Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Flexible temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

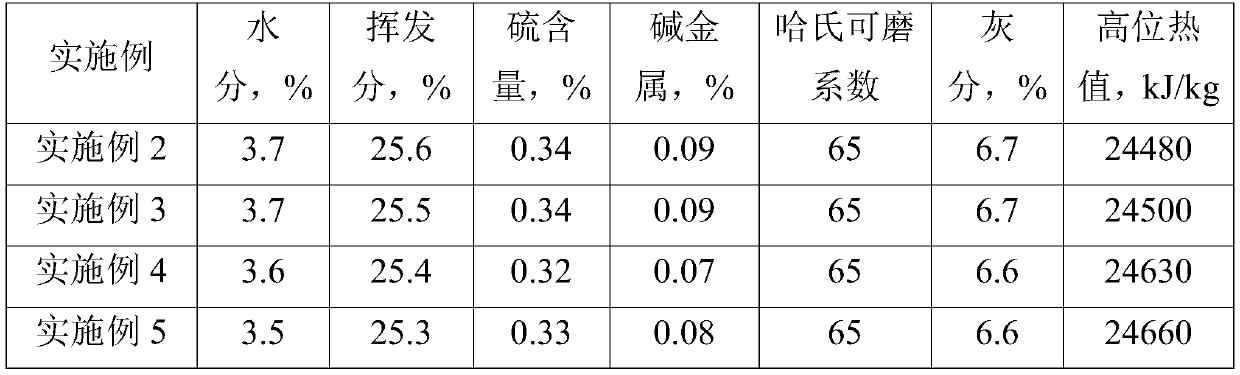

High-quality coal product production equipment and production system

InactiveCN102260559AHigh calorific valueContinuous operationDrying solid materials with heatEnergy inputProduct gasProcess engineering

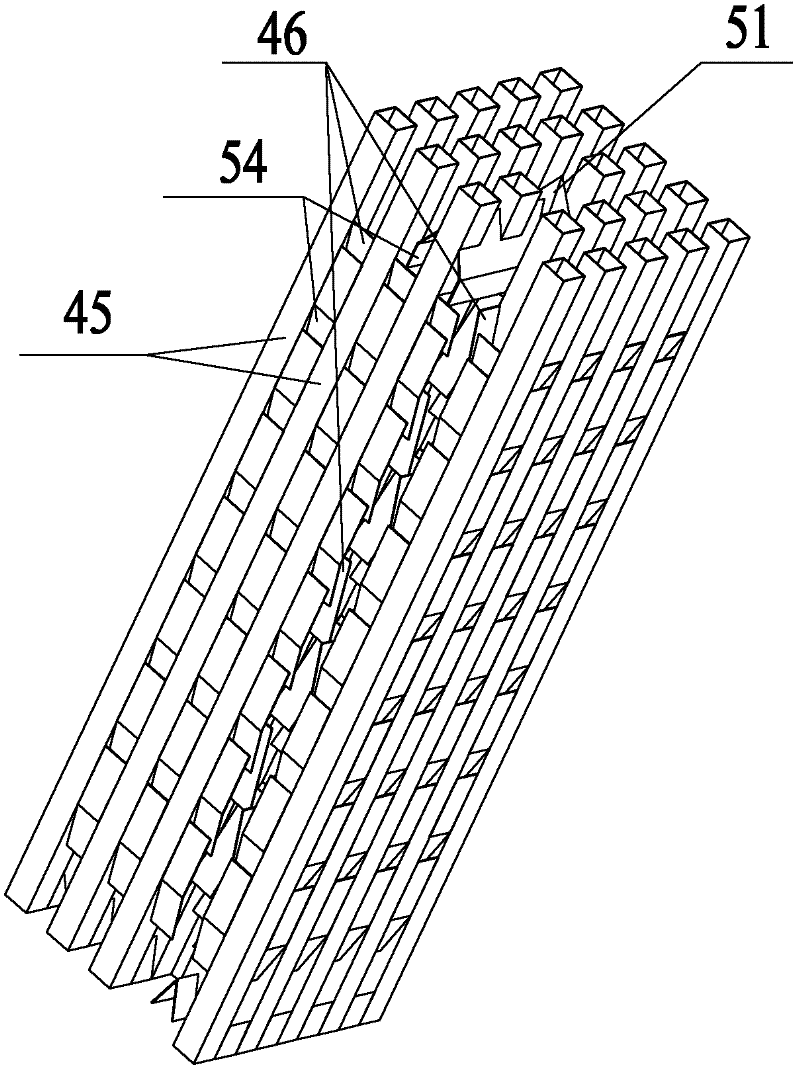

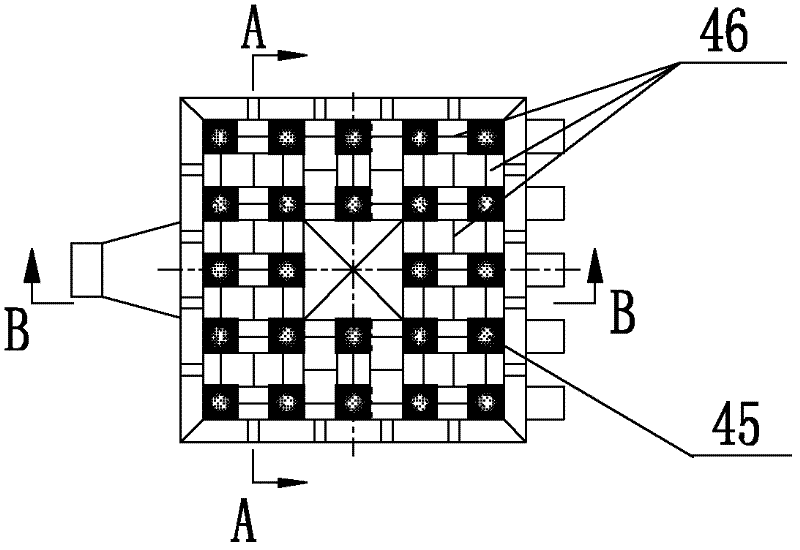

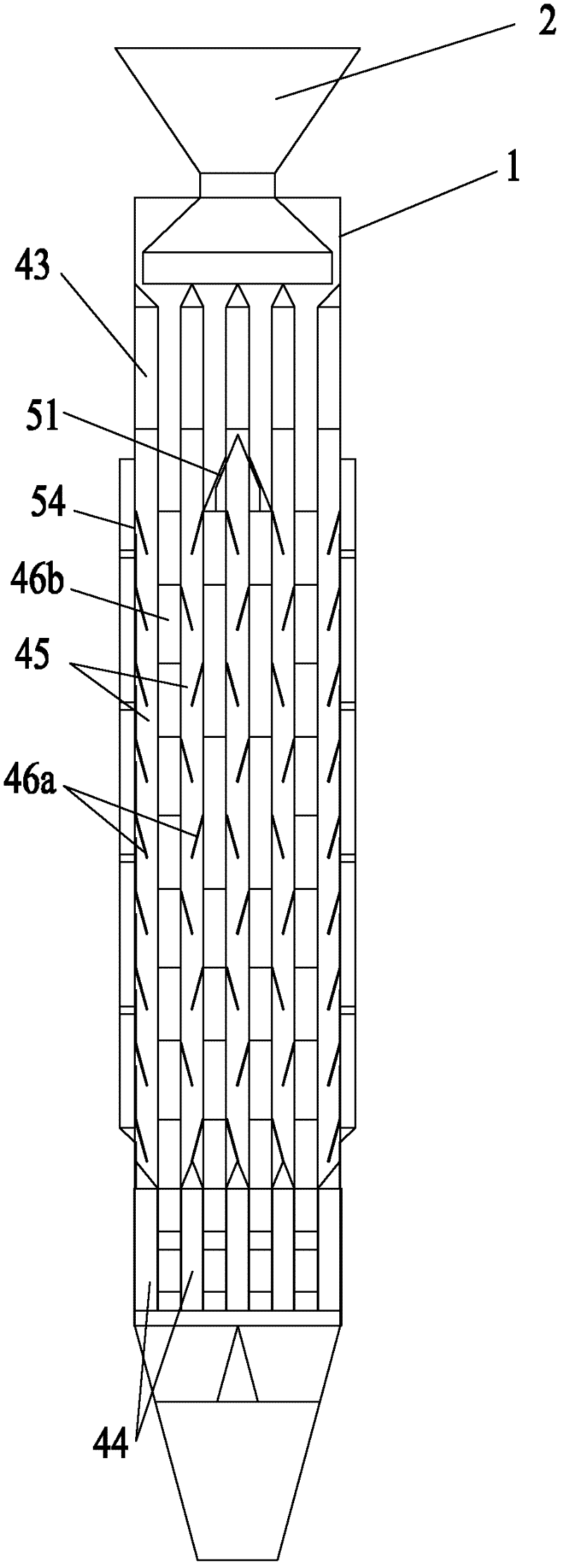

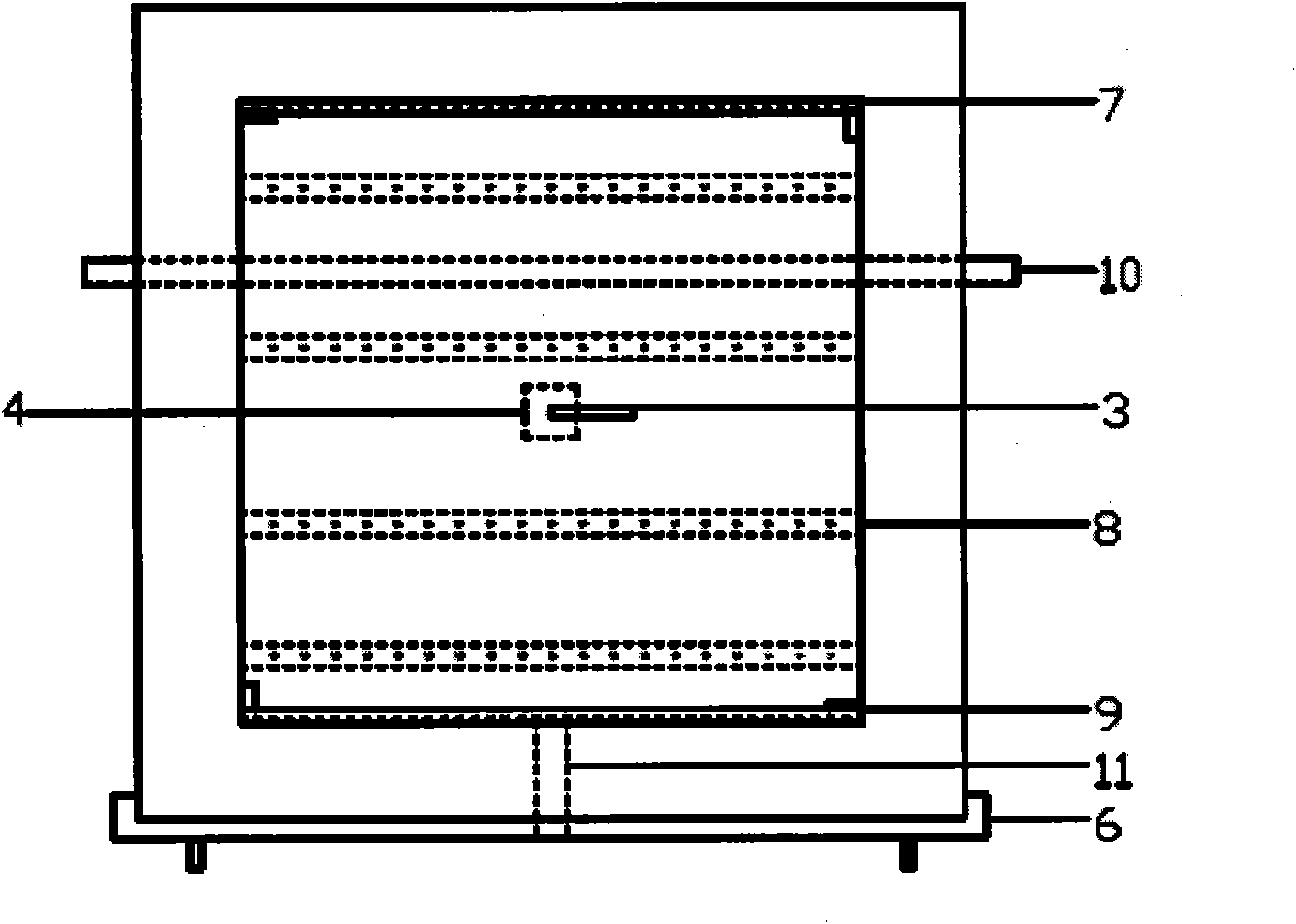

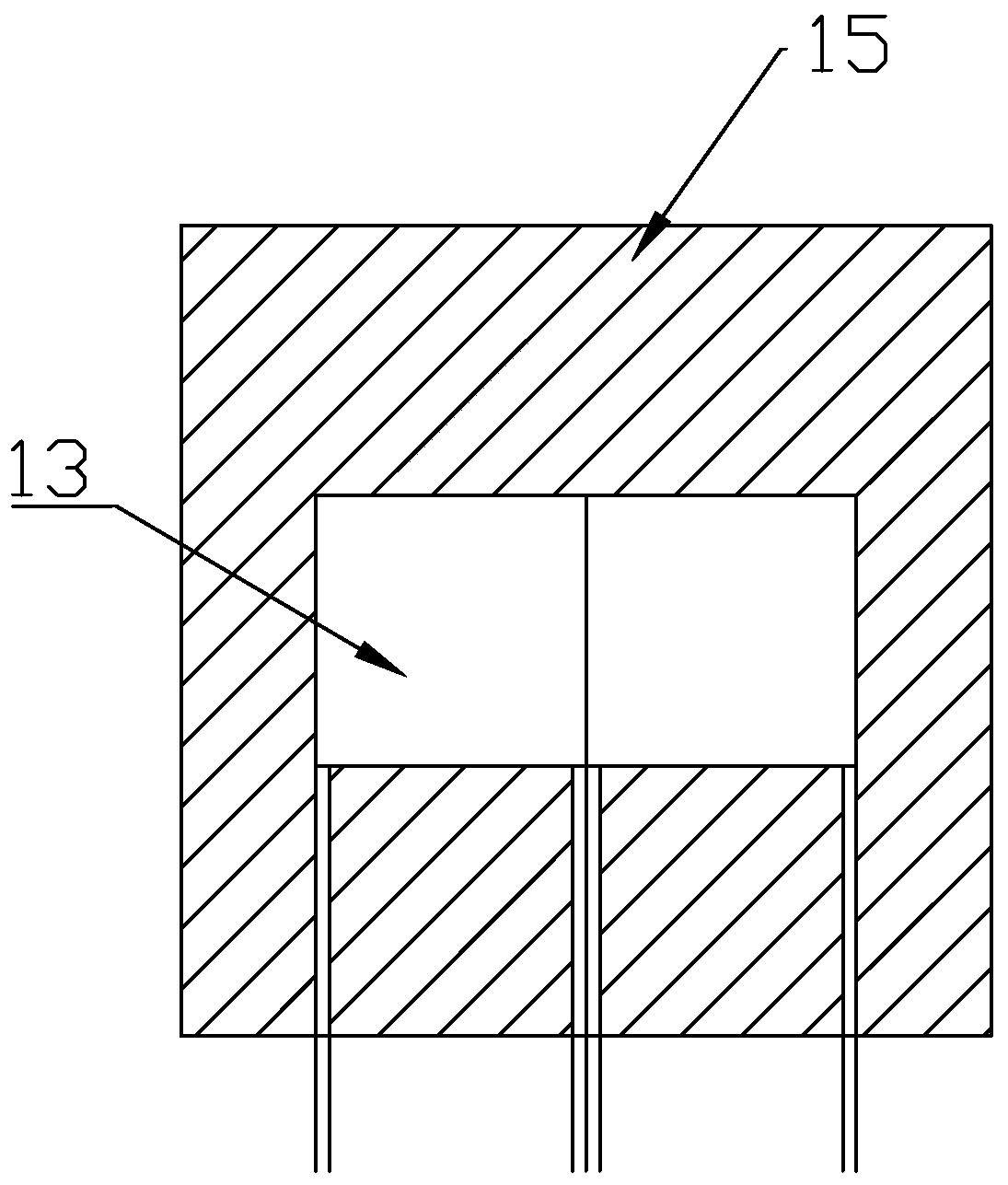

The invention discloses a high-quality coal product production plant which comprises a shell and a heat conduction mechanism arranged in the shell, wherein the heat conduction mechanism is provided with a heat conduction medium inlet near the discharge end, and provided with a heat conduction medium outlet near the feed end; the heat conduction mechanism comprises a plurality of sets of heat conduction units which are distributed at intervals; each heat conduction unit comprises a plurality of heat conduction tubes which are communicated with the heat conduction medium inlet and the heat conduction medium outlet; a plurality of fins, which slope downwards, are longitudinally arranged between adjacent heat conduction tubes; and the lower end of each fin arranged between the heat conduction tubes beside the exhaust passage slopes away from the exhaust passage, so as to shield the exhaust port arranged in the wall surface of the exhaust passage. Since the fins, which are arranged in the blanking space between the heat condition tubes, can turn over the material and discharge gas, the gas can be discharged in time, and heat can be transferred quickly, thereby obtaining the high-quality coal product. The invention also discloses a high-quality coal product production system.

