates and the vertical steel plates form a latticed structure; multiple second clamping grooves are formed in the transverse steel plates; support pieces are mounted in the second clamping grooves, are cylinders with cones at the tops, and are clamped in the second clamping grooves through through grooves; the support pieces are arranged on the transverse steel plates in a lattice manner to form support planes; and the top ends of all the support pieces are positioned on the same horizontal plane. The platform is simple in structure, can use specificity of the support pieces for solving such problems as damage, lagging and tumor hanging in the steel plate cutting process of factories, reduces the replacement frequency of the support plates of the cutting platform, prolongs the service life of a cutting machine, and improves the production safety.

Owner:WUHAN YIYE STEEL STRUCTURE

Stove capable of preventing slagging

InactiveCN102116489ASolve slaggingLighting and heating apparatusStove/ranges for heating waterCombustion chamberSlag

The embodiment of the invention discloses a stove capable of preventing slagging. The stove comprises a combustion chamber in which an ignition rod is arranged, a slag-out rod connected with a feed rod and is positioned in the combustion chamber, a hearth which is arranged on the top of the combustion chamber and is communicated with the combustion chamber, a hopper of which the bottom is provided with an emptying port communicated with a feed pipe, and an air distribution chamber communicated with an air inlet of the combustion chamber; the feed pipe is connected with the feed port of the combustion chamber; the feed rod is arranged in the feed pipe and is provided with a feed spiral sheet; a slag-out spiral sheet is arranged on the end of the slag-out rod far away from the feed rod, and a plurality of slag crushing nails are arranged at one end of the slag-out rod close to the feed rod; and the external wall of the emptying port is provided with a feed motor and the output end of the feed motor is connected with the feed rod. The stove capable of preventing slagging, which is provided by the embodiment of the invention, solves the slagging problem of the stove in the combustion process.

Owner:朱宏锋 +1

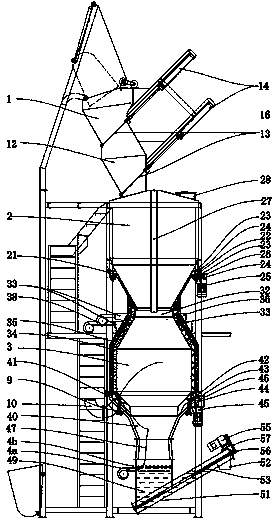

External fire down-flow fixed bed type front-furnace carbonization-coupling fire coal power generating device for straws

InactiveCN109181723APrecise temperature controlSolve slaggingBiofuelsIndirect heating destructive distillationCombustion chamberFour-way valve

The invention discloses an external fire down-flow fixed bed type front-furnace carbonization-coupling fire coal power generating device for straws. The device comprises a conveying machine, a feedingmachine, an air lock, a main material bin, a carbonization chamber, an air distribution chamber, a slag discharging chamber, an air collector, a heat exchanger, a four-way valve, a first circulatingfan, a combustor, a combustion chamber, an ignition combustor, a temperature adjusting chamber, a second circulating fan, a fan, a fourth circulating fan and a monitoring unit, wherein the conveying machine is connected with the air lock through the feeding machine; the air lock is connected with the slag discharging chamber through the carbonization chamber; the carbonization chamber is connectedwith the heat exchanger; the heat exchanger is connected with a four-way valve; a first outlet of the four-way valve is connected with the combustor through a first circulating fan; the fan is connected with the combustor; the combustor is connected with the combustion chamber; the combustion chamber is connected with the temperature adjusting chamber; an outlet of the temperature adjusting chamber is connected with the carbonization chamber; a second outlet of the four-way valve is connected with the temperature adjusting chamber through the second circulating fan; a third outlet of the four-way valve is connected with the third circulating fan; the circulating fan is connected with a power station boiler; and the monitoring unit is used for monitoring the temperatures of the outlets ofthe combustion chamber and the temperate adjusting chamber. According to the device, the scorification and corrosion problems are solved.

Owner:NANJING UNIV OF SCI & TECH

Anti-slagging stove

InactiveCN102121710ASolve slaggingLighting and heating apparatusStove/ranges for heating waterCombustion chamberSlag

The embodiment of the invention discloses an anti-slagging stove, comprising a burning chamber provided with an ignition rod, a first motor, a hopper, a second motor and a hearth, wherein the burning chamber is internally provided with a first stirring rod; the two ends of the first stirring rod are respectively provided with a spiral piece, and the middle of the first stirring rod is provided with a plurality of slag crushing nails; one end of the first stirring rod penetrates through the feeding port of the burning chamber, and the other end of the first stirring rod penetrates through the slag hole of the burning chamber; the output end of the first motor is connected with the first stirring rod; the bottom of the hopper is provided with a feeding pipe communicated with the feeding port of the burning chamber; the feeding pipe is internally provided with a second stirring rod which is provided with spiral pieces; one end, close to the feeding port, of the second stirring rod is higher than one end, close to the feeding port, of the first stirring rod; the output end of the second motor is connected with the second stirring rod; and the hearth is arranged at the top of the burning chamber and is communicated with the burning chamber. By utilizing the anti-slagging stove disclosed by the embodiment of the invention, the problem of slagging of the stove in the process of burning is solved.

