Thermal field for aluminum nitride crystal growth furnace

A technology of crystal growth furnace and aluminum nitride, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of polluting crystals, increasing costs, frequent replacement of graphite thermal field systems, etc., and achieves the effect of convenient regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

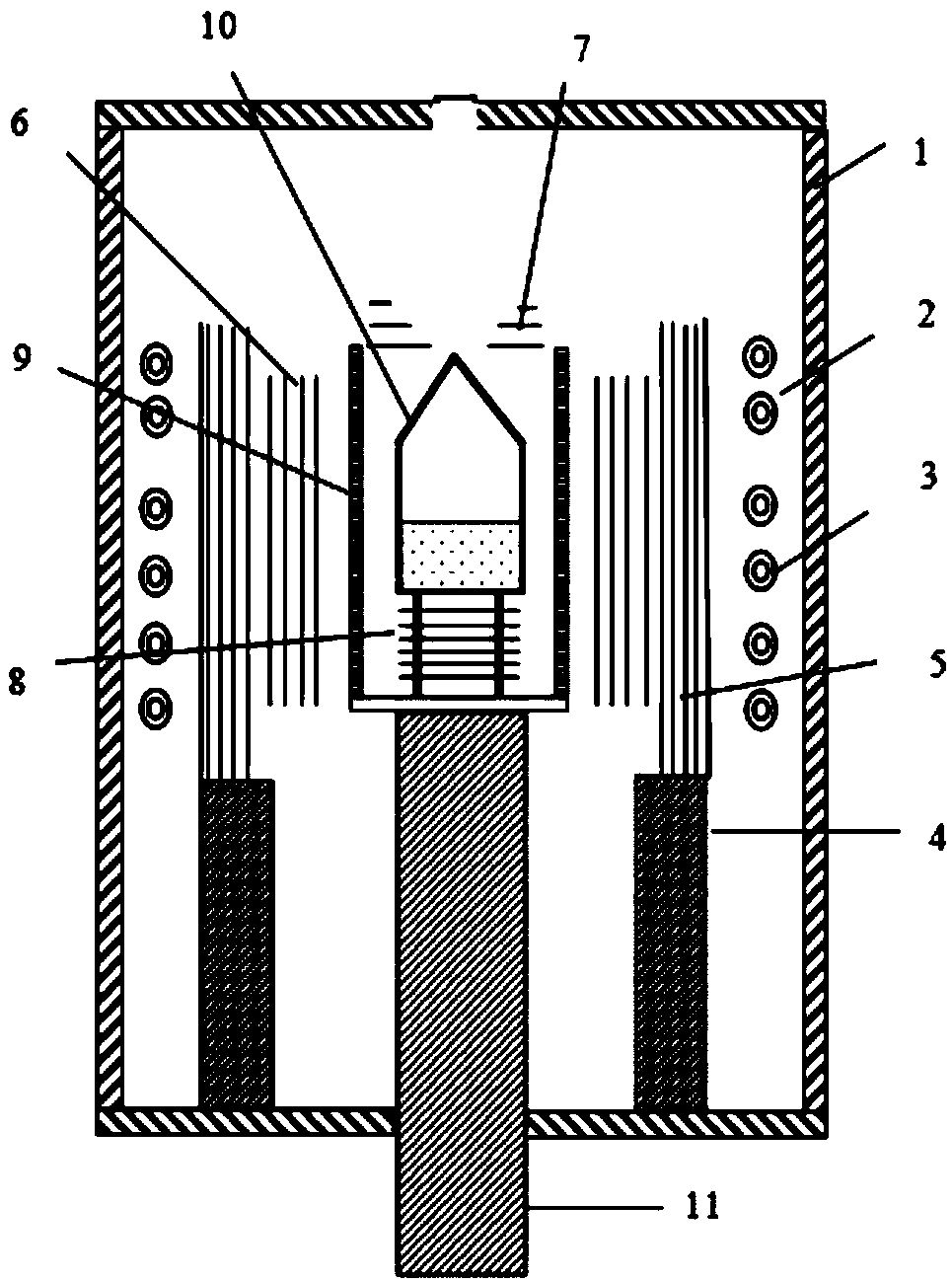

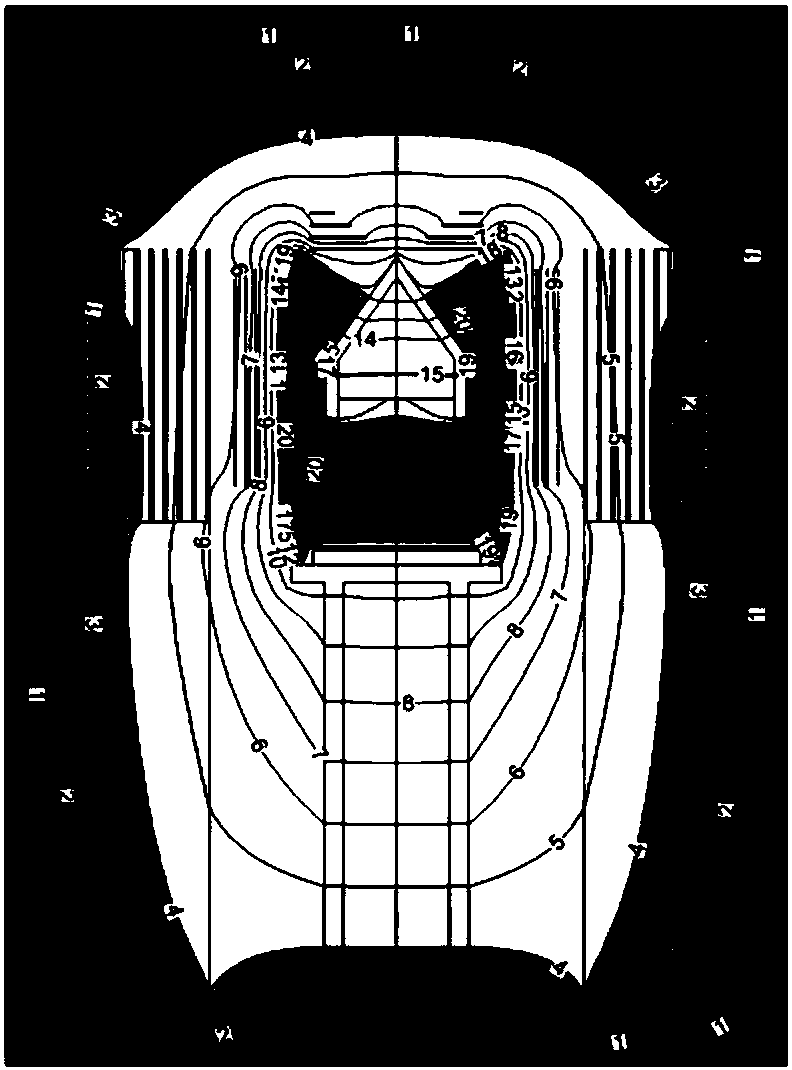

[0025] see figure 1 As shown, a growth furnace for growing aluminum nitride crystals by PVT method includes a furnace body 1, a support rod 11 that moves up and down through the bottom surface of the furnace body 1, and a support ring 4 disposed in the furnace body 1. The heat field is arranged in the furnace body 1 . The growth furnace also includes a furnace wall, and a pipe for circulating cooling water is arranged in the furnace wall. By passing cooling water into the furnace wall, the temperature of the furnace wall can be prevented from being too high due to the distribution of the internal heat field.

[0026] The thermal field includes a crucible 10 arranged on the top of a support rod 11 , the crucible 10 includes a cylindrical body with an opening facing upwards, and a cover arranged above the body. In this embodiment, the cover i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com