Owner:QIANQIU ENERGY SHANGHAI

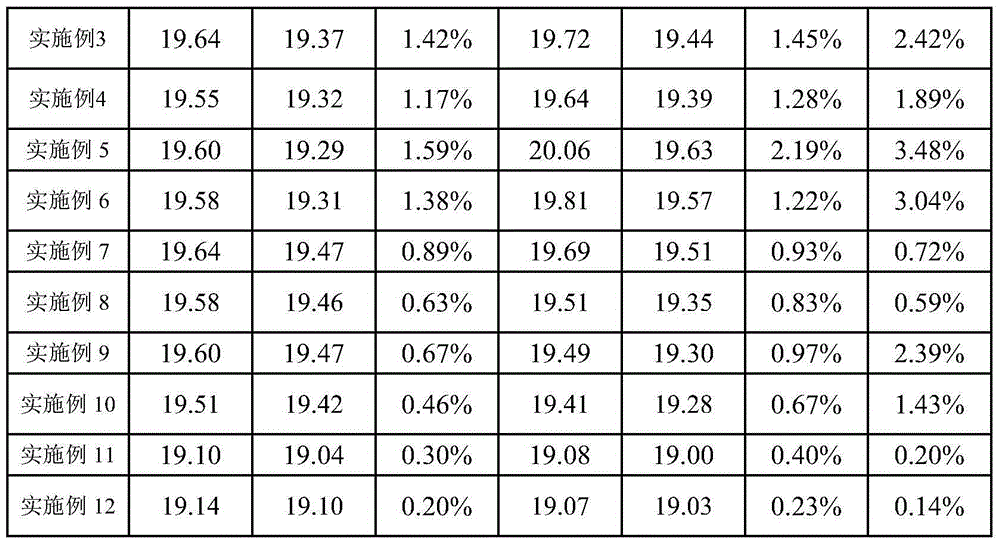

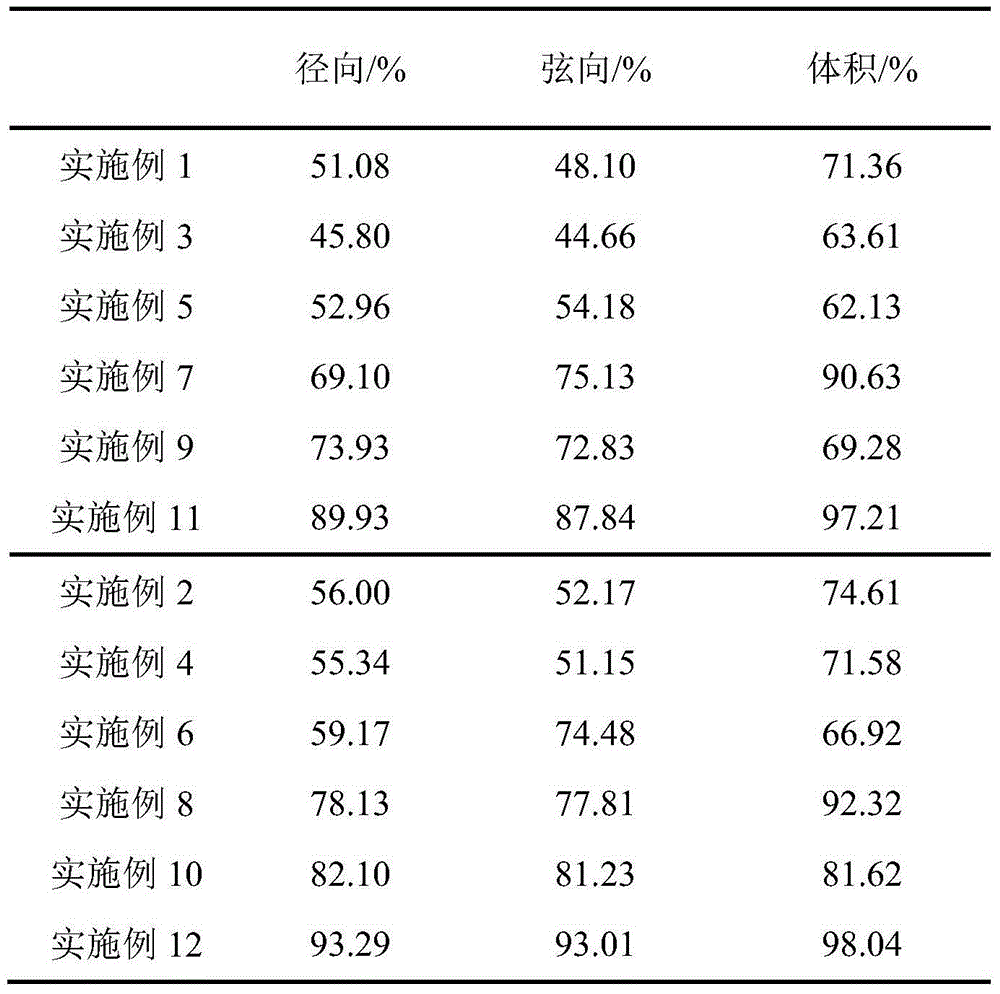

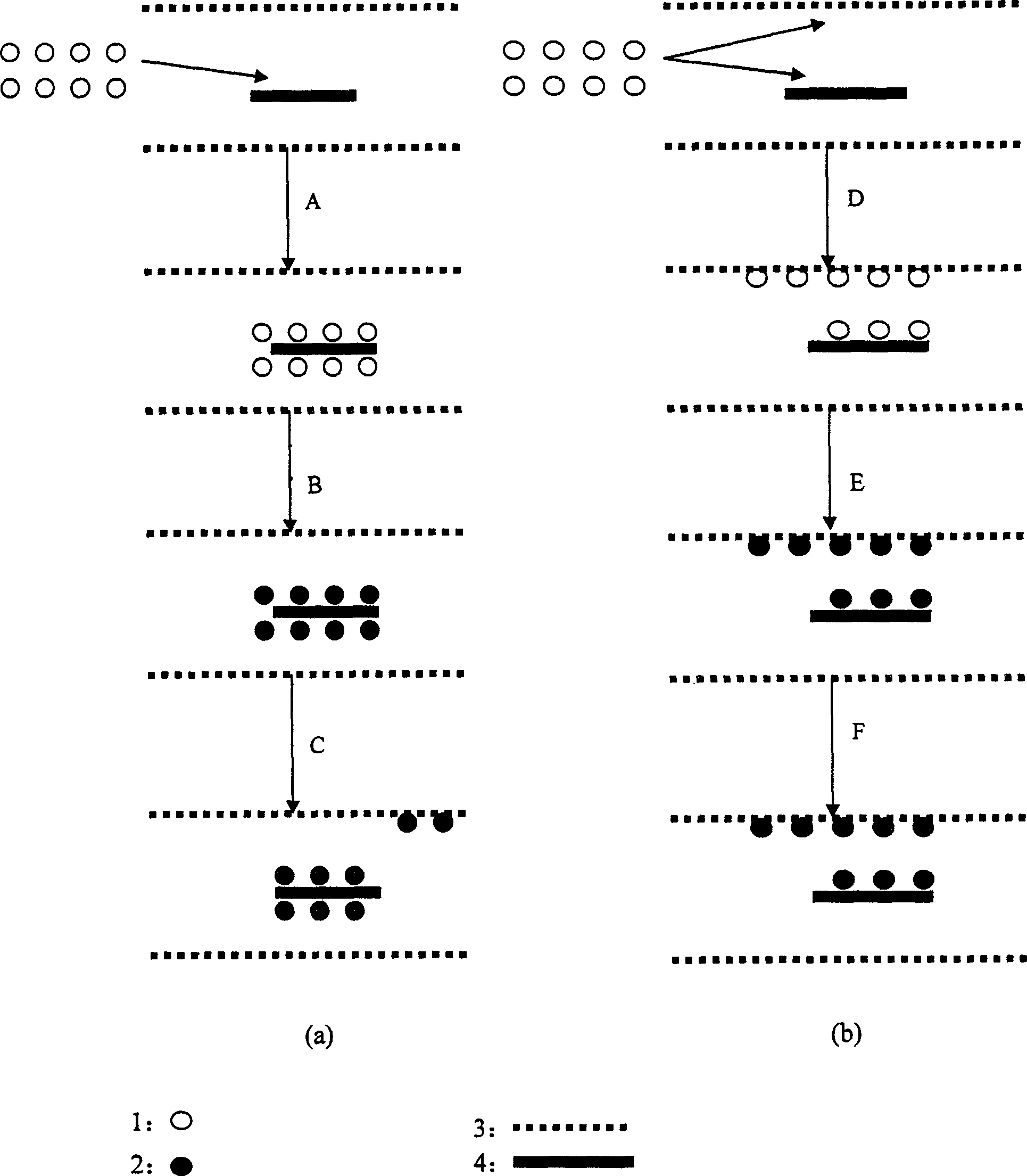

Method for improving dimensional stabilization of wood

InactiveCN105082282AGood dimensional stabilityEven contactWood impregnation detailsWaxProcess conditions

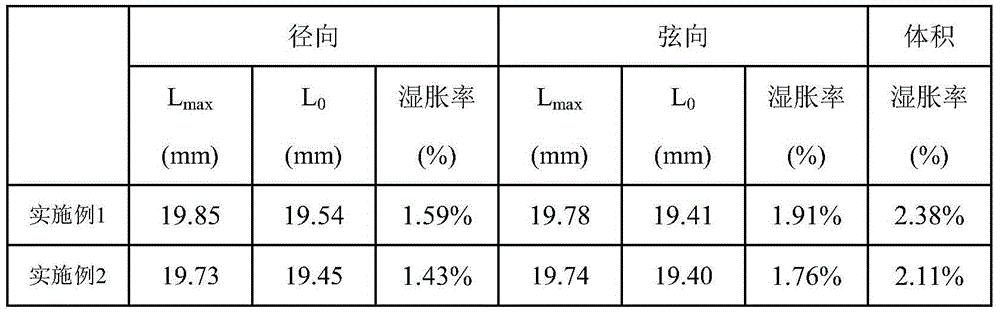

The invention discloses a method for improving the dimensional stabilization of wood. The method comprises the steps of soaking wood in petroleum wax, carrying out soaking process on the wood and making wood absorbing petroleum wax to obtain wood with good dimensional stabilization. According to the method, wax injection process is carried out on the wood in the normal pressure condition, and the petroleum wax is injected into the wood on the premise without damaging performance of the wood. Thus, redundant moisture in the wood can be drained out. Meanwhile, pipe holes of the wood and gaps between cells can be sealed, and the purpose of improving the dimensional stabilization of the wood is achieved. Furthermore, the method is simple in equipment, convenient to operate, controllable in processing condition and suitable for processing various kinds of wood.

Owner:BEIJING FORESTRY UNIVERSITY

Control method for realizing sustained release of smoke of heating non-combustion tobacco products

The invention relates to a control method for realizing sustained release of smoke of heating non-combustion tobacco products. According to the control method, a heating device adopts the heating modecomprising a preheating stage I, as well as a thermal insulation stage II and a smoking stage III which are circularly and alternately carried out, wherein the circulating times of the thermal insulation stage II and the smoking stage III is 5-20 times. With the control method, the puff number can be controlled, the smoke amount is sufficient, the irritation is small, the aftertaste is clean, theobvious miscellaneous qi and residue do not exist, the strength is moderate, the temperature of the smoke is moderate and free of the burning heat sensation, and when not in smoking, no sidestream smoke is emitted.

Owner:CHINA TOBACCO ANHUI IND CO LTD

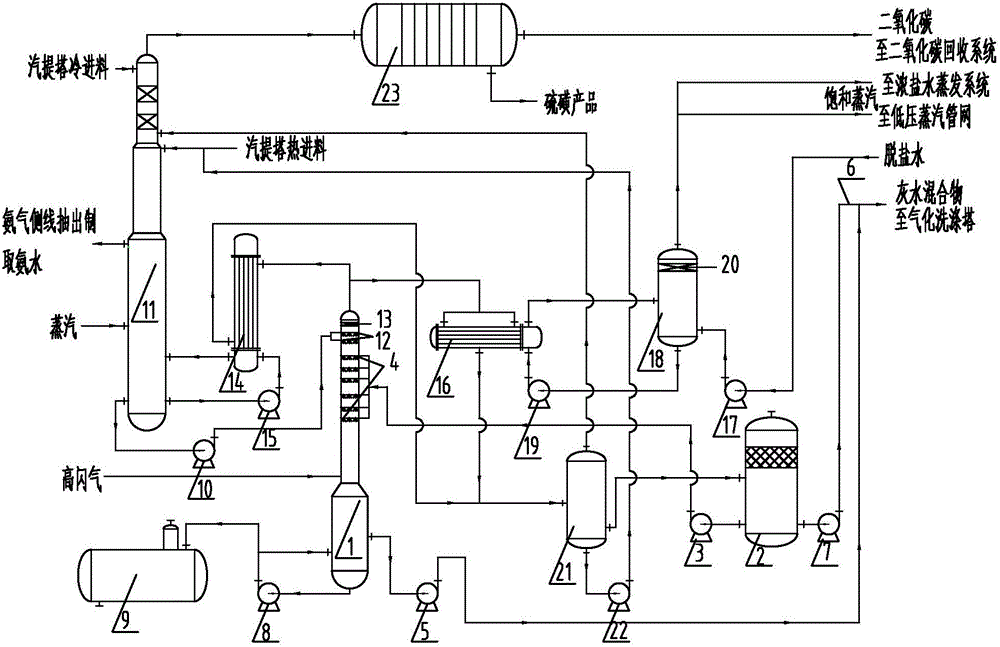

Comprehensive utilization method for coal chemical industry gasified black water high-temperature flashing steam

ActiveCN106587233AFlexible temperature controlAvoid badGas treatmentUsing liquid separation agentDeaeratorEngineering

The invention relates to a comprehensive utilization method for coal chemistry industry gasified washing black water high-temperature flashing steam. The high-temperature flashing steam first directly heats part of a grey water mixture to high temperature in a combined purifying tower, and then grey water and a low-temperature grey water mixture which is discharged through a deaerator are mixed and pumped into a vaporization washing tower to be recycled after set temperature is reached; the non-condensation high-temperature flashing steam is purified on the upper section of the tower, a first high-temperature flashing steam condenser and a second high-temperature flashing steam condenser are introduced to prepare secondary steam, the secondary steam is used for a raw ammonia recycling stripping tower and a strong brine evaporating system, and excessive secondary steam is introduced into a low-pressure steam pipeline net; part of high-temperature flashing steam condensate is introduced into the gasification deaerator, the remaining condensate and non-condensation high-temperature flashing steam enter the ammonia recycling stripping tower for separation, ammonia gas is pumped out along a lateral line to prepare ammonium hydroxide, carbon dioxide, hydrogen sulfide and other gas are introduced into a sulfur recycling system for sulfur recycling and then enter a carbon dioxide recycling system. Finally, the high-temperature flashing steam is sufficiently utilized.

Owner:中诚和易(北京)国际科技有限公司

Supercritical hydrothermal combustion reactor for recovering salt from organic wastewater and application thereof

PendingCN111470559ASolve corrosiveSolving Salt Deposition ProblemsWater contaminantsMultistage water/sewage treatmentSaline waterSalt water

Owner:成都九翼环保科技有限公司

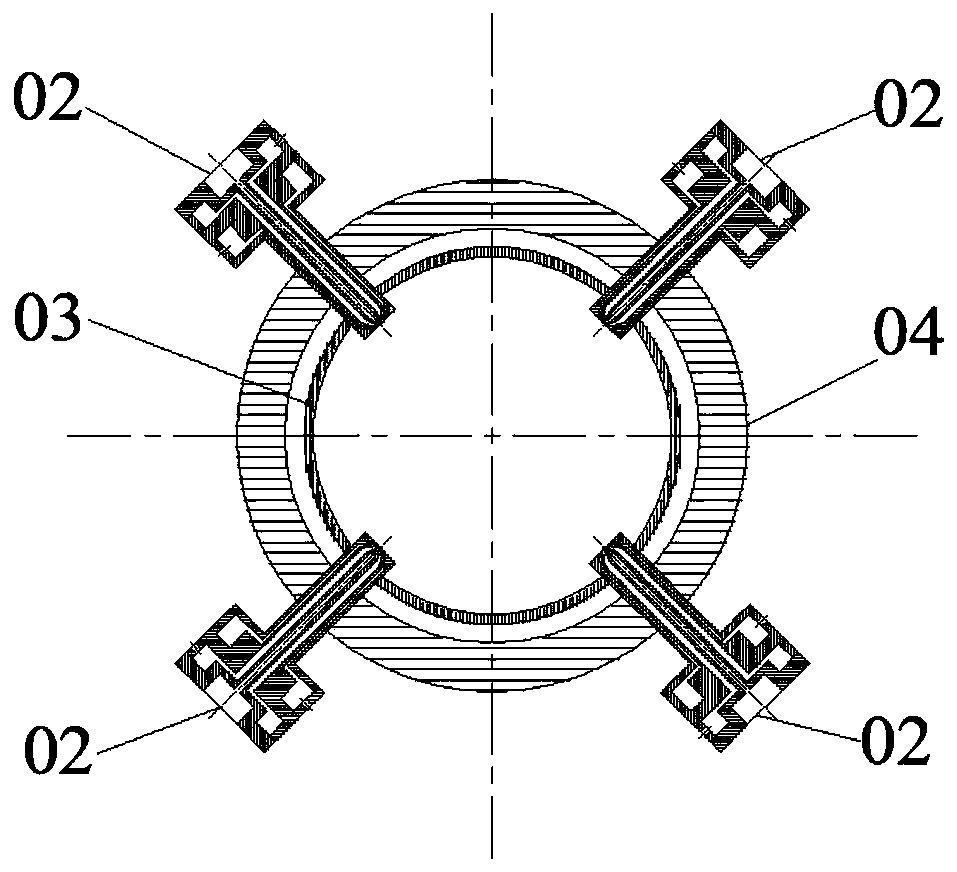

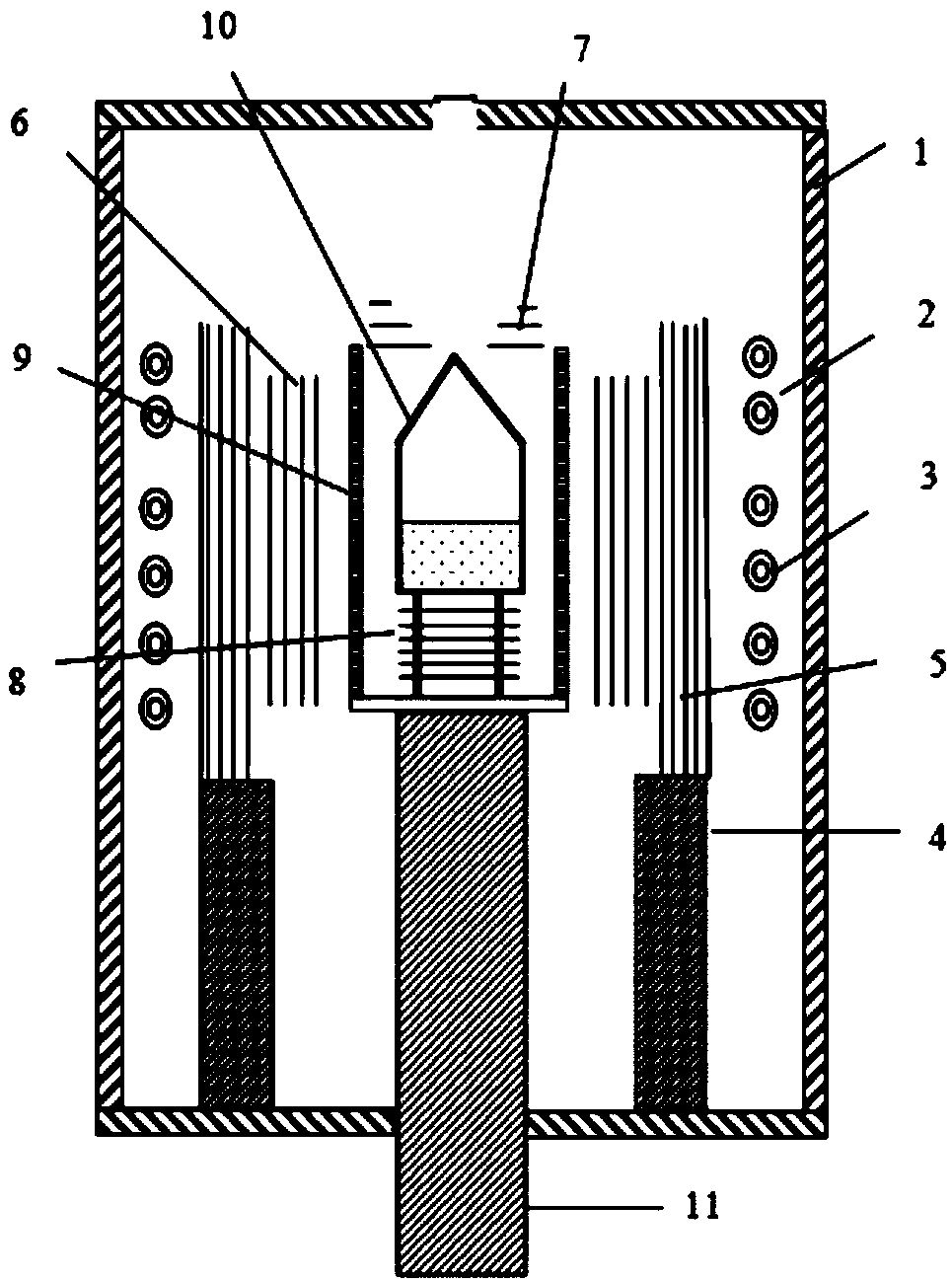

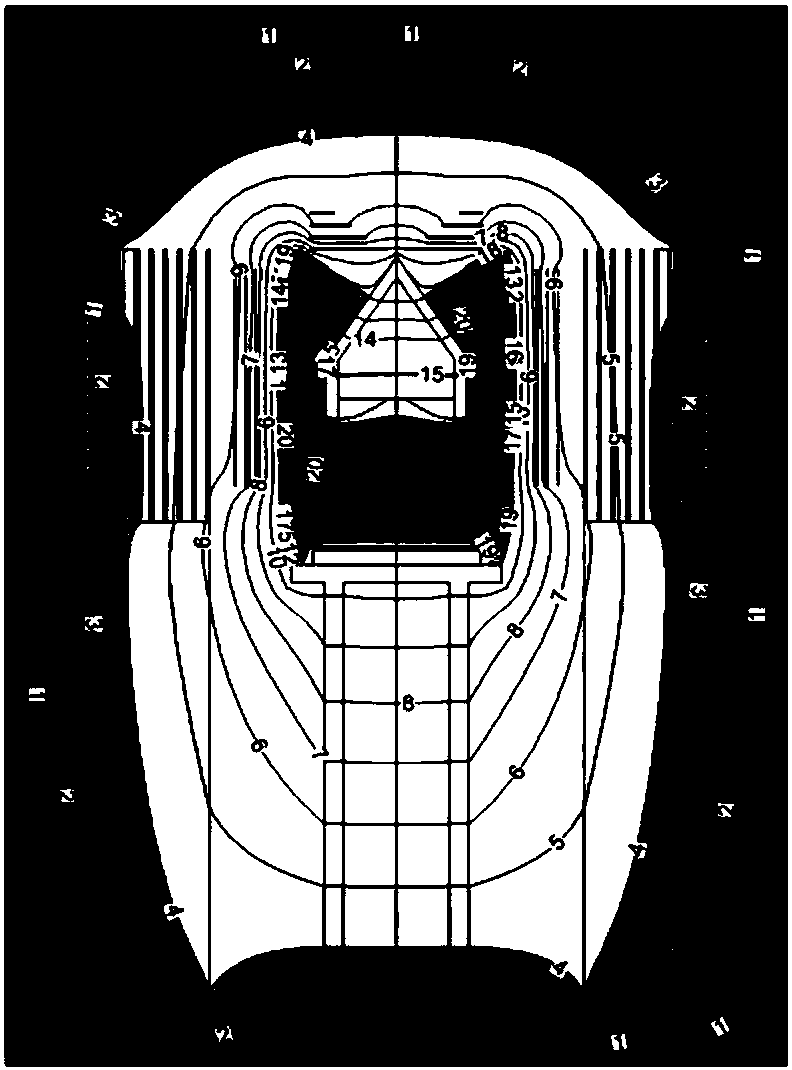

Thermal field for aluminum nitride crystal growth furnace

InactiveCN107916454AFlexible control of temperature gradientsFlexible temperature controlPolycrystalline material growthFrom condensed vaporsThermal insulationCarbon impurities

The invention discloses a thermal field for an aluminum nitride crystal growth furnace. The growth furnace comprises a furnace body and a support rod penetrating through the lower part of the furnacebody, the thermal field comprises a crucible arranged above the support rod, a thermal insulation mechanism as well as multistage heating mechanisms sequentially distributed in the vertical directionin the furnace body and used for heating the crucible, and the thermal insulation mechanism comprises a first thermal insulation screen, a second thermal insulation screen arranged between the crucible and the support rod, a third thermal insulation screen arranged on the outer side of the crucible in a surrounding manner as well as a fourth thermal insulating screen arranged between the third thermal insulation screen and the inner wall of the furnace body in a surrounding manner. The thermal field for the aluminum nitride crystal growth furnace is made of tungsten and boron nitride materials, so that impurity effects of oxygen and carbon impurities in the graphite thermal field on crystal growth are effectively prevented; the temperatures of the top end and the bottom end of the cruciblecan be flexibly regulated by the aid of the multistage heating mechanisms; by means of the movable support rod, the temperature gradient for crystal growth can be controlled conveniently, the crucible can be taken out conveniently, and thus, a furnace chamber can be cleaned.