Owner:朱宏锋 +1

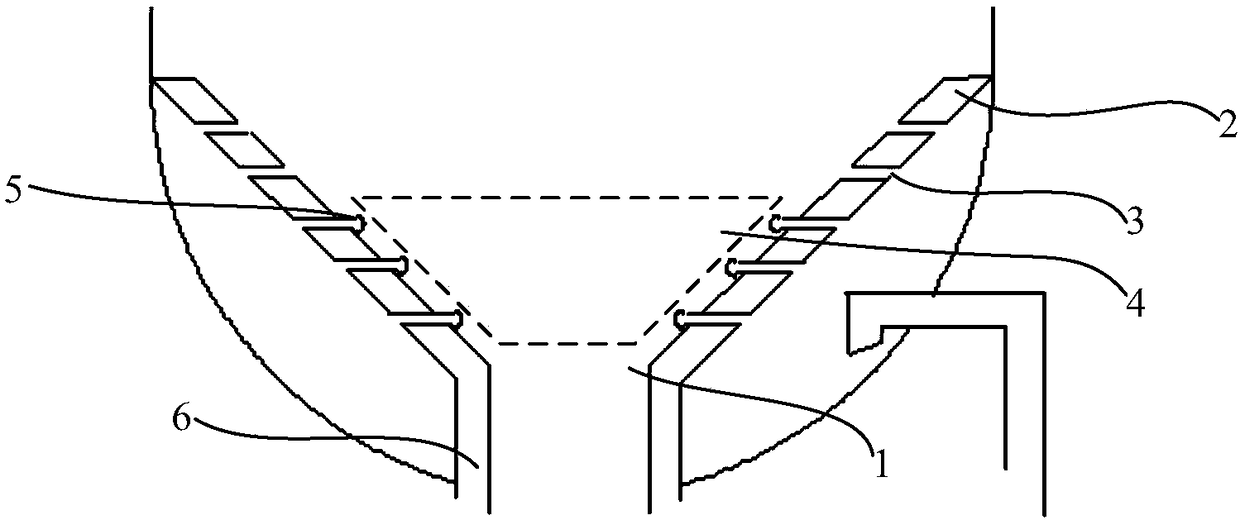

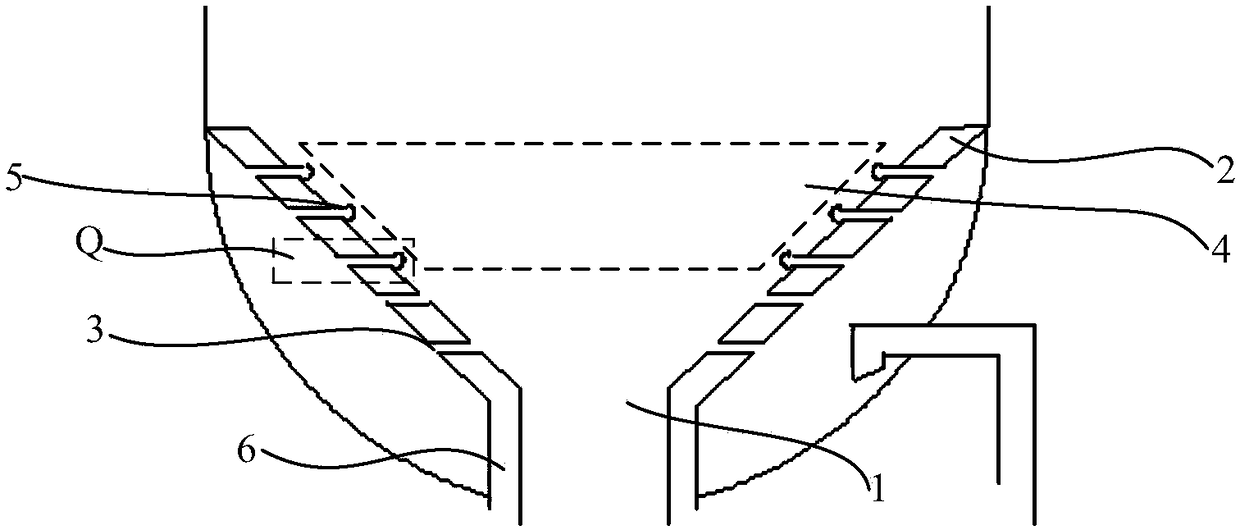

Gas distributor and gasification furnace

ActiveCN108485715ASolve slaggingEven contactGasifier feeding meansGranular/pulverulent flues gasificationSlagEngineering

The invention relates to the technical field of chemical equipment, in particular to a gas distributor and a gasification furnace. The gas distributor can distribute part of airflow passing through horizontal openings along a vertical direction as required, so that the distribution of a flow field can be optimized, a flow dead zone caused by uneven distribution of the flow field can be avoided, smooth slag discharge can be realized, and the operation and maintenance cost of the gasification furnace can be reduced. The embodiment of the invention provides a gas distributor, which comprises a conical distribution plate with a slag discharge port at the bottom; the conical distribution plate is provided with a plurality of horizontal openings penetrating through inner and outer annular surfaces; the horizontal openings of the conical distribution plate corresponding to a first fluidization area are positioned on the inner side of the conical distribution plate and are connected with a gasdistribution structure respectively; and the gas distribution structure is used for re-distributing the air flow introduced into the horizontal openings of the conical distribution plate corresponding to the first fluidization area, so that the air flow passing through the horizontal openings of the conical distribution plate corresponding to the first fluidization area is uniformly dispersed ina vertical direction. The gas distributor provided by the embodiment of the invention is used for distributing gas in the gasification furnace.

