Temperature control device for use in civil engineering temperature stress measurement

A temperature control device and temperature stress technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of inability to simulate the temperature field of large-volume objects, and achieve good airtightness, flexible temperature control, The effect of uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

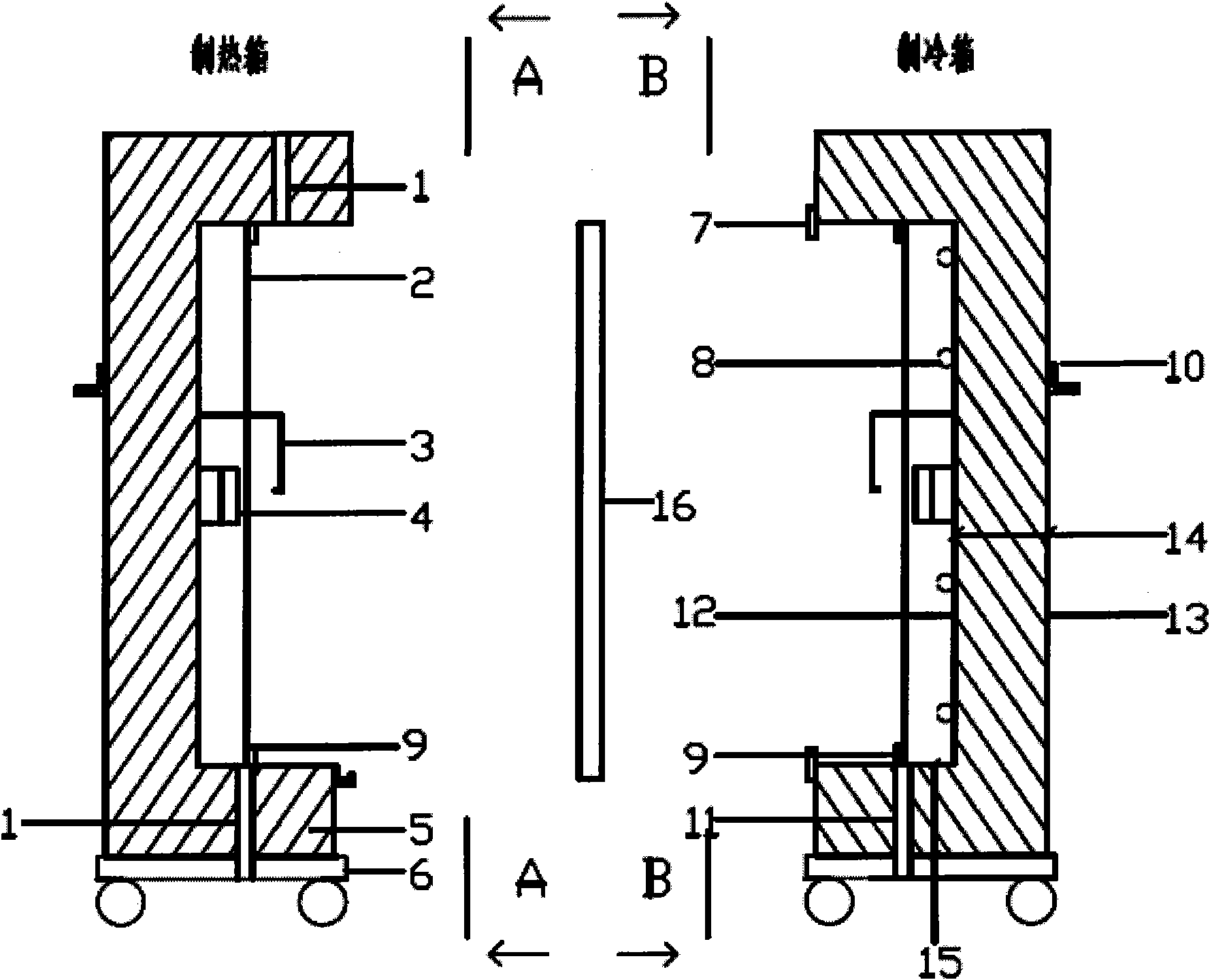

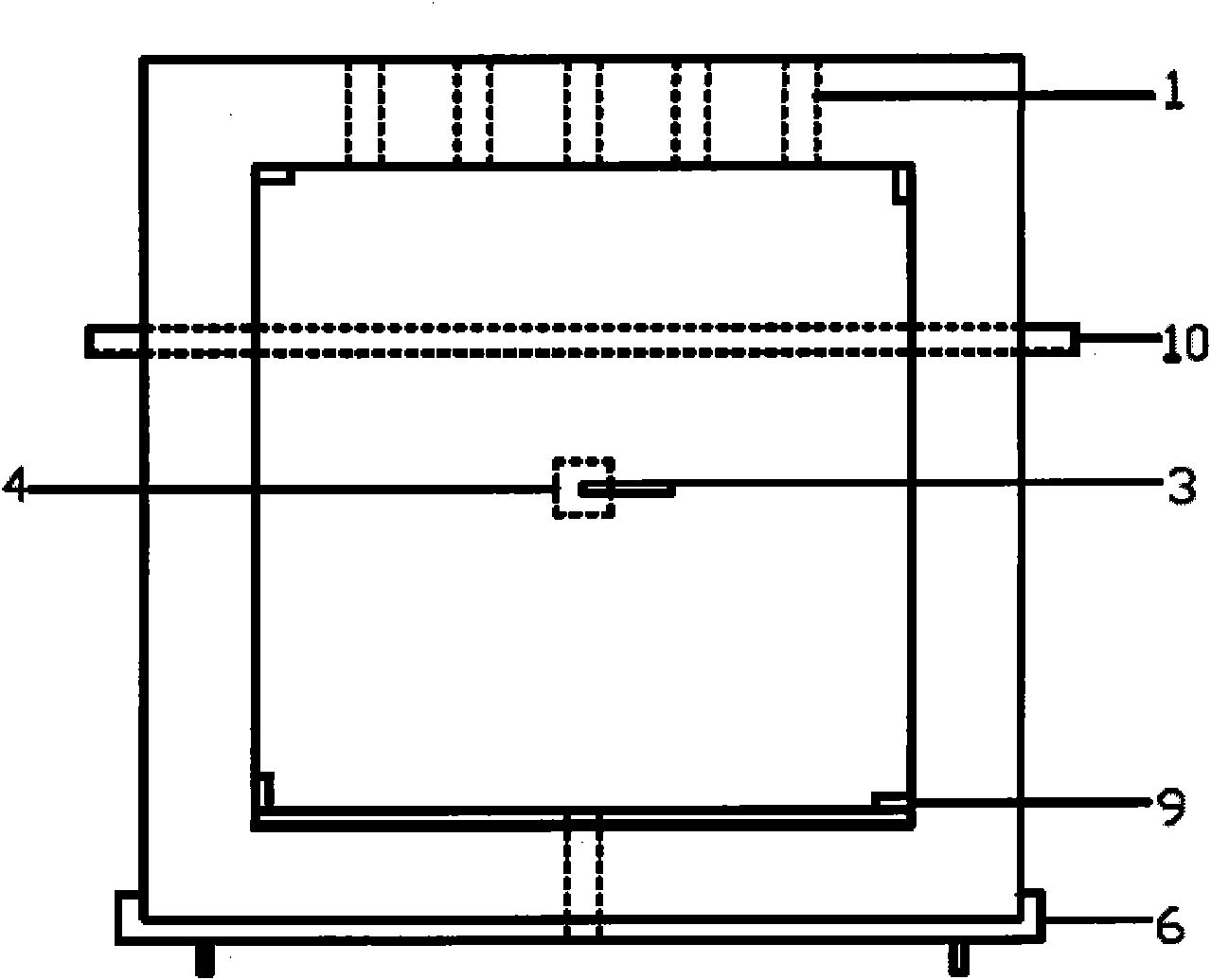

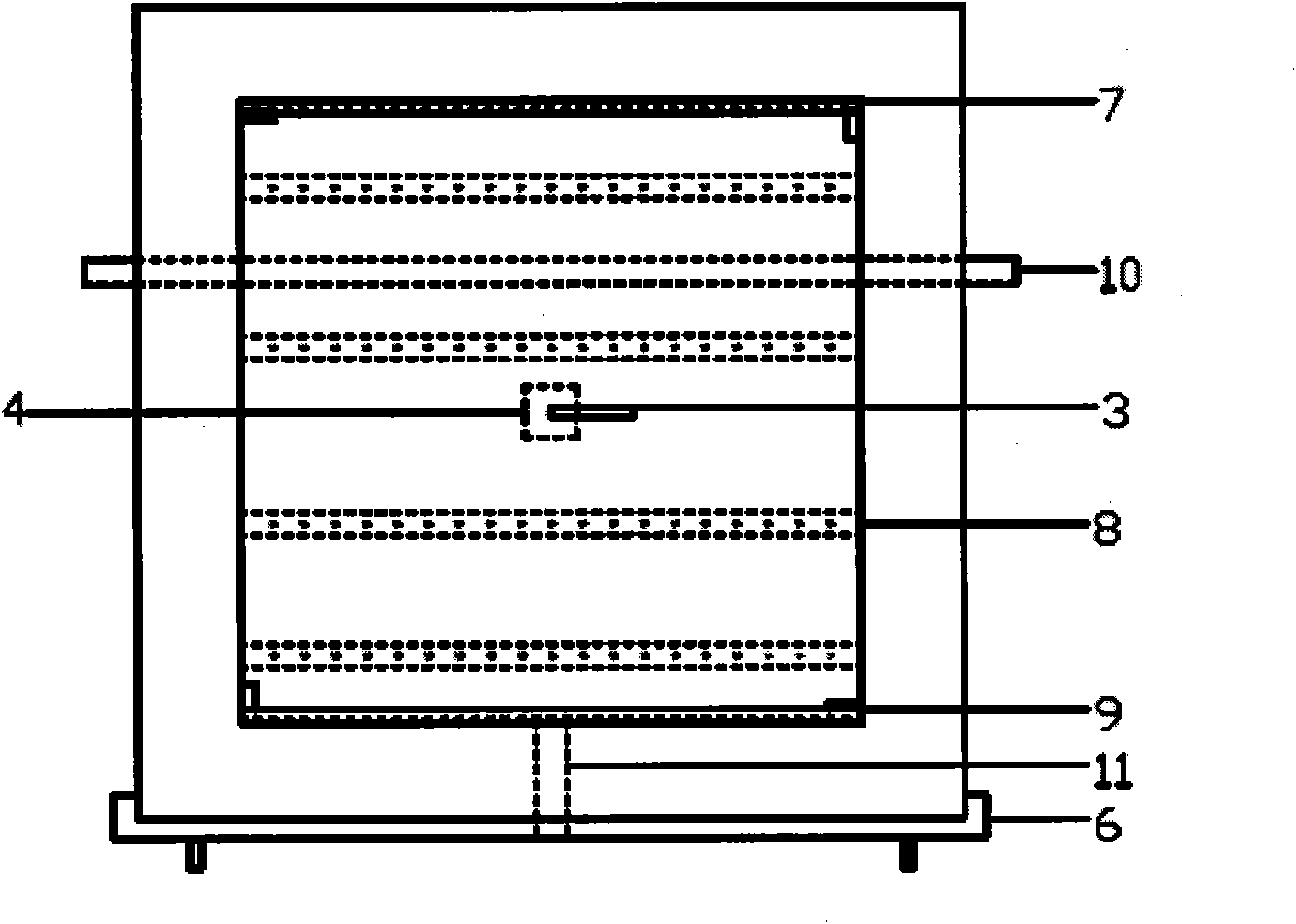

[0019] A temperature control device used for temperature stress measurement in civil engineering, its side view structure schematic diagram is as follows figure 1 As shown, the schematic diagram of the structure along the direction A-A is shown in figure 2 As shown, the schematic diagram of the structure along the B-B direction is as image 3 As shown, the temperature control device comprises a heating box and a cooling box, and the heating box and the cooling box are independent of each other, and are respectively placed on both sides of the object to be measured (glass specimen) 16; Layer box, and between the inner and outer two-layer box (inner box 12 and outer box 13), fill the insulation foam 5 to keep the temperature in the box constant; 14, the heating plate 4 is fixed so that the air temperature in the box can be raised, and in order to make the heat spread evenly, an iron plate 2 is installed on the outside of the heating plate 4; Refrigeration pipe 8, the hole on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com