Owner:SUZHOU AOQU OPTOELECTRONICS TECH CO LTD

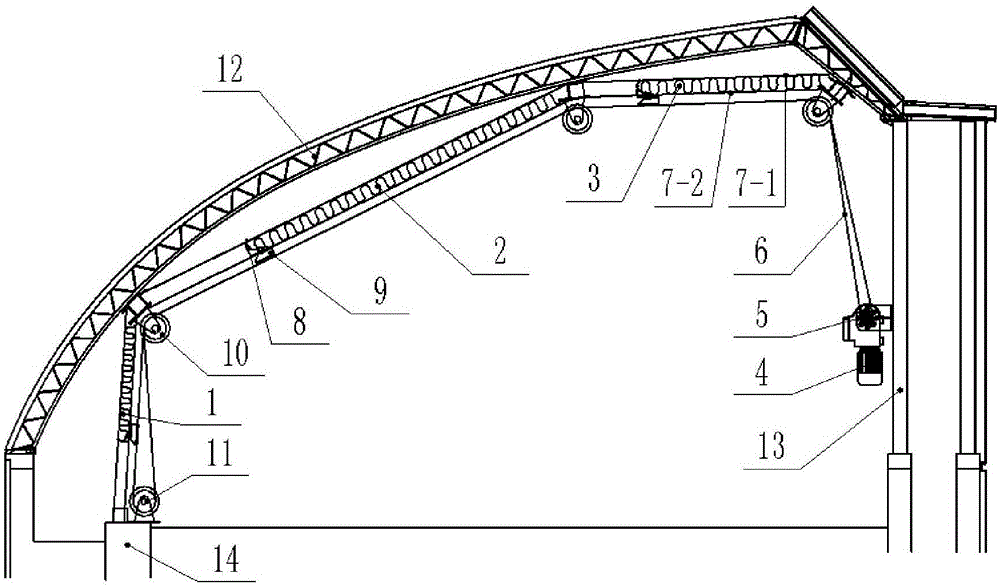

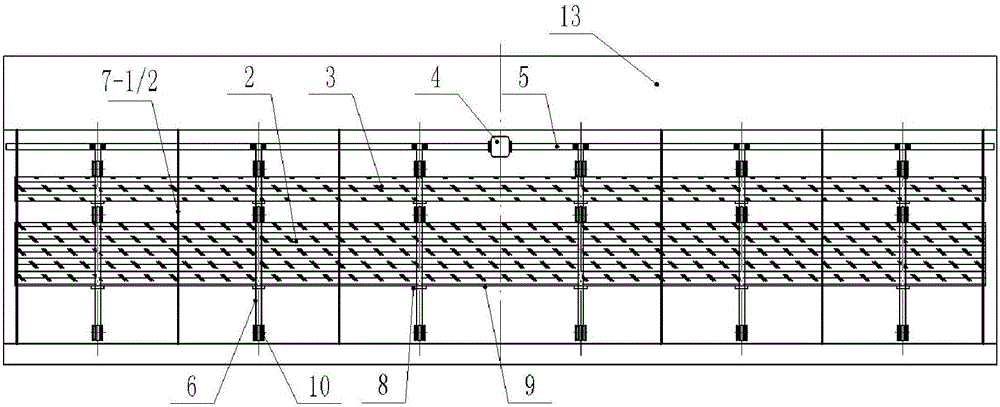

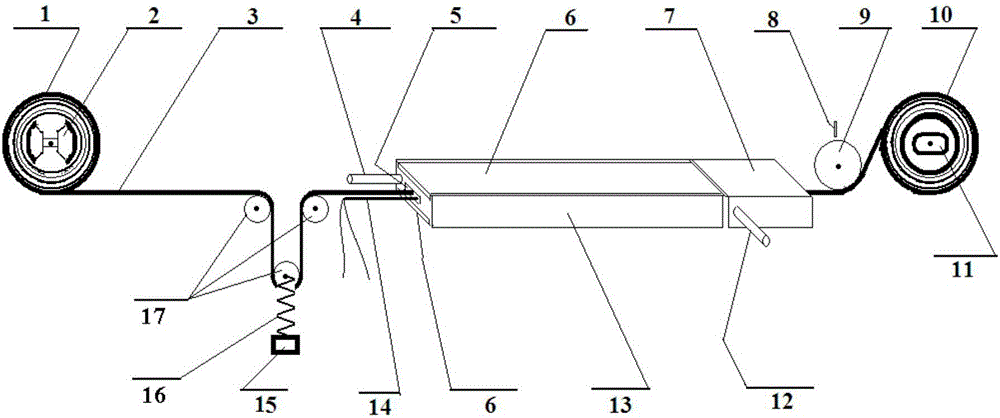

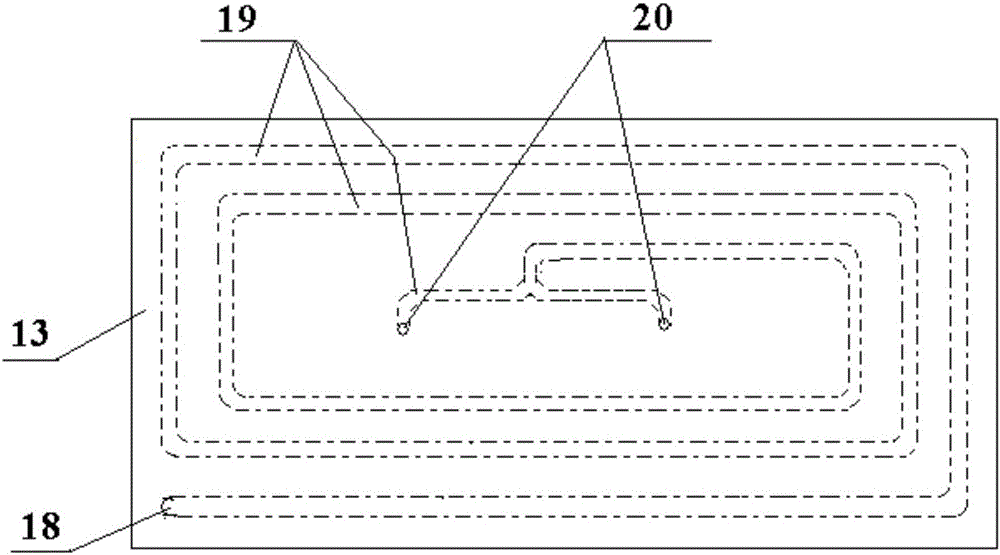

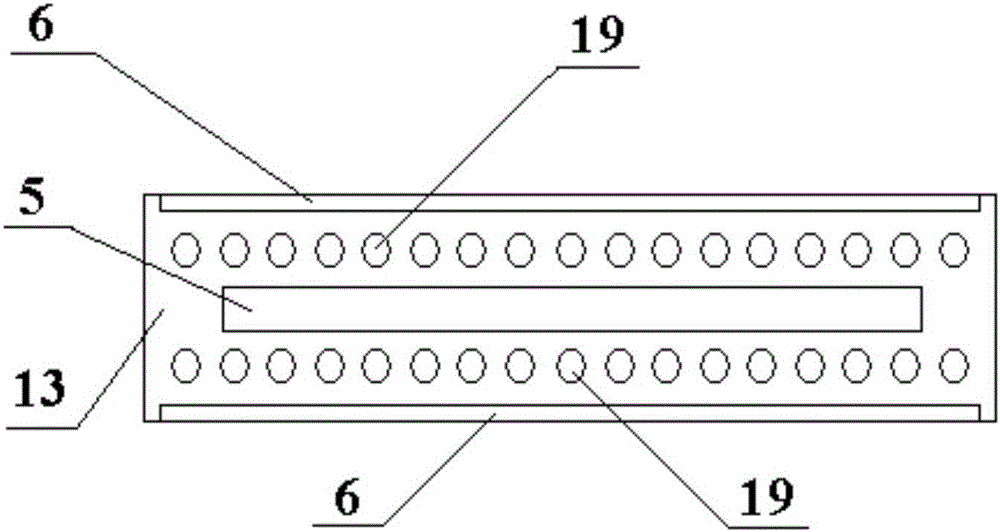

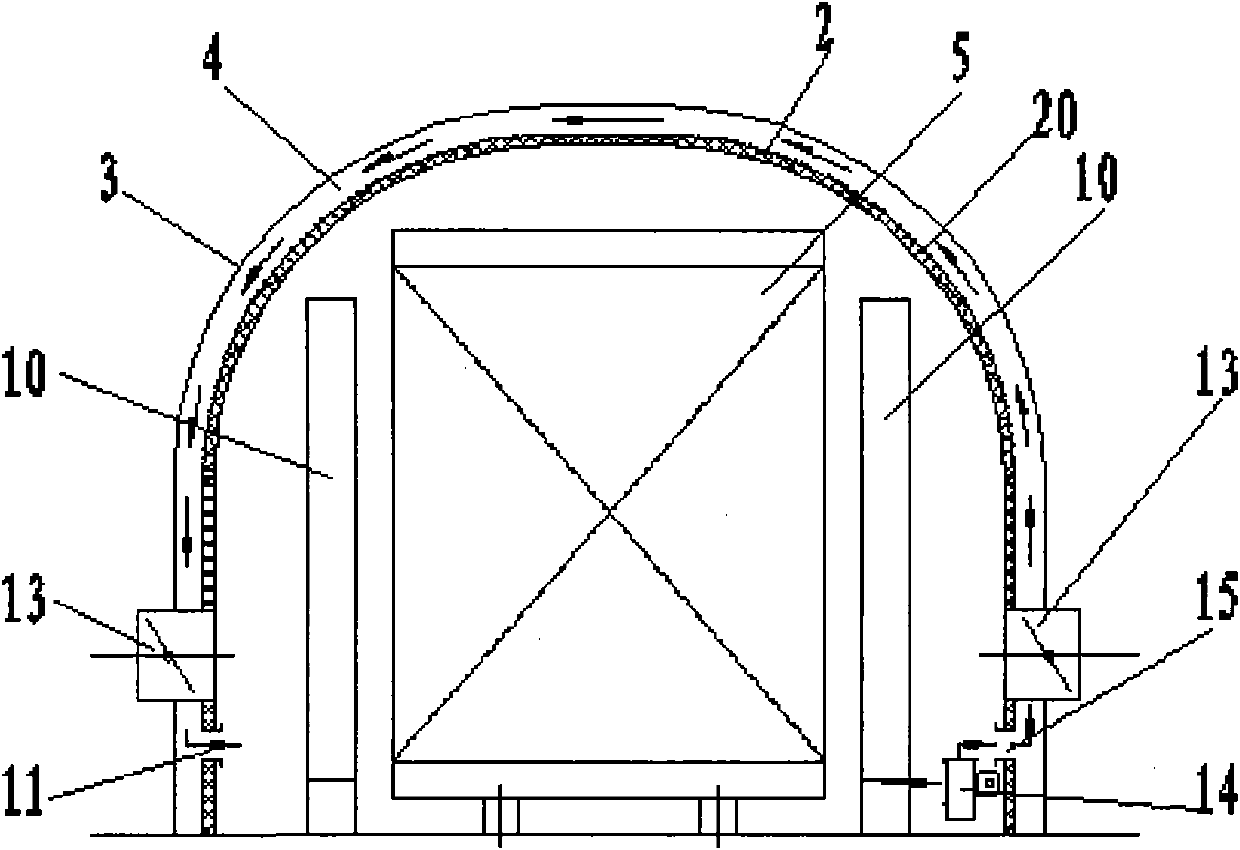

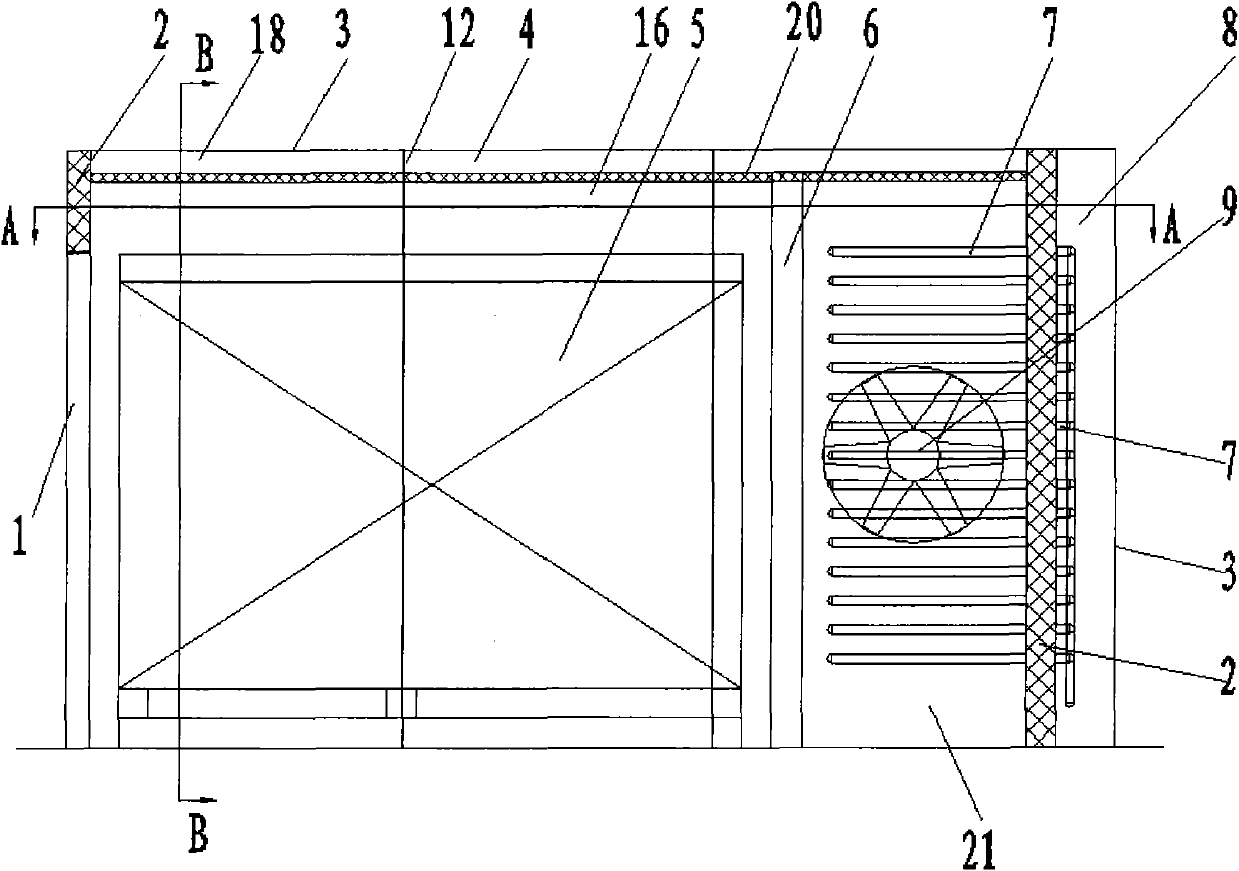

Multi-stage internal heat insulation shading system for greenhouse and greenhouse containing same

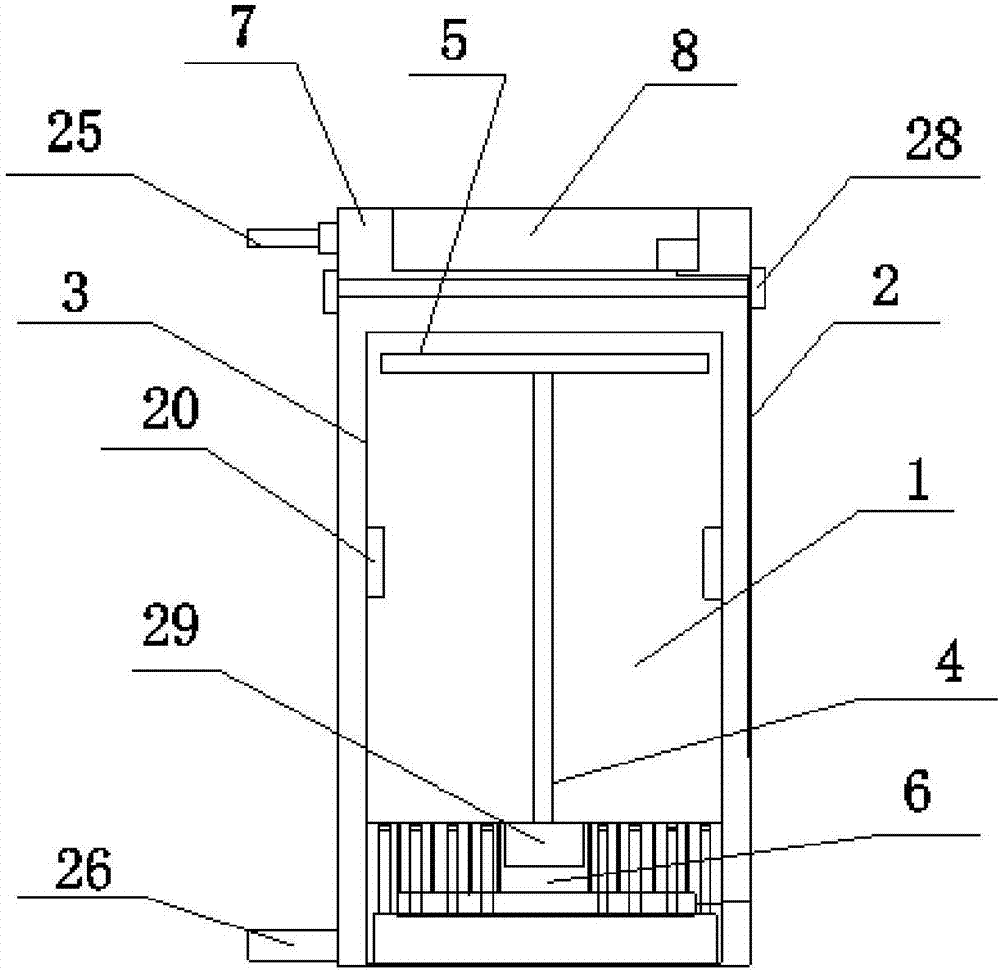

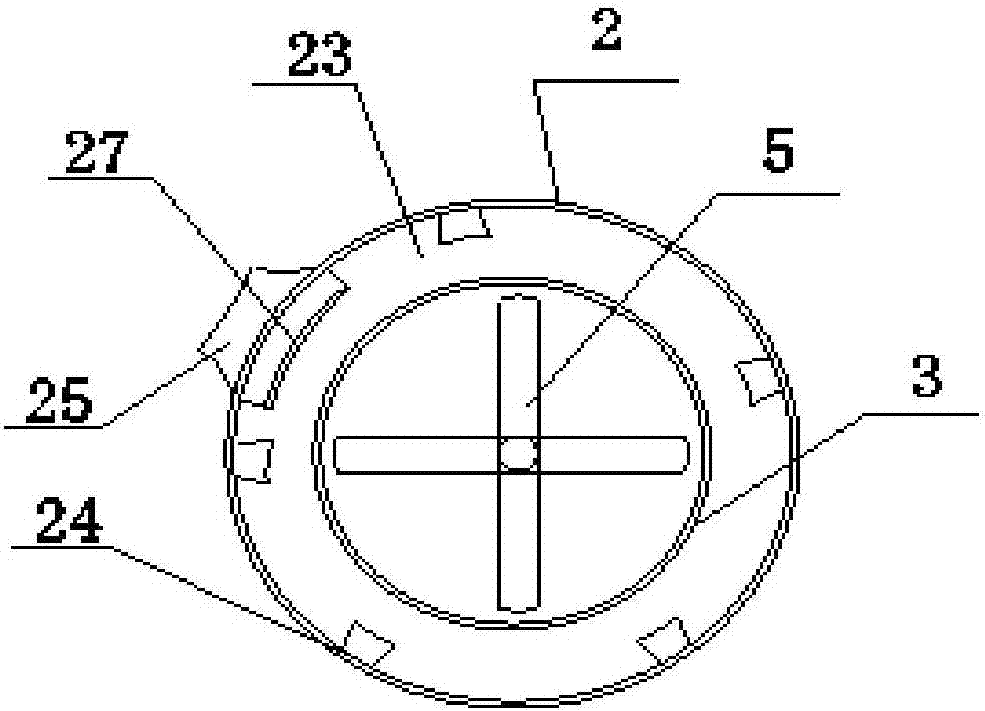

InactiveCN106034851AFlexible regulationReduce shadow areaClimate change adaptationGreenhouse cultivationDrive shaftGreenhouse

The invention relates to the field of environmental control of a sunlight greenhouse, in particular to a multi-stage internal heat insulation shading system for a greenhouse and the greenhouse containing the system. The internal heat insulation shading system comprises multi-stage internal heat-insulation shading screens, a screen pressing line and a screen supporting line, a plurality of pulling screen mechanisms, a driving shaft and a motor for driving the rotation of the driving shaft; each pulling screen mechanism comprises a driving steel cable and a reversing pulley, wherein one ends of the driving steel cables are wound on the driving shaft, and the other ends of the driving steel cables are wound on the reversing pulleys; one sides of the inner heat insulation screens are fixed, and the other ends of the inner heat insulation screens, as retracting and releasing ends, are respectively connected with the driving steel cables. The internal thermal insulation shading system not only has the advantages of simple structure, saving production cost, but also can flexibly regulate and control the indoor temperature and light according to the different needs of temperature and light by crops in different growing seasons and different time. Compared with traditional internal insulation and shading systems, the system provided by the invention has a greater application and promotion value.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