Owner:ENN SCI & TECH DEV

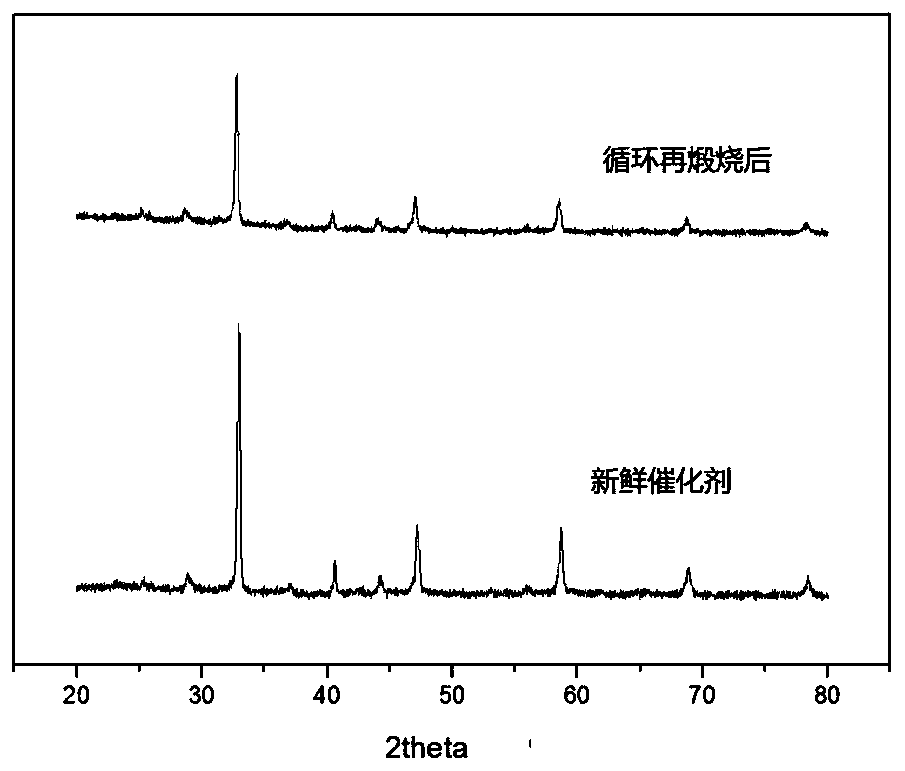

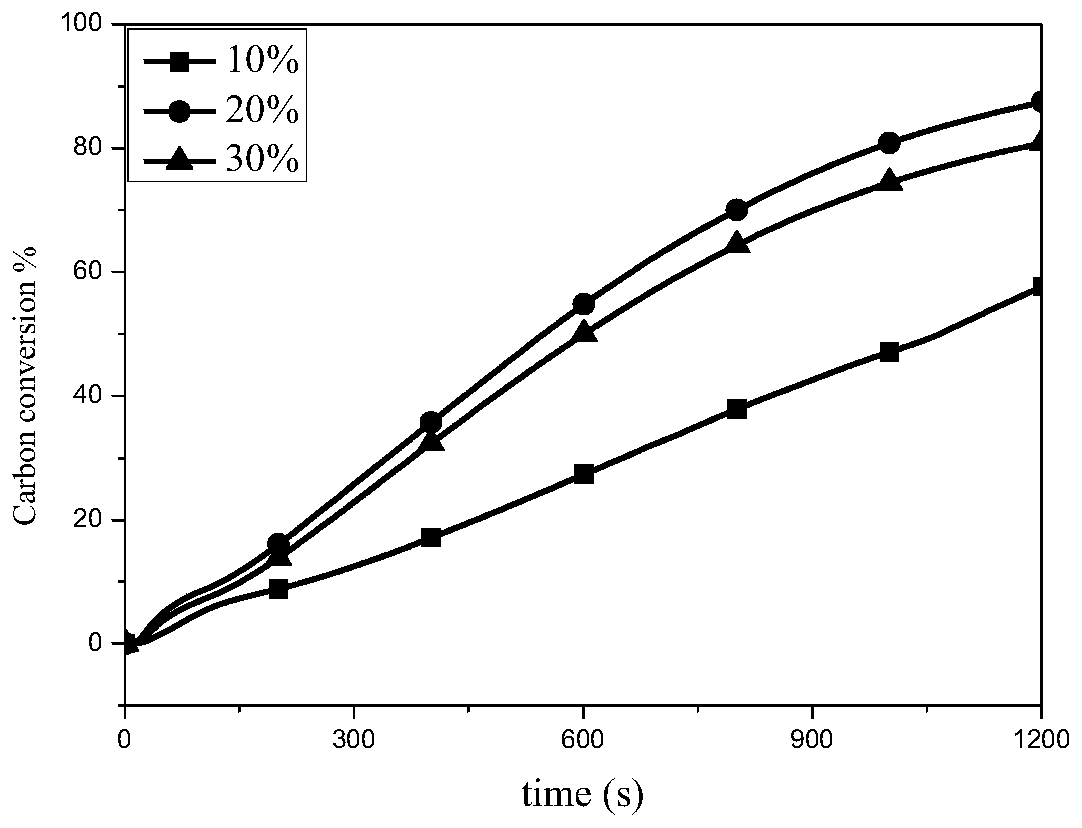

Preparation method and application of composite metal oxide catalysts for coal gasification

InactiveCN109745991AReturn to normal structureNo sinteringChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsWater bathsEthylene diamine

The invention discloses a preparation method and application of a composite metal oxide catalyst for coal gasification. According to the preparation method, lanthanum nitrate, nitrate metal salt A, ferric nitrate and nitrate metal salt B are added into water and mixed evenly to prepare a metal nitrate solution; then EDTA (ethylene diamine tetraacetic acid) and citric acid are mixed evenly, the pHvalue is adjusted to 7-9, and the mixture is stirred evenly in a constant temperature water bath to prepare a precursor solution; the metal nitrate solution is added to the precursor solution, and stirring is performed until a wet gel is formed; and the composite metal oxide catalyst is obtained by drying, calcining and cooling. The composite metal oxide catalyst for coal gasification can not onlyeffectively increase the gasification rate of coal, with the conversion rate reaching 90%; but also maintain the original structure and catalytic activity after the reaction, so that reutilization can be achieved through recycling.

