Solid waste incineration cyclone furnace and incineration process for liquid slag of solid waste incineration cyclone furnace

A liquid slag discharge and cyclone furnace technology, applied in incinerators, combustion methods, combustion types, etc., can solve the secondary pollution recovery of waste slag, can not meet the rapid increase of hazardous waste, and the viscous asphalt material cannot be processed or is not ideally processed. and other problems to achieve the effect of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

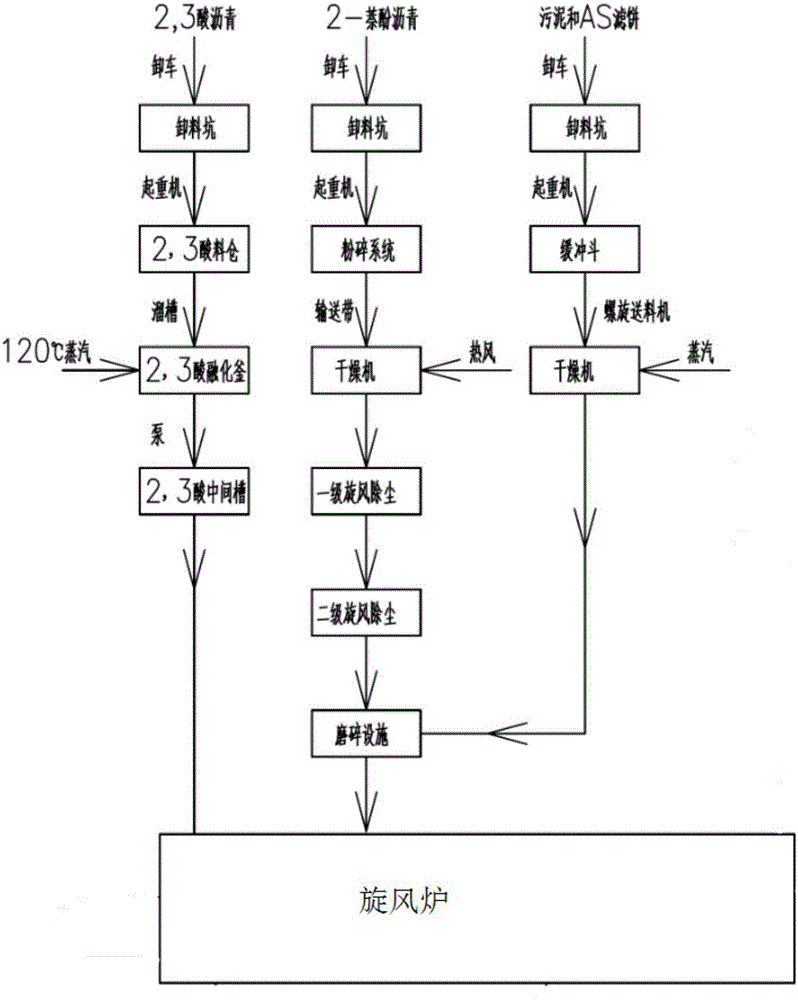

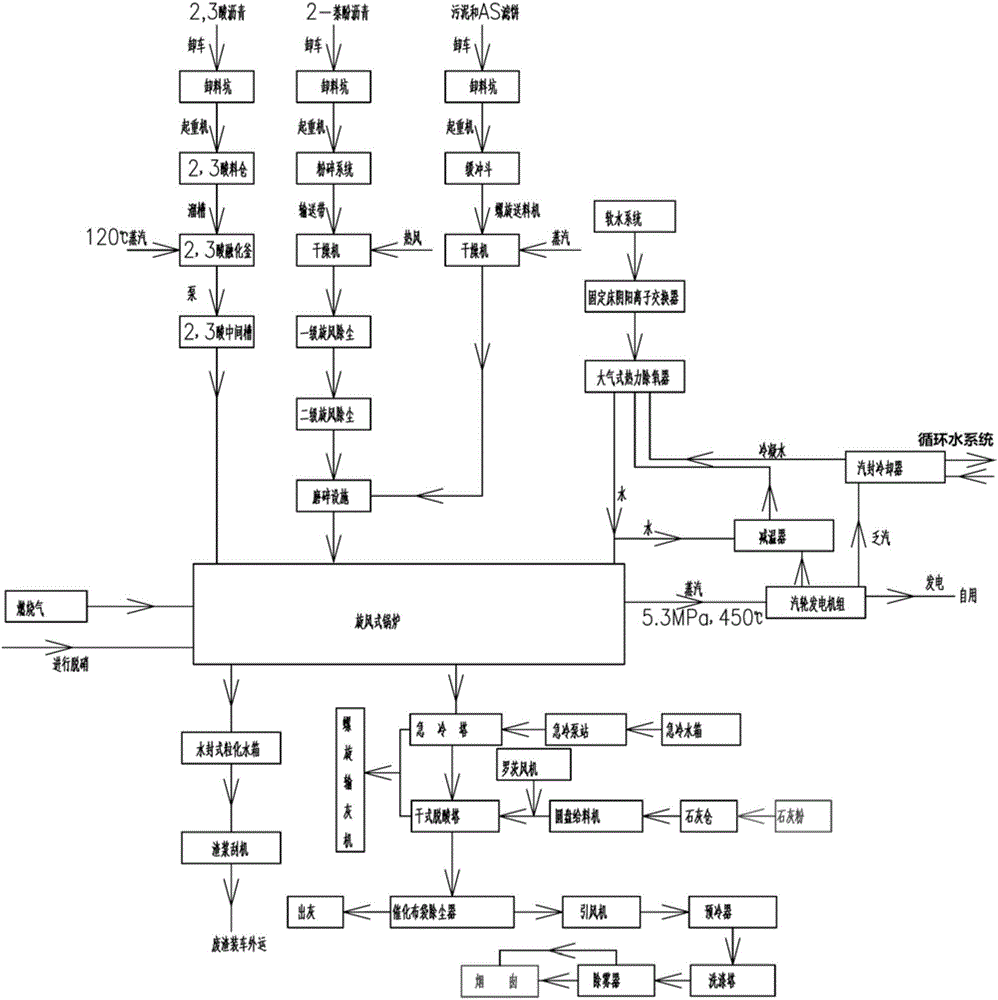

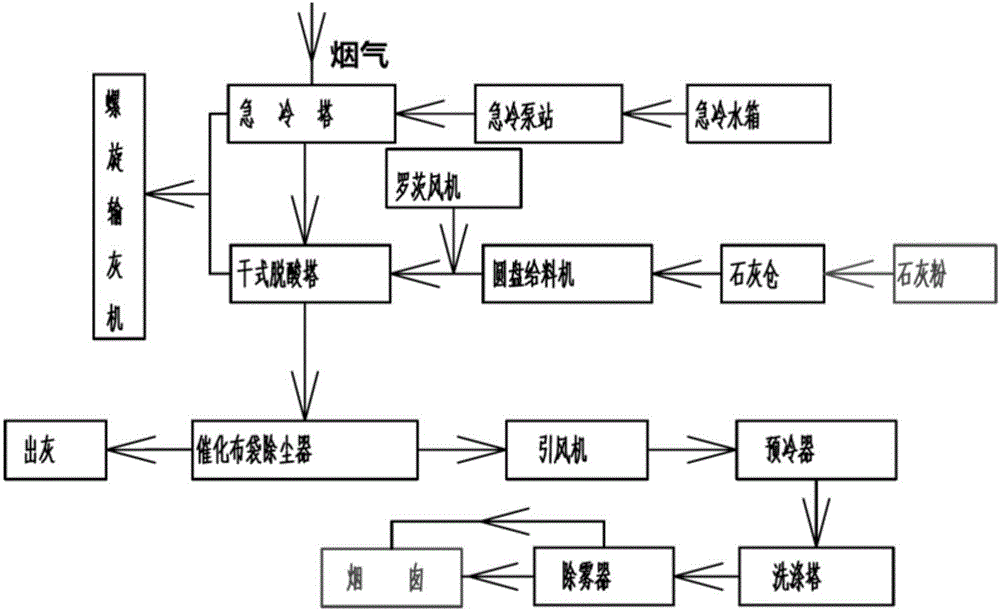

[0039] combined with Figures 1 to 4 The concrete real-time mode of the present invention is described further:

[0040] Solid waste incineration cyclone furnace, the cyclone furnace is used as a waste incineration equipment, the waste in the cyclone furnace undergoes three stages of preheating, ignition, burning and burning in sequence to decompose the waste, which is the best way to achieve waste reduction and harmless treatment main venue.

[0041] The purpose of the second combustion chamber 8 is to completely burn and completely decompose the combustible components and harmful substances in the unburned flue gas of the cyclone furnace. The secondary combustion chamber is equipped with a combustion aid to ensure that the flue gas is in full contact with oxygen at high temperature and has sufficient residence time. The flue gas forms a vortex in the secondary combustion chamber, which strengthens the disturbance of the flue gas, greatly improves the combustion efficiency,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com