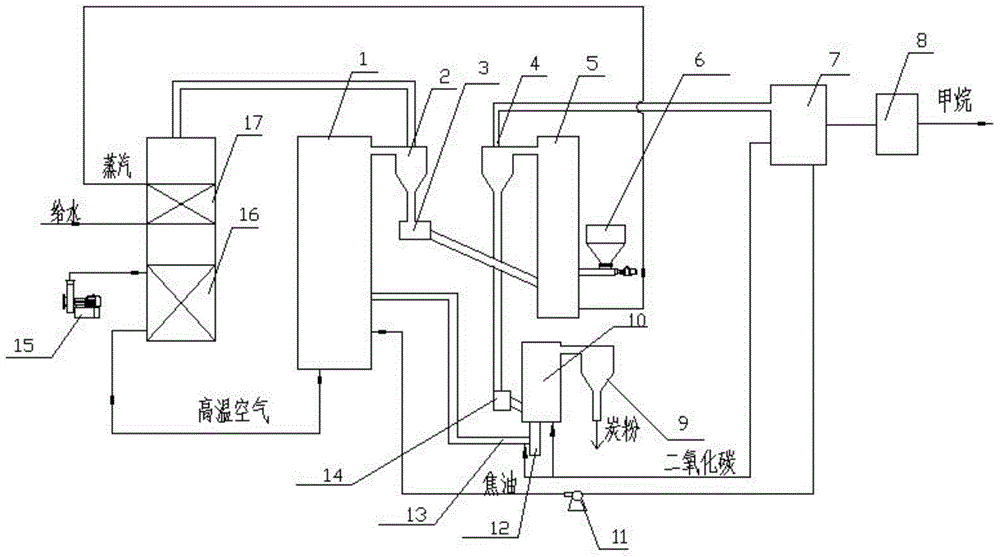

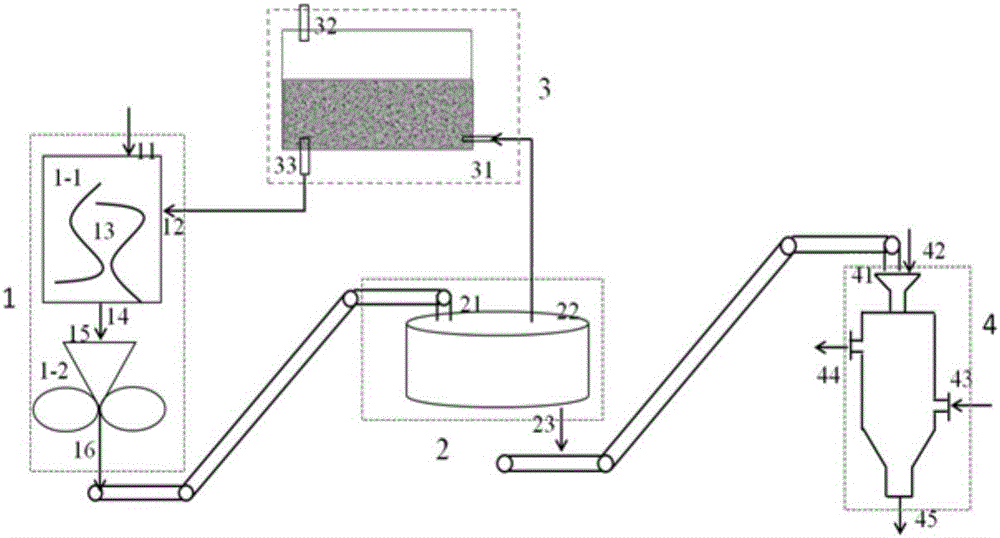

Device and process for preparing natural gas by virtue of double-fluidization bed gasification of biomass

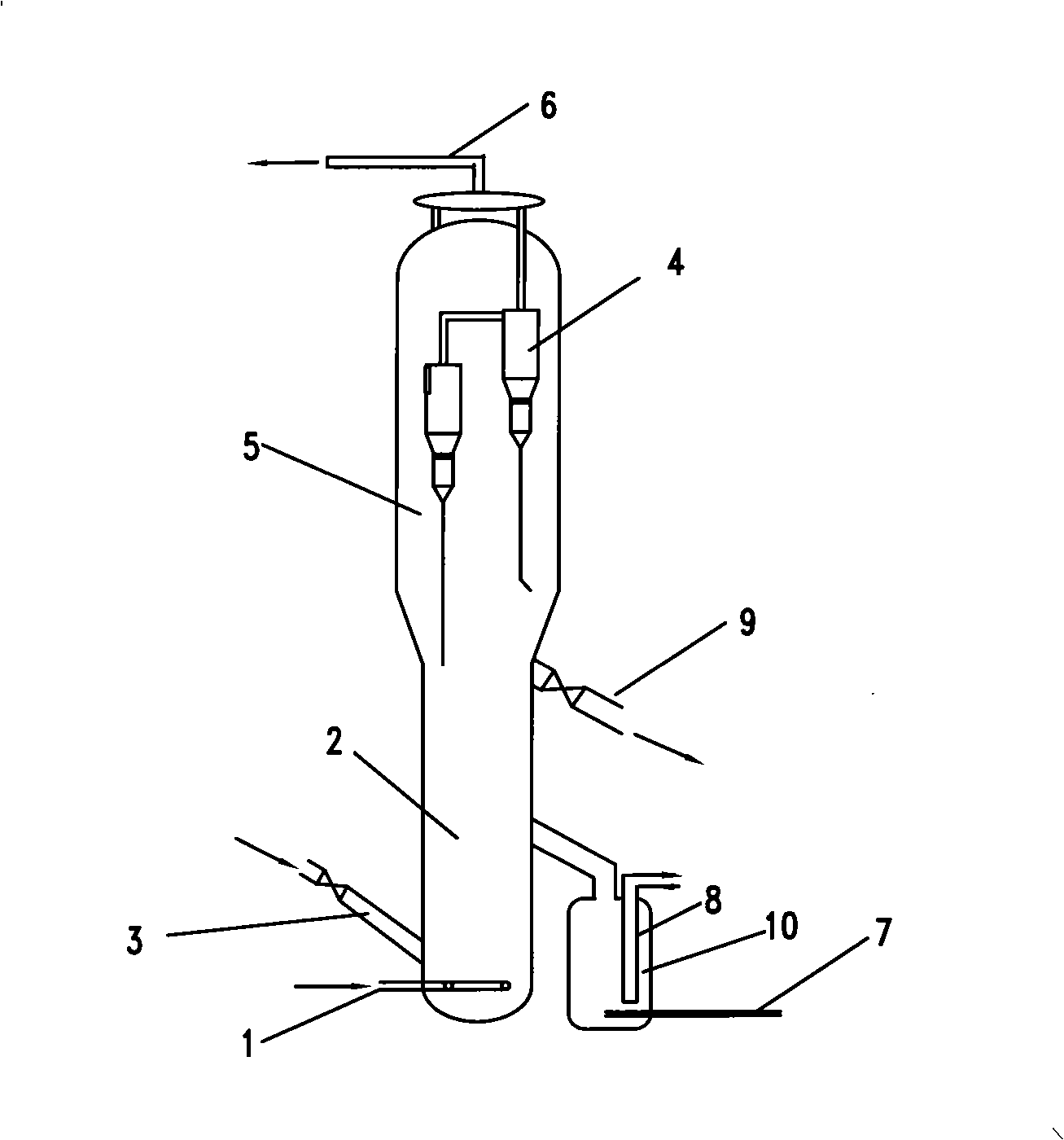

ActiveCN104910986AFlexible temperature controlRelieve pressureGaseous fuelsEnergy inputMethane gasHydrolysis

The invention provides a device and a process for preparing natural gas by virtue of double-fluidization bed gasification of a biomass. The device comprises a burning carrier heating unit, a pyrolysis gasification unit, a biological carbon / carrier separation and conveying unit and a methane synthesis and tar returning unit, wherein the pyrolysis gasification unit is connected with the burning carrier heating unit, the biological carbon / carrier separation and conveying unit and the methane synthesis and tar returning unit. The other components are converted into methane gas as much as possible while the biological carbon is obtained, the content of methane in a pyrolysis product is about 10%, the pressure for subsequent synthesis is reduced, the tar in hydrolysis gas is used as a fuel for a double-fluidization bed, and the problems that combustion cannot be stabilized at a low temperature and alkali metals causes scorification in a high-temperature state when other double-fluidization beds adopt biological carbon combustion can be avoided to ensure that the temperature of a combustion furnace can be controlled very flexibly. The device and the process provided by the invention fully use different pyrolysis products of the biomass, can realize treatment of various biomasses, and are wide in raw material application range.

Owner:合肥德博电力有限公司

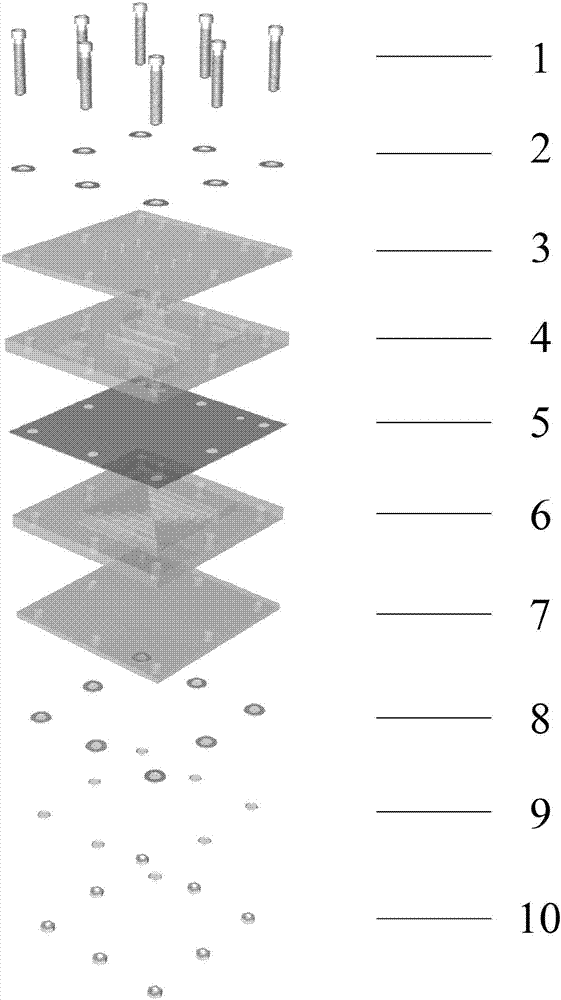

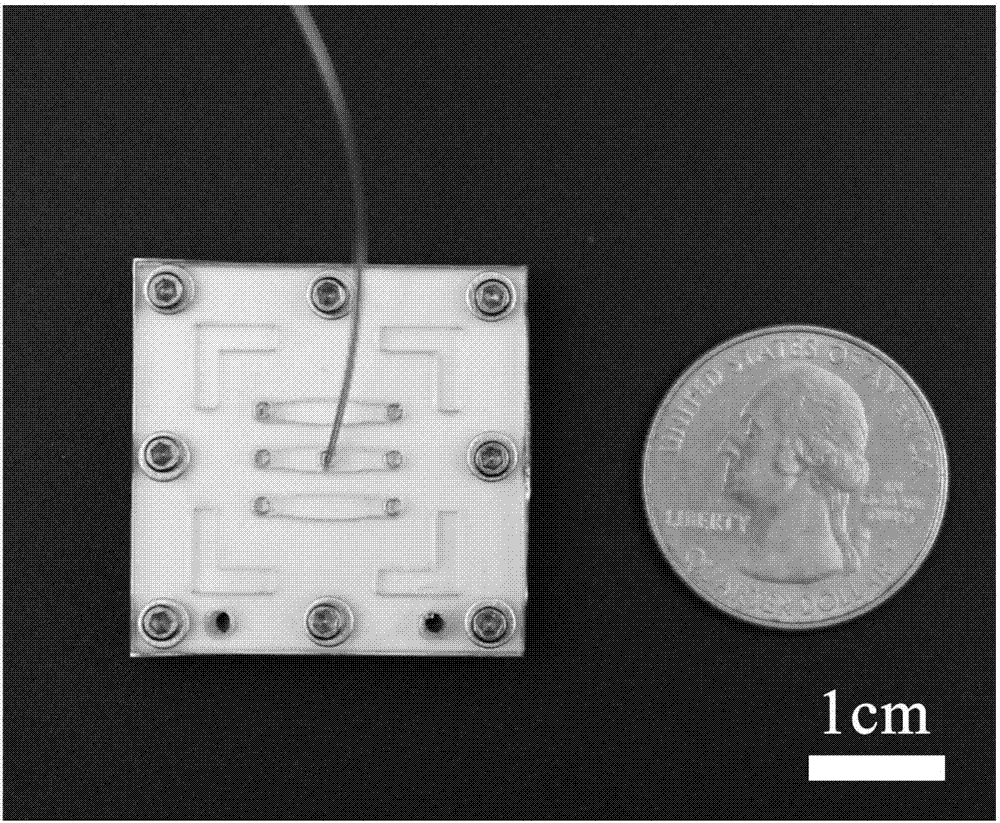

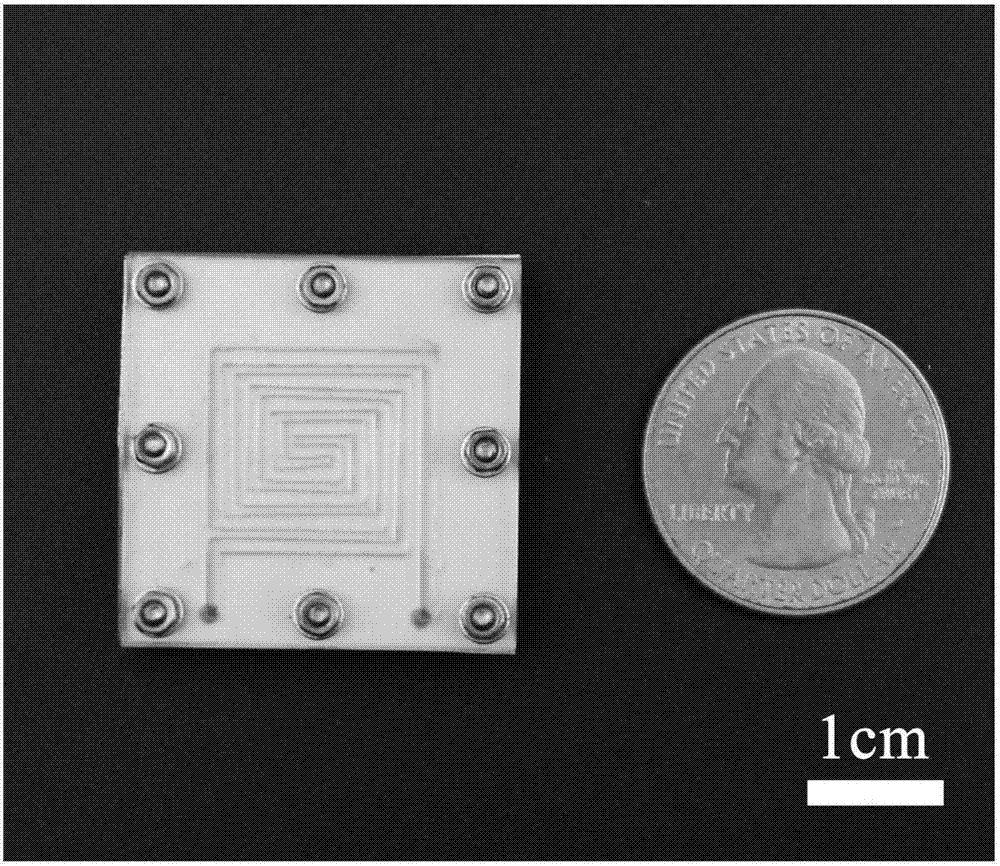

PCR micro-fluidic chip and preparation and using methods thereof and PCR equipment

InactiveCN107051598ASimple designEasy to processLaboratory glasswaresPeristaltic pumpHeat conducting

The invention discloses a PCR micro-fluidic chip which comprises a sample cavity and a heat-conducting channel; a heat-conducting liquid is arranged in the heat-conducting channel; and the heat-conducting liquid can absorb infrared rays. The invention also discloses preparation and using methods of the chip as well as PCR equipment comprising the chip. The PCR equipment also comprises a PCR temperature control platform which comprises a peristaltic pump, a fuel tank, an infrared light source, a data collecting card, a thermocouple, a thermocouple cold end compensating circuit and a power supply circuit board for controlling the infrared ray light source and the peristaltic pump. The PCR micro-fluidic chip disclosed by the invention is simple in design, convenient to process, saved in step and low in cost; and the PCR temperature control platform is simple in temperature control mode, convenient to integrate systematically, and convenient to use and carry.

Owner:SHANGHAI JIAO TONG UNIV

Stress annealing method and device capable of accurately controlling annealing process parameters

ActiveCN105695683AHigh consistency of annealing treatment effectFlexible temperature controlFurnace typesHeat treatment process controlDynamic annealingTemperature control

The invention discloses a stress annealing method and device capable of accurately controlling annealing process parameters. During annealing, an amorphous alloy material is made to automatically pass through an annealing cavity at a constant speed, and the tensile stress, the annealing temperature and the conveying speed are automatically and accurately regulated and controlled online. The annealing cavity is small in size, stress control is flexible and accurate, temperature control is flexible, rapid and convenient, and the energy-saving advantage is achieved. In the prior art, a box type annealing cavity is adopted, the box type annealing cavity is large in size, an annealing position is away from a heat source, heat conductivity is poor, thick and large heat insulating walls are adopted by the cavity, and heat capacity is large, so that temperature control is slow and difficult, and energy consumption is large in the annealing process. The channel type annealing cavity is adopted, the cavity is small in size, the cavity walls are made of a high-heat-conductivity material, heat conduction is rapid, temperature control is flexible and rapid, and energy consumption is small. The dynamic annealing mode that an annealed material is conveyed to pass through the channel type annealing cavity at a constant speed is adopted, and compared with static annealing mode through box type annealing cavities commonly used at present, the advantages of accurate control over the annealing parameters and high uniformity of the batch material annealing effect are achieved.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for drying wood by using solar energy

InactiveCN101907381AIncrease the areaImprove thermal efficiencySolar heating energyDrying solid materials with heatThermodynamicsSolar drying

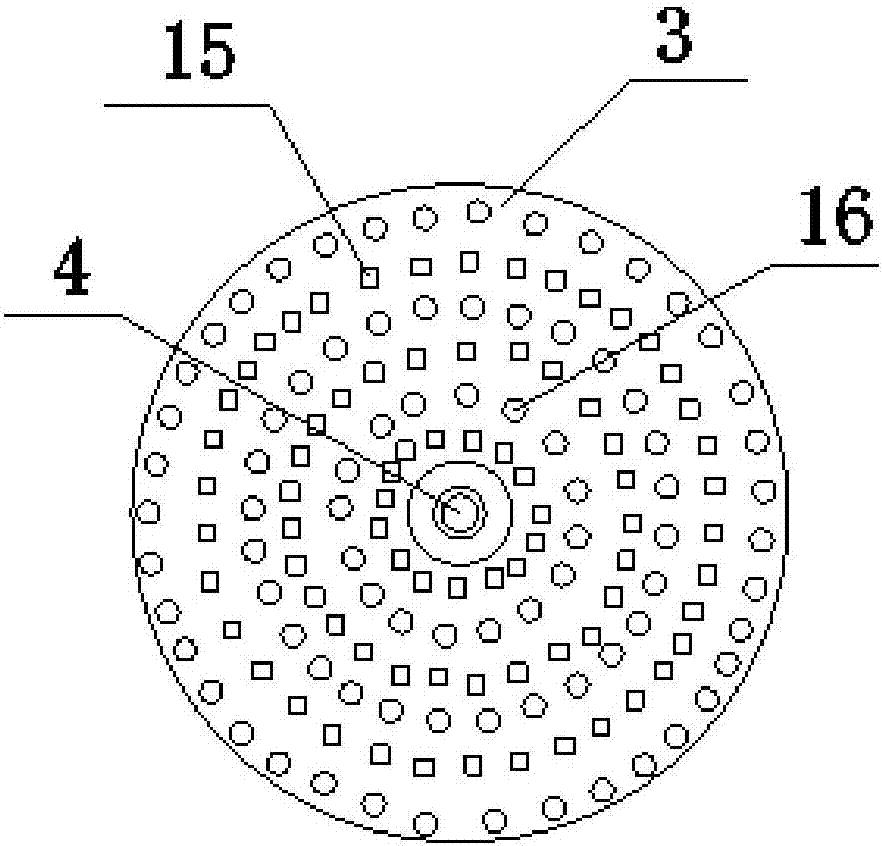

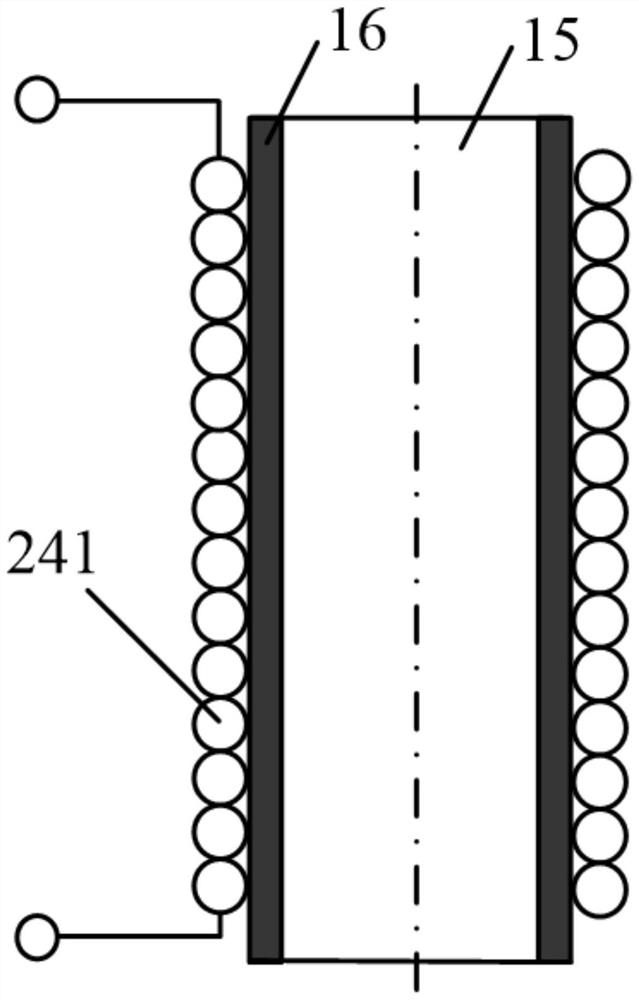

The invention relates to a method for drying wood by using solar energy. The method comprises the following steps of: placing a wood to be dried in a drying chamber (16); supplying heat to the drying chamber, and when the temperature T3 of the drying chamber (16) rises and is 2 DEG C higher than the set drying temperature of the wood, stopping the heat supplying of a greenhouse-type heat collector (4) to the drying chamber (16) in order to dry the wood at the set drying temperature. The method for drying wood by using solar energy of the invention is convenient to run and flexible to control the temperature; the drying temperature can be constant and the continuous drying is realized; moreover, the drying energy consumption is reduced remarkably, the drying cost is reduced and the better drying quality is obtained; in addition, the solar heat collector in the method of the invention has large area, high heat efficiency and high conversion efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

Chemical vapor deposition method of integrating heating and depositing of silicon slices

InactiveCN1546723AFlexible temperature controlRapid temperature changeChemical vapor deposition coatingVacuum pumpingGas phase

The invention relates to a chemical gas phase deposition method of integrating heating and depositing of silicon slices which comprises, placing the silicon chips on the electrode, vacuum-pumping, starting silicon chip micro area to heat controller power source, using silicon chips directly as heating arrangement, initializing silicon chip temperature, letting in or charging in reactant, reacting the reactants on silicon chip surface to obtain the product, using the silicon chip as substrate, and depositing the reaction product on silicon chip surface.