Owner:DALIAN MARITIME UNIVERSITY

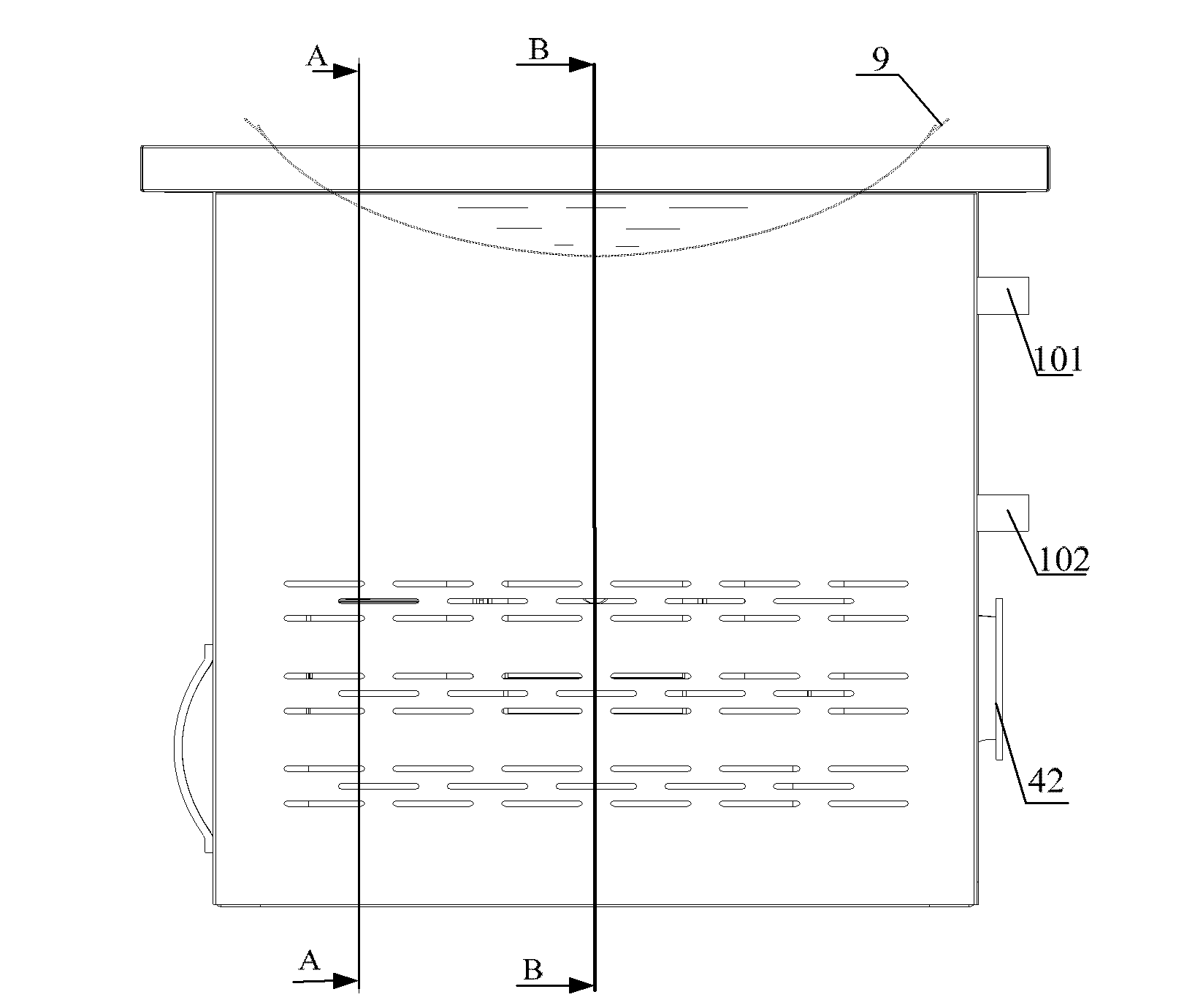

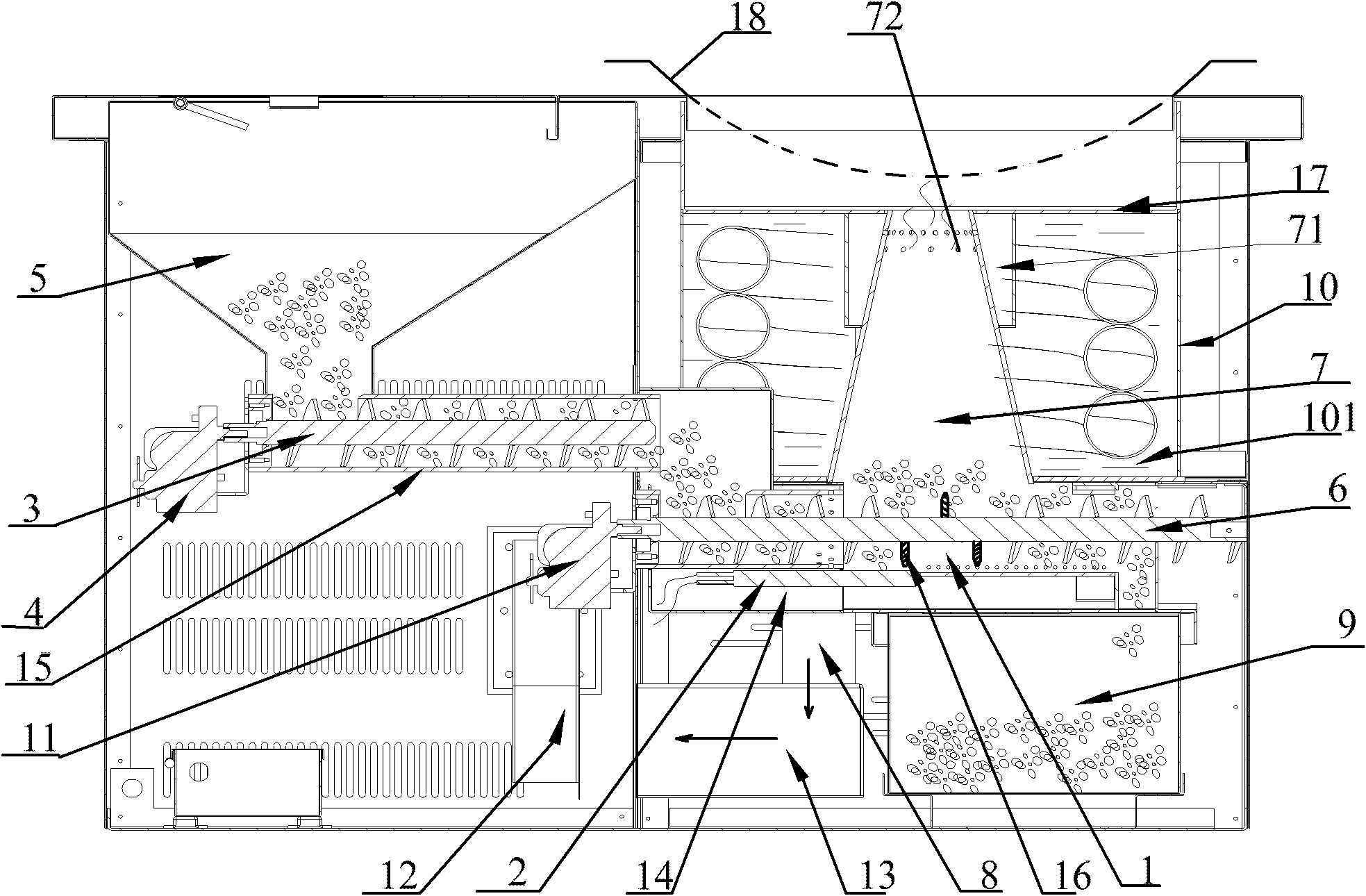

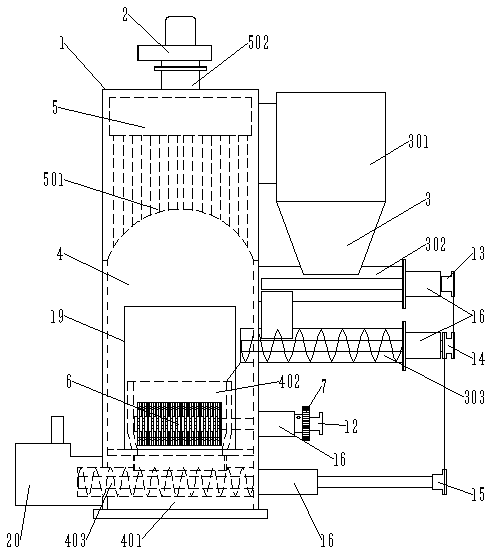

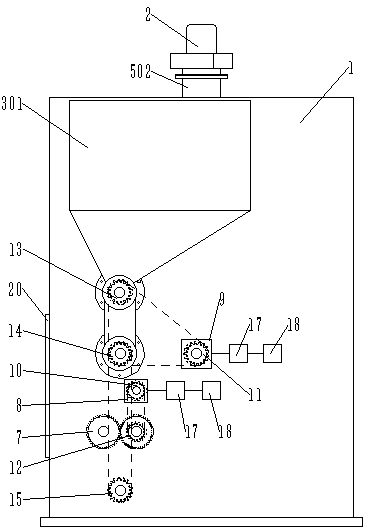

Biomass particle combustion furnace

PendingCN109855087AAchieve dynamic combustionSolve slaggingSolid fuel combustionCombustion apparatusCombustion chamberEngineering

The present invention relates to the technical field of combustion equipment, in particular to a biomass particle combustion furnace. A combustion chamber is internally provided with two fire grates,and rotating shafts of the two fire grates respectively extend out of a furnace body and are connected with a fire grate transmission mechanism. An ash clearing auger is arranged in an ash falling bin, and one end of an auger shaft of the ash clearing auger extends out of the furnace body and is connected with an ash clearing transmission mechanism. An ash outlet of the ash clearing auger is arranged on the other side away from the furnace body and a feeding device. A storage bin of the feeding device is arranged at the side upper part of the combustion bin, and the storage bin is arranged above an upper feeding auger. The discharge end of a lower feeding auger is arranged at the side upper part of the combustion bin in the furnace body, and the upper feeding auger and the lower feeding auger are connected with a feeding transmission mechanism. The grate rotating with fixed axis realizes dynamic combustion and solves the slagging problem. The ash removal auger and the synchronous transmission mechanism for feeding and ash removal can solve the problem that accumulated ash cannot be cleaned in time.

Owner:唐山市丰润区神火新能源开发有限公司

Low-ash-fusion coal fired boiler adopting horizontal extended furnace

InactiveCN104534456ASolve slaggingGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention discloses a low-ash-fusion coal fired boiler adopting a horizontal extended furnace and belongs to the technical field of industrial pulverized-coal fired boilers. The boiler is used for solving the problem of the existing pulverized-coal fired boilers that furnace hearths are subjected to slag-bonding during the combustion of low-ash-fusion coal. The low-ash-fusion coal fired boiler adopting the horizontal extended furnace comprises the horizontal extended furnace which is fixed at the front part of a furnace body, wherein the horizontal extended furnace is formed by water-cooled walls through enclosing, and fireproof coating layers are laid on the internal surfaces of the water-cooled walls; a furnace hearth outlet of the horizontal extended furnace is communicated with a cooling chamber, a sloping furnace bottom is arranged at the front end of the furnace hearth outlet, a slag coagulating pipe bundle is arranged at the junction of the furnace hearth outlet and the cooling chamber, and a slag basin is arranged at the lower part of the furnace hearth outlet; combustors, an after-combustion air nozzle and furnace arches are arranged on the horizontal extended furnace, the after-combustion air nozzle is arranged at a position which is away from primary air ports of the lowest layer by 4-5 meters, and the furnace arches are arranged at the front part of the sloping furnace bottom. According to the boiler, the structure is simple, the operation is convenient, the problem of slag-bonding of low-ash-fusion pulverized-coal fired boilers can be effectively solved, and the normal operation of the boiler is guaranteed.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

Parallel mixed combustion system and method

InactiveCN105546506AImprove parameters and overall conversion efficiencyAvoid instabilityEnergy industrySteam generation plantsSuperheaterBiomass fuels

The invention belongs to the technical field of biomass application and particularly relates to a parallel mixed combustion system and method. The parallel mixed combustion system is composed of a biomass direct-fired boiler and a pulverized coal fired boiler, wherein biomass fuel in a storage bin enters the biomass direct-fired boiler through a conveying device and combusts on a fire grate to generate heat which is exchanged with heat of a superheater, and the generated low-parameter steam is conveyed to an inlet of a low-temperature reheater of the pulverized coal fired boiler through a steam conveying device; and smoke of the biomass direct-fired boiler is conveyed to the front side of an induced draft fan of the pulverized coal fired boiler after passing through a coal economizer, an air preheater and a dust collector, is introduced to a chimney and is discharged into the atmosphere. According to the parallel mixed combustion system, a biomass combustion system is completely separated from a coal combustion system, and the low-parameter steam generated by the biomass direct-fired boiler is conveyed to the coal fired boiler, so that parameters and the overall conversion efficiency are increased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

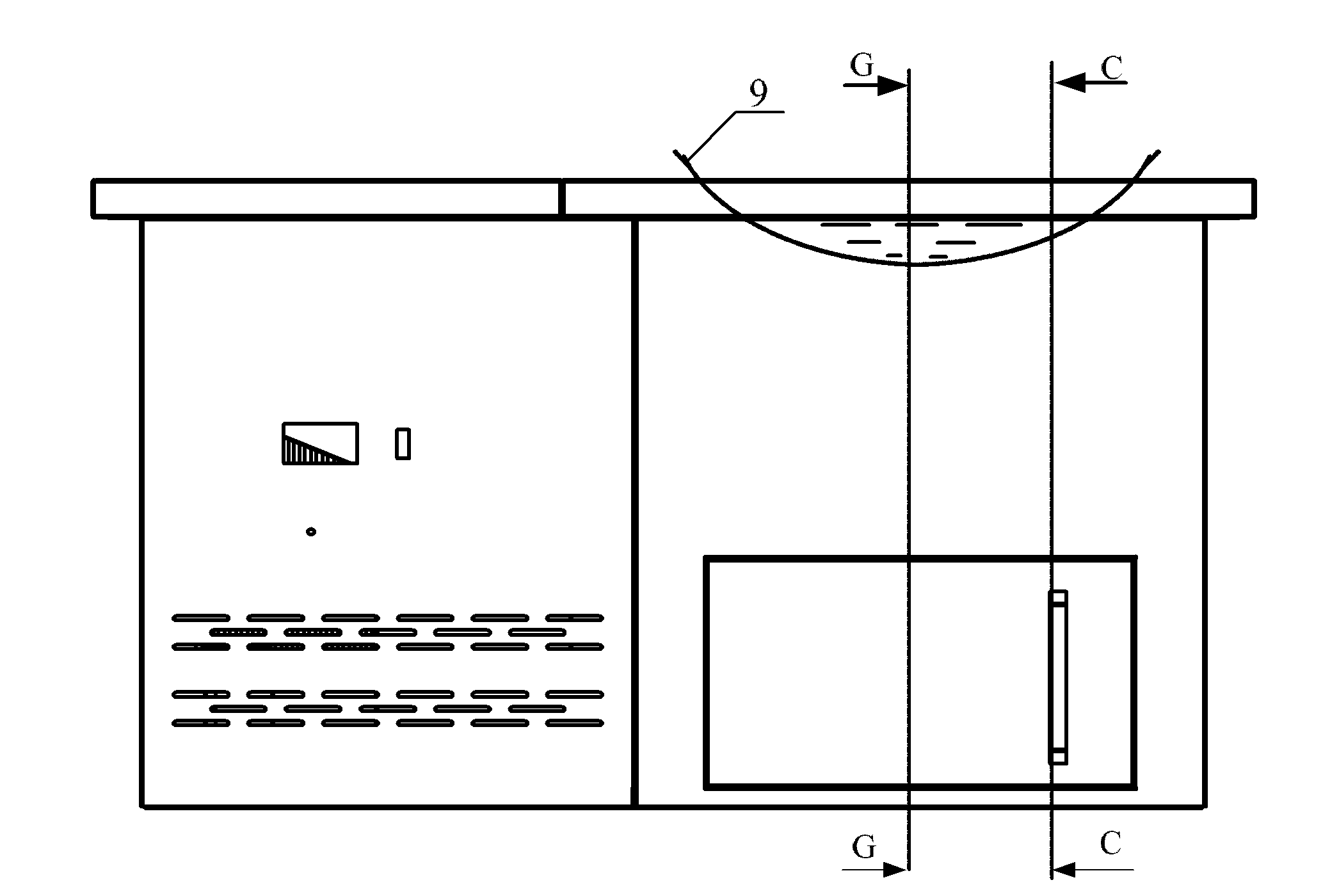

Primary air opposite-flushing device for preventing boiler rear wall water cooling wall from slagging and corroding