Owner:XIAMEN UNIV

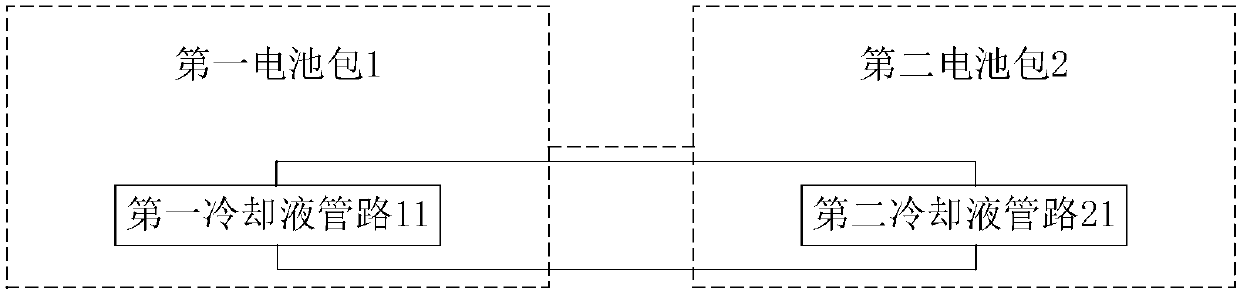

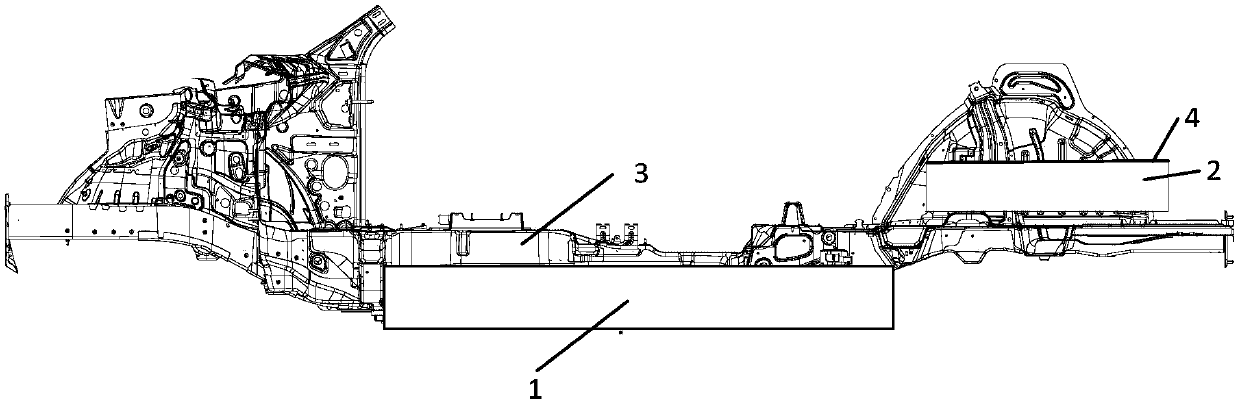

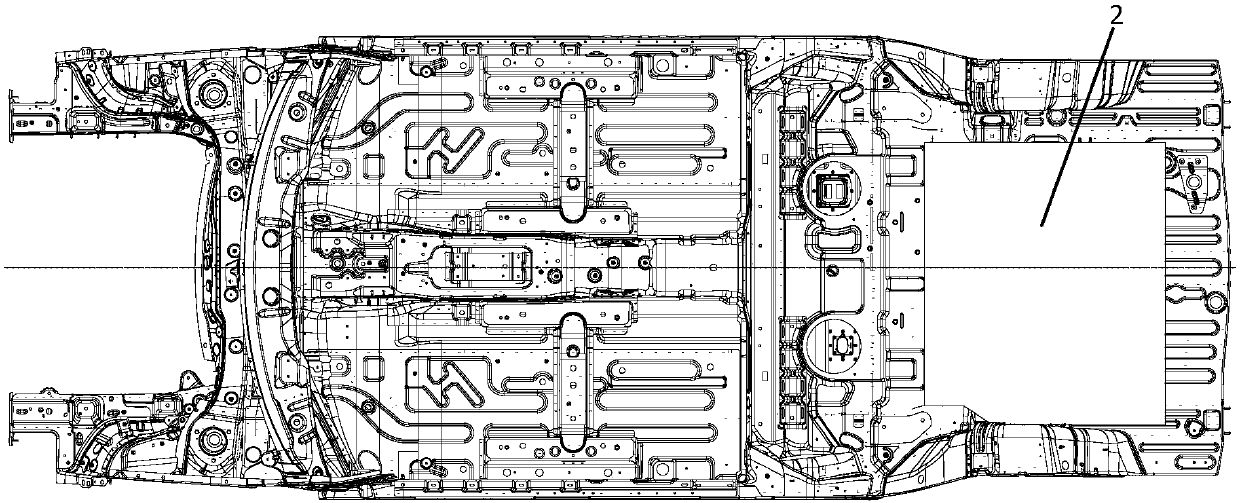

Power battery system and vehicle

ActiveCN107845843AFlexible temperature controlExtended service lifeSecondary cellsCell component detailsElectricityPower battery

The invention relates to a power battery system and a vehicle. The power battery system comprises a first battery pack (1) and a second battery pack (2); a first coolant pipeline (11) is formed in thefirst battery pack (1); the second battery pack (2) is electrically connected with the first battery pack (1); a second coolant pipeline (21) is formed in the second battery pack (2), wherein the second coolant pipeline (21) is connected with the first coolant pipeline (11) in parallel; and the flow of the coolant which flows through the first coolant pipeline (11) and the second coolant pipeline(21) is adjustable. Therefore, the battery electric quantity and the cruising power of the vehicle can be increased and improved; and in addition, by regulating the flow of the coolant which flows through the two coolant pipelines, the temperatures of the two battery packs can be flexibly adjusted and controlled correspondingly and the cooling efficiency is improved effectively, thereby prolonging the service lives of the battery packs, giving full play to the maximum output capabilities of the two battery packs, and improving the power performance of the finished automobile.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

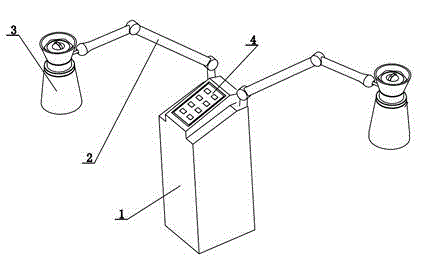

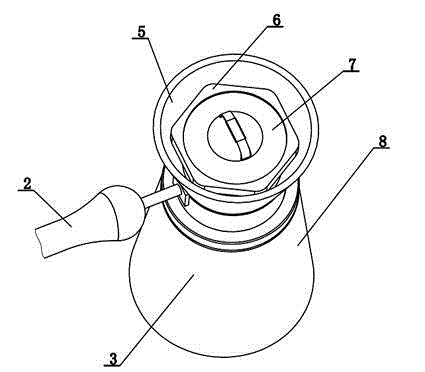

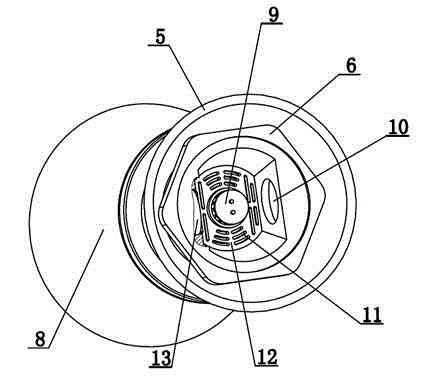

Light-medicine integrated moxibustion therapy apparatus

InactiveCN104958175APromote full volatilizationIncrease profitDevices for heating/cooling reflex pointsMedical devicesMedical equipmentControl system

The invention discloses a light-medicine integrated moxibustion therapy apparatus, pertaining to the technical field of medical equipment. The moxibustion therapy apparatus comprises a base, support arms, light-medicine moxibustion therapy devices and a control system. One ends of the support arms are mounted to the base and the other ends of the support arms are fixedly connected with the light-medicine moxibustion therapy devices. Each light-medicine moxibustion therapy device comprises a shell, in which a medicine bin and a heating device are arranged. Two side walls of the medicine bin are fixedly provided with axial flow fans. Multiple red light sources and infrared light sources are arranged on the circular surface at the lower end of the shell. Heating plates, temperature measurement components, the red light sources and the infrared light sources are all connected to the control system. The light-medicine integrated moxibustion therapy apparatus is provided with a dumping disconnecting protective switch. The light-medicine integrated moxibustion therapy apparatus has following beneficial effects: utilization rate of medicine is improved; according to needs of a patient and the type of medicine, temperature can be flexibly controlled; and by adoption of a flow-guide cover, medicine can be easily collected in order to increase smoke concentration and target ability of medicine.

Owner:ANYANG XIANGYU MEDICAL EQUIP

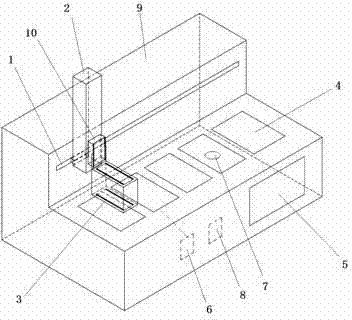

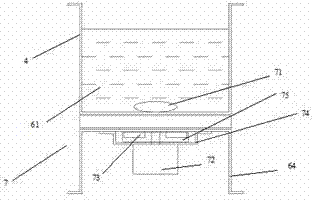

Biological sample treating instrument

InactiveCN104849121ASuitable for processing requirementsPrecise temperature regulationPreparing sample for investigationHydraulic cylinderTemperature control

The invention discloses a biological sample treating instrument. The biological sample treating instrument comprises an instrument supporting frame, hydraulic cylinders, a temperature module, a stirrer, a central control system, an X-Z two-axial plane moving device and a human-computer interface, temperature control is carried out on a solution in the hydraulic cylinder by virtue of the central control system, the central control system controls the stirrer to stir the solution in each hydraulic cylinder, and the X-Z two-axial plane moving device is arranged on the instrument supporting frame, the central control system controls the tail end of a moving part of the X-Z two-axial plane moving device to output X-Z two-axial planar motion, so that a glass slide frame can be hoisted in each hydraulic cylinder, location switching of the glass slide frame is carried out among the different hydraulic cylinders, the glass slide frame moves in different hydraulic cylinders, and batch treatment on a biological sample is realized. The biological sample treating instrument has the advantages that various treatment can be carried out on the sample adhered onto the surface of a glass slide in batch, efficiency is high, repeatability and consistency are good, size is small, production cost is low, mounting and maintenance are convenient, and energy consumption is low.

Owner:SHANGHAI LECHEN BIOLOGICAL SCI & TECH

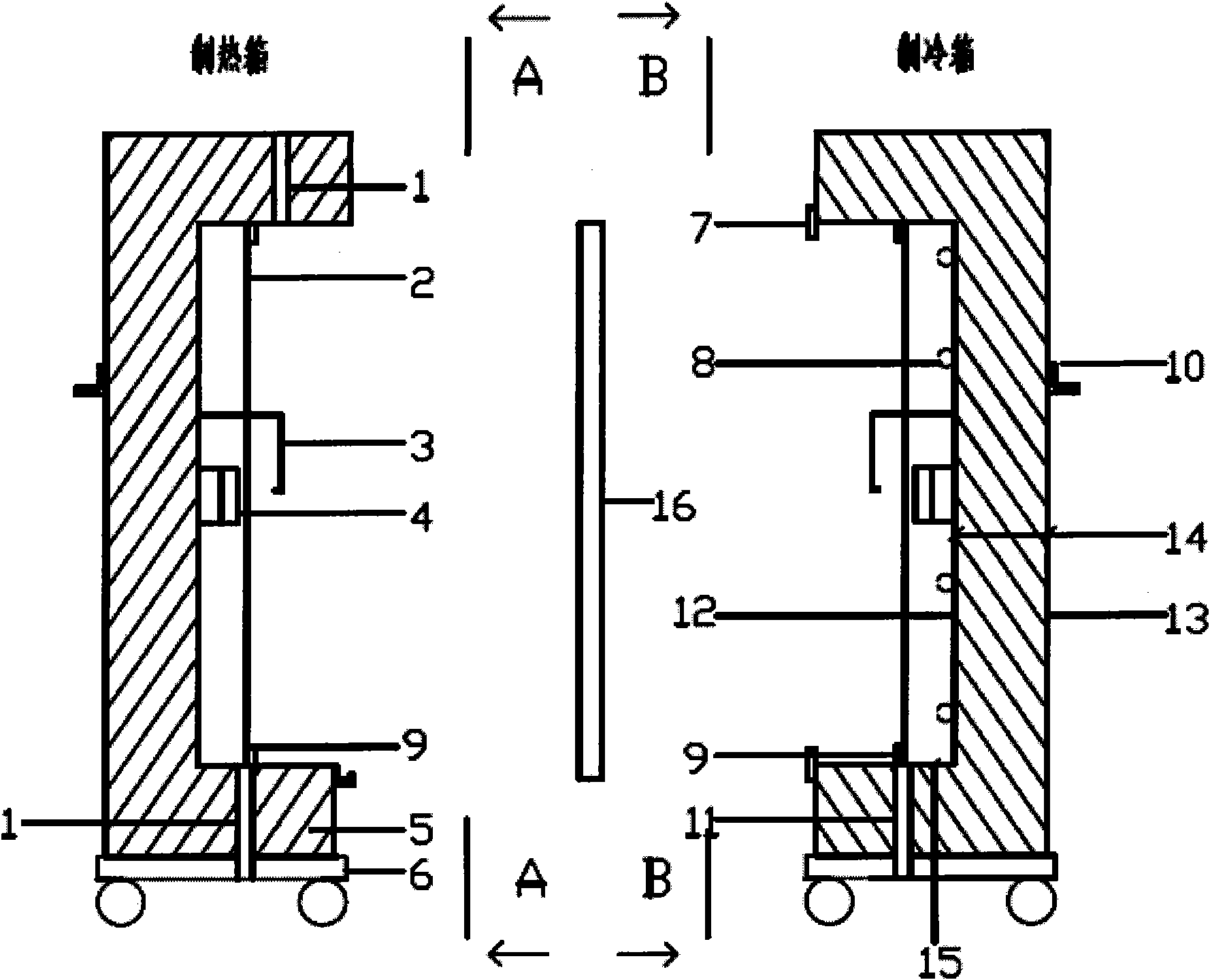

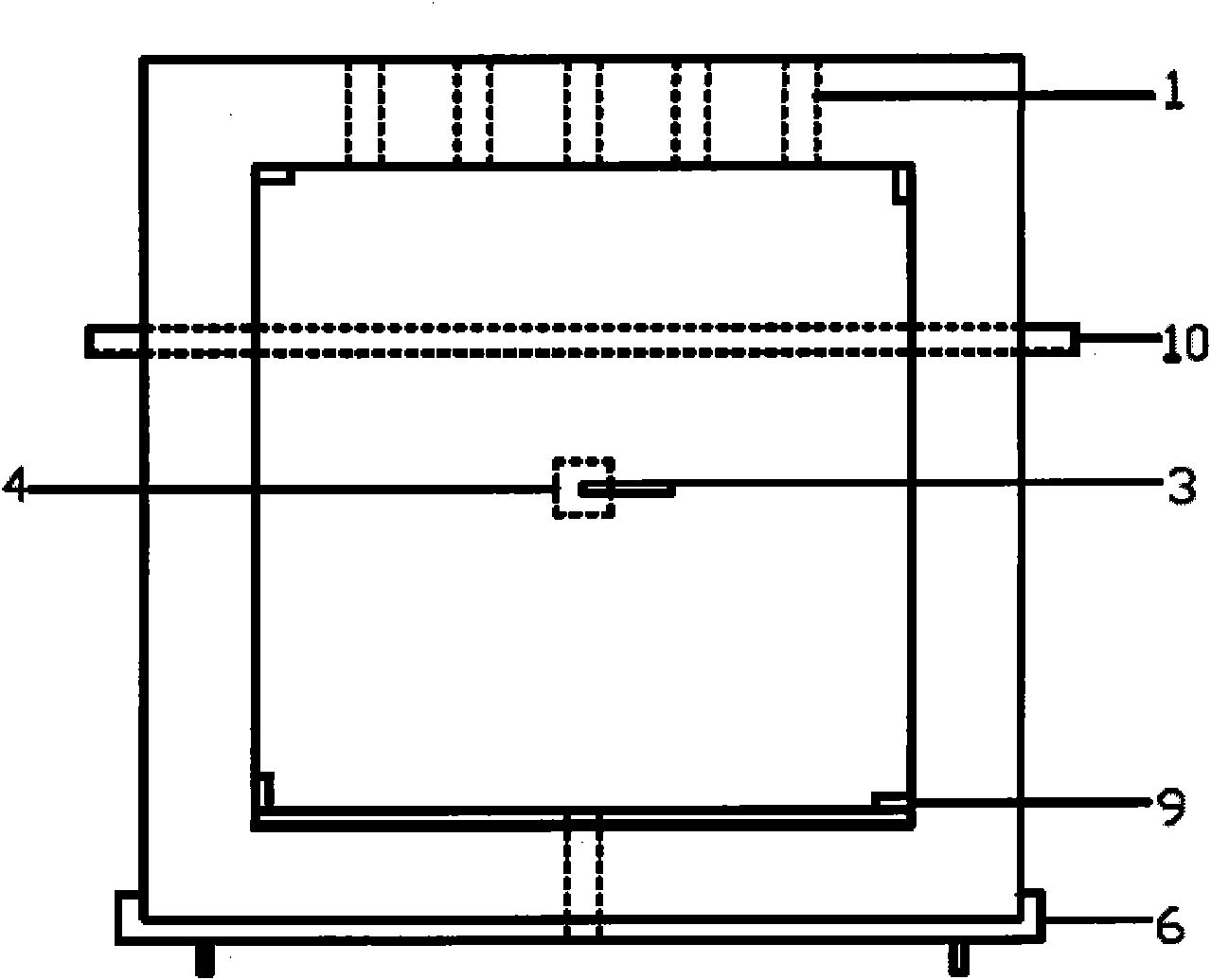

Temperature control device for use in civil engineering temperature stress measurement

InactiveCN101866189AImprove airtightnessUniform temperature fieldTemperatue controlEfficient regulation technologiesTemperature stressTemperature control

The invention discloses a temperature control device for use in civil engineering temperature stress measurement, which belongs to the technical field of glass curtain wall temperature control. The temperature control device comprises a heating box and a cooling box, which are independent of each other and are positioned on two sides of a measured object, wherein both the heating box and the cooling box have an open double-layer box body, and thermal-insulation foam is filled between the inner-layer box bodies and the out-layer box bodies; the bottom surfaces of the inner-layer box bodies of the heating box and the cooling box are both fixed with a heating plate and iron plates are arranged on the outer side of the heating plates; cooling pipes are arranged between the inner-layer box body and the iron plate of the cooling box and is provided with holes for charging liquid nitrogen for cooling; and thermocouples are arranged in the box bodies of the heating box and the cooling box, the heating box is provided with openings, and fans are arranged in the box bodies on the outer sides of the iron plates. The whole device is well sealed, the temperature fields are uniform, and the influence of various side effects caused by temperature on a test piece is slight. The temperature control is flexible and simple and different temperature fields are realizes conveniently on two sides of the test piece.

Owner:TSINGHUA UNIV

Large-scale intelligent laundry device with sterilizing and drying functions

InactiveCN106930037AWith sterilization and drying functionSimple structureOther washing machinesControl devices for washing apparatusProcess engineeringSteam heating

The invention discloses a large-scale intelligent laundry device with sterilizing and drying functions. The large-scale intelligent laundry device comprises an intelligent laundry device body, wherein the intelligent laundry device body is composed of an outer shell and an inner washing drum; a main rotating shaft is arranged at the center of the inner washing drum; a crossing support frame is welded on the main rotating shaft; a connecting base is arranged under the intelligent laundry device body; a sealing cover is arranged above the intelligent laundry device body; a master control module is arranged on the sealing cover; the master control module comprises a timing system, a temperature control module, a drying control module and a sterilizing control module; a steam heating component and a drying heating component are arranged in the connecting base; the steam heating component is electrically connected with the sterilizing control module; the drying heating component is electrically connected with the drying control module; a drying hole and a steam jetting hole are formed under the inner washing drum. The large-scale intelligent laundry device has a simple structure, sterilizing and drying functions, high safety and capability of realizing intelligent temperature control.