PendingCN112879899ASolve slaggingReduce NOxPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationAir volumeStaged combustion

The invention discloses a primary air opposite-flushing device for preventing a boiler rear wall water cooling wall from slagging and corroding. The device comprises primary air opposite-flushing nozzles arranged on a rear wall of a boiler in a layered manner, and the primary air opposite-flushing nozzles and turbulent combustors arranged on a front wall of the boiler in a layered manner are arranged in a one-to-one opposite manner. The primary air opposite-flushing nozzles and primary air pipes of the turbulent combustors are positioned on the same central axis; and the primary air opposite-flushing nozzles are connected with an opposite-flushing air mother pipe through pipelines with valves. On one hand, the rear wall water cooling wall can be prevented from being scoured by pulverized coal, the problems of slagging and high-temperature corrosion are solved, the primary air speed and the secondary air rotational flow strength of the turbulent combustors on the front wall can be flexibly adjusted by combining the unit load and the fire coal quality, and the adherence atmosphere of the rear wall water cooling wall does not need to be considered; and on the other hand, under the condition that the amount of air entering a hearth is certain, part of air enters the hearth through the primary air opposite-flushing nozzles of the rear wall, the air staged combustion effect can be achieved, and NOx generated by combustion is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Vent plug for ventilation and stirring of bottom of smelting furnace and metal smelting furnace

InactiveCN109141016APrevent disengagementImprove sealingStirring devicesCharge treatment typeRefractoryEngineering

The invention relates to a vent plug for ventilation and stirring of the bottom of a smelting furnace. The vent plug is installed on the bottom of a furnace body of the smelting furnace and comprisesa ventilating core which is made of a high-temperature resisting material and is internally provided with air holes, the lower end face of the ventilating core is provided with a groove, and the groove is internally provided with an insertion hole. One end of a high-temperature resisting seamless pipe is provided with a first end expanding disk, the end portion of the high-temperature resisting seamless pipe is inserted into the insertion hole of the ventilating core, and the first expanding disk is located in the groove. A first refractory castable cured structural body is formed by curing high-strength refractory castable filled in the groove. A second refractory castable cured structural body is formed by curing high-strength refractor castable wrapping the ventilating core, the first refractory castable cured structural body and the outer surface of high-temperature resisting seamless pipe. The invention further relates to the metal smelting furnace comprising the vent plug. The vent plug is provided with multiple structures preventing the ventilating core from disengaging and multiple sealing structures and can reinforce the fixation of the ventilating core and the high-temperature resisting seamless pipe, and the service life of the whole furnace body is prolonged.

Owner:FUJIAN METAL NEW ALU TECH

Composite biomass gasification furnace

PendingCN110577845APrevent escapeAvoid burnsGasification processes detailsGasification apparatus detailsCarbon layerWater vapor

The invention discloses a composite biomass gasification furnace, which mainly comprises a gasification reaction chamber and a carbon layer gasification chamber for high-temperature reaction to generate fuel gas to form a composite gas. A biomass fuel is firstly subjected to a high-temperature cracking gasification reaction in the gasification reaction chamber to generate the fuel gas, the biomassfuel which is not completely reacted in the gasification reaction chamber is converted into biomass carbon which falls into the carbon layer gasification chamber, and then the high-temperature biomass carbon is subjected to an oxidation reduction reaction with incoming air below and water vapor generated by high temperature in a sealed water tank to generate carbon monoxide and hydrogen, so thatthe biomass fuel is converted into the fuel gas as much as possible. The composite biomass gasification furnace is characterized in that the structure is scientific, ingenious and compact, and a feedhopper with a double-layer structure can prevent the fuel gas from escaping during feeding. A hopper-cone-shaped material pulling disc prevents bridging and arching of a stock bin; a air supply pipe serves as a middle air inlet channel, and air inletting is more uniform without dead angles; a sealed water tank can prevent the fuel gas from leaking during ash discharge; and a slag breaking fire grate is extruded to break coking blocks formed by biomass ash at high temperature.

Owner:周勇

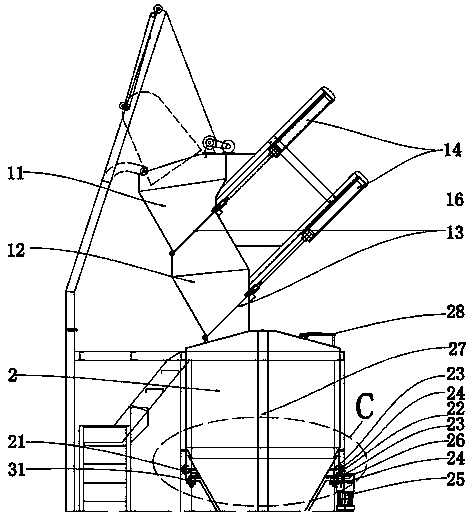

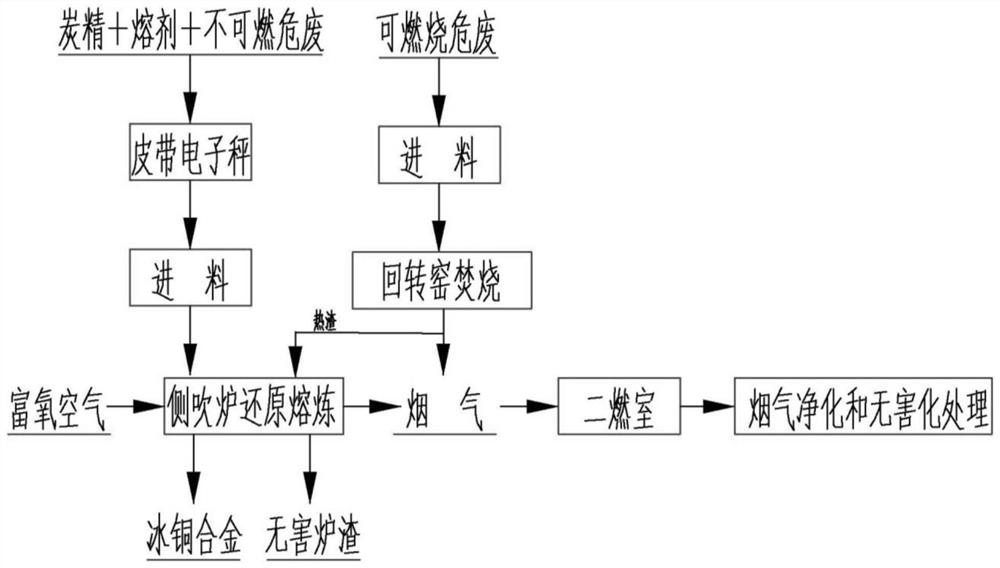

Process method and process device for cooperatively treating hazardous waste through rotary kiln incineration and side-blown converter reduction smelting

PendingCN112923377AImprove working conditionsImprove work rateRotary drum furnacesIndirect carbon-dioxide mitigationSlagProcess engineering

Owner:CHANGSHA JINMA METALLURGICAL EQUIP

Fuel dealkalization device and method thereof and circulating fluidized bed gasification device and method thereof

ActiveCN112852498ASimplify dealkalization processRun at scaleGranular/pulverulent flues gasificationSlagSolid fuel

The invention discloses a fuel dealkalization device and a method and a circulating fluidized bed gasification device and a method thereof, and the fuel dealkalization device is a bubbling fluidized bed and comprises a fuel inlet which is located at the upper part of the fuel dealkalization device and is used for conveying fuel to the fuel dealkalization device; an auxiliary gasifying agent inlet positioned at the lower part of the fuel dealkalization device and used for conveying an auxiliary gasifying agent to the fuel dealkalization device, wherein the fuel and the auxiliary gasifying agent are subjected to dealkalization reaction under heating; a dealkalized solid fuel overflow port positioned at the upper part of the fuel dealkalization device and used for outputting the dealkalized solid fuel generated by the dealkalization reaction; and an alkali-rich fuel gas outlet is positioned at the upper part of the fuel dealkalization device and used for outputting alkali-rich fuel gas generated by the dealkalization reaction. The invention further provides the fuel dealkalization method and the circulating fluidized bed gasification device and the method thereof. The method solves the technical problem of slag bonding caused by high alkali metal content of the high-alkali coal, realizes safe and reliable utilization of the high-alkali coal, and has a wide market application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1279145CSimple structureLow costSpecial form destructive distillationGranular/pulverulent flues gasificationRaw materialWater washing

The invention discloses a process and device for preparing coal gas using fluffy biomass raw materials. The process includes raw material pretreatment, raw material gasification, slag separation, gas purification, and gas transportation steps; the device includes a raw material pretreatment system, a gas generation system, a gas purification system, and a gas transportation and storage system. The built-in rapid fluidized bed gasifier used in the present invention has the characteristics of high production intensity, high gasification efficiency, low gas tar content, and good operating stability. The gasification reaction is completed at pneumatic conveying speed, and the built-in separator realizes rapid circulation of biomass raw materials in the gasification furnace. The gas purification method uses a combination of water washing and organic solvent washing, which has a high tar removal rate and a low tar content in the gas. Characteristics include small changes and fluctuations. The process and equipment of the present invention can continuously gasify fluffy biomass raw materials, and the gas generated by gasification can be used as a gas source for gas generators, and can also be used to supply gas to surrounding residential users through the pipeline network.

Owner:NANJING TECH UNIV

Downlink high-temperature gasified product chilling device

ActiveCN105602629APrevent fallingAvoid contaminationEnergy inputCombustible gas productionWater vaporSlag

The invention provides a downlink high-temperature gasified product chilling device which comprises a gasifying section, a chilling section and a cooler section. The gasifying section is used for generating a gasified product. The chilling section is used for chilling the gasified product generated by the gasifying section to enable the gasified product to be cured fast and lose cohesiveness. The cooler section is used for further cooling the product chilled by the chilling section and recovering waste heat. High-temperature synthesis gas with molten ash is chilled by low-temperature chilling gas nearby an outlet of a gasifying furnace, the temperature falls abruptly below an ash fusion point, the surface of slag is cured instantly, the slag is gathered to a center area to descend under carrying of chilling gas flow, the ash is prevented from falling into a synthesis gas cooler in a slag form to the maximum, and the situation that ash particles make contact with the water cooling wall face of the synthesis gas cooler and cause contamination is effectively prevented. Water vapor is adopted as the chilling gas, the shift reaction can be promoted, the volume fraction of H2 in the synthesis gas is greatly increased, and loads and shift cost of a follow-up shift system are greatly reduced. The system is easy to operate and has a large-scale application and popularization prospect.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com