Owner:付小东

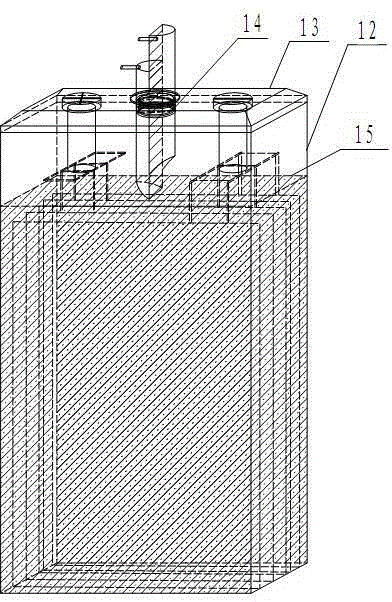

Phase change temperature control device applied to battery pack

InactiveCN110581327AFlexible temperature controlSimple structureSecondary cellsPower batteryTemperature control

The invention discloses a phase change temperature control device applied to a battery pack. The phase change temperature control device comprises a housing. A plurality of unit cavities for placing batteries are arranged in the housing. The unit cavities are filled with composite fillers. A temperature control module is arranged on the outer side of the housing. The temperature control module comprises semiconductor refrigeration sheets. Through cooperation of the semiconductor refrigeration sheets and the composite fillers, temperature control is achieved; the temperature of the battery packcan be controlled through heat absorption or heat release of the composite fillers; and the temperature of the battery pack can be controlled by starting cooperative work of the semiconductor refrigeration sheets and the composite fillers, so that the temperature of the battery pack is flexibly controlled. The provided device is simple in structure and can be widely applied to the technical fieldof power battery pack thermal management.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Regeneration method for preparing light olefins catalyst from oxygen-containing compounds

InactiveCN101402050AEffective removalFlexible temperature controlMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveFluidized bed

The invention relates to a method for regenerating a catalyst for preparing low-carbon olefin from an oxygen-containing compound, which mainly solves the problem that the temperature of a regenerator is difficult to control in the prior art. The method adopts a technical proposal which comprises the following steps: putting a regenerating medium of which the temperature is between 100 and 300 DEG C into a regeneration dense phase zone of a fluidized bed regenerator to be contacted with a catalyst which is to be regenerated and contains an aluminosilicophosphate molecular sieve with 0.5 to 7.5 weight percent of coke, performing an oxidation reaction on the mixture at a regeneration temperature of between 600 and 700 DEG C to generate large amount of heat while generating a gas phase material flow which contains O2, CO, and CO2, and delivering removing the heat out of the regeneration dense phase zone through an external heat-removing device of the regenerator, wherein the external heat-removing device of the regenerator is a full back mixing type external heat-removing device, and the distance between the connecting position of the external heat-removing device of the regenerator and the regeneration dense phase zone and a feed distributor for bottom regeneration media is less than or equal to 0.5 of the height of a bed layer in the regeneration dense phase zone. The technical proposal better solves the problem and can be used for the industrial production of the low-carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogen electric heating method and system for in-situ pyrolysis of oil-rich coal

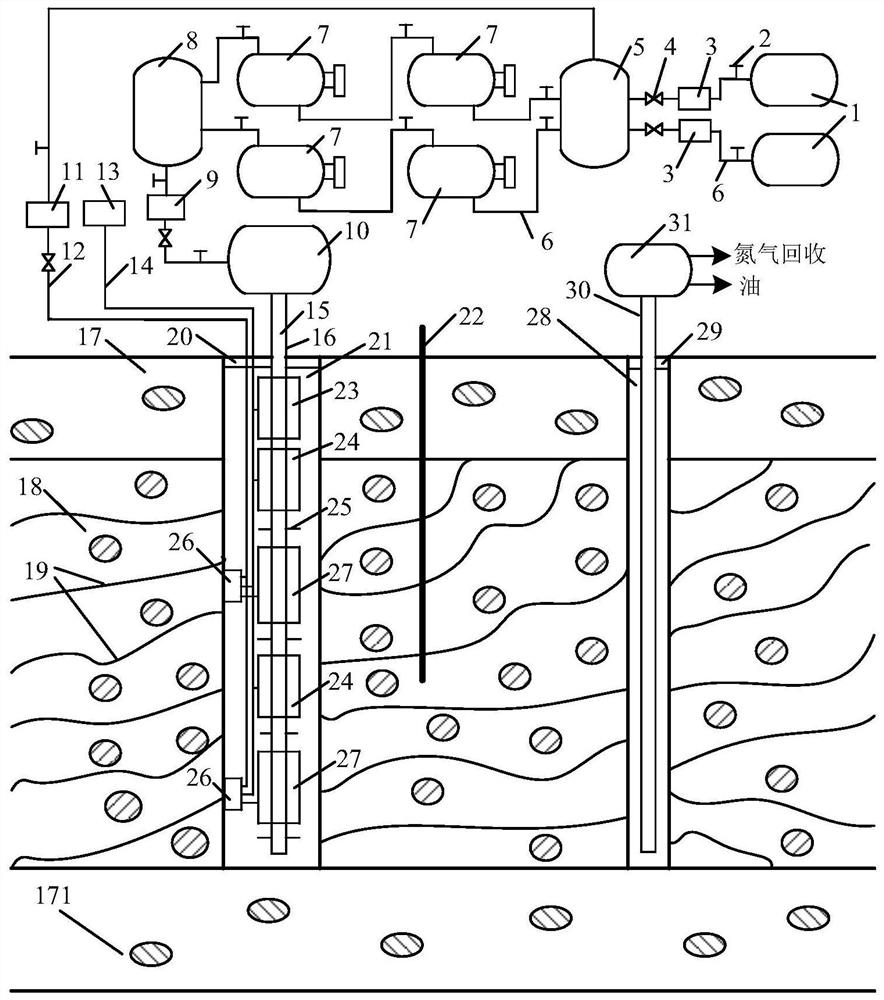

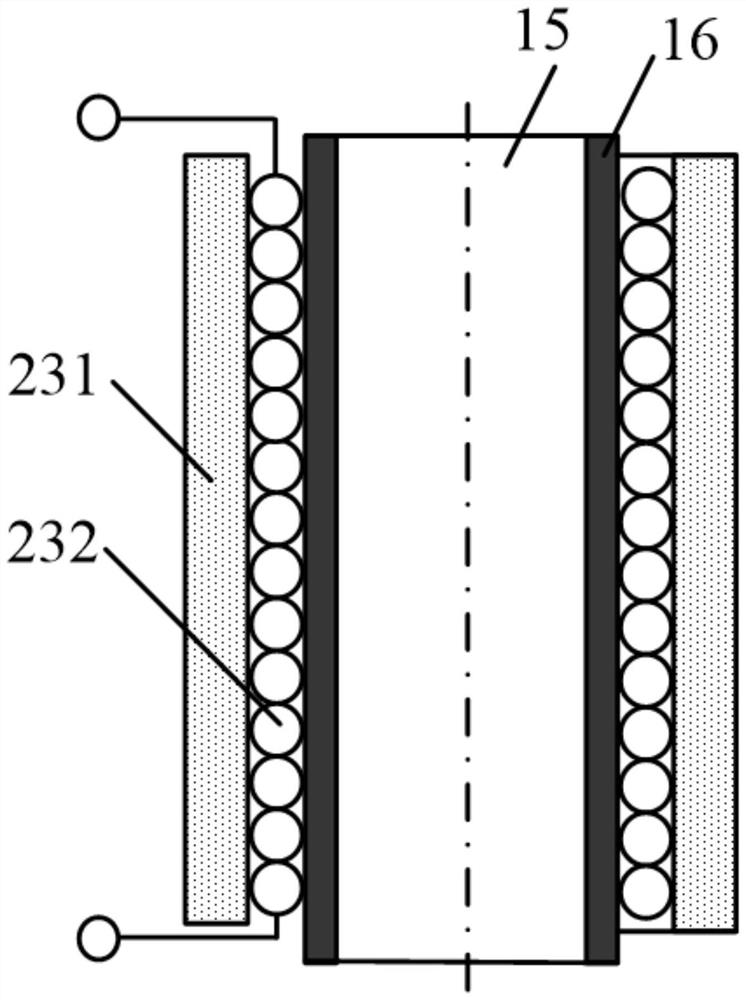

ActiveCN113685161AImprove heating efficiencyEasy to implementConstructionsFluid removalInjection wellGas pipeline

The ivnention discloses a nitrogen electric heating method and system for in-situ pyrolysis of oil-rich coal. One end of a second gas pipeline is connected with a high-temperature and high-pressure nitrogen storage tank, the other end of the second gas pipeline extends into a heat injection well and sequentially penetrates through a heating cable heating structure and an electromagnetic induction heating structure, and the electromagnetic induction heating structure is connected with a variable-frequency power source device and a cooling system. The heating cable heating structure and the variable-frequency power source device and cooling system are respectively connected with a power source and a control system; high-temperature and high-pressure nitrogen enters the heat injection well through the second gas pipeline, and the second gas pipeline is heated through a heating structure; the heat injection well communicates with a mining well through a fracture, and the high-temperature and high-pressure nitrogen enters the fracture; mixed gas generated by heating of an oil-rich coal seam enters the mining well; and transmitting to an oil-gas comprehensive separation device through an oil-gas collection pipeline to obtain a series solution of the oil-rich coal seam. According to the nitrogen electric heating method and system for in-situ pyrolysis of the oil-rich coal, the efficiency of a heating system is improved, and the environmental adaptability of an underground heating device and the controllability of the heating temperature of the oil-rich coal seam are enhanced.

Owner:XI AN JIAOTONG UNIV +1

Catalytic combustion purification process and device

ActiveCN107504506AEliminate the phenomenon of overheatingReduce loadIncinerator apparatusChemistryFlammability limit

The invention discloses a catalytic combustion purification process and device. According to the catalytic combustion purification process and device, firstly, organic waste gas and air and / or oxygen are mixed, and the mixing ratio of the organic waste gas and the air and / or the oxygen can be flexibly regulated and controlled according to the requirement for the subsequent catalytic combustion technology; it is guaranteed that the concentration of the organic waste gas in the mixed gas is within the explosion limit; more importantly, the subsequent catalytic combustion temperature is regulated and controlled, and the phenomenon of temperature runaway of catalytic combustion sections is eradicated; secondly, the mixed gas is divided into two parts, one part is used for catalytic combustion, and the remaining part conducts heat exchange with mixed gas at outlets of all the stages of the catalytic combustion sections. In this manner, the amount of the two parts can be regulated flexibly in time; the temperature of the mixed gas going in the next stage of catalytic combustion is maintained by using the remaining part; finally, catalytic combustion can be smoothly carried out, and the phenomenon of temperature runaway is prevented.

Owner:FUZHOU UNIVERSITY +1

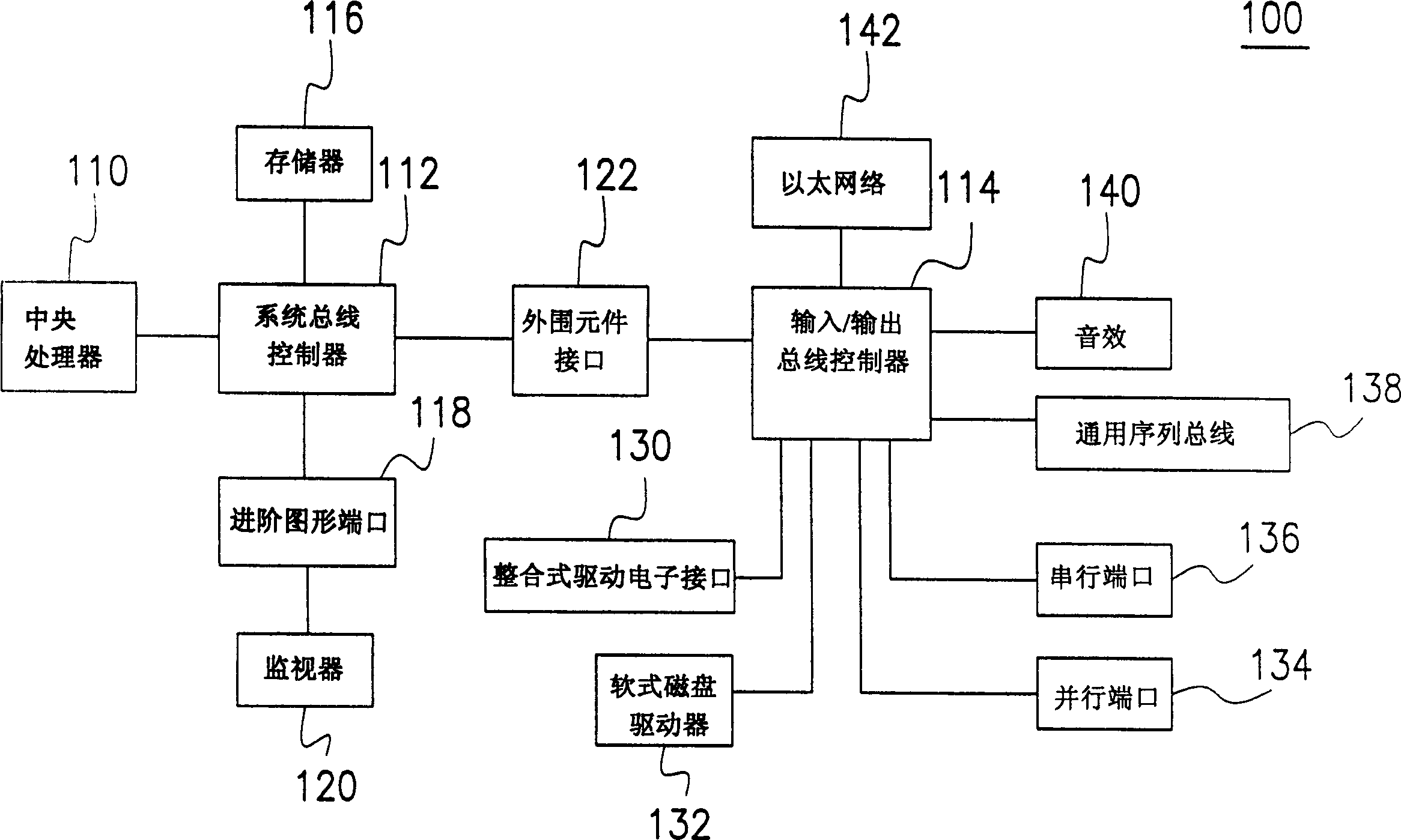

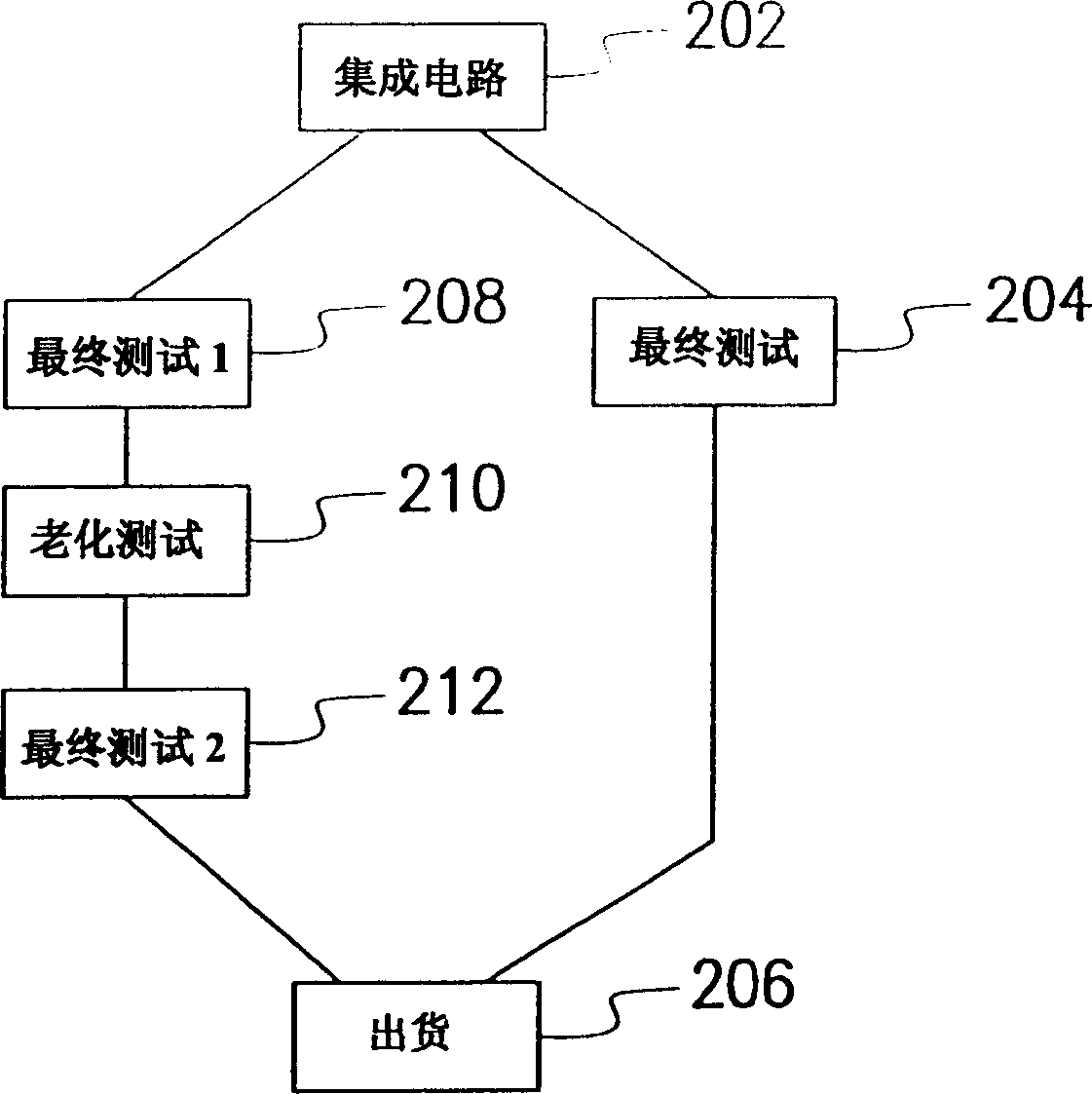

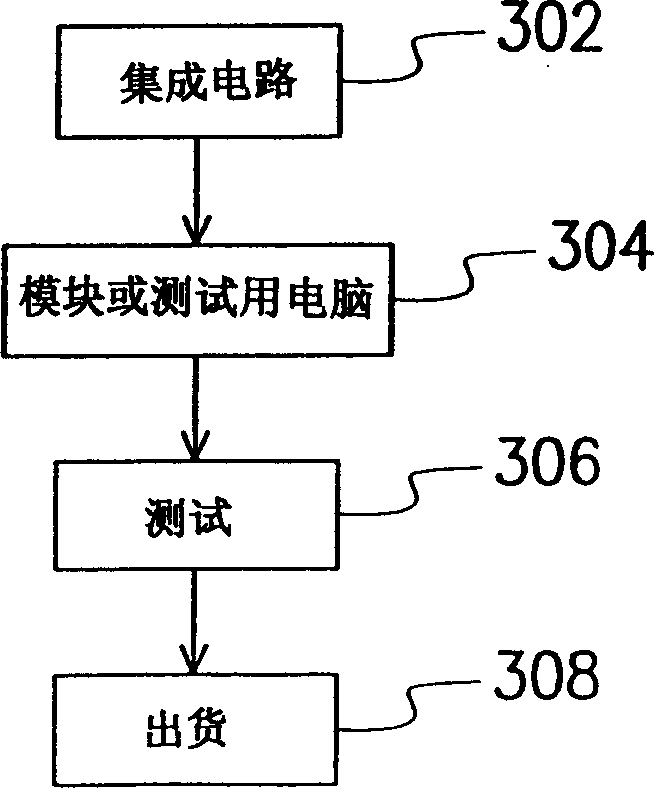

System, equipment and method for automatic testing IC complete device

InactiveCN1416164AGuarantee the quality of useImprove accuracySemiconductor/solid-state device testing/measurementContactless circuit testingTemperature controlControl set

The testing system includes the testing computer, the automatic plugging and pulling out mechanism, the temp control set and the control set. The testing computer is used for holding and testing the IC to be bested. The automatic plugging and pulling out mechansm puts the IC to be tested on the testing computer and takes the IC tested off from the testing computer. The temp control set controls the temp of the IC to be tested. The control set is connected to the testing computer and the plugging and pulling out mechanism electrically, controlling the operation of the plugging and pulling out mechanism. The testing computer combines the IC to be tested forming an integrated computer. The temp control set controls the temp at preset condition. The control set carriage out the integrated testing.

Owner:威盛电子(深圳)有限公司

System and method for pyrolyzing biomass and liquefied residue

InactiveCN106675596ARealize comprehensive utilizationLow costBiofuelsCalcium carbideProcess engineeringEngineering

The invention discloses a system and a method for pyrolyzing biomass and liquefied residue. The system comprises a mixed moulding unit, a co-pyrolyzing unit, a liquefied residue dedusting unit and a calcium carbide producing unit, wherein the mixed moulding unit comprises a biomass inlet, a liquefied residue inlet and a moulded ball outlet; the co-pyrolyzing unit comprises a moulded ball inlet, a pyrolyzed oil gas outlet and a mixed semicoke outlet; the liquefied residue dedusting unit is provided with a pyrolyzed gas inlet, a dedusted gas outlet and a dust-containing liquefied residue outlet; the calcium carbide producing unit is provided with a mixed semicoke inlet, a quick lime inlet, an oxygen-enriched gas nozzle, a calcium carbide furnace gas outlet and a calcium carbide outlet. According to the system and the method, provided by the invention, the liquid liquefied residue is used for dedusting the pyrolyzed gas obtained by pyrolyzing the biomass, the dust-containing liquefied residue is recycled and is mixed with the biomass for preparing the mixed semicoke through copyrolysis, and the sensible heat of the mixed semicoke is utilized for preparing calcium carbide, so that high-value utilization of the liquefied residue as well as energy conservation of the system are achieved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

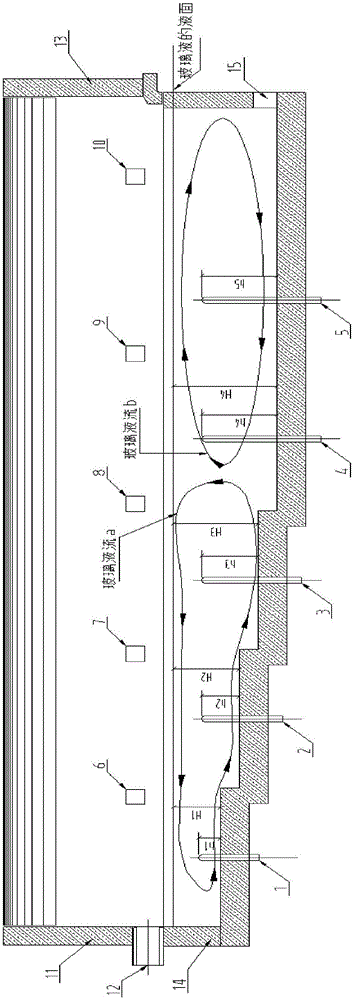

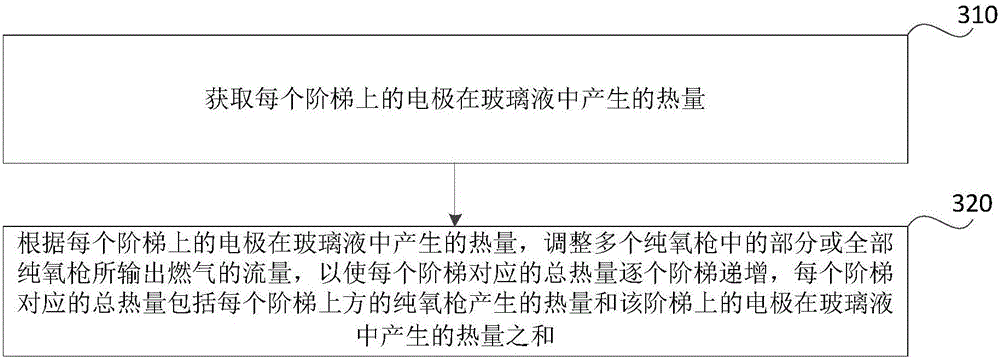

Glass kiln and glass melting control method

ActiveCN106746490AFlexible temperature controlAvoid uniformityGlass furnace apparatusElectric furnaceGlass meltingMolten glass

The invention discloses a glass kiln and a glass melting control method. A charge port and a discharge port are formed in the glass kiln; the glass kiln comprises a kiln top and a kiln bottom; the kiln bottom is of a step structure for placing molten glass and comprises multiple steps; the depths of the steps are increased in sequence; the depth of each step is the distance from each step to the liquid surface of the molten glass; at least one electrode is arranged on each step; the electrode on each step is positioned below the liquid surface of the molten glass; the kiln top and the liquid surface of the molten glass form a combustion space; multiple pure oxygen lances are uniformly distributed in the combustion space; the charge port is positioned on the kiln wall at one end of the shallowest step of the kiln bottom and is higher than the liquid surface of the molten glass; and the discharge port is positioned on the kiln wall of one end of the deepest step of the kiln bottom and is lower than the liquid surface of the molten glass. In the invention, the effects of high molten glass uniformity and high quality are realized.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Integrated device and method for removing sulfur oxide and heavy metal in non-ferrous metal smelting and acid-making flue gas

InactiveCN108499315AFlexible temperature controlQuality assuranceCombination devicesGas treatmentResource utilizationNon-ferrous extractive metallurgy

The invention discloses an integrated device and method for removing sulfur oxide and heavy metal in non-ferrous metal smelting and acid-making flue gas. The integrated device comprises a gas inlet flue, a heat exchanger, a U-shaped flue, a venturi tube bundle, a circulating fluidized bed reactor and a dust remover, which are connected in sequence; the acid-making flue gas enters the heat exchanger from the gas inlet flue and enters a U-shaped pipeline through the heat exchanger from top to bottom; then the acid-making flue gas enters the venturi tube bundle through the U-shaped pipeline frombottom to top and enters the fluidized bed reactor from the venturi tube bundle; finally, the acid-making flue gas is subjected to dust removal through the dust remover and then is exhausted. According to the device disclosed by the invention, the temperature of the flue gas can be flexibly controlled according to the acid dew point of the flue gas and SO3 is selectively absorbed; meanwhile, impurities including dust, arsenic, fluorine, mercury and the like are captured and the purification efficiency is high; the quality of the acid-making flue gas can be ensured; a system has a simple structure and a small occupied area; resource utilization of byproducts can be directly realized and no secondary pollution is caused.

Owner:CEEP CO LTD

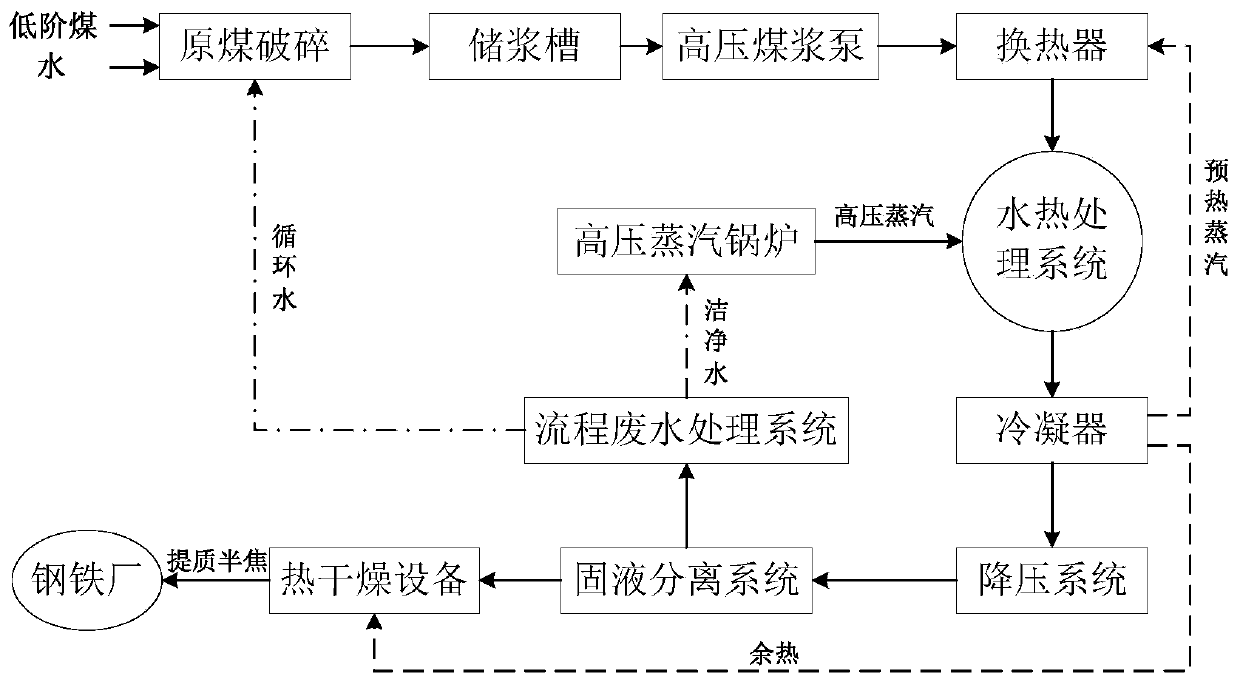

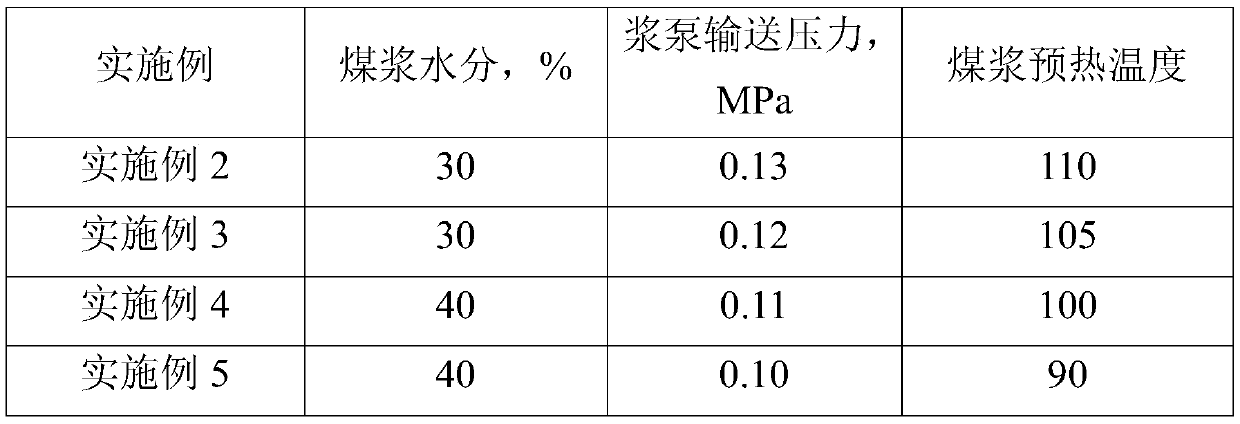

Method for preparing blast furnace blowing semicoke from low-rank coal based on high-pressure hydrothermal reaction

ActiveCN110982542ALow fixed carbon contentHigh fixed carbon contentEnergy inputSpecial form destructive distillationThermodynamicsProcess engineering

The invention relates to a treatment method for dehydrating and upgrading high-moisture and high-volatile low-rank coal, and discloses a method for preparing blast furnace blowing semicoke by upgrading low-rank coal based on a high-pressure hydrothermal reaction, wherein the method comprises four steps of low-rank coal pretreatment, high-pressure hydrothermal upgrading, waste heat recycling and upgraded semicoke dehydration and drying. According to the method, low-heat-value low-rank coal is converted into high-quality blast furnace blowing upgrading semicoke by utilizing a high-pressure hydrothermal reaction upgrading technology, wherein the moisture content of the semicoke air drying base is less than 6%, the volatile component content is less than 25%, the Hardgrove grind ability indexis greater than 60, the high-order heat generation value is greater than 24000 kJ / kg, soluble potassium salt, sodium salt and sulfate components in ash are dissolved out, the organic sulfur in coal iseffectively separated out, and the upgraded semicoke can meet the performance index requirements of coal for blast furnace blowing; and the method provided by the invention effectively solves the problems of high water content, high volatile component content, low heat value and high harmful element content of blast furnace blowing of low-rank coal, and provides a clean, efficient, low-energy-consumption and high-added-value low-rank coal upgrading utilization method.

Owner:UNIV OF SCI & TECH BEIJING

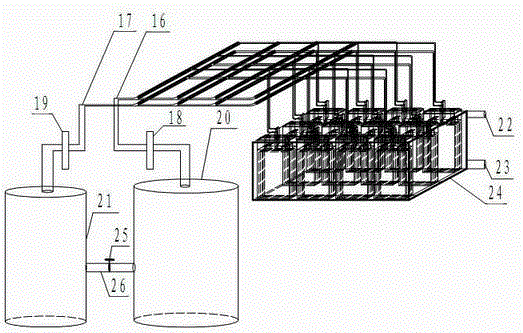

Storage battery acid circulation adjusting formation method and adjusting system

InactiveCN103606711AFlexible temperature controlAccurate temperature controlElectrolyte moving arrangementsFinal product manufactureTemperature controlLiquid density

The invention relates to a storage battery acid circulation adjusting formation method and an adjusting system, and relates to the formation of a storage battery. At present, the electrolytic liquid density maintaining method for the domestic storage battery pregnant solution formation is as follows: 1, the acid is manually pumped and supplemented, but the timeliness is insufficient, and the efficiency is low; 2, the simple closed cycling way is adopted, but the precision of the electrolyte density is low, and the formation temperature is greatly fluctuated. The invention relates to a storage battery acid circulation adjusting formation method and an adjusting system. The adjusting system comprises a formation tank, a transfusion circulation pipeline, a liquid pumping circulation pipeline, a liquid adjusting tank, a liquid storage tank, a water pump and a pressure machine, and the adjusting system is characterized by also comprising a liquid-level adjusting device, a liquid return pipe and a loop valve, wherein the liquid return pipe is communicated with the liquid adjusting tank and the liquid storage tank, and the liquid return pipe is provided with the loop valve. The adjusting formation method and the adjusting system have the beneficial effects that the advantages of flexibility, precision and temperature control can be realized.

Owner:SHANDONG SACRED SUN POWER SOURCES

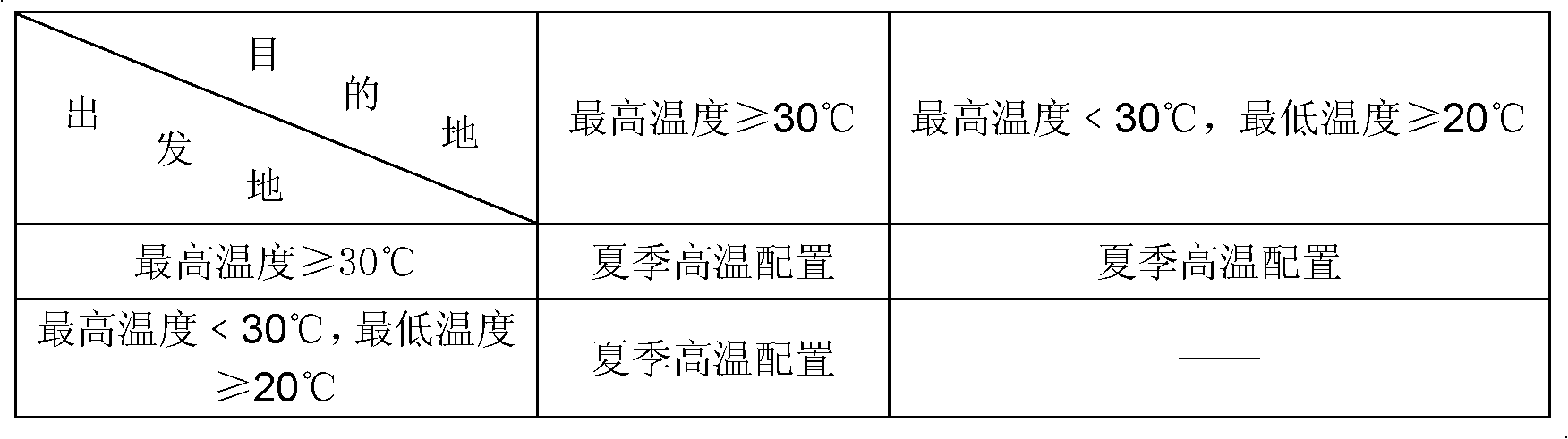

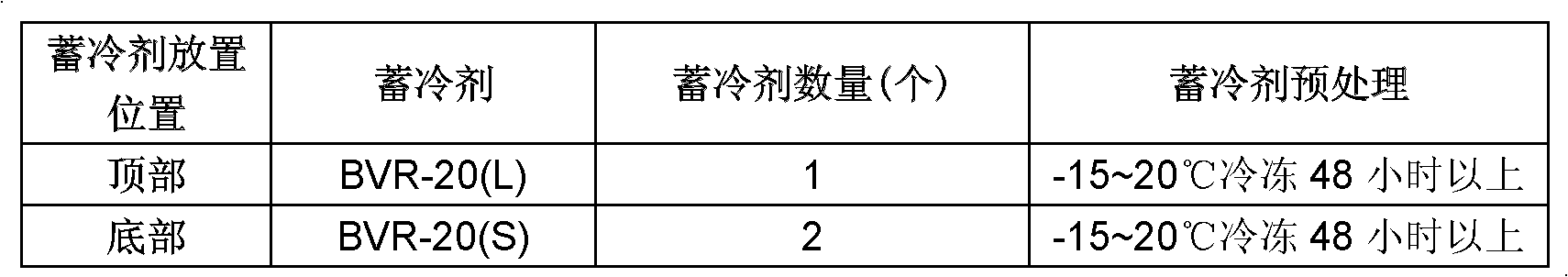

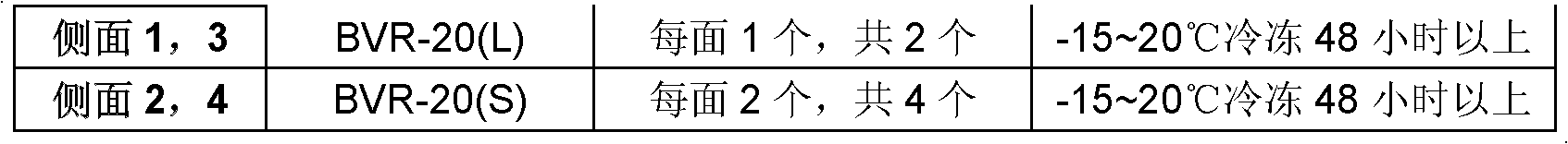

Insulation can configuration method

InactiveCN102490991ASignificant advantagesSignificant beneficial effectShock-sensitive articlesEngineeringCoolant

The invention relates to an insulation can configuration method, comprising the following steps of: (1) setting an insulation can configuration table; (2) determining conditions when an insulation object is transported; (3) selecting a corresponding configuration scheme according to the set insulation can configuration table, determining type and quantity of coolant, a processing method and an assembly method; and (4) packing the coolant and the insulation object according to the insulation can configuration table, and making preparation for transportation. The insulation can configuration method provided by the invention can flexibly control temperature of an insulation can as required, is not influenced by variation of seasons and ambient temperature and can reliably guarantee that specified preservation effect or transportation temperature of medicines can be reached.

Owner:SHANGHAI VISION INDS

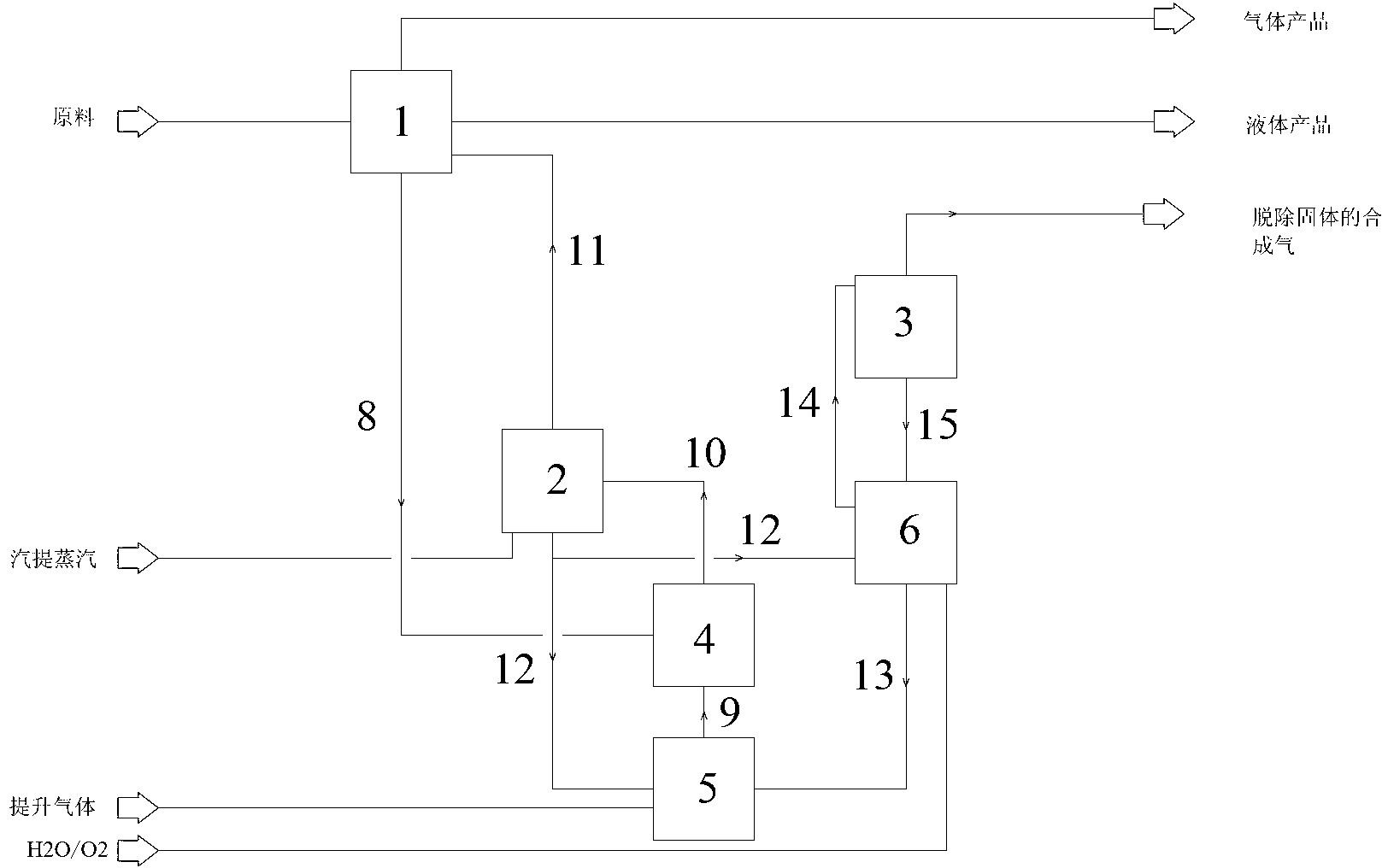

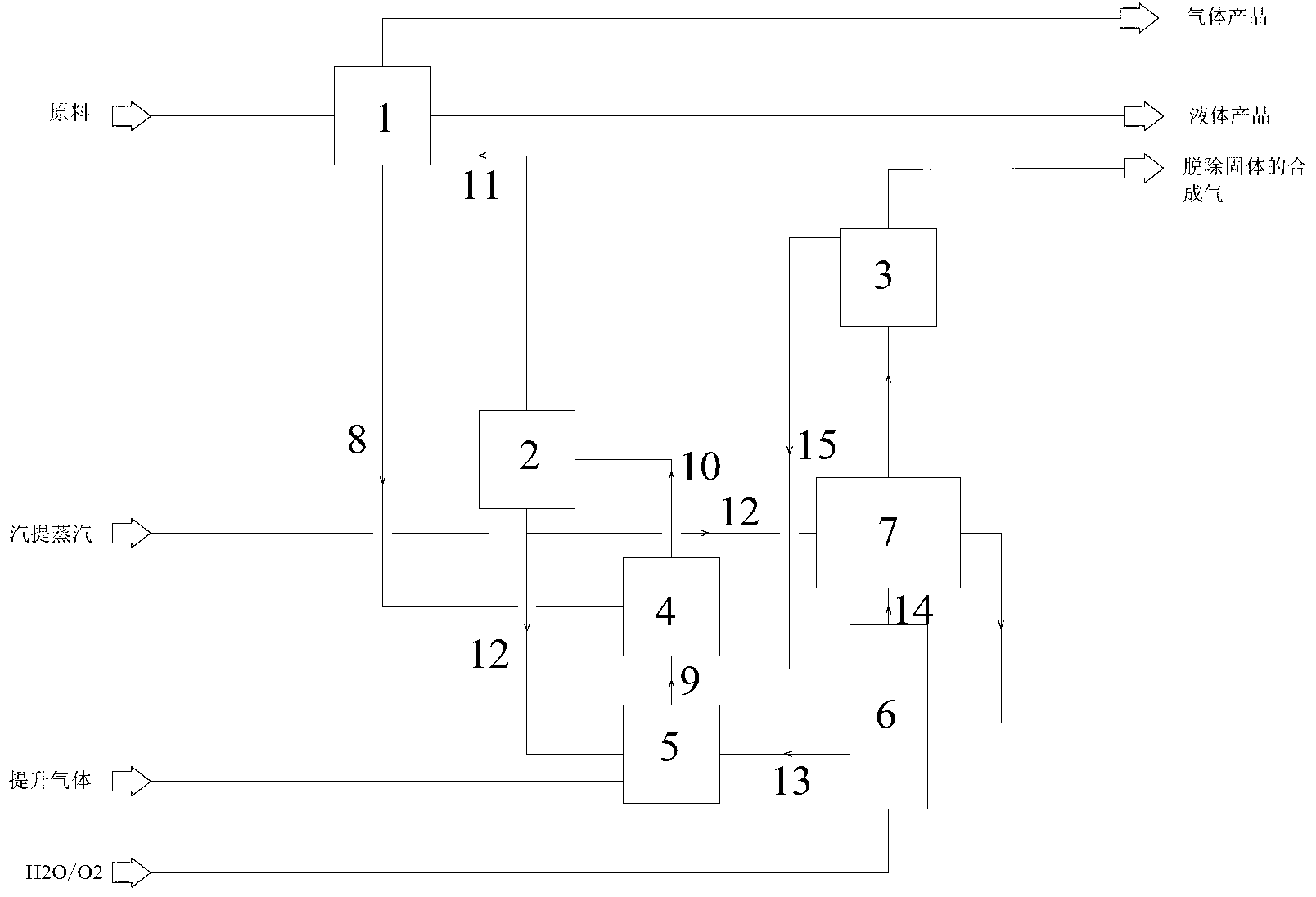

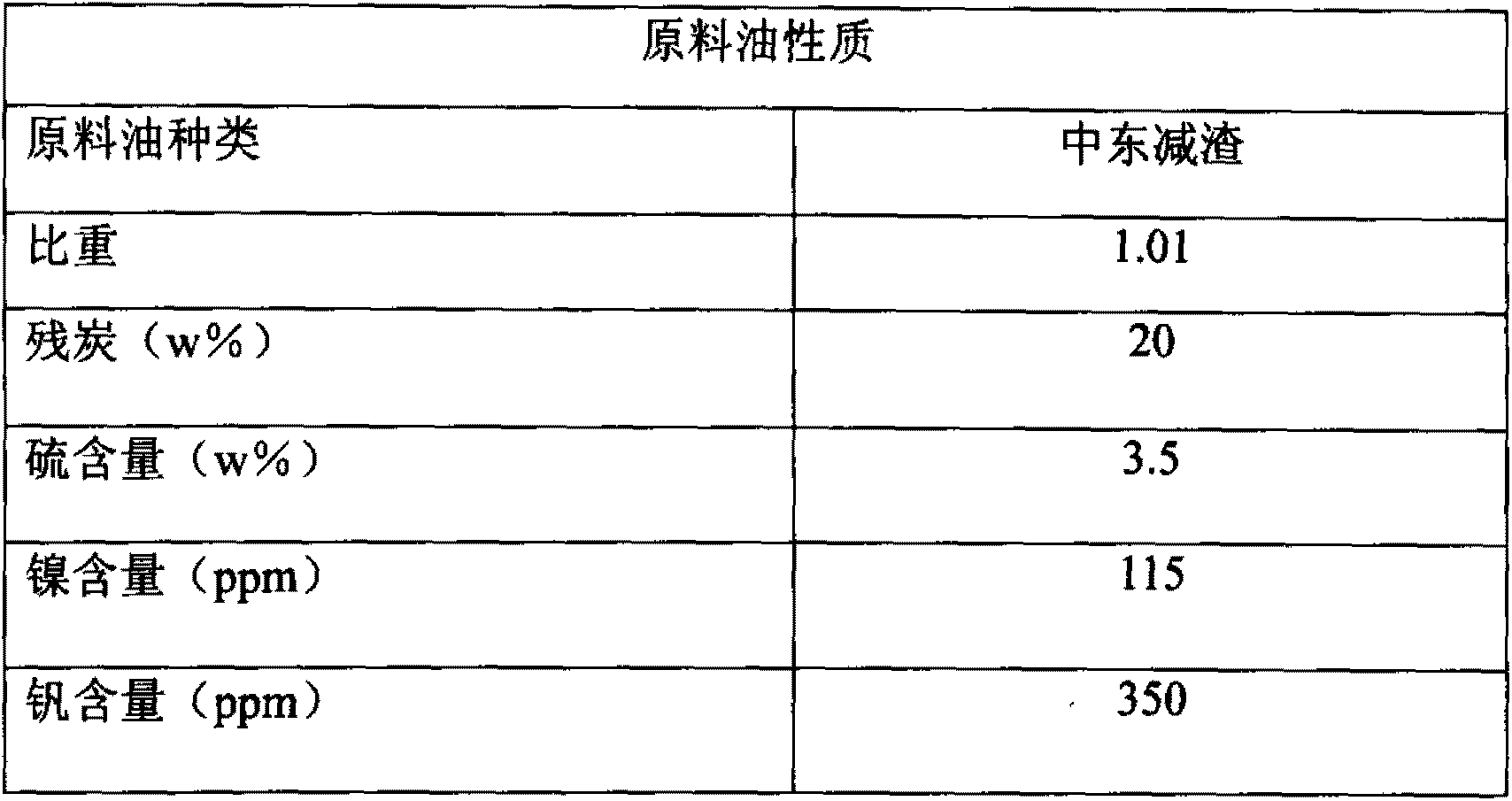

Inferior heavy oil fluidization conversion technology

ActiveCN103224808ALow calorific valueQuality improvementTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasThermal energy

The invention relates to an inferior heavy oil fluidization conversion technology. The inferior heavy oil fluidization conversion technology comprises that raw material oil is treated by a fractionating tower, then enters into a lifting pipe reactor, undergoes a contact reaction with coke carriers from a coke carrier mixer, then enters into a first gas-solid separation device and is separated; the separated reaction oil gas is fed into the fractionating tower and is subjected to product division; the coke carriers with coke is stripped and is divided into two parts, one of the two parts is fed into the coke carrier mixer, then is mixed with the high-temperature coke carriers from a vaporizer and then is fed back to the lifting pipe reactor, and other one of the two parts is fed into the vaporizer, contacts with oxygen-containing gas and water vapor and undergoes a gasification reaction; the produced synthetic gas is separated by a second gas-solid separation device, is fed into a follow-up section, and is subjected to heat recovery and conversion; and the vaporized coke carriers are fed into the coke carrier mixer and is mixed with the coke carriers with the coke. Compared with the prior art, the inferior heavy oil fluidization conversion technology has the advantages of simple process, low investment, strong raw material adaptability, good product distribution and good environmental benefits.

Owner:SHANGHAI HOTO PETROCHEM ENG

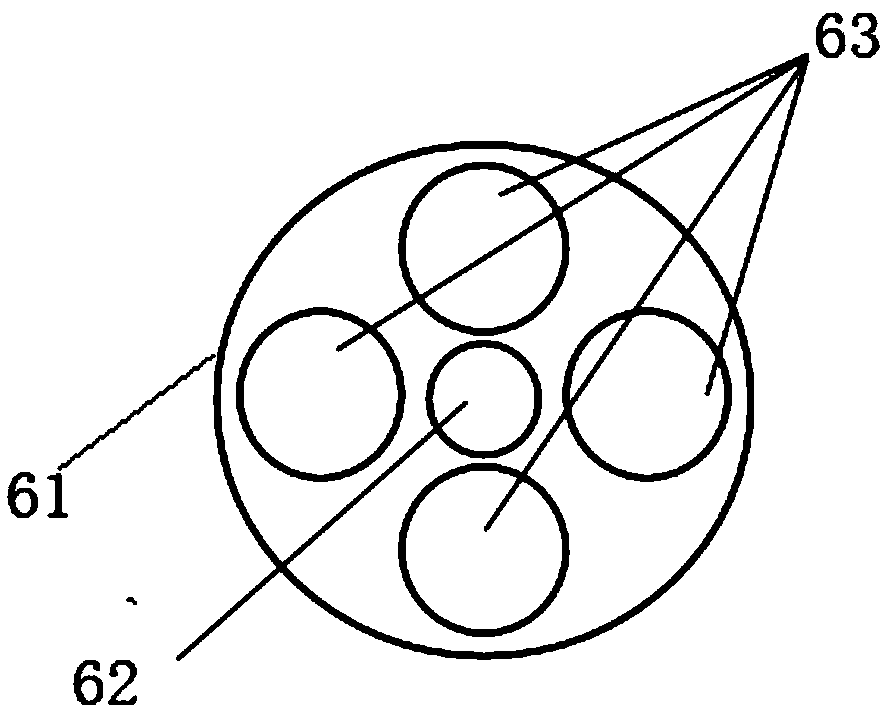

Production equipment for manufacturing excellent optical fiber preforms by VAD (vapor axial deposition) method

InactiveCN107827348AImprove product qualityWider and more uniform feed rangeGlass deposition burnersLaser transmitterEngineering

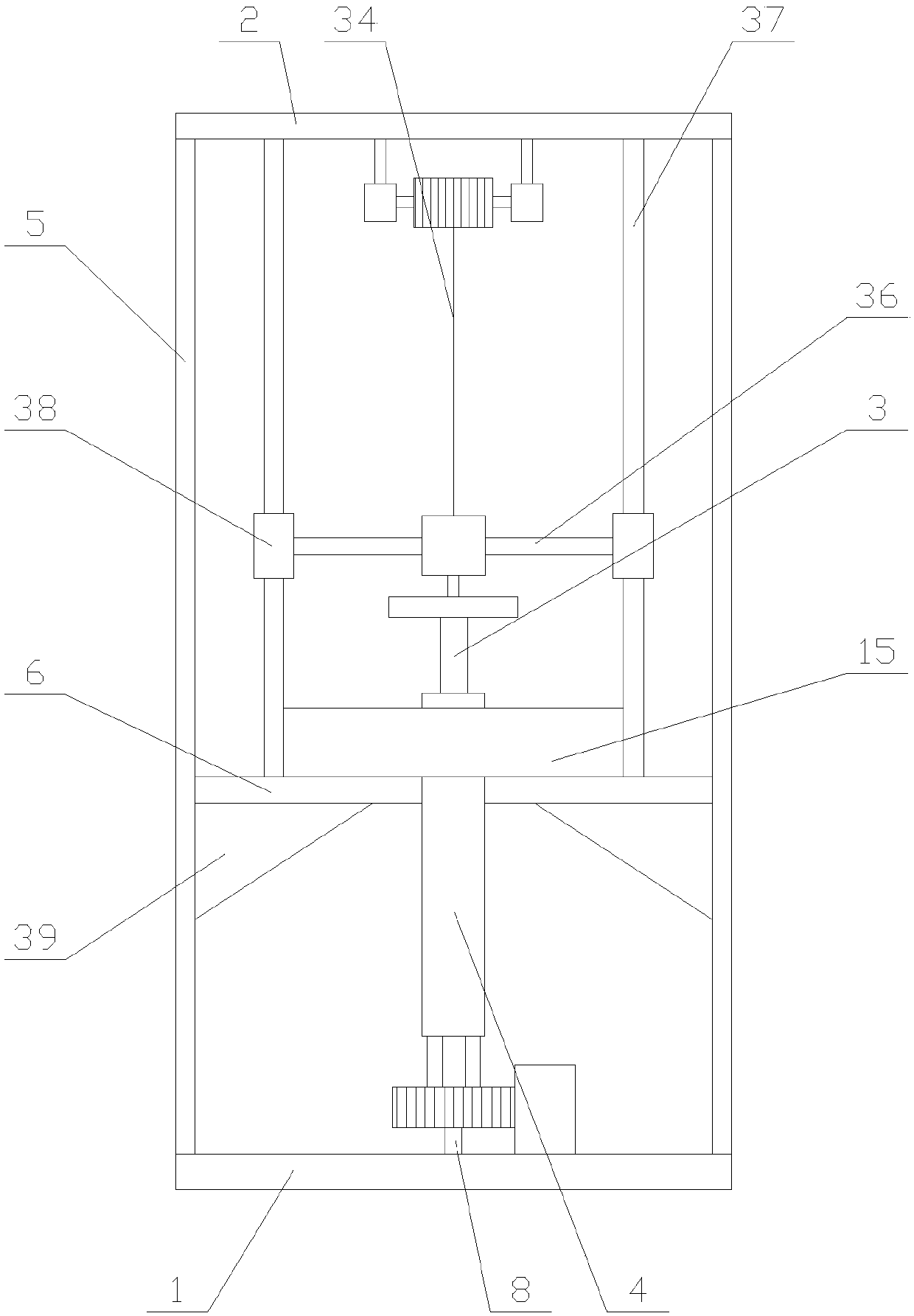

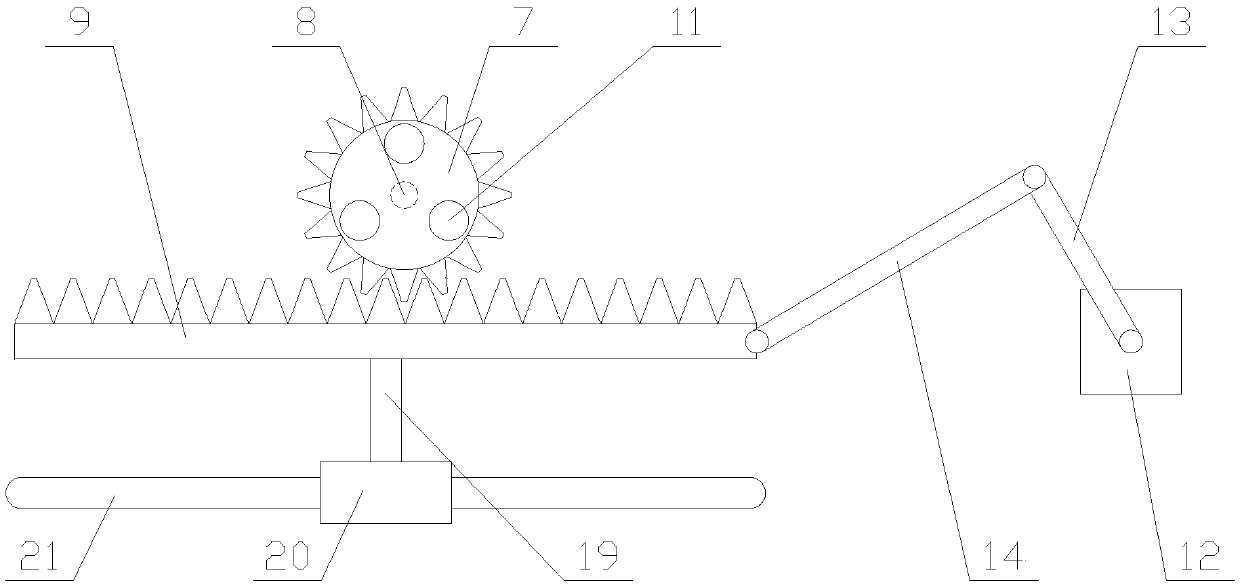

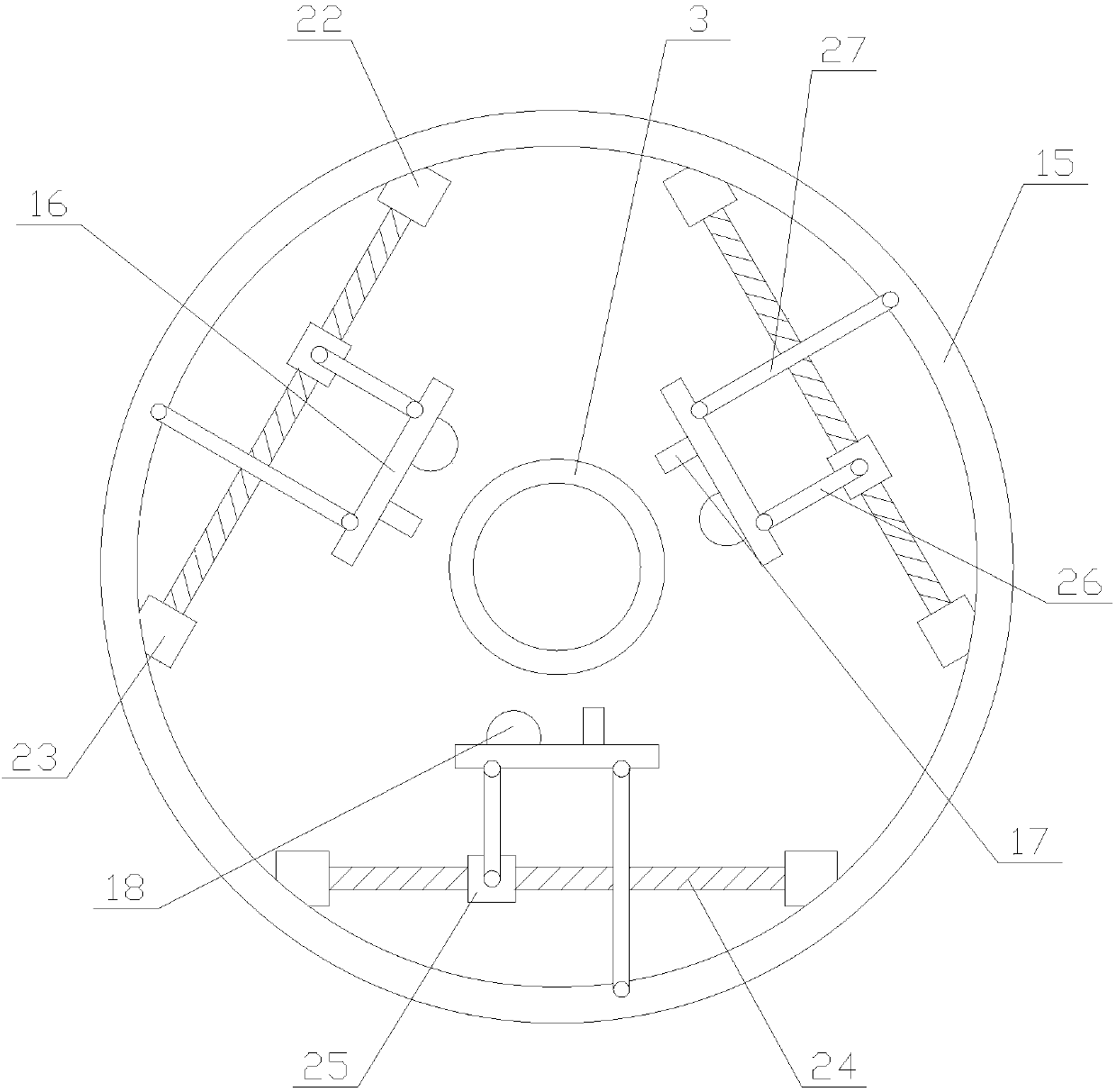

The invention relates to production equipment for manufacturing excellent optical fiber preforms by a VAD (vapor axial deposition) method. The production equipment comprises a seed rod, a blank rod, atransmission mechanism, a supply mechanism, a heating mechanism and two supporting mechanisms. The supply mechanism comprises a gear, a supporting shaft, a rack, a translation unit and at least two oxyhydrogen flame blast burners. The translation unit comprises a first motor, a first connecting rod and a second connecting rod. The heating mechanism comprises a heating ring and at least two heating components, and each heating component comprises a regulating plate, an X-ray detector, a laser emitter and a regulating unit. The production equipment for manufacturing the excellent optical fiberpreforms by the VAD (vapor axial deposition) method has advantages that the supply mechanism enables the oxyhydrogen flame blast burners to rotate, reaction gas is supplied to each position at the bottom end of the blank rod, uniform attachment of dust on the outer periphery of the seed rod is benefited, heating conditions at each position of the outer periphery of the blank rod are controlled through the heating mechanism, the reaction degree at each position is controlled according to production conditions to enable uniform attachment of dust on the surface of the seed rod, and accordingly optical fiber preform production quality is improved.

Owner:南京卓茨机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com